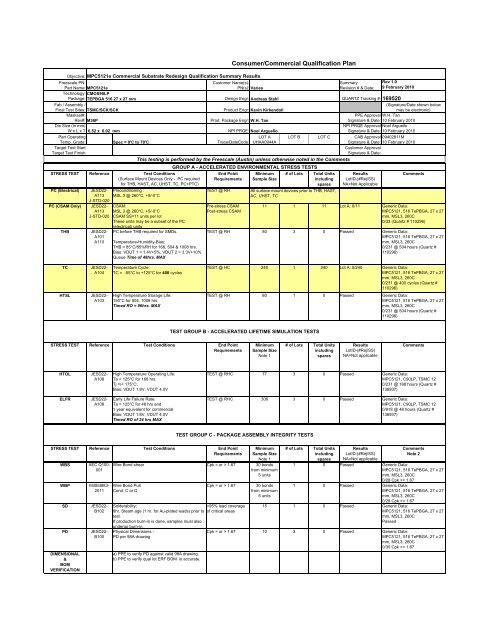

Consumer/Commercial Qualification Plan

Consumer/Commercial Qualification Plan

Consumer/Commercial Qualification Plan

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Objective: MPC5121e <strong>Commercial</strong> Substrate Redesign <strong>Qualification</strong> Summary Results<br />

Freescale PN:<br />

Customer Name(s):<br />

Summary<br />

Rev 1.0<br />

Part Name: MPC5121e PN(s): Varies<br />

Revision # & Date: 9 February 2010<br />

Technology: CMOS90LP<br />

Package: TEPBGA 516 27 x 27 mm Design Engr: Andreas Stahl<br />

QUARTZ Tracking #: 169520<br />

Fab / Assembly /<br />

(Signature/Date shown below<br />

Final Test Sites: TSMC/SCK/SCK Product Engr: Kevin Kirkendoll<br />

may be electronic)<br />

Maskset#:<br />

PPE Approval W.H. Tan<br />

Rev#: M36P Prod. Package Engr: W.H. Tan<br />

Signature & Date: 10 February 2010<br />

Die Size (in mm)<br />

NPI PRQE Approval Noel Arguello<br />

W x L x T 6.52 x 6.02 mm NPI PRQE: Noel Arguello<br />

Signature & Date: 10 February 2010<br />

Part Operating<br />

LOT A LOT B LOT C CAB Approval 09402811M<br />

Temp. Grade: Spec = 0'C to 70'C Trace/DateCode: UHAA0944A<br />

Signature & Date: 10 February 2010<br />

Target Test Start<br />

Customer Approval<br />

Target Test Finish<br />

Signature & Date:<br />

This testing is performed by the Freescale (Austin) unless otherwise noted in the Comments<br />

