Astrapak & SOS Children's Village change lives

Astrapak & SOS Children's Village change lives

Astrapak & SOS Children's Village change lives

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

South Africa’s leading plastic packaging Group<br />

edition three, 2009<br />

<strong>Astrapak</strong> & <strong>SOS</strong> Children’s <strong>Village</strong> <strong>change</strong> <strong>lives</strong><br />

<strong>Astrapak</strong> has always striven to go beyond the call of duty when it comes<br />

to corporate social responsibility and 5 years ago embarked on a<br />

relationship with the <strong>SOS</strong> Children’s <strong>Village</strong>.<br />

The <strong>SOS</strong> Children’s <strong>Village</strong> was<br />

started by Herman Gmeiner in<br />

1949 in Imst, Austria, after the tragic<br />

events of World War II. Through the<br />

support of donors and co-workers, the<br />

<strong>SOS</strong> Children’s <strong>Village</strong> has grown to help<br />

children around the globe the globe,<br />

and is now the largest private welfare<br />

organization for children in the world. A<br />

group of children are placed within a<br />

home, attended to by an <strong>SOS</strong> mother,<br />

and are raised in that house as a family<br />

so the children grow as a unit, and not<br />

just as individuals. <strong>Astrapak</strong> assists in the<br />

funding of five different <strong>SOS</strong> Children’s<br />

<strong>Village</strong> houses around South Africa;<br />

Cape Town, Mthatha, Pietermaritzberg,<br />

Mamelodi and Rustenburg.<br />

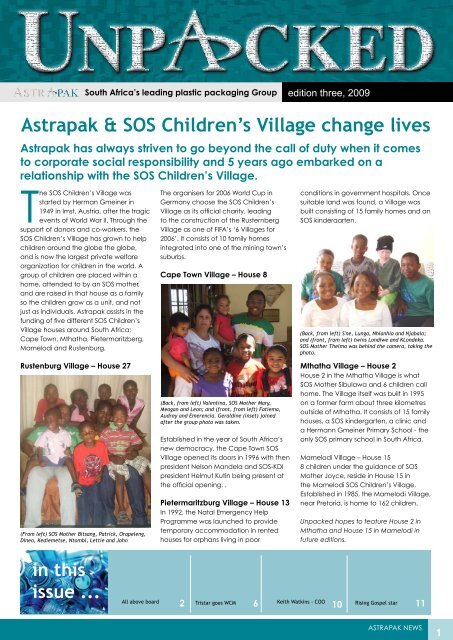

Rustenburg <strong>Village</strong> – House 27<br />

(From left) <strong>SOS</strong> Mother Bitsang, Patrick, Orapeleng,<br />

Dineo, Kediemetse, Ntombi, Lettie and John<br />

The organisers for 2006 World Cup in<br />

Germany choose the <strong>SOS</strong> Children’s<br />

<strong>Village</strong> as its official charity, leading<br />

to the construction of the Rusternberg<br />

<strong>Village</strong> as one of FIFA’s ‘6 <strong>Village</strong>s for<br />

2006’. It consists of 10 family homes<br />

integrated into one of the mining town’s<br />

suburbs.<br />

Cape Town <strong>Village</strong> – House 8<br />

(Back, from left) Valentina, <strong>SOS</strong> Mother Mary,<br />

Meagan and Leon; and (front, from left) Fatiema,<br />

Audrey and Emerencia. Geraldine (inset) joined<br />

after the group photo was taken.<br />

Established in the year of South Africa’s<br />

new democracy, the Cape Town <strong>SOS</strong><br />

<strong>Village</strong> opened its doors in 1996 with then<br />

president Nelson Mandela and <strong>SOS</strong>-KDI<br />

president Helmut Kutin being present at<br />

the official opening. .<br />

Pietermaritzburg <strong>Village</strong> – House 13<br />

In 1992, the Natal Emergency Help<br />

Programme was launched to provide<br />

temporary accommodation in rented<br />

houses for orphans living in poor<br />

conditions in government hospitals. Once<br />

suitable land was found, a <strong>Village</strong> was<br />

built consisting of 15 family homes and an<br />

<strong>SOS</strong> kindergarten.<br />

(Back, from left) S'ne, Lunga, Nhlanhla and Njabalo;<br />

and (front, from left) twins Londiwe and KLondeka.<br />

<strong>SOS</strong> Mother Thelma was behind the camera, taking the<br />

photo.<br />

Mthatha <strong>Village</strong> – House 2<br />

House 2 in the Mthatha <strong>Village</strong> is what<br />

<strong>SOS</strong> Mother Sibulawa and 6 children call<br />

home. The <strong>Village</strong> itself was built in 1995<br />

on a former farm about three kilometres<br />

outside of Mthatha. It consists of 15 family<br />

houses, a <strong>SOS</strong> kindergarten, a clinic and<br />

a Hermann Gmeiner Primary School - the<br />

only <strong>SOS</strong> primary school in South Africa.<br />

Mamelodi <strong>Village</strong> – House 15<br />

8 children under the guidance of <strong>SOS</strong><br />

Mother Joyce, reside in House 15 in<br />

the Mamelodi <strong>SOS</strong> Children’s <strong>Village</strong>.<br />

Established in 1985, the Mamelodi <strong>Village</strong>,<br />

near Pretoria, is home to 162 children.<br />

Unpacked hopes to feature House 2 in<br />

Mthatha and House 15 in Mamelodi in<br />

future editions.<br />

in this<br />

issue ...<br />

All above board<br />

2 Tristar goes WCM Keith Watkins -<br />

6<br />

COO Rising Gospel star<br />

10<br />

11<br />

ASTRAPAK NEWS<br />

1

Syspro helps sales<br />

The importance of integrating sales with production is fast becoming plain to see with Syspro, Pak @00’s Ryan Croft – Marketing Manager, Stanley Chetty – Planning Manager,<br />

Pam Baxter – Internal Sales and Peter Verster – Sales Manager show off their Visual Performance Monitor board.<br />

