19 - Design of Timber Floor Joists.pdf

19 - Design of Timber Floor Joists.pdf

19 - Design of Timber Floor Joists.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36<br />

<strong>Design</strong> principles<br />

TheStructuralEngineer<br />

November 2012<br />

<strong>Timber</strong> is a natural material and is variable<br />

both in strength and stiffness. The strength<br />

and stiffness <strong>of</strong> a piece <strong>of</strong> timber depends<br />

on its species, where it was grown, the<br />

rate <strong>of</strong> growth, the number <strong>of</strong> ‘defects’<br />

(e.g. knots) and the angle <strong>of</strong> the grain. In<br />

order to make effective structural use <strong>of</strong><br />

timber it needs to be graded and allocated<br />

directly or indirectly to a strength class. The<br />

strength <strong>of</strong> a piece <strong>of</strong> timber also depends<br />

on its moisture content and structural<br />

timber should be installed when its moisture<br />

content is similar to that experienced during<br />

growth. Allowances have to be made for<br />

this moisture content when the structure is<br />

designed.<br />

It should be noted that this Technical<br />

Guidance Note is solely concerned with<br />

the design <strong>of</strong> solid timber floor joists and<br />

not other forms <strong>of</strong> compound timber floor<br />

joists available. This includes Glulam and<br />

›<br />

Note 18 Level 1<br />

Technical<br />

Technical Guidance Note<br />

<strong>Design</strong> <strong>of</strong> timber floor joists<br />

Introduction<br />

One <strong>of</strong> the most common structural elements is the timber floor joist. This<br />

is normally found in residential properties, but can also be seen in medium<br />

sized commercial developments. This Technical Guidance Note will explain<br />

the principles behind the design <strong>of</strong> timber floor joists and provide a worked<br />

example. All <strong>of</strong> the advice given will be in accordance with BS EN <strong>19</strong>95-1-1<br />

Eurocode 5: <strong>Design</strong> <strong>of</strong> <strong>Timber</strong> Structures – Part 1-1: General – Common<br />

rules and rules for buildings.<br />

Laminated Veneer Lumber (LVL) joists as<br />

they are beyond the scope <strong>of</strong> this note.<br />

<strong>Timber</strong> floor joist strength<br />

grades and classes<br />

S<strong>of</strong>twood timber can be visually graded<br />

to General Structural (GS) and Special<br />

Structural (SS) grades. These grades are<br />

then allocated to a particular Strength<br />

Class. With respect to timber floor joists,<br />

in the UK they are typically sawn from GS<br />

and SS s<strong>of</strong>twoods and are graded in two<br />

strength classes respectively: C16 and C24.<br />

C16 is the more common grade but weaker<br />

class and is therefore easier and cheaper<br />

to procure. C24 is a little stronger, but more<br />

expensive and is generally used where<br />

restrictions such as geometry and depth <strong>of</strong><br />

floor construction play a significant part in<br />

the design <strong>of</strong> the structure. An example <strong>of</strong><br />

such an instance would be joists that have<br />

long spans or a trimming beam around a<br />

large void.<br />

The material properties <strong>of</strong> C16 and C24<br />

timber are given in Table 1.<br />

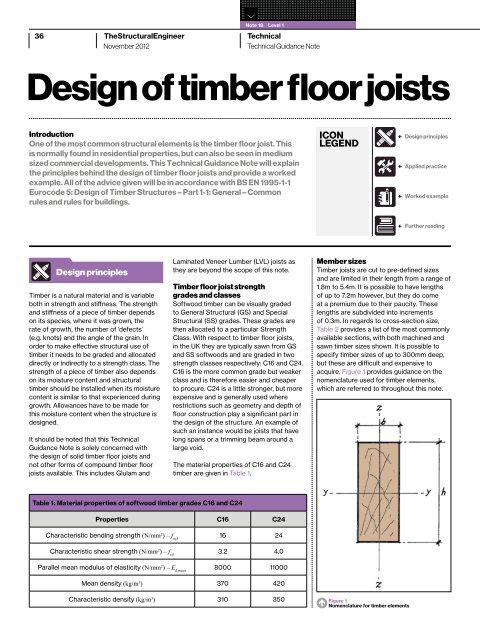

Table 1: Material properties <strong>of</strong> s<strong>of</strong>twood timber grades C16 and C24<br />

