You'll never have to cry over spilt milk - Astrapak

You'll never have to cry over spilt milk - Astrapak

You'll never have to cry over spilt milk - Astrapak

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12<br />

Unpacked is the official newsletter for employees of the <strong>Astrapak</strong> Group. If you <strong>have</strong> an<br />

interesting s<strong>to</strong>ry or news about a colleague who has excelled in any field, let us know. If<br />

it’s of interest <strong>to</strong> you, it would probably make interesting reading for others in the Group!<br />

All material published in Unpacked is protected by copyright and may not be reproduced without the permission of the <strong>Astrapak</strong> Group.<br />

Cullum Johns<strong>to</strong>n<br />

Tel: 021 671 9143 • Fax 021 683 0644<br />

cullum@imbongisa.com<br />

in this<br />

issue ...<br />

A world of opportunities<br />

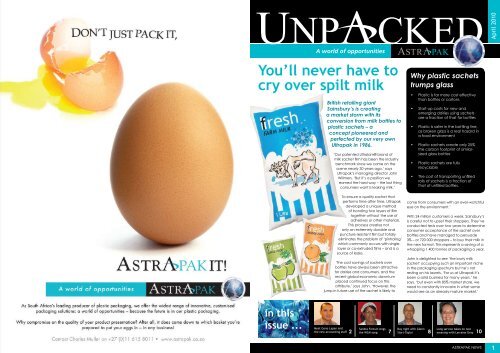

You’ll <strong>never</strong> <strong>have</strong> <strong>to</strong><br />

<strong>cry</strong> <strong>over</strong> <strong>spilt</strong> <strong>milk</strong><br />

British retailing giant<br />

Sainsbury’s is creating<br />

a market s<strong>to</strong>rm with its<br />

conversion from <strong>milk</strong> bottles <strong>to</strong><br />

plastic sachets – a<br />

concept pioneered and<br />

perfected by our very own<br />

Ultrapak in 1986.<br />

Meet Gene Lapan and<br />

the new accounting staff<br />

‘Our patented Ultralam® brand of<br />

<strong>milk</strong> sachet film has been the industry<br />

benchmark since we came on the<br />

scene nearly 30 years ago,’ says<br />

Ultrapak’s managing direc<strong>to</strong>r John<br />

Willmers. ‘But it’s a position we<br />

earned the hard way – the last thing<br />

consumers want is leaking <strong>milk</strong>.’<br />

To ensure a quality sachet that<br />

performs time after time, Ultrapak<br />

developed a unique method<br />

of bonding two layers of film<br />

<strong>to</strong>gether without the use of<br />

adhesives or other materials.<br />

This process creates not<br />

only an extremely durable and<br />

puncture-resistant film but <strong>to</strong>tally<br />

eliminates the problem of ‘pinholing’<br />

which commonly occurs with singlelayer<br />

or co-extruded films – and is a<br />

source of leaks.<br />

‘The cost savings of sachets <strong>over</strong><br />

bottles <strong>have</strong> always been attractive<br />

for dairies and consumers, and the<br />

recent global economic downturn<br />

placed continued focus on this<br />

attribute,’ says John. ‘However, the<br />

jump in future use of the sachet is likely <strong>to</strong><br />

Sandra Fortuin sings<br />

Why plastic sachets<br />

trumps glass<br />

come from consumers with an ever-watchful<br />

eye on the environment.’<br />

With 24 million cus<strong>to</strong>mers a week, Sainsbury’s<br />

is careful not <strong>to</strong> upset their shoppers. They’ve<br />

conducted tests <strong>over</strong> two years <strong>to</strong> determine<br />

consumer acceptance of the sachet <strong>over</strong><br />

bottles and <strong>have</strong> managed <strong>to</strong> persuade<br />

3% – or 720 000 shoppers – <strong>to</strong> buy their <strong>milk</strong> in<br />

the new format. This represents a saving of a<br />

whopping 1 400 <strong>to</strong>nnes of packaging a year.<br />

John is delighted <strong>to</strong> see ‘the lowly <strong>milk</strong><br />

sachet’ occupying such an important niche<br />

in the packaging spectrum but he’s not<br />

resting on his laurels. ‘For us at Ultrapak it’s<br />

been a solid business for many years,’ he<br />

says, ‘but even with 85% market share, we<br />

need <strong>to</strong> constantly innovate in what some<br />

would see as an already-mature market.’<br />

Buy right with Glenn<br />

Plastic is far more cost effective<br />

than bottles or car<strong>to</strong>ns<br />

Long service takes on new<br />

meaning with Larraine Gray<br />

2 the WCM song 7 Start-Taylor 8<br />

10<br />

ASTRAPAK NEWS ASTRAPAK NEWS 1<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Start-up costs for new and<br />