One of the secrets to<br />

effective selling is the<br />

ability to understand<br />

what the true cost<br />

of producing an<br />

item is and Syspro,<br />

the enterprise<br />

management system<br />

adopted Group-wide<br />

by <strong>Astrapak</strong>, is key to<br />

ensuring that sales staff<br />

have access to this<br />

information.<br />

‘If you can’t accurately determine what<br />

it costs to produce a tube, bottle or<br />

bag you are doomed before you even<br />

start,’ says consultant Renee Kirkham.<br />

‘All too often sales people are so keen<br />

to secure the order that they are willing<br />

to compromise price at the expense of<br />

profitability. But the company needs to<br />

not only recoup direct inputs like raw<br />

materials but also general overheads<br />

and margin on each product produced.<br />

Sure, some items are more profitable than<br />

others but each item manufactured must<br />

contribute to the bottom line.’<br />

Syspro is the system that keeps track of<br />

every aspect of the business to ensure<br />

accurate production costs can be<br />

verified.<br />

Gareth Elcox, general manager at Pak<br />

2000 explains: ‘Purchase orders are an<br />

important component. Not only do<br />

they ensure that the correct price is<br />

paid for the input but they help with the<br />

production planning process so that<br />

stock is on hand when needed. And this is<br />

critical to efficient production runs. At the<br />

same time it makes sure that we are not<br />

overstocked on raw materials.’<br />

‘The sales order function enables sales<br />

staff to see the state of their order book<br />

at any point in time. In fact, within<br />

24hours of placing their order, customers<br />

receive confirmation of the amount and<br />

expected delivery date. This is a win:win<br />

situation because we benefit from more<br />

efficient production runs and the client<br />

is fully informed of when their order will<br />

arrive.’<br />

Sales staff have access to a wide variety<br />

of reports from Syspro. These can be<br />

used to identify the profitability of every<br />

product they sell, the value that each<br />

customer brings to the company as well<br />

help greatly with forecasting.<br />

‘Syspro implementation throughout<br />

the Group is almost complete. While<br />

an intensive and detailed process, the<br />

benefits are clearly evident for all to<br />

see. From production to sales everyone<br />

benefits,’ concludes Renee.<br />

2<br />

ASTRAPAK NEWS

It may look a soft touch…<br />

Message from Marco<br />

Preparing for the upswing<br />

The past 12 months<br />

have been a relatively<br />

turbulent time for many<br />

<strong>Astrapak</strong> employees<br />

as the Group has gone<br />

through a period of<br />

adjustment and refocus.<br />

And this coincided with a<br />

time when the local and<br />

international economies<br />

were going through<br />

turmoil.<br />

Cinqpet’s sales team expects success. From left,<br />

Sales people have such a cushy job: they get to drive a<br />

company car, have an entertainment allowance and float<br />

in and out of the office at will. But do they really?<br />

In any business, it’s sales that<br />

generate turnover, create<br />

jobs and provide profits for the<br />

shareholders – and making a<br />

success of this tough career takes<br />

guts, stamina, self-organisation<br />

and huge amounts of personal<br />

motivation.<br />

So, to provide the <strong>Astrapak</strong> sales<br />

force with the skills to become<br />

super-achievers, various Institute<br />

of Marketing Management (IMM)<br />

training programmes are being<br />

rolled out.<br />

Cinqpet’s sales team, headed up<br />

by livewire manager Kirsty Keith, is<br />

an example of one of the many that<br />

have completed several of the IMM<br />

modules this year. Says Kirsty, ‘A big<br />

part of selling is psychological: you<br />

have to be on top of your game,<br />

from product knowledge to human<br />

relationship skills and everything<br />

in between. I’ve personally<br />

benefited from the negotiating<br />

skills programme; I think I’m now a<br />

better listener and definitely more<br />

organised – before I leave the office<br />

I have my objectives for the day<br />

identified.’<br />

For internal sales person Angelina<br />

Mkhondo, the training has helped<br />

her deal with difficult customers.<br />

She says the ability to build trust<br />

and keep promises creates better<br />

relationships with clients: once<br />

you’re on better terms and things<br />

go pear-shaped, it’s easier to<br />

negotiate a suitable way out that’s<br />

still beneficial for the client.<br />

Ria Venter concurs. ‘As key account<br />

manager, it’s vital that I build longterm<br />

