Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

First Responder <strong>Awareness</strong> training is provided to employees who are assigned duties by the Facility<br />

Emergency Coordinators (FEC).<br />

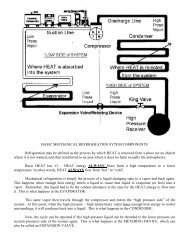

Pre-Incident: These are critical first steps to operations BEFORE considering any move to control an<br />

emergency event:<br />

• Response plan agreement between all of the responders and response agencies (public safety and<br />

local regulator)<br />

• PPE readiness and safety – PROTECT your team members by having them wear proper PPE<br />

before the system is opened or manipulated<br />

• Valve and pipeline readiness concerns:<br />

o Consider all lines to be pressurized – never open a system and think it’s completely void of<br />

ammonia – special caution for the sub-cooled liquid<br />

o Double check valves before you open the system, downstream and upstream<br />

o When you work on a system and you aren’t sure of the consequences of your actions<br />

DON’T do it. Check the protocols and SOPs and work with a supervisor or a systems<br />

engineer to understand the consequences of a possible failure in the system!<br />

General: Upon discovery of an incident, it’s important for the First Responder to size up an emergency<br />

situation and identify what happened. Are lives and the environment at risk? What stage of the event is<br />

happening now? What needs to be done next? Answer these key questions in order to prioritize which<br />

actions to take and determine what the initial response will be.<br />

Employees will be required to take the following action in the event of an emergency due to an<br />

unintentional ammonia release, fire or other emergency:<br />

1. Upon notification, employees and visitors immediately follow the procedures described in the<br />

Emergency Action and Fire Prevention plans for evacuation. They will either assemble at a designated<br />

meeting location or shelter in place, and will be accounted for by the emergency coordinator.<br />

2. The engineering manager, the refrigeration operators, or refrigeration contractor, are permitted to take<br />

defensive action to control the leak to the extent of their training but will take no aggressive action that<br />

would require entry into an area containing ammonia concentrations above the permissible exposure<br />

limits without first donning the appropriate level of respiratory protection and personal protective<br />

equipment.<br />

On Site Readiness: Facility Emergency Coordinator (FEC): The person in charge of any emergency<br />

incident must be designated and trained to fill that position. At least 2 people for each working shift<br />

should be trained at that level. <strong>Training</strong> will be in accordance with the following:<br />

Level 1: Defense only, under 300 PPM, supported by local public safety trained to a pre-described level of<br />

readiness: a minimum of 8 hours of Operational training annually refreshed (8 hours) is recommended for<br />

response team members. FECs shall be trained to Technician level with special training on how to engage<br />

and utilize the Incident Command System.<br />

Level 2: Offense to 5,000 PPM with continuous monitoring while inside the hot zone. SCBA and<br />

chemical resistant suits recommended to have at least 60 minutes impermeability for ammonia, with the<br />

best being 480 minutes; Technician trained with 24 hours of training supported by 8 hours of refresher<br />

mandated; skill tested with Level B equipment at least 3 times per year for each response team member;<br />

12<br />

©ASTI – www.ammonia-safety.com – August 2008