emerging dairies using sachets<br />

are a fraction of that for bottles<br />

Plastic is safer in the bottling line,<br />

as broken glass is a real hazard in<br />

a food environment<br />

Plastic sachets create only 25%<br />

the carbon footprint of similarsized<br />

glass bottles<br />

Plastic sachets are fully<br />

recyclable<br />

The cost of transporting unfilled<br />

rolls of sachets is a fraction of<br />

that of unfilled bottles.<br />

April 2010

2<br />

Appointments that<br />

add up <strong>to</strong> good news<br />

The finance department<br />

has, along with almost<br />

every aspect of<br />

<strong>Astrapak</strong>’s business,<br />

undergone a major<br />

reorganisation in an<br />

effort <strong>to</strong> streamline<br />

systems, improve<br />

reporting and ensure<br />

more stringent controls.<br />

Financial results that accurately<br />

reflect the state of a business are<br />

vital if that business is <strong>to</strong> succeed<br />

and grow, and this is one of the<br />

areas in which increased numbers and<br />

capabilities of accounting staff has<br />

made a difference, says chief financial<br />

officer Manley Diedloff. In addition <strong>to</strong> the<br />

appointment of George Toop, Renée<br />

Kirkham and André Smit as regional<br />

financial managers, the head office<br />

accounting staff has been bolstered with<br />

a new Group financial manager and<br />

three regional internal audi<strong>to</strong>rs.<br />

Gene Lapan<br />

Group financial manager<br />

Gene is a chartered accountant and<br />

comes <strong>to</strong> <strong>Astrapak</strong> from one of the<br />

country’s largest construction groups.<br />

He’s responsible for, among other<br />

things, all the company secretarial<br />

requirements, consolidating the returns of<br />

the Group results, preparing tax returns,<br />

managing the treasury accounts and<br />

foreign payments. He sees <strong>Astrapak</strong> as a<br />

dynamic organisation with a challenging<br />

yet supportive management style. In<br />

his spare time he provides volunteer<br />

administrative support for an NGO and<br />

socialises with family and friends.<br />

Cobus S<strong>to</strong>fberg<br />

internal audi<strong>to</strong>r, Eastern & Western Cape<br />

A graduate of the University of<br />

Stellenbosch, Cobus completed his<br />

articles at PriceWaterhouseCoopers<br />

(PWC) and has several years’ experience<br />

as an external audi<strong>to</strong>r. In his new role as<br />

an internal audi<strong>to</strong>r he’ll be keeping an<br />

eye on operations in the Eastern and<br />

Western Cape. He’s a bit of a cycle<br />

junkie, with more than 10 Argus Tours<br />

under his belt. Finding sufficient training<br />

time is always a challenge but Cobus was<br />

pleased <strong>to</strong> once again finish this year’s<br />

event within the cut-off time.<br />

Avisha Budhal<br />

internal audi<strong>to</strong>r, KwaZulu-Natal<br />

Avisha is a Unisa Bachelor of Accounting<br />

Science graduate and has almost<br />

completed her Certified Internal Audi<strong>to</strong>r<br />

(CIA) qualification. She was most recently<br />

with Ernst & Young Advisory Services,<br />

where she included a packaging<br />

company on her client list. She’s looking<br />

forward <strong>to</strong> a career with <strong>Astrapak</strong><br />

because of the exposure <strong>to</strong> the FMCG<br />

market and the challenges such an<br />

environment brings. She strongly supports<br />

Bafana Bafana and is confident that<br />

South Africa is going <strong>to</strong> host a wonderful<br />

World Cup.<br />

Vashnee Mahadeo<br />

internal audi<strong>to</strong>r, Gauteng<br />

Vashnee’s demure exterior hides a<br />

serious sports l<strong>over</strong>. Not only does she<br />

gym and play tennis, she also does<br />

karate – ideal skills <strong>to</strong> chop her way<br />

through a complicated audit. After<br />

completing her articles at the Office of<br />

the Audi<strong>to</strong>r General and some time in<br />

provincial audit, she went on <strong>to</strong> PWC and<br />

also worked at one of the large mining<br />

entities. She sees auditing as an effective<br />

management <strong>to</strong>ol, one that helps<br />

an organisation achieve its business<br />

goals through better management<br />

and controls.<br />

Trends changed and as business<br />

became less stiff and formal, Larraine<br />

had <strong>to</strong> adjust <strong>to</strong> being called by her<br />

first name by younger staffers and <strong>to</strong><br />

operating a computer rather than a<br />

manual typewriter (which she loved)<br />

and telex machine, not <strong>to</strong> mention<br />

getting her head around cellphone<br />

and email communication.<br />

Do you remember the classic Henry J?<br />

Marie-France Sullivan, a<br />

commercial manager at Alex<br />

White & Co, has an amazing<br />

40 years of service under her belt.<br />

Fresh from Mauritius, ‘with a French<br />

accent and Cambridge University<br />

education’, she began her career<br />

with the company as secretary <strong>to</strong><br />

the chairman, Alex White, and<br />

managing direc<strong>to</strong>r, Jack Kay. She<br />

laughingly recalls how patient Jack<br />

was as she battled <strong>to</strong> understand his<br />

Scots accent.<br />

‘In the early days, before I had my<br />

own car, I would catch the train in<strong>to</strong><br />

Joburg city centre and then walk <strong>to</strong><br />

the office in Sauer Street, whatever<br />

the season or the weather. And those<br />

were the days of the mini-skirt!’<br />

Marie-France thought the fax<br />

machine and her first Olivetti word<br />

processor were the greatest inventions<br />

ever and is still gobsmacked by how<br />

technology has progressed <strong>to</strong> enable<br />

It was obviously hard at times <strong>to</strong><br />

say goodbye <strong>to</strong> those who left the<br />

company or passed on but Larraine<br />

has always found strength in her<br />

faith and believes she couldn’t <strong>have</strong><br />

survived the good days – and the<br />

not-so-good days – without the grace<br />

of God.<br />

‘The years roll by and people come<br />

and go, and suddenly you realise<br />

you’ve got <strong>to</strong>o old <strong>to</strong> adjust <strong>to</strong> a new<br />

environment. And besides, my car<br />

wouldn’t cope with a different route<br />

<strong>to</strong> work; it would simply make an<br />

au<strong>to</strong>matic de<strong>to</strong>ur <strong>to</strong> Elsies River!’<br />