relationships with customers. I<br />

need to ensure that we do business<br />

for years to come and it takes a<br />

lot of ongoing hard work to ensure<br />

each customer is continually<br />

happy.’<br />

Development manager Steve Baker,<br />

also part of the sales team, agrees<br />

with his colleagues, and adds that<br />

the team-based approach has<br />

contributed to their overall success.<br />

Sales coordinator Nomsa<br />

Ramothwala is a firm believer in<br />

giving customers a 110% service<br />

experience with every transaction.<br />

‘The IMM training has helped me<br />

understand the value of great<br />

service. It not only makes the client<br />

happy but I feel happier when I’ve<br />

done my best.’<br />

The IMM training is ongoing and<br />

will resume in the new year. It’s<br />

anticipated that all client-facing<br />

staff will eventually complete the<br />

various modules that are relevant to<br />

their particular job.<br />

While we’ve achieved<br />

an incredible amount from an <strong>Astrapak</strong><br />

perspective, we’re not out of the woods from a<br />

general economic point of view. There are signs<br />

of a recovery but the average consumer is still<br />

under huge pressure and he/she is the ultimate<br />

consumer of all of our packaging products.<br />

Internally we’re well positioned for the economic<br />

recovery when it starts to really swing around.<br />

We’ve refocused our operations to closer reflect<br />

the areas where we see long-term growth and<br />

opportunities by disposing of those that didn’t<br />

reflect this new outlook.<br />

We’ve put an enormous amount of money and<br />

time into introducing World Class Manufacturing to<br />

ensure every company will be able to benchmark<br />

themselves to the very best in the world. Our new<br />

advertising strapline, ‘A world of opportunities’,<br />

reflects this need and desire to be globally<br />

competitive.<br />

With production facilities upgrading their<br />

capabilities, it only made sense that client-facing<br />

staff also upskill. A range of IMM-accredited<br />

courses have now been rolled out across the<br />

Group and early indications are that positive<br />

results are already being experienced.<br />

Any large, modern organisation relies on upto-the-minute<br />

information and <strong>Astrapak</strong> is no<br />

exception. With manufacturing operations spread<br />

across the country, millions of Rands in raw<br />

material and finished goods in stock at any one<br />

point, and more than 3 000 people on staff, we<br />

need to know exactly what’s happening in each<br />

operation all the time. Thanks to Syspro, this is<br />

now a reality. And what’s important for me is that<br />

everyone throughout the Group benefits from this<br />

initiative.<br />

This year has flown past and 2010 holds much<br />

promise for us and South Africa as a whole. Let’s<br />

embrace the future. Let’s be positive about<br />

the year ahead and make the most of the<br />

opportunities, both business and personal, that<br />

come our way.<br />

If you’re taking time over the festive season<br />

for holidays, please drive safely. Enjoy the time<br />

with friends and family and return rested and<br />

rejuvenated for what promises to be one of the<br />

most exciting years in South Africa’s modern<br />

history.<br />

Viva 2010, viva!<br />

Best wishes<br />

ASTRAPAK NEWS<br />

3

Here are some<br />

WCM success stories<br />

from companies<br />

within the Group:<br />

One team, one vision at Packline<br />

Launched under the slogan Isipani esinye, sinembono<br />

enye – ‘one team, one vision’ – East London-based<br />

Packline have got off to a racing start with their WCM<br />

programme and have already reduced their scrap levels<br />

by almost three percent. ‘The Eastern Cape is probably a lot<br />

harder hit than most in the current economic slump and we’re<br />

wholeheartedly embracing WCM as a way to make ourselves<br />

more competitive,’ says general manager Wally van Rensburg.<br />

‘Our goal is to become the Eastern Cape’s least-cost producer<br />

of quality film and related products.’<br />

Wally sees the role of training as a key element in changing<br />

staff attitudes, lifting morale and re-energising personnel. ‘In<br />

addition to reducing scrap, watching inputs and becoming<br />

more electricity efficient, training is where we hope to add the<br />

most value. And, importantly, it’s skills that employees will have<br />

forever.<br />

‘We’re working hard to overcome the short-term challenges but<br />

I do commend the staff for the way they’ve embraced WCM<br />

and see it as an integral part of their future.’<br />

No, it’s not a strike, it’s Packline staff embracing Isipani esinye, sinembono enye.<br />