Properties C16 C24<br />

Characteristic bending strength (N/mm 2 ) – f m,k 16 24<br />

Characteristic shear strength (N/mm 2 ) – f v,k 3.2 4.0<br />

Parallel mean modulus <strong>of</strong> elasticity (N/mm 2 ) – E 0,mean 8000 11000<br />

Mean density (kg/m 3 ) 370 420<br />

ICON<br />

LEGEND<br />

• <strong>Design</strong> principles<br />

• Applied practice<br />

• Worked example<br />

• Further reading<br />

Member sizes<br />

<strong>Timber</strong> joists are cut to pre-defined sizes<br />

and are limited in their length from a range <strong>of</strong><br />

1.8m to 5.4m. It is possible to have lengths<br />

<strong>of</strong> up to 7.2m however, but they do come<br />

at a premium due to their paucity. These<br />

lengths are subdivided into increments<br />

<strong>of</strong> 0.3m. In regards to cross-section size,<br />

Table 2 provides a list <strong>of</strong> the most commonly<br />

available sections, with both machined and<br />

sawn timber sizes shown. It is possible to<br />

specify timber sizes <strong>of</strong> up to 300mm deep,<br />

but these are difficult and expensive to<br />

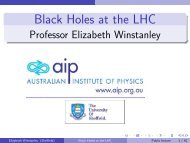

acquire. Figure 1 provides guidance on the<br />

nomenclature used for timber elements,<br />

which are referred to throughout this note.<br />

Characteristic density (kg/m3 ) 310 350 Figure 1 • Nomenclature for timber elements

Table 2: Common sizes <strong>of</strong> timber floor joists<br />

Sawn depth<br />

(h) mm<br />

Sawn width<br />

(b) mm<br />

Exposure conditions<br />

<strong>Timber</strong> is a hygroscopic material that<br />

absorbs/releases moisture from/to its<br />

surrounding environment depending on the<br />

amount <strong>of</strong> moisture in that environment. As<br />

the strength and stiffness properties are<br />

dependent on the moisture content, it is<br />

necessary to account for the environment<br />

around the timber. Three service classes<br />

have been defined. Examples <strong>of</strong> typical<br />

environments and the respective service<br />

class are:<br />

• Service class 1 – intermediate floors, warm<br />

ro<strong>of</strong>s, internal and party timber frame walls<br />

• Service class 2 – ground floors, cold ro<strong>of</strong>s,<br />

timber frame walls that are against the outer<br />

skin <strong>of</strong> cladding and all other instances<br />

where the timber is protected from direct<br />

exposure to water<br />

• Service class 3 – external, fully exposed<br />

Load duration<br />

The strength <strong>of</strong> a piece <strong>of</strong> timber is<br />

dependent <strong>of</strong> the duration <strong>of</strong> the load. The<br />

