Evaluating the reliability of optical connectors

Evaluating the reliability of optical connectors

Evaluating the reliability of optical connectors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Evaluating</strong> <strong>the</strong> <strong>reliability</strong> <strong>of</strong> <strong>optical</strong> <strong>connectors</strong><br />

5<br />

Test method<br />

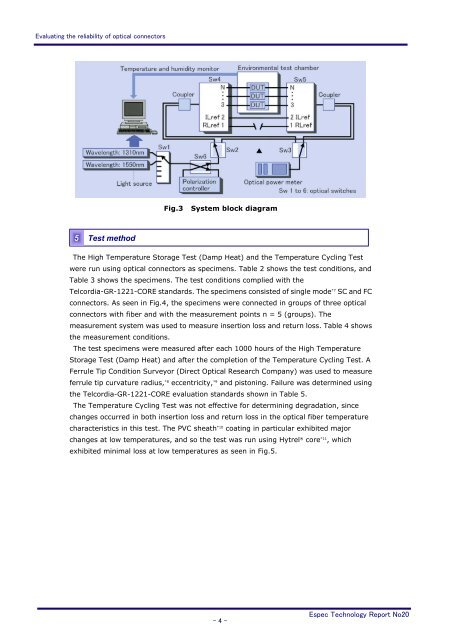

Fig.3 System block diagram<br />

The High Temperature Storage Test (Damp Heat) and <strong>the</strong> Temperature Cycling Test<br />

were run using <strong>optical</strong> <strong>connectors</strong> as specimens. Table 2 shows <strong>the</strong> test conditions, and<br />

Table 3 shows <strong>the</strong> specimens. The test conditions complied with <strong>the</strong><br />

Telcordia-GR-1221-CORE standards. The specimens consisted <strong>of</strong> single mode *7 SC and FC<br />

<strong>connectors</strong>. As seen in Fig.4, <strong>the</strong> specimens were connected in groups <strong>of</strong> three <strong>optical</strong><br />

<strong>connectors</strong> with fiber and with <strong>the</strong> measurement points n = 5 (groups). The<br />

measurement system was used to measure insertion loss and return loss. Table 4 shows<br />

<strong>the</strong> measurement conditions.<br />

The test specimens were measured after each 1000 hours <strong>of</strong> <strong>the</strong> High Temperature<br />

Storage Test (Damp Heat) and after <strong>the</strong> completion <strong>of</strong> <strong>the</strong> Temperature Cycling Test. A<br />

Ferrule Tip Condition Surveyor (Direct Optical Research Company) was used to measure<br />

ferrule tip curvature radius, *8 eccentricity, *9 and pistoning. Failure was determined using<br />

<strong>the</strong> Telcordia-GR-1221-CORE evaluation standards shown in Table 5.<br />

The Temperature Cycling Test was not effective for determining degradation, since<br />

changes occurred in both insertion loss and return loss in <strong>the</strong> <strong>optical</strong> fiber temperature<br />

characteristics in this test. The PVC sheath *10 coating in particular exhibited major<br />

changes at low temperatures, and so <strong>the</strong> test was run using Hytrel ® core *11 , which<br />

exhibited minimal loss at low temperatures as seen in Fig.5.<br />

- 4 -<br />

Espec Technology Report No20