Effect of Large Shear Deformation on Rail Steels and Pure Metals

Effect of Large Shear Deformation on Rail Steels and Pure Metals

Effect of Large Shear Deformation on Rail Steels and Pure Metals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3<br />

3 Results <strong>and</strong> Discussi<strong>on</strong><br />

3.3 Mechanical Properties<br />

In order to characterize the changes in the mechanical properties due to the large shear deformati<strong>on</strong>,<br />

various methods were applied either after or during the deformati<strong>on</strong>. In the following<br />

secti<strong>on</strong>, the results <str<strong>on</strong>g>of</str<strong>on</strong>g> these measurements are shortly described.<br />

3.3.1 In-situ Measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> the Torque<br />

The development <str<strong>on</strong>g>of</str<strong>on</strong>g> a reliable <strong>and</strong> accurate possibility to measure the torque during deformati<strong>on</strong><br />

42, 69 allowed it to quickly determine changes in the mechanical strength without applying<br />

other methods afterwards. The torque that is measured c<strong>on</strong>tains next to the torque necessary to<br />

deform the sample MD solely a c<strong>on</strong>tributi<strong>on</strong> from the regi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the burr, MB. From the torque<br />

MD, the shear stress can be calculated according to Equati<strong>on</strong> 3.1:<br />

<br />

Md = 2πτ(r)r 2 dr (3.1)<br />

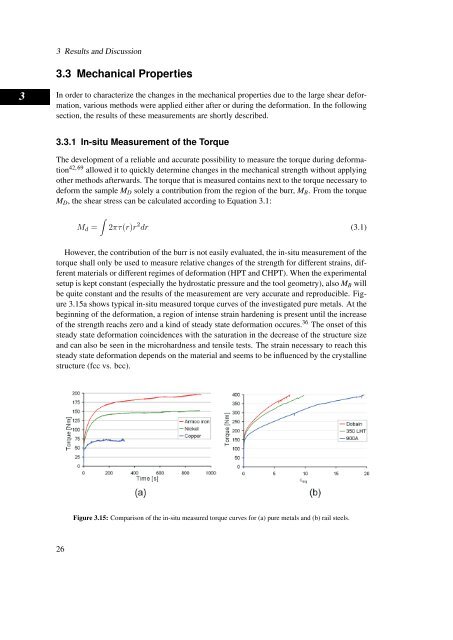

However, the c<strong>on</strong>tributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the burr is not easily evaluated, the in-situ measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

torque shall <strong>on</strong>ly be used to measure relative changes <str<strong>on</strong>g>of</str<strong>on</strong>g> the strength for different strains, different<br />

materials or different regimes <str<strong>on</strong>g>of</str<strong>on</strong>g> deformati<strong>on</strong> (HPT <strong>and</strong> CHPT). When the experimental<br />

setup is kept c<strong>on</strong>stant (especially the hydrostatic pressure <strong>and</strong> the tool geometry), also MB will<br />

be quite c<strong>on</strong>stant <strong>and</strong> the results <str<strong>on</strong>g>of</str<strong>on</strong>g> the measurement are very accurate <strong>and</strong> reproducible. Figure<br />

3.15a shows typical in-situ measured torque curves <str<strong>on</strong>g>of</str<strong>on</strong>g> the investigated pure metals. At the<br />

beginning <str<strong>on</strong>g>of</str<strong>on</strong>g> the deformati<strong>on</strong>, a regi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> intense strain hardening is present until the increase<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the strength reachs zero <strong>and</strong> a kind <str<strong>on</strong>g>of</str<strong>on</strong>g> steady state deformati<strong>on</strong> occures. 36 The <strong>on</strong>set <str<strong>on</strong>g>of</str<strong>on</strong>g> this<br />

steady state deformati<strong>on</strong> coincidences with the saturati<strong>on</strong> in the decrease <str<strong>on</strong>g>of</str<strong>on</strong>g> the structure size<br />

<strong>and</strong> can also be seen in the microhardness <strong>and</strong> tensile tests. The strain necessary to reach this<br />

steady state deformati<strong>on</strong> depends <strong>on</strong> the material <strong>and</strong> seems to be influenced by the crystalline<br />

structure (fcc vs. bcc).<br />

26<br />

Figure 3.15: Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the in-situ measured torque curves for (a) pure metals <strong>and</strong> (b) rail steels.