Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

Awareness Training Goals - Salinas Valley Ammonia Safety Day

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Ammonia</strong> <strong>Safety</strong> <strong>Day</strong><br />

Initiate emergency action plan. Set the hot zone and define the area most at risk for the first stage of your<br />

response; help people escape - rescue (when properly trained and PPE equipped). If the leak is incidental,<br />

stop the leak by following equipment shutdown procedures if it’s possible to do so without being exposed<br />

to ammonia above the permissible exposure limit or IDLH when wearing proper PPE.<br />

Alert facility response team<br />

Contact the Facility Emergency Coordinator and on-site response team. When the personnel arrive, inform<br />

them of the site status, employee location, medical emergencies and severity of the incident. The Facility<br />

Emergency Coordinator (FEC) should take command and implement LANCE and SIMPLE protocols. All<br />

members of the response team must be properly trained and equipped with PPE.<br />

Notify<br />

Call 911 for local emergency response support; call them early to stop the problem when it is small. Also<br />

report to local, state, and national response officials immediately (within 15 minutes) if containment of the<br />

release is not achieved and the release is perceived to have reached the reportable quantity, or if exposure<br />

to offsite receptors is likely or has occurred. The Facility Emergency coordinator may request trained<br />

office staff to make the actual calls using the “One Plan” forms. Reporting requirements for local and state<br />

regulatory agencies must be incorporated into the response plan.<br />

Contain and Control<br />

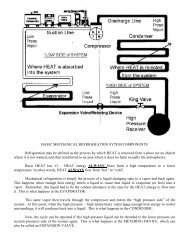

Restrict the release by closing doors. Consider closing the king valve or the main liquid and hot gas<br />

supply valve to stop the flow of ammonia to the affected equipment if applicable to the situation. These<br />

valves are defined in the P&IDs, valve tags, pipeline labels, and leak control SOP’s with digital<br />

photographs. In some instances the trained operator may elect to operate certain equipment in order to<br />

help minimize the release in affected areas.<br />

Evacuate<br />

Move laterally and upwind. Some instances may be suited for sheltering in place. Move all personnel not<br />

involved in refrigeration control activities to a safe distance from the affected area. Assess the extent of a<br />

release area with monitoring equipment and include the property perimeter to determine whether any<br />

neighboring off-site receptors are affected and notification must be issued. Refer to the building and site<br />

plans and map out the evacuation strategy. The FEC should consider appointing an Evacuation<br />

Coordinator and use Public Address System communications to alert facility employees to the direction of<br />

the ammonia release and any specific evacuation considerations.<br />

Transition to SIMPLE Plan: When LANCE is completed, take a breath, gather your composure and<br />

consider the containment and control plan by reviewing the SIMPLE plan.<br />

Injury Prevention & Health Concerns<br />

22. Give an example of Prevention, Mitigation, and Preparation?<br />

23. What type of personal protective equipment (PPE) should an operator wear when working around the<br />

ammonia system?<br />

24. What’s the immediate area of concern should a problem develop while working on the system?<br />

©ASTI – www.ammonia-safety.com – August 2008 7