Thermal Arc 95 S Brochure Click here to receive your free copy.

Thermal Arc 95 S Brochure Click here to receive your free copy.

Thermal Arc 95 S Brochure Click here to receive your free copy.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

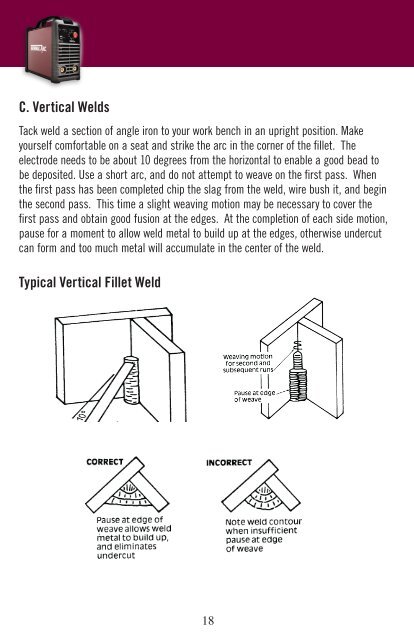

C. Vertical Welds<br />

Tack weld a section of angle iron <strong>to</strong> <strong>your</strong> work bench in an upright position. Make<br />

<strong>your</strong>self comfortable on a seat and strike the arc in the corner of the fillet. The<br />

electrode needs <strong>to</strong> be about 10 degrees from the horizontal <strong>to</strong> enable a good bead <strong>to</strong><br />

be deposited. Use a short arc, and do not attempt <strong>to</strong> weave on the first pass. When<br />

the first pass has been completed chip the slag from the weld, wire bush it, and begin<br />

the second pass. This time a slight weaving motion may be necessary <strong>to</strong> cover the<br />

first pass and obtain good fusion at the edges. At the completion of each side motion,<br />

pause for a moment <strong>to</strong> allow weld metal <strong>to</strong> build up at the edges, otherwise undercut<br />

can form and <strong>to</strong>o much metal will accumulate in the center of the weld.<br />

Typical Vertical Fillet Weld<br />

18