Larraine has been happily married <strong>to</strong><br />

the driver of the Henry J, Robert, for<br />

nearly 43 years and has two children<br />

and five granddaughters.<br />

us <strong>to</strong> do so much more in an eighthour<br />

day.<br />

One of the highlights of her career<br />

was in 1990 when she was appointed<br />

general manager and then direc<strong>to</strong>r of<br />

one of the subsidiary companies.<br />

It’s largely the wonderful people that<br />

<strong>have</strong> made it a wonderful journey,<br />

reflects Marie-France, and the fact<br />

that she’s still learning new things<br />

every day, which keeps her young.<br />

‘In my youth I was very sporty. I cycled<br />

and played volleyball, basketball and<br />

table tennis. These days I enjoying<br />

playing brain games like Sudoku and I<br />

love <strong>to</strong> cook and socialise.’<br />

She feels credit for her long service<br />

must also go <strong>to</strong> her husband, Gilbert,<br />

who remains her pillar of strength<br />

through good times and bad. Their<br />

daughter lives in the USA with<br />

her husband and Marie-France’s<br />

three grandchildren.<br />

It’s been an interesting 23 years<br />

of service for Jackie Koen, sales<br />

coordina<strong>to</strong>r for Hilfort Plastics.<br />

She remembers having <strong>to</strong> do<br />

everything manually back in the<br />

days of carbon paper, adding<br />

machines with tally rolls and writing<br />

out hundreds of railway labels.<br />

‘In the good ol’ days I’d walk<br />

through the fac<strong>to</strong>ry <strong>to</strong> pick up a<br />

bottle sample <strong>to</strong> show clients – an<br />

absolute no-no <strong>to</strong>day,’ explains<br />

Jackie, ‘and I knew every face<br />

and every bottle code. With our<br />

expansion <strong>over</strong> the last few years<br />

there are now <strong>to</strong>o many faces and<br />

<strong>to</strong>o many codes <strong>to</strong> remember, not<br />

<strong>to</strong> mention the new pack sizes.’<br />

She’d just clocked up 10 years<br />

at Trident-Kohler-Xactics Plastics<br />

when Dave Balkwill, ex-managing<br />

direc<strong>to</strong>r of Hilfort, asked her <strong>to</strong><br />

join the old Lindale Plastics family<br />

again. ‘There were just six of us in<br />

the office and we used <strong>to</strong> get the<br />

most delicious ham rolls for lunch.’<br />

Jackie has been married <strong>to</strong> Danie<br />

for 34 years and they <strong>have</strong> a<br />

daughter in London and a son<br />

who’s in charge of the buffet<br />

section on the ocean liner Odyssey.<br />

She enjoys watching sport on TV<br />

and is a committed Chelsea fan.<br />

She also breeds Siamese, Oriental<br />

and American Curl cats.<br />

ASTRAPAK NEWS ASTRAPAK NEWS<br />

11

10<br />

Cus<strong>to</strong>mers certainly aren’t slippery<br />

fish for Marcom’s key account<br />

manager and koi collec<strong>to</strong>r<br />

Gerhard van Reenen: he recently<br />

landed the order for Parmalat SA’s<br />

entire range of yoghurt containers.<br />

Keeping koi<br />

Koi fish are ornamental,<br />

domesticated varieties of<br />

common carp, originally<br />

bred in the Far East for their<br />

gorgeous colour mutations.<br />

These cold-water fish are hardy<br />

little creatures and make<br />

delightful pets – they quickly<br />

come <strong>to</strong> recognise their keeper and will gather<br />

around enthusiastically at feeding times, and<br />

can even be trained <strong>to</strong> take food directly from<br />

their feeder’s hand.<br />

Koi can live for centuries – a particularly famous<br />

scarlet koi, Hanako, was 226 years old when she<br />

died in 1977 and had had several owners.<br />

Koi are symbols of love and friendship in the Far<br />

East.<br />

Source: Wikipedia<br />

One that didn’t get away<br />

Pre<strong>to</strong>ria-based Marcom Plastics<br />

is a leader in in-mould labelling<br />

(IML), a method of bonding the<br />

label <strong>to</strong> the container in the injection-moulding<br />

process. This creates a<br />

finished package that’s branded <strong>to</strong><br />

the most exacting quality standards<br />

and offers great visual attraction<br />

for shoppers.<br />

‘Conventional printing often<br />

performed poorly in the dairy<br />

environment. Temperature<br />

fluctuations, water and<br />

condensation are all issues<br />

that contributed <strong>to</strong> making the<br />

appearance and, consequently,<br />

the finished product unappealing,’<br />

explains key account manager<br />

Gerhard van Reenen. ‘IML has<br />

revolutionised that because the<br />

package and the label are one<br />

seamless unit. The move from<br />

conventional labelling <strong>to</strong> IML has<br />

caused<br />

some of our cus<strong>to</strong>mers <strong>to</strong> increase<br />

volumes by <strong>over</strong> 40%.’<br />

IML isn’t an easy sell, however. The<br />

process is more expensive than<br />

traditional forms and some of the<br />

larger dairies <strong>have</strong> been hesitant<br />

<strong>to</strong> make the move. But Marcom’s<br />

strategy of piloting the technology<br />

with smaller dairies has paid off, with<br />

the larger outfits now accepting IML<br />

as the future packaging wave.<br />

Gerhard’s success didn’t happen<br />

<strong>over</strong>night. This dedicated family<br />

man joined Marcom 12 years ago<br />

Staying through<br />

decades of change<br />

Larraine Gray, personal assistant <strong>to</strong> Henk<br />

de Klerk at Thermopac, has racked up<br />

an as<strong>to</strong>nishing 47 years of service with<br />

the Group.<br />

She was just 15 when she was hired as a typist<br />

by then-MD Willi Schutten and was thrilled<br />

with her starting salary of R60 per month –<br />

good earnings then, when a Coke from a<br />

colddrink machine cost five cents and R30<br />

got you a night at a hotel.<br />

She worked for Willi for 25 years and they’re<br />

still in contact <strong>to</strong>day. ‘What started as a<br />

job very soon became a way of life,’ says<br />

Larraine with her wonderful infectious laugh.<br />

as a print supervisor on a fivecolour<br />

machine and has steadily<br />

progressed through the production<br />

ranks. In 2008 he <strong>to</strong>ok <strong>over</strong> the sales<br />

responsibilities of a key account<br />

manager who left – and he hasn’t<br />

looked back.<br />

‘I see cus<strong>to</strong>mer service as the<br />

key differentiating fac<strong>to</strong>r in our<br />

industry and believe this is an area<br />

where <strong>Astrapak</strong> must dominate.<br />

My secret <strong>to</strong> success has been my<br />

willingness <strong>to</strong> address the issues<br />

that affect my clients’ ability <strong>to</strong><br />

manufacture. Coming from a handson<br />

background, I’ve found myself<br />

getting involved in and resolving<br />

technical, logistical and marketrelated<br />

problems. But the results<br />

<strong>have</strong> been worth it: with these issues<br />

out of the way, sales <strong>have</strong> grown<br />

naturally.’ And phenomenally –<br />

Gerhard’s annual turn<strong>over</strong> has<br />

grown almost 14-fold in two years.<br />

‘Gerhard is a diamond in<br />

the rough,’ says Rigids’ Exco<br />

direc<strong>to</strong>r Craig Lowe. ‘His handson<br />

knowledge is coupled with<br />

an uncompromising attitude<br />

<strong>to</strong> value and service delivery –<br />

skills that he used in Marcom’s<br />

supply chain function and is<br />

now applying <strong>to</strong> cus<strong>to</strong>mers’<br />

benefit. His achievements<br />

in securing new blue-chip<br />

business is an integral part<br />

of Marcom’s success and I<br />

commend Gerhard for his<br />

efforts so far.’<br />

We’re truly fortunate <strong>to</strong> <strong>have</strong> many committed<br />

