Evaluating the reliability of optical connectors

Evaluating the reliability of optical connectors

Evaluating the reliability of optical connectors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Evaluating</strong> <strong>the</strong> <strong>reliability</strong> <strong>of</strong> <strong>optical</strong> <strong>connectors</strong><br />

2<br />

The Telcordia standards that require simultaneously measuring <strong>optical</strong> characteristics <strong>of</strong><br />

multiple specimens are mainly concerned with passive <strong>optical</strong> components. In this report<br />

<strong>the</strong> term "passive <strong>optical</strong> components" refers to such items as fiber, <strong>connectors</strong>,<br />

switches, couplers, attenuators, and all types <strong>of</strong> filters. Table 1 shows <strong>reliability</strong> tests for<br />

typical <strong>optical</strong> components.<br />

3<br />

Test standards for passive <strong>optical</strong> components<br />

Table 1 Telcordia test standards<br />

Standard Title<br />

GR-326-CORE<br />

Generic Requirements for Single-Mode Optical Connectors and<br />

Jumper Assemblies<br />

GR-1209-CORE Generic Requirements for Passive Optical Components<br />

GR-1221-CORE<br />

Generic Reliability Assurance Requirements for Passive Optical<br />

Components<br />

Structure <strong>of</strong> <strong>optical</strong> <strong>connectors</strong> and factors affecting <strong>the</strong>ir <strong>reliability</strong><br />

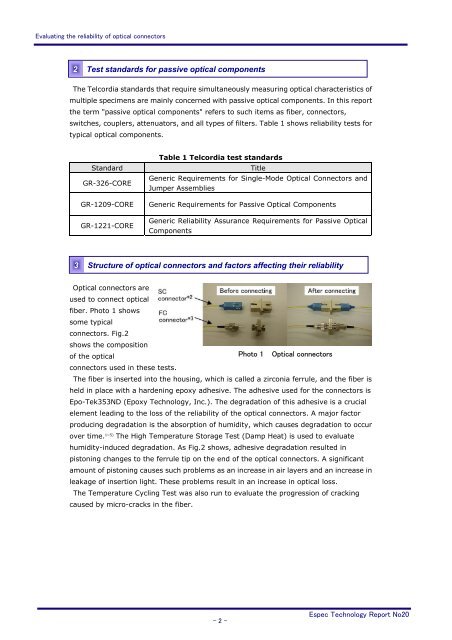

Optical <strong>connectors</strong> are<br />

used to connect <strong>optical</strong><br />

fiber. Photo 1 shows<br />

some typical<br />

<strong>connectors</strong>. Fig.2<br />

shows <strong>the</strong> composition<br />

<strong>of</strong> <strong>the</strong> <strong>optical</strong><br />

<strong>connectors</strong> used in <strong>the</strong>se tests.<br />

The fiber is inserted into <strong>the</strong> housing, which is called a zirconia ferrule, and <strong>the</strong> fiber is<br />

held in place with a hardening epoxy adhesive. The adhesive used for <strong>the</strong> <strong>connectors</strong> is<br />

Epo-Tek353ND (Epoxy Technology, Inc.). The degradation <strong>of</strong> this adhesive is a crucial<br />

element leading to <strong>the</strong> loss <strong>of</strong> <strong>the</strong> <strong>reliability</strong> <strong>of</strong> <strong>the</strong> <strong>optical</strong> <strong>connectors</strong>. A major factor<br />

producing degradation is <strong>the</strong> absorption <strong>of</strong> humidity, which causes degradation to occur<br />

over time. 1~5) Photo 1 Optical <strong>connectors</strong><br />

The High Temperature Storage Test (Damp Heat) is used to evaluate<br />

humidity-induced degradation. As Fig.2 shows, adhesive degradation resulted in<br />

pistoning changes to <strong>the</strong> ferrule tip on <strong>the</strong> end <strong>of</strong> <strong>the</strong> <strong>optical</strong> <strong>connectors</strong>. A significant<br />

amount <strong>of</strong> pistoning causes such problems as an increase in air layers and an increase in<br />

leakage <strong>of</strong> insertion light. These problems result in an increase in <strong>optical</strong> loss.<br />

The Temperature Cycling Test was also run to evaluate <strong>the</strong> progression <strong>of</strong> cracking<br />

caused by micro-cracks in <strong>the</strong> fiber.<br />

- 2 -<br />

Espec Technology Report No20