longer the duration <strong>of</strong> the load the higher the<br />

strength <strong>of</strong> timber that must be provided in<br />

order to resist that load. To this end there<br />

are a number <strong>of</strong> factors that are applied to<br />

the characteristic properties <strong>of</strong> the timber<br />

as defined in Table 1. The UK National Annex<br />

to Eurocode BS EN <strong>19</strong>95-1-1 classifies load<br />

durations as follows:<br />

• Permanent – more than 10 years, e.g. selfweight<br />

including finishes<br />

• Long term – 6 months to 10 years e.g.<br />

storage loading<br />

• Medium term – 1 week to 6 months e.g.<br />

imposed floor loads<br />

Machined depth<br />

(h) mm<br />

Machined width<br />

(b) mm<br />

150 25 145 22<br />

175 38 170 35<br />

200 47 <strong>19</strong>5 44<br />

225 63 220 60<br />

250 75 245 72<br />

Table 3: Values <strong>of</strong> k mod for solid timber joists<br />

• Short term – less than 1 week e.g.<br />

snow loads, maintenance access and<br />

accidental loads<br />

• Instantaneous – fractions <strong>of</strong> a second e.g.<br />

wind, impact and explosive loads<br />

The figures given in Table 3 provide the<br />

values for the factor k mod , which is the factor<br />

that is applied to the strength properties <strong>of</strong><br />

timber and is based on the imposed load<br />

(variable action) duration. Note that in the<br />

case <strong>of</strong> load combinations the load condition<br />

with the shortest time period defines the<br />

value <strong>of</strong> k mod . When designing timber<br />

elements it is important to check for all<br />

conditions and to design the element based<br />

on the most critical. These conditions along<br />

with their respective k mod values are:<br />

• Permanent loads with k mod = 0.6<br />

• Permanent loads + long term loads<br />

with k mod = 0.7<br />

• Permanent loads + long term loads +<br />

medium term loads with k mod = 0.8<br />

• Permanent loads + long term loads +<br />

medium term loads + short term loads<br />

with k mod = 0.9<br />

• Permanent loads + long term loads +<br />

medium term loads + short term loads +<br />

instantaneous loads with k mod = 1<br />

For timber floor joists within a building the<br />

typical critical condition is the imposed<br />

floor load with the self-weight <strong>of</strong> the joists<br />

and super-imposed dead load. This load<br />

condition results in a value <strong>of</strong> k mod <strong>of</strong> 0.8<br />