and dedicated people across all the<br />

companies in the Group. Among them are<br />

staffers who’ve travelled interesting journeys<br />

and who fondly recall the good ol’ days.<br />

Larraine remembers being driven <strong>to</strong> work by<br />

her boyfriend in his grey 1950s left-hand-drive<br />

Classic Henry J, a unique car with a long front<br />

seat. She also recalls how much more formal<br />

the dress code was then.<br />

The annual shutdown was a time of great<br />

festivity. ‘There was always huge excitement on<br />

the last day of work before everyone went off<br />

on holiday and the female staffers would come<br />

all dolled up in their Sunday best <strong>to</strong> celebrate.’<br />

She also fondly remembers how the tea lady<br />

at the time dressed up <strong>to</strong> the nines on Board<br />

meeting day because all the direc<strong>to</strong>rs<br />

were coming.<br />

Waste not and be<br />

well rewarded<br />

Care for a condom? From left, Diedericks Diseko, Rina<br />

Sekatane, Alpheus Masebe, Carol Kleinhans, Deon<br />

Swart, Robin Teasdale, Deedee Mudzunga and Evelyn<br />

Noge (kneeling, front).<br />

Debbie Kidwell, executive PA<br />

at Cinqpet, and colleagues<br />

decided <strong>to</strong> do something<br />

different <strong>to</strong> celebrate national<br />

Aids Day at the end of last year. Dressed<br />

in their bright-red corporate T-shirts and<br />

armed with all things proudly South<br />

African, they <strong>to</strong>ok <strong>to</strong> the streets <strong>to</strong> spread<br />

the message of safe sex by handing out<br />

condoms courtesy of the Department<br />

of Health. Their first s<strong>to</strong>p was their own<br />

fac<strong>to</strong>ry and they ended up at Cinqplast<br />

down the road.<br />

Bernelene Narayanasami was justly<br />

rewarded when she used the plastic<br />

offcuts from Pacon’s fac<strong>to</strong>ry floor <strong>to</strong><br />

create a unique recycled dress for a<br />

school project – she scored full marks.<br />

The 15-year-old daughter of Booysen,<br />

Pacon’s driver for the past six years,<br />

approached her dad for help with a<br />

consumer studies assignment on recyclable<br />

material. Booysen and some colleagues<br />

collected the offcuts while Bernelene went<br />

<strong>to</strong> work on the style and design of the<br />

fashion ensemble, complete with handbag<br />

and shoes.<br />

Bernelene didn’t just receive 100% for the<br />

project; her teachers were so impressed with<br />

the end result that they invited her <strong>to</strong> model<br />

her unique creation for a wider audience at<br />

the school <strong>to</strong> show what can be achieved<br />

with innovation and hard work.<br />

Pounding the pavement<br />

for Aids awareness<br />

Message from Marco<br />

We need <strong>to</strong><br />

keep our eye<br />

on the ball<br />

We’re in<strong>to</strong> the final<br />

countdown <strong>to</strong> kick-off<br />

and the excitement<br />

around World Cup 2010<br />

is starting <strong>to</strong> become<br />

real. The stadiums are<br />

looking stunning and<br />

South Africa is ready <strong>to</strong><br />

host this extravaganza.<br />

Still, in the face of this<br />

global party, we need <strong>to</strong> keep our focus on<br />

matters closer <strong>to</strong> home – running our business as<br />

productively as we can.<br />

First off, it’s a very big thankyou <strong>to</strong> each and every<br />

staff member for your hard work and commitment<br />

<strong>over</strong> the past financial year. As you know, 1 March<br />

was the start of a new accounting period and this<br />

brings new budgets, new projects, new strategies<br />

and, probably, a few<br />

new challenges.<br />

While we’re not yet able <strong>to</strong> divulge the details<br />

of the past year’s financial performance, I’m<br />

positive that when we release the figures in May,<br />

we’ll be reporting results that the market will find<br />

acceptable.<br />

One of the areas where we’ve made significant<br />

progress is on the subject of our culture change.<br />

As a business, we’ve started <strong>to</strong> do things<br />

differently. Through programmes like WCM<br />

we’re empowering every employee <strong>to</strong> make a<br />

contribution and we’re already seeing significant<br />

improvement in morale, production<br />

and efficiencies.<br />

A culture can’t be imposed. An organisation can<br />

be guided through actions but it needs <strong>to</strong> earn<br />

its own identity. It’s a sort of rite of passage – you<br />

<strong>have</strong> <strong>to</strong> <strong>have</strong> done the hard yards first. I’d like<br />

<strong>Astrapak</strong> <strong>to</strong> be a place where every employee<br />

sees themselves as a vital part of the bigger team.<br />

This is a <strong>to</strong>pic of great importance <strong>to</strong> me and I’ll<br />

