Sym Attila RS-21 EFI150 (HE15W) servicemanual - Scootergrisen

Sym Attila RS-21 EFI150 (HE15W) servicemanual - Scootergrisen

Sym Attila RS-21 EFI150 (HE15W) servicemanual - Scootergrisen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

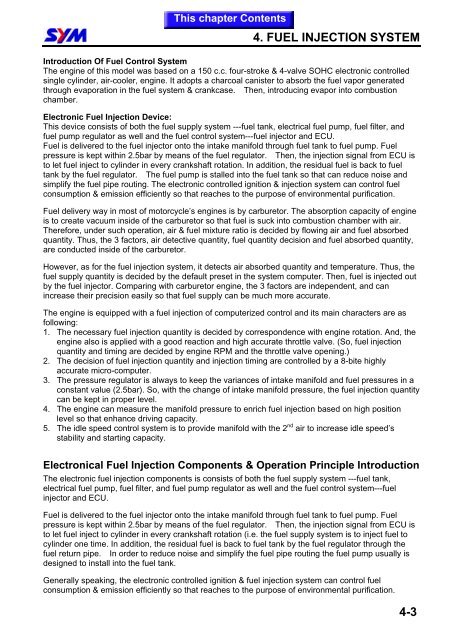

This chapter Contents<br />

4. FUEL INJECTION SYSTEM<br />

Introduction Of Fuel Control System<br />

The engine of this model was based on a 150 c.c. four-stroke & 4-valve SOHC electronic controlled<br />

single cylinder, air-cooler, engine. It adopts a charcoal canister to absorb the fuel vapor generated<br />

through evaporation in the fuel system & crankcase. Then, introducing evapor into combustion<br />

chamber.<br />

Electronic Fuel Injection Device:<br />

This device consists of both the fuel supply system ---fuel tank, electrical fuel pump, fuel filter, and<br />

fuel pump regulator as well and the fuel control system---fuel injector and ECU.<br />

Fuel is delivered to the fuel injector onto the intake manifold through fuel tank to fuel pump. Fuel<br />

pressure is kept within 2.5bar by means of the fuel regulator. Then, the injection signal from ECU is<br />

to let fuel inject to cylinder in every crankshaft rotation. In addition, the residual fuel is back to fuel<br />

tank by the fuel regulator. The fuel pump is stalled into the fuel tank so that can reduce noise and<br />

simplify the fuel pipe routing. The electronic controlled ignition & injection system can control fuel<br />

consumption & emission efficiently so that reaches to the purpose of environmental purification.<br />

Fuel delivery way in most of motorcycle’s engines is by carburetor. The absorption capacity of engine<br />

is to create vacuum inside of the carburetor so that fuel is suck into combustion chamber with air.<br />

Therefore, under such operation, air & fuel mixture ratio is decided by flowing air and fuel absorbed<br />

quantity. Thus, the 3 factors, air detective quantity, fuel quantity decision and fuel absorbed quantity,<br />

are conducted inside of the carburetor.<br />

However, as for the fuel injection system, it detects air absorbed quantity and temperature. Thus, the<br />

fuel supply quantity is decided by the default preset in the system computer. Then, fuel is injected out<br />

by the fuel injector. Comparing with carburetor engine, the 3 factors are independent, and can<br />

increase their precision easily so that fuel supply can be much more accurate.<br />

The engine is equipped with a fuel injection of computerized control and its main characters are as<br />

following:<br />

1. The necessary fuel injection quantity is decided by correspondence with engine rotation. And, the<br />

engine also is applied with a good reaction and high accurate throttle valve. (So, fuel injection<br />

quantity and timing are decided by engine RPM and the throttle valve opening.)<br />

2. The decision of fuel injection quantity and injection timing are controlled by a 8-bite highly<br />

accurate micro-computer.<br />

3. The pressure regulator is always to keep the variances of intake manifold and fuel pressures in a<br />

constant value (2.5bar). So, with the change of intake manifold pressure, the fuel injection quantity<br />

can be kept in proper level.<br />

4. The engine can measure the manifold pressure to enrich fuel injection based on high position<br />

level so that enhance driving capacity.<br />

5. The idle speed control system is to provide manifold with the 2 nd air to increase idle speed’s<br />

stability and starting capacity.<br />

Electronical Fuel Injection Components & Operation Principle Introduction<br />

The electronic fuel injection components is consists of both the fuel supply system ---fuel tank,<br />

electrical fuel pump, fuel filter, and fuel pump regulator as well and the fuel control system---fuel<br />

injector and ECU.<br />

Fuel is delivered to the fuel injector onto the intake manifold through fuel tank to fuel pump. Fuel<br />

pressure is kept within 2.5bar by means of the fuel regulator. Then, the injection signal from ECU is<br />

to let fuel inject to cylinder in every crankshaft rotation (i.e. the fuel supply system is to inject fuel to<br />

cylinder one time. In addition, the residual fuel is back to fuel tank by the fuel regulator through the<br />

fuel return pipe. In order to reduce noise and simplify the fuel pipe routing the fuel pump usually is<br />

designed to install into the fuel tank.<br />

Generally speaking, the electronic controlled ignition & fuel injection system can control fuel<br />

consumption & emission efficiently so that reaches to the purpose of environmental purification.<br />

4-3