as it is subject to an imposed load, which<br />

is defined as medium term, as well as<br />

self-weight.<br />

Service class Permanent Long term Medium term Short term Instantaneous<br />

1 & 2 0.6 0.7 0.8 0.9 1.10<br />

3 0.5 0.55 0.65 0.7 0.9<br />

www.thestructuralengineer.org<br />

37<br />

Deformation<br />

The elastic properties <strong>of</strong> a timber structure<br />

depend on the moisture content <strong>of</strong> the<br />

timber and consequently the deflection<br />

will be dependent on the service class.<br />

To take this into account the factor k def is<br />

applied to the elastic modulus properties<br />

<strong>of</strong> the timber. Table 4 defines these values.<br />

Table 4: Values <strong>of</strong> k def for solid timber joists<br />

Service<br />

class<br />

Enhancement due to shallow<br />

member size<br />

The way that the grading rules for structural<br />

timber work, means that for joists less than<br />

150mm in depth, some enhancement <strong>of</strong> the<br />

strength is allowed.<br />

To reflect this, a modification factor k h is<br />

applied to bending strength <strong>of</strong> the timber. If a<br />

member is less than or equal to 150mm deep<br />

and has a material density <strong>of</strong> less than 700<br />

kg/m 3 , then k h factor is defined thus:<br />

150 . 02<br />

kh<br />

= a k<br />

h<br />

1 2 3<br />

k def 0.6 0.8 2.00<br />

or 1.3 whichever is the lesser.<br />

For all members that are greater than<br />

150mm deep, the value <strong>of</strong> k h is taken to<br />

be 1.0.<br />

(1)<br />

Load sharing<br />

<strong>Timber</strong> floor joists are generally placed at<br />

fairly close centres with decking/boarding<br />

across them which will distribute load<br />

between the joists. To account for this,<br />

the modification factor ksys is applied to<br />

characteristic strength properties <strong>of</strong> the<br />

timber joist which enhances its resistance to<br />

bending and shear stress. Provided the floor<br />

boards/boarding has staggered connections<br />

and are continuous over at least two spans,<br />

the value <strong>of</strong> ksys is taken to be 1.1. In all other<br />

instances the value <strong>of</strong> ksys is taken to be 1.0.<br />

Lateral torsional buckling <strong>of</strong><br />

timber joists<br />

In most instances the risk <strong>of</strong> lateral torsional<br />

buckling affecting a floor joist is not present.<br />

This is due to the existence <strong>of</strong> a floor<br />

finish that the joists are supporting acting<br />

as a restraint. In the rare condition where<br />

the compression face <strong>of</strong> floor joists is not<br />

restrained against bending induced torsional<br />

rotation, then the factor k crit is applied to<br />

the bending capacity <strong>of</strong> the joist. For more

38<br />

TheStructuralEngineer<br />

November 2012<br />

information on this, the reader is directed<br />

to clause 6.3.3 <strong>of</strong> BS EN <strong>19</strong>95-1-1, which<br />

describes the derivation <strong>of</strong> k crit .<br />

Applied bending stress<br />

The applied bending stress to floor joists<br />

is associated to its major axis, which is<br />

described as ‘y-y’ in Figure 1. To determine<br />

the design bending stress, the design<br />

bending moment is calculated based on<br />

the applied loads and support conditions<br />

<strong>of</strong> the joist as well as its geometry. The<br />

equation for determining the design<br />

bending stress (σm,y,d ) to a timber joist<br />

is as follows:<br />

My,d<br />

vm,y,d =<br />

(2)<br />

Wy<br />

Where:<br />

My,d is the design bending moment<br />

is the elastic modulus <strong>of</strong> the joist, defined as:<br />

Wy<br />

Wy<br />

=<br />

bh<br />

2<br />

6<br />

Applied shear stress<br />

For a simply supported joist the design<br />

maximum shear force is equal to the design<br />

reaction. In the case <strong>of</strong> timber the maximum<br />

design shear stress (not average shear<br />

stress) needs to be checked against the<br />

design shear resistance. The maximum<br />

design shear stress <strong>of</strong> a rectangular section<br />

is calculated using:<br />

3Vd<br />

xd<br />

=<br />

2bh<br />

Where:<br />

Vd is the design applied shear force<br />

h is the depth <strong>of</strong> section under consideration<br />

at the point <strong>of</strong> support<br />

b is the width <strong>of</strong> the section under<br />

consideration<br />

If the beam is notched on the same side as<br />

the support, the design shear resistance<br />

can be considerably reduced and is a detail<br />

which should be avoided if possible.<br />

(3)<br />

(4)<br />

Partial factor due to material variances<br />

Like all materials used as structural<br />

elements, timber has a partial factor, which<br />

is applied to its strength properties due to<br />

variances within it. In the case <strong>of</strong> solid timber<br />

elements, the partial factor has a value <strong>of</strong> 1.3.<br />

Bending strength and shear strength<br />

Once the applied forces and subsequent<br />

stresses are determined, the design bending<br />

and shear strengths <strong>of</strong> the timber joist<br />

need to be calculated. These are compared<br />

against the applied design stresses in order<br />

to determine the acceptability <strong>of</strong> the chosen<br />

joist size and strength grade.<br />

›<br />

Note 18 Level 1<br />

Technical<br />

Technical Guidance Note<br />

<strong>Design</strong> bending strength is defined as:<br />

kh $ kcrit $ kmod $ ksys $ fm,k<br />

fm,y,d<br />

=<br />

(5)<br />

c M<br />

<strong>Design</strong> shear strength is defined as:<br />

kmod $ ksys $ fv,k<br />

fv,d<br />

=<br />

(6)<br />

c M<br />

The value <strong>of</strong> fv,d is then multiplied against the<br />

effective depth and width <strong>of</strong> the timber floor<br />

joist at the point <strong>of</strong> support. This is compared<br />

against the applied design shear the timber<br />

joist has to support. In order to take into<br />

account cracking within the timber, the width<br />

<strong>of</strong> the joist is reduced via factor kcr which for<br />

solid timber members is taken as 0.67.<br />

Worked example<br />

Serviceability<br />

The deflections <strong>of</strong> timber joists should be<br />

limited so that any brittle finishes they’re<br />

supporting are not damaged. Table 5<br />

provides guidance on the vertical deflection<br />

limits for joists that are based on the<br />

characteristic imposed loads (variable<br />

actions) and dead loads (permanent<br />

actions) that are being applied to the<br />

floor joists.<br />

Creep must also be considered for timber<br />

elements as it is a significant factor when<br />

assessing serviceability limits. To allow for<br />

this, the instantaneous deflection due to the<br />

permanent loads is increased by a factor<br />

A timber floor is to span 4.8m and is supporting a characteristic imposed floor load <strong>of</strong><br />

2.5kN/m 2 . The joists are placed at 400mm spacing and have timber boards fixed on top<br />

that have a self-weight <strong>of</strong> 0.15kN/m 2 . The presence <strong>of</strong> these boards provides full lateral<br />

restraint to the timber floor joists as well as allowing for load sharing between floor joists.<br />

The finish to the floor is brittle. Check to see if a 250mm x 75mm C16 timber joist can<br />

support this load.