be personally driving it this year.<br />

We’re planning <strong>to</strong> communicate with staff<br />

differently from how we <strong>have</strong> in the past and<br />

want <strong>to</strong> include as many people as possible in the<br />

three regional mini-conferences, on 13, 18 and 19<br />

May, in Cape Town, Durban and Johannesburg,<br />

respectively. There’ll be more information on this<br />

closer <strong>to</strong> the time.<br />

The past 24 months <strong>have</strong> been a tumultuous<br />

period in our corporate his<strong>to</strong>ry but I’m extremely<br />

confident that we’ve probably finished with the<br />

hardest parts of reorganising our business. Now<br />

we’re a few weeks in<strong>to</strong> our new financial year and<br />

need <strong>to</strong> become focused on achieving budgets<br />

as projected. We <strong>have</strong> the right team in place<br />

and our systems and plans are prepared. Now,<br />

we just need <strong>to</strong> go and do the job. Remember, at<br />

<strong>Astrapak</strong> there’s a world of opportunities.<br />

Thanks again for last year’s outstanding effort and<br />

here’s <strong>to</strong> an even better one this time round.<br />

ASTRAPAK NEWS ASTRAPAK NEWS<br />

Regards<br />

3

4<br />

This won’t come as a shock<br />

‘It not only makes financial sense<br />

<strong>to</strong> use electricity wisely because<br />

of the significant price increases<br />

we’re about <strong>to</strong> see introduced <strong>over</strong><br />

the next three years, we should do<br />

it because it’s part of our role as<br />

responsible business leaders caring for<br />

the environment,’ says Henk.<br />

<strong>Astrapak</strong>’s energy-management<br />

policy has a number of very specific<br />

objectives.<br />

• To reduce operational costs by at<br />

least 10% by 2015 through energy<br />

conservation and efficiency<br />

practices;<br />

• <strong>to</strong> reduce expenditure on energy<br />

by investing in cost-effective<br />

plant and equipment upgrades<br />

with a simple payback return on<br />

investment of three years or less;<br />

• <strong>to</strong> educate and train employees<br />

<strong>to</strong> be energy efficient; and<br />

• <strong>to</strong> buy energy at the most<br />

economic cost.<br />

An energy management team has<br />

been established, representing all<br />

regions within the Group, and they<br />

are tasked with reporting back <strong>to</strong><br />

Exco bi-monthly on savings goals and<br />

SABC weatherman Simon Gear’s<br />

Going Green is a wonderful little<br />

handbook offering ways <strong>to</strong> make<br />

the planet a better place, one<br />

day at a time. Simon offers 365<br />

easy-<strong>to</strong>-implement ideas – and<br />

we’re going <strong>to</strong> feature some of<br />

them in this and future issues <strong>to</strong><br />

help get you started on<br />

decreasing your carbon footprint and making your<br />

environment more sustainable.<br />

We <strong>have</strong> a copy of this fantastic little guide <strong>to</strong> give away<br />

<strong>to</strong> someone who has their own ‘Going Green’ tip <strong>to</strong> offer<br />

(one that isn’t featured in the book). Email your<br />

suggestion <strong>to</strong> savings@astrapak.co.za by 30 April and<br />

you could soon <strong>have</strong> your very own copy of Going Green:<br />

365 Ways To Change Our World .<br />

We <strong>have</strong> <strong>to</strong> become more<br />

efficient consumers of all<br />

forms of energy, and the<br />

new policy adopted by Exco<br />

is going <strong>to</strong> give us a jumpstart,<br />

says energy champion<br />

Henk de Klerk.<br />

achievements. In addition, they will<br />

be spearheading a communications<br />

programme focused on every staff<br />

member and what they can do <strong>to</strong><br />

reduce energy consumption – some<br />

tips are given alongside as a starting<br />

point.<br />

Measuring consumption is the starting<br />

point and a sophisticated moni<strong>to</strong>ring<br />

program is being installed at every<br />

operation. This online system will<br />

enable remote moni<strong>to</strong>ring of every<br />

aspect of electricity consumption<br />

and includes extensive reporting<br />

mechanisms <strong>to</strong> compare previous<br />

versus current usage levels among<br />

other measurement <strong>to</strong>ols.<br />

This programme isn’t aimed only<br />

at management. ‘We see it as a<br />

programme that everyone can<br />

participate in,’ says Henk. ‘We’ve<br />

included a list alongside of some<br />

simple things that each one of us can<br />

do at work and home <strong>to</strong> reduce our<br />

energy consumption. So let’s look<br />

at all the things we do every day<br />

that use electricity, and identify and<br />

change those habits or processes that<br />

are wasteful.’<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

HANGE<br />

your world<br />

for the better<br />

Give green gifts<br />

The opportunities <strong>to</strong> change people’s<br />

lives with fairly simple gifts are<br />

boundless. Chat <strong>to</strong> your co-workers<br />

and friends <strong>to</strong> get a sense of what sort<br />

•<br />

Simple but smart<br />

Making these easy energy-saving<br />

behaviours a habit will contribute<br />

<strong>to</strong>wards fewer expenses for you and a<br />

better planet for our children.<br />

Switch off all lights and appliances when<br />

they’re not in use, including your cellphone<br />

charger and your computer.<br />

Replace all your ordinary light bulbs with<br />

energy-efficient ones.<br />

In summer, keep the doors and windows closed<br />

during the hottest part of the day and open<br />

them in the evening <strong>to</strong> allow a cool throughflow<br />

of air.<br />

In winter, wear extra jerseys and thick, woolly<br />

socks and use a hot-water bottle rather than<br />

a heater.<br />

When making tea or coffee, fill the kettle with<br />

only the amount of water you need, and use it<br />

immediately rather than letting it cool and then<br />

having <strong>to</strong> reboil it.<br />

When boiling water on the s<strong>to</strong>ve (eg, for pasta<br />

or pota<strong>to</strong>es), put a well-fitting lid on the pot <strong>to</strong><br />

keep the heat in and speed up the process,<br />

and match the pot <strong>to</strong> the correct-sized s<strong>to</strong>ve<br />

