Looking back to the future. 15 years of certified environmental ...

Looking back to the future. 15 years of certified environmental ...

Looking back to the future. 15 years of certified environmental ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

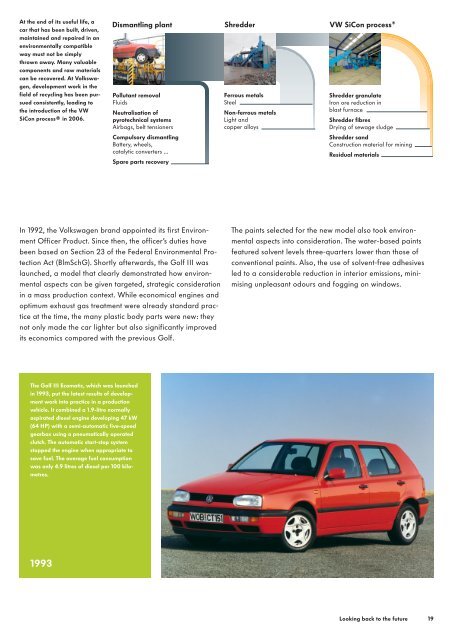

At <strong>the</strong> end <strong>of</strong> its useful life, a<br />

car that has been built, driven,<br />

maintained and repaired in an<br />

<strong>environmental</strong>ly compatible<br />

way must not be simply<br />

thrown away. Many valuable<br />

components and raw materials<br />

can be recovered. At Volkswagen,<br />

development work in <strong>the</strong><br />

field <strong>of</strong> recycling has been pursued<br />

consistently, leading <strong>to</strong><br />

<strong>the</strong> introduction <strong>of</strong> <strong>the</strong> VW<br />

SiCon process® in 2006.<br />

Dismantling plant<br />

Pollutant removal<br />

Fluids<br />

Neutralisation <strong>of</strong><br />

pyrotechnical systems<br />

Airbags, belt tensioners<br />

Compulsory dismantling<br />

Battery, wheels,<br />

catalytic converters …<br />

Spare parts recovery<br />

In 1992, <strong>the</strong> Volkswagen brand appointed its first Environment<br />

Officer Product. Since <strong>the</strong>n, <strong>the</strong> <strong>of</strong>ficer’s duties have<br />

been based on Section 23 <strong>of</strong> <strong>the</strong> Federal Environmental Protection<br />

Act (BlmSchG). Shortly afterwards, <strong>the</strong> Golf III was<br />

launched, a model that clearly demonstrated how <strong>environmental</strong><br />

aspects can be given targeted, strategic consideration<br />

in a mass production context. While economical engines and<br />

optimum exhaust gas treatment were already standard practice<br />

at <strong>the</strong> time, <strong>the</strong> many plastic body parts were new: <strong>the</strong>y<br />

not only made <strong>the</strong> car lighter but also significantly improved<br />

its economics compared with <strong>the</strong> previous Golf.<br />

The Golf III Ecomatic, which was launched<br />

in 1993, put <strong>the</strong> latest results <strong>of</strong> development<br />

work in<strong>to</strong> practice in a production<br />

vehicle. It combined a 1.9-litre normally<br />

aspirated diesel engine developing 47 kW<br />

(64 HP) with a semi-au<strong>to</strong>matic five-speed<br />

gearbox using a pneumatically operated<br />

clutch. The au<strong>to</strong>matic start-s<strong>to</strong>p system<br />

s<strong>to</strong>pped <strong>the</strong> engine when appropriate <strong>to</strong><br />

save fuel. The average fuel consumption<br />

was only 4.9 litres <strong>of</strong> diesel per 100 kilometres.<br />

1993<br />

Shredder VW SiCon process ®<br />

Ferrous metals<br />

Steel<br />

Non-ferrous metals<br />

Light and<br />

copper alloys<br />

Shredder granulate<br />

Iron ore reduction in<br />

blast furnace<br />

Shredder fibres<br />

Drying <strong>of</strong> sewage sludge<br />

Shredder sand<br />

Construction material for mining<br />

Residual materials<br />

The paints selected for <strong>the</strong> new model also <strong>to</strong>ok <strong>environmental</strong><br />

aspects in<strong>to</strong> consideration. The water-based paints<br />

fea tured solvent levels three-quarters lower than those <strong>of</strong><br />

conventional paints. Also, <strong>the</strong> use <strong>of</strong> solvent-free adhesives<br />

led <strong>to</strong> a considerable reduction in interior emissions, minimising<br />

unpleasant odours and fogging on windows.<br />

<strong>Looking</strong> <strong>back</strong> <strong>to</strong> <strong>the</strong> <strong>future</strong><br />

19