Facilitators are key to WCM implementation<br />

The trained Facilitators from six of<br />

the KZN companies (back, from<br />

left) Peter Edwards (Plastop KZN),<br />

Neil Doherty-Bigara (PAK2000),<br />

Trust Ndlela (Consupac), Viren<br />

Rampukar (VPM Champion,<br />

Consupac) and Donavan<br />

Van Niekerk (Thermopac);<br />

and (front, from left) Marc Nel<br />

(JJ Precision Plastics), Balan<br />

Munswami (Consupac) and<br />

Naeem Soobrathi (Packaging<br />

Consultants).<br />

The facilitator plays a key role<br />

in the implementation and<br />

sustainability of World Class<br />

Manufacturing practices.<br />

And, emphasising the importance of<br />

this person, six of the companies in<br />

KwaZulu-Natal have embarked on a<br />

combined comprehensive development<br />

programme for the individuals tasked<br />

with this value-adding role.<br />

What made the development process<br />

particularly effective was that the six<br />

candidates were developed as a team,<br />

rotating their training from one operation<br />

to the next each time they met. The<br />

spin-off has been that not only are they<br />

aware of their roles and responsibilities<br />

but they’ve gained valuable exposure<br />

to other <strong>Astrapak</strong> operations and have<br />

learned to share ideas from the outset.<br />

A Facilitator is the internal expert on<br />

WCM practices and his/her role includes:<br />

* advising the Implementation Task Force<br />

on the next steps in the process;<br />

* coaching and guiding Best Practices<br />

Champions on assessing current<br />

practices and the way forward;<br />

* coaching and supporting the Team<br />

Leaders and Internal Trainers in their roles;<br />

* guiding Profit Improvement Project<br />

Leaders in the correct methodology to<br />

ensure project delivery;<br />

* assisting with logistic arrangements such<br />

as team-building sessions and 5S, clear<br />

and tag exercises; and<br />

* ensuring that new practices are lived in<br />

the workplace.<br />

4<br />

ASTRAPAK NEWS

Marcom and Plastop in the WCM rhythm<br />

The reorganisation of<br />

<strong>Astrapak</strong>’s business model<br />

in recent months has<br />

meant greater cooperation<br />

between operations and so<br />

Marcom and Plastop both<br />

decided to use drumming<br />

as the motivational tool<br />

to introduce World Class<br />

Manufacturing.<br />

With Obakeng<br />

Sebona appointed<br />

continuous<br />

improvement<br />

manager for both Marcom and<br />

Plastop, it fell to him to present<br />

the overview of what World<br />

Class Manufacturing (WCM)<br />

is all about, together with the<br />

roles to be played by all staff<br />

members.<br />

Both operations took time out<br />

from the normal production<br />

schedule to ensure that all<br />

employees attended their<br />

respective WCM launch<br />

programme. Obakeng explains,<br />

‘It’s about securing total buy-in<br />

from everyone. Without that,<br />

this type of initiative won’t work.<br />

Interestingly enough, these two<br />

launches represented the first<br />

time that many staff from admin<br />

and sales had any interaction<br />

with production. The breaking of<br />

perceived barriers between the<br />

two groups of employees was<br />

an important step in the WCM<br />

process.’<br />

Both companies also introduced<br />

a logo and naming competition<br />

to brand their respective<br />

WCM programmes and the<br />

response in both instances was<br />

outstanding.<br />

Plastop received 63 entries; the<br />

top 10 have been shortlisted<br />

and the final design will be<br />