plate – make sure the pot completely c<strong>over</strong>s<br />

the s<strong>to</strong>ve plate.<br />

Defrost your freezer regularly, two or three times<br />

a year. Make sure the fridge and freezer seals<br />

are tight, and don’t site your fridge or freezer<br />

near the s<strong>to</strong>ve.<br />

Open the fridge only when necessary <strong>to</strong> take<br />

out or put food away, and keep the door open<br />

for as short a time as possible.<br />

Wait till you <strong>have</strong> a full load before you run the<br />

dishwasher, and make sure its filters are clear<br />

of debris. Use short wash cycles or the ‘eco’<br />

setting if your dishwasher has one.<br />

Wait until you <strong>have</strong> a full load before you<br />

run the washing machine, and use lowtemperature<br />

settings whe<strong>never</strong> possible.<br />

Dry clothes naturally whe<strong>never</strong> possible.<br />

Showers are much more energy-efficient<br />

than baths.<br />

Turn your geyser temperature down <strong>to</strong> around<br />

55 degrees, and insulate it and the hot-water<br />

pipes with newspaper or old blankets.<br />

of lives they lead and then find<br />

something that will make a difference.<br />

Be creative by considering<br />

alternatives such as a selection of<br />

vegetable seeds, organic <strong>to</strong>iletries or<br />

an LED headlamp for reading in bed<br />

at night, or adopting a zoo animal.<br />

Keeping fit,<br />

losing weight<br />

and seeing the<br />

countryside are just a few of<br />

the benefits you can get from<br />

cycling, so why not dust off your<br />

bike and sign up for the annual<br />

Amashova Durban Classic?<br />

It’s become a regular feature for a<br />

team from <strong>Astrapak</strong> <strong>to</strong> participate in<br />

the 106km Amashova Durban Classic<br />

cycling event and 2010 will be no<br />

exception. It’s a fantastic day out and<br />

there’s loads of entertainment for family<br />

and friends.<br />

Improve your life – cycle<br />

‘We take out all the schlep involved in<br />

entering the race and the logistics prior <strong>to</strong><br />

the event,’ says unofficial organisers Erica<br />

MacDonald and Maureen Haslehurst.<br />

‘We do our best <strong>to</strong> get sponsored with<br />

<strong>Astrapak</strong>-branded cycling gear, collect<br />

and distribute all the goodie bags and<br />

arrange for a hospitality tent after the<br />

race. All you <strong>have</strong> <strong>to</strong> do is let us know<br />

you’re committed and we’ll take care of<br />

the rest.’<br />

This year’s event takes place on Sunday<br />

17 Oc<strong>to</strong>ber, starting in Pietermaritzburg<br />

and finishing at the brand-new Moses<br />

Mabhida Stadium in Durban.<br />

Erica and Maureen are looking for about<br />

70 participants for Team <strong>Astrapak</strong>. If<br />

you’re keen, contact Maureen on<br />

mo@pacon.co.za or phone 031 569 6100.<br />

‘I love <strong>to</strong> go a-wandering…’<br />

At work, Charles Bushby is a buyer for Hilfort Plastics<br />

in the engineering department. At play, he’s happiest<br />

with his hiking buddies exploring a new trail and being<br />

close <strong>to</strong> nature.<br />

Over the 18 years Charles<br />

Bushby has been with the<br />

company, he’s been a<br />

driver and done time in<br />

Design and Development and in the<br />

<strong>to</strong>olroom. Three years ago he was<br />

assigned the task of buying the parts <strong>to</strong><br />

operate the machinery.<br />

It was around the same time that<br />

a friend invited him <strong>to</strong> join a group<br />

tackling a two-day hike in Swellendam,<br />

as one of the team couldn’t make it at<br />

the last minute. It was this that sparked<br />

Charles’s love for backpacking.<br />

Charles has since completed 12 hikes<br />

around the Western Cape, each<br />

presenting unique surroundings and<br />

challenges but all equally inspirational<br />

and cleansing for the mind and soul.<br />

Charles’s latest conquest was the sixday<br />

Outeniqua Trail, one of the <strong>to</strong>ugher<br />

walks c<strong>over</strong>ing almost 90 kilometres<br />

through the mountains between<br />

George and Plettenberg Bay.<br />

‘We were a small group of four that<br />

set off on the first day with backpacks<br />

It’s more about participation and fun than winning,<br />

here Western Cape internal audi<strong>to</strong>r Cobus S<strong>to</strong>fberg<br />

races across the finish line.<br />

weighing in at almost 20 kilograms. It<br />

was a challenging trail with plenty of<br />

climbs up and down mountains and<br />

walks through forests and across rivers,<br />

but there’s nothing like the feeling of<br />

being removed from everything and<br />

<strong>to</strong>tally focused on your next step. And<br />

the simplest of foods taste absolutely<br />

magnificent when you’re in the<br />

wilderness; my most memorable was an<br />

avo-and-ham sarmie and boiled egg at<br />

the lunch s<strong>to</strong>p on day two.<br />

‘There were some really sweaty<br />

moments, like when we had <strong>to</strong><br />

negotiate our way around the cliffs<br />

<strong>over</strong>looking the sea knowing that two<br />

American <strong>to</strong>urists had fallen there a<br />

few years ago, and coming across an<br />

angry puffadder. Fortunately, we had<br />

an experienced leader and great team<br />

spirit, a must for a successful hike.’<br />

With the many pressures and stresses of<br />

business <strong>to</strong>day, it’s important <strong>to</strong> pursue<br />

leisure activities that are both physically<br />

and spiritually rewarding. Hiking, says<br />

Charles, is definitely worth considering –<br />

but not, he adds, without a good supply<br />

of Voltaren and Deep Heat!<br />

ASTRAPAK NEWS ASTRAPAK NEWS 9

8<br />

Opening the doors The<br />

A<br />

group of 25 post-matric students from the National<br />

Tooling Initiative recently <strong>to</strong>ured Cinqpet in Denver<br />

as part of a Department of Trade and Industry<br />

programme <strong>to</strong> boost the number of people<br />

embarking on <strong>to</strong>ol-and-die-making apprenticeships.<br />

In recent years the number of candidates signing up for<br />

traditional apprenticeships has fallen and this coincides with a<br />

corresponding massive skills shortage throughout South Africa.<br />

Cinqpet general manager Jeff Carder supports the<br />

programme. ‘I was really impressed with the quality of the<br />

trainees <strong>to</strong>uring our operation and think the initiative is<br />

great,’ he says. ‘I’m sure that <strong>Astrapak</strong> as a Group will likely<br />

be recruiting from this type of programme. It was impressive<br />

<strong>to</strong> see how many women were also interested in taking on<br />

an apprenticeship – clear signs that the traditionally maledominated<br />

shop floor may be a thing of the past.’<br />

The saving potential of procurement<br />

‘Best practice’ is a process, technique<br />

or innovative use of resources that has<br />

a proven record of success in providing<br />

significant improvement in cost, schedule,<br />

quality, performance, safety, environment<br />

or other measurable fac<strong>to</strong>rs that impact the<br />

health of an organisation.<br />

Durban-based Group procurement manager<br />

Glenn Start-Taylor gives us the bot<strong>to</strong>m line.<br />

Main responsibilities of a procurement manager?<br />

I coordinate and negotiate purchasing contracts so that we can achieve our<br />

goal of lowest-cost producer. To do this, we need <strong>to</strong> bring <strong>to</strong>gether the <strong>to</strong>tal<br />

buying power of all the business units.<br />

Aren’t the people in each operation closer <strong>to</strong> the action, so better able <strong>to</strong> know<br />

their needs?<br />

In some instances this is true and, where required, we call on their expertise.<br />