Table 5: Deflection limits for<br />

solid timber joists<br />

Use Deflection limit<br />

Brittle finishes<br />

e.g. plasterboard,<br />

ceilings, walls<br />

No brittle finishes<br />

e.g. ro<strong>of</strong>s<br />

Accidental<br />

e.g. during a fire<br />

Span/250<br />

Span/150<br />

Span/20<br />

(1+k def ). The instantaneous deflection<br />

for imposed (variable) load is increased by<br />

a factor (1+ψ 2,1k def ), assuming only one<br />

variable load. The sum <strong>of</strong> these deflections,<br />

less any precamber, provides the overall<br />

deflection due to bending.<br />

There is also the issue <strong>of</strong> deflection due to<br />

shear. This is rarely a critical condition, but it<br />

is prudent to add 10% to the overall deflection<br />

to arrive at a final value to allow for it.<br />

Additionally floor joists should be checked<br />

to ensure that their vibration performance is<br />

acceptable, this can be <strong>of</strong> concern with joists<br />

which span is in excess <strong>of</strong> 4.0m.<br />

www.thestructuralengineer.org<br />

Eurocode 0.<br />

Applied practice<br />

BS EN <strong>19</strong>95-1-1 Eurocode 5: <strong>Design</strong> <strong>of</strong><br />

<strong>Timber</strong> Structures – Part 1-1: General –<br />

Common rules and rules for buildings<br />

39<br />

<strong>Timber</strong> joist span tables<br />

It is possible to refer to timber joist span<br />

tables for sizing <strong>of</strong> joists, such as those<br />

included in Table 7 <strong>of</strong> BS 8103:3 2009. These<br />

tables however are limited to imposed loads<br />

<strong>of</strong> 1.5 kN/m 2 .<br />

Alternatively it is possible to use the<br />

Eurocode 5 Span Tables, that have been<br />

developed by TRADA. These have a similar<br />

set <strong>of</strong> tables, but again are limited to imposed<br />

loads <strong>of</strong> no greater than 1.5 kN/m 2 .<br />

BS EN <strong>19</strong>95-1-1 UK National Annex to<br />

Eurocode 5: <strong>Design</strong> <strong>of</strong> <strong>Timber</strong> Structures –<br />

Part 1-1: General – Common rules and rules<br />

for buildings<br />

BS EN 336 2009: Structural <strong>Timber</strong> –<br />

Sizes, permitted deviations<br />

BS EN 338 2009: Structural <strong>Timber</strong> –<br />

Strength classes<br />

BS 8103:3 2009: Structural <strong>Design</strong> <strong>of</strong> Lowrise<br />

Buildings Part 3: Code <strong>of</strong> practice for<br />

timber floors and ro<strong>of</strong>s for housing<br />

Glossary and<br />

further reading<br />

Hygroscopic – Moisture absorbing.<br />

Modification factors – Factors that<br />

are applied to the characteristic material<br />

properties <strong>of</strong> timber elements.<br />

Precamber – A forced deformation <strong>of</strong> a<br />

member that reduces the effect <strong>of</strong> deflection<br />

following the application <strong>of</strong> loads.<br />

Further Reading<br />

The Institution <strong>of</strong> Structural Engineers/<br />

TRADA (2010) Manual for the design <strong>of</strong><br />

timber building structures to Eurocode<br />

5 London: The Institution <strong>of</strong> Structural<br />

Engineers/TRADA<br />

TRADA (2009) Eurocode 5 span tables<br />

for solid timber members (3rd ed.) High<br />

Wycombe: TRADA<br />

Porteous, J. and Kermani, A. (2007)<br />

Structural <strong>Timber</strong> <strong>Design</strong> to Eurocode 5<br />

Chichester: John Wiley & Sons