based on these submissions.<br />

However, all 10 finalists will be<br />

embarking on a plant visit to an<br />

<strong>Astrapak</strong> operation in KwaZulu-<br />

Natal as reward for their efforts.<br />

Marcom’s winning entry was<br />

submitted by Abbey Nkitle.<br />

Entitled Singano, local slang for<br />

‘together we survive’, the logo<br />

has now been adopted across<br />

the company for use with any<br />

WCM initiative.<br />

A show of hands. Each person had the opportunity of ‘signing’ and committing<br />

to the WCM programme by making a handmark on a canvas frame.<br />

Marcom staff take time for a group photo on WCM launch day<br />

Sales adopts WCM at Cinqpet<br />

World Class Manufacturing is gaining<br />

momentum throughout the Group<br />

and at Cinqpet: the sales team has<br />

become intricately involved in the<br />

process.<br />

‘Sales and Manufacturing approach a<br />

customer’s need from opposite ends<br />

of the spectrum,’ says sales manager<br />

Kirsty Keith. ‘Manufacturing wants to<br />

see large orders with long lead times<br />

so they can plan production and gain<br />

efficiencies. Sales people want to<br />

make the client happy: short runs, lots<br />

of variants and, you want it tomorrow,<br />

no problem! Clearly the two parties<br />

need to work together to satisfy the<br />

customer.’<br />

Kirsty’s team have adopted the 5s<br />

system as well as a visual performance<br />

monitor board, albeit with their own<br />

measurement criteria. In addition,<br />

Sales has introduced the Apple award,<br />

their own reward system for superior<br />

performance.<br />

Manufacturing manager Deon Swart is<br />

delighted with the way Manufacturing<br />

and Sales have integrated over WCM.<br />

‘At the end of the day we both have<br />

the same goals: keep the clients happy<br />

and ensure a safe and productive<br />

manufacturing environment. The results<br />

for us so far have been outstanding.<br />

Not only are we operating at greater<br />

efficiencies but the feeling of teamwork<br />

is palpable.’<br />

Kirsty agrees. ‘It’s all about teamwork,<br />

from Manufacturing to Sales and on<br />

to the client. We need to educate<br />

customers about the need for<br />

forecasting and sharing of information,<br />

because if we understand their needs<br />

in good time, we’ll be in a position to<br />

deliver timeously and with maximum<br />

efficiencies. It’s a win-win for everyone.’<br />

And the proof is in the pudding: this<br />

year, for the first time in many years,<br />

Cinqpet is scheduled to have its<br />

Christmas shutdown with perhaps only<br />

Distribution having to be on standby to<br />

meet customers’ emergency needs.<br />

‘You do have to be realistic about<br />

the challenges faced when looking<br />

to adopt anything new, and WCM is<br />

no different. We all work ourselves into<br />

a comfort zone and <strong>change</strong> is not<br />

easy. Often, in fact, we actively work<br />

against it until we can be convinced<br />

that there are benefits that will accrue.<br />

But I can vouch, that by including all<br />

the members of the operation into<br />

the WCM <strong>change</strong> team we have<br />

noticed a significant <strong>change</strong> in culture<br />

in the company and it’s all positive,’<br />

concludes Deon.<br />

Key account manager Ria Venter, the first winner of<br />

the Apple award, with sales manager Kirsty Keith and<br />

manufacturing manager Deon Swart. The word Apple is an<br />

acronym for: Attitude, Passion, Perseverance, Leadership<br />

and Energy – all necessary ingredients when tackling <strong>change</strong>!<br />