However, we need <strong>to</strong> ensure we use ‘best practices’ across the Group <strong>to</strong><br />

maximise our purchasing power.<br />

Experience you bring <strong>to</strong> the table?<br />

I <strong>have</strong> 25 years’ experience in plastic packaging and I’m a qualified Cost and<br />

Management Accountant. I’ve spent time in senior management positions<br />

within Finance, as well as having held senior positions at various packaging<br />

companies.<br />

Does your work really save us money?<br />

Most definitely. The <strong>Astrapak</strong> Group spends in excess of R1.5 billion per annum<br />

in the area of controllable costs. Each 1% saving would add R15 million <strong>to</strong> the<br />

bot<strong>to</strong>m line.<br />

When not keeping tabs on our spending, what do you do <strong>to</strong> relax?<br />

I play golf and enjoy gardening.<br />

The Group’s organisational structure<br />

has been streamlined<br />

Group has been reorganised in<strong>to</strong> two divisions, Flexibles<br />

and Rigids, with those companies in Industrial now<br />

becoming part of the renamed Flexible unit. The name<br />

Alex White<br />

Barrier Films<br />

City Pack<br />

East Rand Plastics<br />

Knilam<br />

Packaging Consultants<br />

Pack-Line<br />

Peninsula Packaging<br />

Plusnet<br />

Saflite<br />

Tristar<br />

Ultrapak<br />

• Marco Baglione – chairperson<br />

• Manley Diedloff<br />

• Keith Watkins<br />

• Charles Muller<br />

• Geoff Cuttler<br />

• Henk de Klerk<br />

• Herman Jacobs<br />

• Craig Lowe<br />

• Robin Olbrich<br />

• Alan Payne<br />

Manley Diedloff and Marco Baglione<br />

serve on the main Board of Direc<strong>to</strong>rs<br />

and report on all matters <strong>to</strong> them.<br />

change from Films <strong>to</strong> Flexibles is in keeping with international<br />

terminology and the reduction in divisions emphasises our desire<br />

<strong>to</strong> increase focus as we grow in<strong>to</strong> the future.<br />

Flexibles Rigids<br />

Overseeing the activities of each business unit is a Divisional Board.<br />

Keith Watkins – chairperson<br />

Charles Muller<br />

Geoff Cuttler<br />

Henk de Klerk<br />

Herman Jacobs<br />

André Smit<br />

Deon van der Merwe<br />

Cinqpet<br />

Cinqplast Plas<strong>to</strong>p Denver<br />

Consupaq<br />

Hilfort Plastics<br />

JJ Precision Plastics<br />

Marcom Plastics<br />

Pak2000<br />

Plastech<br />

Plastform<br />

Plas<strong>to</strong>p Bronkhorstspruit<br />

Plas<strong>to</strong>p KZN<br />

Thermopac<br />

Weener Plas<strong>to</strong>p (changed from<br />

Euromatic Plas<strong>to</strong>p)<br />

The operations <strong>have</strong> also been arranged in<strong>to</strong> business units so they can extract the maximum efficiencies and synergies among<br />

like-focused product ranges.<br />

Flexibles – Coastal<br />

• Packaging Consultants<br />

• Pack-Line<br />

• Peninsula Packaging<br />

• Ultrapak<br />

PET Unit<br />

• Cinqpet<br />

• Hilfort Plastics<br />

• Plastech<br />

The<br />

operational<br />

buck s<strong>to</strong>ps<br />

at the Exco<br />

team<br />

Flexibles – Inland<br />

• City Pack<br />

• East Rand Plastics<br />

• Plusnet/Geotex<br />

• Tristar Plastics<br />

Rigids – Coastal<br />

• Consupaq<br />

• JJ Precision Plastics<br />

• Pak2000<br />

• Plas<strong>to</strong>p KZN<br />

Barrier Unit<br />

• Barrier Films<br />

• Knilam<br />

• Thermopac<br />

• Saflite<br />

Flexibles Rigids<br />

Keith Watkins – chairperson<br />

Charles Muller<br />

Craig Lowe<br />

Robin Olbrich<br />

Alan Payne<br />

George Toop<br />

Rigids – Inland<br />

• Alex White<br />

• Cinqplast Plas<strong>to</strong>p Denver<br />

• Marcom Plastics<br />

• Plastform<br />

• Plas<strong>to</strong>p Bronkhorstpruit<br />

• Weener Plastics<br />

ASTRAPAK NEWS ASTRAPAK NEWS 5

6<br />

The correct type<br />

and quantity-onhand<br />

of raw<br />

material is the<br />

corners<strong>to</strong>ne<br />

of efficient<br />

manufacturing.<br />

Thanks <strong>to</strong> Syspro,<br />

the process<br />

of managing<br />

this important<br />

resource has<br />

become much<br />

easier and more<br />

accurate.<br />

Accurate s<strong>to</strong>ck control, be it raw materials or finished goods, is a corners<strong>to</strong>ne of efficient production techniques, thanks <strong>to</strong> hand-held scanners and the Syspro enterprise<br />

management system this is now a breeze in most <strong>Astrapak</strong> operations.<br />

