Fendt 900 Vario - AGCO GmbH

Fendt 900 Vario - AGCO GmbH

Fendt 900 Vario - AGCO GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Linkage with power reserves<br />

Powerful hydraulics<br />

for modern implements<br />

The lift capacities of the front and rear linkage on the <strong>900</strong> <strong>Vario</strong> have been signi cantly increased<br />

compared to the previous models. The EHR rear linkage has a maximum capacity of 11800 daN and<br />

the front power lift 5550 daN. This allows the <strong>900</strong> <strong>Vario</strong> to lift heavy implements without a problem.<br />

The front power lift is an integral part of the tractor design. The coupling point is therefore relatively<br />

close to the vehicle, which has a favourable e ect on the weight distribution of the tractor when<br />

equipped with mounted front implements. Regarding linkage design, the <strong>900</strong> <strong>Vario</strong> is well thoughtout<br />

into the very last detail. For example, the top link can remain on the tractor as it is, even when<br />

it is not required.<br />

Premium class hydraulic equipment<br />

In the Pro version, the <strong>900</strong> <strong>Vario</strong> is tted with hydraulic equipment that leaves no wishes<br />

open. The EPC rear linkage can be switched over to double acting mode with the terminal. Pulling<br />

implements down in hard soil is no longer a problem and even dismounting implements is<br />

easier, since the rear power lift can always be lowered, even if the balls ends are wedged.<br />

A double-acting comfort front power lift is available as an option instead of the standard front<br />

power lift. In the Pro version, up to eight electric da auxiliary control units are optionally<br />

available. The connections at the rear are all connect-under-pressure lever couplings.<br />

Modern implements demand ever greater<br />

flexibility and performance from the<br />

tractor hydraulics. Fast lifting and high oil<br />

delivery rates are required for economical<br />

operation. The <strong>900</strong> <strong>Vario</strong> models, with<br />

their load sensing hydraulics and electrical<br />

hydraulic valves, are well-equipped for<br />

comfortable operation.<br />

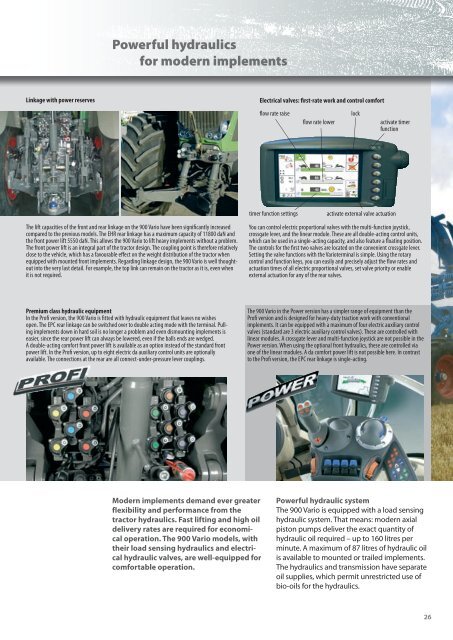

Electrical valves: rst-rate work and control comfort<br />

ow rate raise<br />

timer function settings<br />

ow rate lower<br />

The <strong>900</strong> <strong>Vario</strong> in the Power version has a simpler range of equipment than the<br />

Pro version and is designed for heavy-duty traction work with conventional<br />

implements. It can be equipped with a maximum of four electric auxiliary control<br />

valves (standard are 3 electric auxiliary control valves). These are controlled with<br />

linear modules. A crossgate lever and multi-function joystick are not possible in the<br />

Power version. When using the optional front hydraulics, these are controlled via<br />

one of the linear modules. A da comfort power lift is not possible here. In contrast<br />

to the Pro version, the EPC rear linkage is single-acting.<br />

lock<br />

activate timer<br />

function<br />

activate external valve actuation<br />

You can control electric proportional valves with the multi-function joystick,<br />

crossgate lever, and the linear module. These are all double-acting control units,<br />

which can be used in a single-acting capacity, and also feature a oating position.<br />

The controls for the rst two valves are located on the convenient crossgate lever.<br />

Setting the valve functions with the <strong>Vario</strong>terminal is simple. Using the rotary<br />

control and function keys, you can easily and precisely adjust the ow rates and<br />

actuation times of all electric proportional valves, set valve priority or enable<br />

external actuation for any of the rear valves.<br />

Powerful hydraulic system<br />

The <strong>900</strong> <strong>Vario</strong> is equipped with a load sensing<br />

hydraulic system. That means: modern axial<br />

piston pumps deliver the exact quantity of<br />

hydraulic oil required – up to 160 litres per<br />

minute. A maximum of 87 litres of hydraulic oil<br />

is available to mounted or trailed implements.<br />

The hydraulics and transmission have separate<br />

oil supplies, which permit unrestricted use of<br />

bio-oils for the hydraulics.<br />

26