ASTRAPAK NEWS<br />

5

NEWS<br />

<strong>Astrapak</strong> on the Propak map<br />

Congratulations to Charles Muller and his team for the exhibition at<br />

this year’s Propak show. The innovative colouring and bold design<br />

created a significant impression and attracted many favourable<br />

comments from visitors.<br />

East Rand takes to the road<br />

Congratulations to Gold Pack winners<br />

The Group won eight Gold Packs at this<br />

year’s annual packaging awards held in<br />

Johannesburg to coincide with the Propak<br />

exhibition. This is a significant event on the<br />

calendar and has become regarded as the<br />

Oscars of the packaging industry.<br />

The competition is more than 30 years old<br />

and is the judging benchmark for locally<br />

produced packaging. There were 167 entries<br />

this year and 81 winners, so for <strong>Astrapak</strong><br />

to garner eight of those is a significant<br />

achievement.<br />

The winners were:<br />

Cinqplast<br />

Consupaq (2)<br />

Plastop Bronkhorstspruit<br />

Hilfort Plastics<br />

Thermopac (2)<br />

Knilam Packaging.<br />

Looking sweet for<br />

Pacon and Tristar<br />

Coming up smiling at this year’s East Rand Plasticssponsored<br />

Garbie Relay are (from left) Traver Museenzi,<br />

Carol Wallace, Irene Mayorkinos, Wanda Molefe and<br />

(seated) John Polori. What started out as a teambuilding<br />

fun-run last year – a by-product of the WCM<br />

initiative – has grown into a fully fledged corporate<br />

challenge among other companies and running clubs<br />

in Gauteng. Added incentive has been created with<br />

several other <strong>Astrapak</strong> companies taking part. If you’re<br />

based in Gauteng, why not take up the challenge and<br />

enter a team next year?<br />

Denis Campbell from Pacon proudly displays the Supplier of<br />

the Year award received from TSB Sugar earlier in the year.<br />

Tristar Plastics and Pacon both received awards from TSB<br />

Sugar, with the latter a significant achievement when you<br />

consider there were 38 companies vying for only six awards.<br />

6<br />

ASTRAPAK NEWS

Pacon cleanup<br />

Plastic is often fingered as the guilty party<br />

when it comes to environmental waste, with<br />

discarded plastic bags and bottles scattered<br />

across the country. But as the Plastics<br />

Federation maintains, ‘Plastic doesn’t litter,<br />

people do.’<br />

It was with this<br />

in mind that<br />

Johnson Nagaser,<br />

Praven Ranjith,<br />

Ken Swanepoel,<br />

Geoff Cuttler<br />

and James van<br />

Tonder from Pacon<br />

joined 8 000 other<br />

concerned citizens<br />

and braved a cold<br />

and wet Saturday<br />

in September to<br />

participate in the<br />

annual International<br />

Coastal Clean-up<br />

Day.<br />

The event focuses<br />

on cleaning coastal<br />

Pravin Ranjith, extrusion manager at Pacon,<br />

makes light of an unpleasant task during the<br />

annual clean-up day.<br />

and riverine environments and this time round it was the<br />

turn of the Umhlangane River, a waterway that bisects<br />

the Riverhorse Valley Business Estate where Pacon is<br />

situated.<br />

The campaign was a resounding success, with about 16<br />

000 bags of litter collected weighing about 51 tonnes.<br />

About 70% of the collected waste was plastic.<br />

Innovation brings savings<br />

When the motherboard on one of the Cinqpet’s<br />

injection moulding machines blew up, they were<br />

faced with a R300 000 problem: that was the cost of the<br />

replacement part.<br />

But for electrician Tumelo Moseki and charge-hand Johan Greef,<br />

this seemed a lot of money for something they felt could be<br />

done more innovatively. Off they went to look what was on offer<br />

at a couple of computer shops and they soon found a card<br />

which, with a bit of tweaking and adjustment, ended up working<br />

perfectly – at a total cost of R240!<br />

Cinqpet’s ‘McGyvers’, Tumelo Moseki and Johan Greef (right), with Cinqpet<br />

maintenance manager Martin Botha (left).<br />

Penpak celebrates<br />

Peninsula Packaging celebrated its 30th year of operation<br />

with a company braai, sing-a-long and talent competition.<br />

Designer of<br />

Marcom’s WCM<br />

logo Abbey<br />

Nkitle’s career<br />

epitomises<br />

the kind of<br />

commitment that<br />

is expected from<br />

everyone on WCM. He started with the company<br />

as a packer in 2008, progressed to grinder<br />

operator at the beginning of 2009 and is now on a<br />

mentorship programme to become a production<br />

clerk. In addition, he has attended WCM Team<br />

Leader training and will become one of Marcom’s<br />

champions for the project.<br />

Winners of Miss Penpak 2009 with the judges. Back row, from left: Deon van der Merwe,<br />