Syspro takes the hassle<br />

out of s<strong>to</strong>ck control<br />

‘It all starts with a bill of material,’<br />

says systems consultant Renée<br />

Kirkham. This bill – it’s called a BOM<br />

– lists quantities of all the materials<br />

required <strong>to</strong> produce a particular product,<br />

the machine needed <strong>to</strong> run the product<br />

on and the amount of time needed<br />

<strong>to</strong> run it.<br />

‘You can imagine, in our Group, there are<br />

thousands of these records,’ says Renée.<br />

‘Each one must be kept accurate and<br />

up <strong>to</strong> date because, <strong>to</strong>gether with the<br />

current s<strong>to</strong>ck on hand, other orders in the<br />

system, jobs currently planned and<br />

safety s<strong>to</strong>ck levels, that’s what the<br />

system uses <strong>to</strong> calculate the quantity<br />

of product required when the sales order<br />

is received.’<br />

The system determines if additional<br />

raw materials are required and can<br />

produce a purchase order at that point.<br />

Importantly, input costs are established<br />

right up front <strong>to</strong> ensure that product<br />

won’t be manufactured at a loss.<br />

S<strong>to</strong>ck management is another important<br />

aspect. All material should be controlled<br />

on a first-in, first-out (FIFO) basis, and<br />

Syspro generates picking slips <strong>to</strong> help<br />

with this.<br />

Reconciliation of theoretical s<strong>to</strong>ck<br />

levels with actual material in the<br />

warehouse is also a fundamental of<br />

good manufacturing, and daily cyclical<br />

counts <strong>have</strong> <strong>to</strong> be carried out. These are<br />

entered in<strong>to</strong> the system and a variance<br />

report showing the difference between<br />

system s<strong>to</strong>ck and physical s<strong>to</strong>ck is<br />

generated by Syspro for investigation.<br />

‘One area that was often forgotten<br />

was the scrap,’ Renée says. ‘Taking<br />

greater interest in this item not only<br />

raises awareness of trying <strong>to</strong> reduce its<br />

occurrence, but in the average plant<br />

it’s worth a substantial amount of<br />

money and needs <strong>to</strong> be looked after<br />

and reused.’<br />

As with any system, though, the quality<br />

of the information coming out is directly<br />

linked <strong>to</strong> the data entered throughout<br />

the capturing process. For this reason,<br />

it’s vital that absolutely everything – raw<br />

material, semi-finished and finished<br />

goods, consignment s<strong>to</strong>ck, consumables,<br />

engineering spares, scrap, inks, labels – is<br />

properly updated on Syspro.<br />

‘We <strong>have</strong>n’t yet completed the rollout<br />

<strong>to</strong> every operation but the savings<br />

experienced are already significant,’<br />

says Renée of the Syspro system.<br />

‘For example, in Pak2000, while sales<br />

increased significantly this year, the s<strong>to</strong>ck<br />

levels <strong>have</strong> only increased by 4%: this is<br />

because they’re using the MRP system<br />

<strong>to</strong> its potential and their s<strong>to</strong>ck levels on<br />

Syspro are correct.’<br />

Sandra’s song<br />

We are the family of Penpak.<br />

We now know what cleanliness is.<br />

We learned a lot what 5S is -<br />

Sort, Shine, S<strong>to</strong>re, we all agree.<br />

Roll-on the<br />

good times<br />

If you’re one of the increasing number of consumers<br />

who’ve ditched aerosol deodorant for roll-on, give a<br />

thought <strong>to</strong> the guys at Bronkhorstspruit because that’s<br />

where the perfectly shaped ball gliding smoothly<br />

around your armpit probably comes from.<br />

Weener Plas<strong>to</strong>p – formerly known as Euromatic<br />

Plas<strong>to</strong>p – is in the process of completing a massive<br />

technology upgrade <strong>to</strong> bring production and<br />

quality standards up <strong>to</strong> international benchmarks.<br />

‘We supply product <strong>to</strong> many local and international brands<br />

– including L’Oreal and Revlon, among many more – and<br />

consequently <strong>have</strong> <strong>to</strong> meet the most stringent manufacturing<br />

<strong>to</strong>lerances. The upgrade has seen the installation of fully<br />

electric Engel machines that use a patented injectionmoulding<br />

process <strong>to</strong> create zero-defect balls,’ says general<br />

manager Brent Grant.<br />

Weener Plas<strong>to</strong>p is now the largest manufacturer of roll-on balls<br />

for the personal-care industry in Africa. The company is a joint<br />

venture between <strong>Astrapak</strong> and Weener Plastik AG in Germany,<br />

one of the world’s premier manufacturers of roll-on balls and<br />

other plastic packaging.<br />

Sing, sing a song...<br />

Penpak’s Sandra Fortuin expresses herself in a<br />

particularly creative way – she writes songs. This<br />

one sings the praises of 5S training.<br />

Sandra Fortuin, a quality controller in the bag-making department<br />

of Penpak, recently underwent 5S training and was so inspired by<br />

the principles of world-class manufacturing that she immediately<br />

composed a song about her experience.<br />

General manager Deon van der Merwe asked her <strong>to</strong> sing her composition<br />

for Marco Baglione and the other direc<strong>to</strong>rs attending a budget meeting.<br />

Although Sandra was initially very nervous, enthusiasm and pride in being part<br />

of the Penpak family helped her <strong>over</strong>come her stage-fright, and she delivered<br />

a great performance, <strong>to</strong> the delight of her audience.<br />

We all begin <strong>to</strong> clean our place:<br />

No more dirt; what a pretty face!<br />

We can set our standards now.<br />

Surely, our bosses can be proud.<br />

Thank you, trainers, for your time;<br />

You really opened all our minds.<br />

We all know now what 5S is.<br />

That is the key <strong>to</strong> a world-class team.<br />

Nelson Mokoena, Evelyn Westcott and Annies Malete show off their excitement<br />

with the commissioning of a new technology welding machine.<br />

According <strong>to</strong> Brent, the state-of-the-art machines are not only<br />

highly precise and efficient but they operate <strong>to</strong> the most<br />

exacting environmental standards. They incorporate a<br />

patented water-filtration system and contribute <strong>to</strong> reducing the<br />

carbon footprint – an important environmental measure.<br />

‘This development is a significant achievement for a local<br />

company and will contribute <strong>to</strong> replacing roll-on balls that<br />

were previously imported. In addition, it has meant skills and<br />

technology transfer <strong>to</strong> South Africans, as employees <strong>have</strong> had<br />

<strong>to</strong> go <strong>over</strong>seas for training in Ireland and Austria.<br />

‘The lowly roll-on ball hardly seems <strong>to</strong> be at the leading edge of<br />

technology but, in fact, it is and we’re proud <strong>to</strong> be leading the<br />

South African charge on that front,’ concludes Brent.<br />

ASTRAPAK NEWS ASTRAPAK NEWS 7