Marius Floris, Patrick Meyer and Adriaan Engelbrecht. Middle row, from left: Alvester<br />

Chadow, Theresa van Vuuren, Magdel Aggenbach and Leon Mias. Front row, from left:<br />

second princess Louisa Louw, Miss Penpak Tanya Esau and first princess Merlé Faro.<br />

The tone for the Saturday event, held at Penpak’s premises<br />

was set after the Boks beat New Zealand at rugby, and from<br />

there the party was on. The tea ladies gave a performance of<br />

‘Koekie Loekie’ while another group performed a ‘Single Ladies’<br />

number that rivalled Beyonce’s.<br />

The highlight of the day was the crowing of Miss Penpak, but with<br />

so many beautiful people working for the company, the judges’ job<br />

wasn’t easy.<br />

ASTRAPAK NEWS<br />

7

Our new strap line tells it like it is...<br />

A world of opportunities<br />

The last 12 months have witnessed a re-birth of <strong>Astrapak</strong> and our<br />

new corporate slogan and branding sums it all up: A world of<br />

opportunities<br />

‘The <strong>Astrapak</strong> A has been overlaid on Africa and the globe. It emphasises that while we<br />

see our roots on this continent, we are ultimately a member of the global village and see<br />

ourselves as a world-class player,’ explains Group marketing director Charles Muller. ‘We<br />

are at an incredibly exciting phase of the Group’s life and the strap line could not be more<br />

appropriate: there are opportunities for all stakeholders – employees, customers, suppliers<br />

and investors. We need to embrace and maximise them.’<br />

Specialised plastic packaging like Saflite’s Astrapouch<br />

is fast replacing glass and not only for the budget<br />

wines.<br />

Advances in packaging technology have opened<br />

the door for the use of plastic instead of glass<br />

in the wine industry and both Hilfort and Saflite<br />

have experience in this fickle field. And while<br />

traditionalists may want to retain glass they are going to be<br />

under huge environmental pressure to adopt alternatives,<br />

with plastic being the most obvious.<br />

The three major components when comparing carbon<br />

footprints are; manufacture, transportation and disposal.<br />

There’s no CO2 debate,<br />

plastic is the winner<br />

With carbon footprint becoming an increasingly significant<br />

topic much has been made about the comparison<br />

between plastic bottles and glass, particularly for wine<br />

where a large volume of intercontinental traffic takes<br />

place.<br />

According to independent studies, glass creates about<br />

7.3 times more the CO2 of plastic during manufacture and<br />

1.8 times more during transport. Even if you assume that all<br />

glass bottles were recycled and no recycled plastic was<br />

used to make new bottles, plastic still comes up favourably.<br />

‘The research is clear,’ says Charles Muller. ‘Manufacturing<br />

a typical wine bottle creates about 295g of CO2, while a<br />

comparable plastic bottle is only 108g. That means from<br />

an environmental perspective, you can manufacture 2.7<br />

plastic bottles for every one glass. And that’s a significant<br />

benefit for our environment.’<br />

One-stop shop<br />

The scope of <strong>Astrapak</strong>’s product offering is<br />

mind boggling to say the least with very few<br />

people in the Group really understanding<br />

the entire range.<br />

So, to make it easier for staff members, customers and<br />

potential customers alike Charles Muller took one of<br />

the unused rooms at Cinqplast and converted it into a<br />

showroom complete with projection screen.<br />

Each company has been allocated its own display cabinet<br />

which can be used to showcase examples of its capabilities.<br />

Product brochures and other promotional literature can also<br />

be placed there for interested parties to access.<br />

It is going to be largely up to each company to ensure their<br />

display presents their most recent and innovative offering. For<br />

more information contact Garath Hendrikz on<br />

garath@astrapak.co.za<br />

Also on show will be products manufactured by <strong>Astrapak</strong>’s<br />

international alliance partners as well as innovative packaging<br />

designs from around the world that have been collected on<br />

one of Charles’s business sojourns.<br />

IMBONGI COMMUNICATIONS TEL: 021 671 9143 www.imbongisa.com<br />

8<br />

ASTRAPAK NEWS