GROUP A - ACCELERATED ENVIRONMENTAL STRESS TESTS<br />

STRESS TEST Reference Test Conditions<br />

End Point Minimum # of Lots Total Units Results<br />

Comments<br />

(Surface Mount Devices Only - PC required Requirements Sample Size<br />

including LotID-(#Rej/SS)<br />

for THB, HAST, AC, UHST, TC, PC+PTC)<br />

spares NA=Not Applicable<br />

PC (Electrical) JESD22- Preconditioning :<br />

TEST @ RH All surface mount devices prior to THB, HAST,<br />

A113<br />

J-STD-020<br />

MSL 3 @ 260°C, +5/-0°C<br />

AC, UHST, TC<br />

PC (CSAM Only) JESD22- CSAM:<br />

Pre-stress CSAM<br />

11 1 11 Lot A: 0/11 Generic Data:<br />

A113 MSL 3 @ 260°C, +5/-0°C<br />

Post-stress CSAM<br />

MPC5121, 516 TePBGA, 27 x 27<br />

J-STD-020 CSAM SS=11 units per lot<br />

mm, MSL3, 260C<br />

These units may be a subset of the PC<br />

(electrical) units<br />

0/33 (Quartz # 110296)<br />

THB JESD22- PC before THB required for SMDs.<br />

TEST @ RH 80 3 0 Passed Generic Data:<br />

A101<br />

MPC5121, 516 TePBGA, 27 x 27<br />

A110 Temperature-Humidity-Bias:<br />

mm, MSL3, 260C<br />

THB = 85°C/85%RH for 168, 504 & 1008 hrs.<br />

0/231 @ 504 hours (Quartz #<br />

Bias: VDUT 1 = 1.4V+5%, VDUT 2 = 3.3V+10%<br />

Queue Time of 48hrs. MAX<br />

110296)<br />

TC JESD22-<br />

A104<br />

HTSL JESD22-<br />

A103<br />

Temperature Cycle:<br />

TC = -55°C to +125°C for 400 cycles<br />

High Temperature Storage Life:<br />

150°C for 504, 1008 hrs<br />

Timed RO = 96hrs. MAX<br />

STRESS TEST Reference Test Conditions End Point<br />

Requirements<br />

HTOL JESD22-<br />

A108<br />

ELFR JESD22-<br />

A108<br />

High Temperature Operating Life:<br />

Ta = 125°C for 168 hrs.<br />

Tj =/< 175°C;<br />

Bias: VDUT 1.8V, VDUT 4.0V<br />

Early Life Failure Rate:<br />

Ta = 125°C for 48 hrs and<br />

1 year equivalent for commercial.<br />

Bias: VDUT 1.8V, VDUT 4.0V<br />

Timed RO of 24 hrs MAX<br />

STRESS TEST Reference Test Conditions End Point<br />

Requirements<br />

WBS AEC Q100-<br />

001<br />

WBP MilStd883-<br />

2011<br />

SD JESD22-<br />

B102<br />

PD JESD22-<br />

B100<br />

DIMENSIONAL<br />

&<br />

BOM<br />

VERIFICATION<br />

TEST @ HC 240 1 240 Lot A: 0/240 Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/231 @ 400 cycles (Quartz #<br />

110296)<br />

TEST @ RH 80 1 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/231 @ 504 hours (Quartz #<br />

110296)<br />

Minimum<br />

Sample Size<br />

Note 1<br />

# of Lots Total Units<br />

including<br />

spares<br />

Results<br />

LotID-(#Rej/SS)<br />

NA=Not applicable<br />

Comments<br />

TEST @ RHC 77 3 0 Passed Generic Data:<br />

MPC5121, C90LP, TSMC 12<br />

0/231 @ 168 hours (Quartz #<br />

136937)<br />

TEST @ RHC 306 3 0 Passed Generic Data:<br />

MPC5121, C90LP, TSMC 12<br />

0/918 @ 48 hours (Quartz #<br />

136937)<br />

Minimum<br />

Sample Size<br />

Note 1<br />

Wire Bond shear Cpk = or > 1.67 30 bonds<br />

from minimum<br />

5 units<br />

Wire Bond Pull<br />

Cond. C or D<br />

Cpk = or > 1.67 30 bonds<br />

from minimum<br />

5 units<br />

Solderability;<br />

>95% lead coverage<br />

8hr. Steam age (1 hr. for Au-plated leads) prior to of critical areas<br />

test.<br />

If production burn-in is done, samples must also<br />

undergo burn-in.<br />

Physical Dimensions -<br />

PD per 98A drawing<br />

a) PPE to verify PD against valid 98A drawing.<br />

b) PPE to verify qual lot ERF BOM is accurate.<br />

<strong>Consumer</strong>/<strong>Commercial</strong> <strong>Qualification</strong> <strong>Plan</strong><br />

TEST GROUP B - ACCELERATED LIFETIME SIMULATION TESTS<br />

TEST GROUP C - PACKAGE ASSEMBLY INTEGRITY TESTS<br />

# of Lots Total Units<br />

including<br />

spares<br />

Results<br />

LotID-(#Rej/SS)<br />

NA=Not applicable<br />

Comments<br />

Note 2<br />

1 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/28 Cpk >= 1.67<br />

1 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/28 Cpk >= 1.67<br />

15 1 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

Passed<br />

Cpk = or > 1.67 10 3 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/30 Cpk >= 1.67

SBS AEC-Q100- Solder Ball Shear;<br />

010 Performed on all solder ball mounted packages<br />

e.g. PBGA, Chip Scale, Micro Lead Frame (but<br />

NOT Flip Chip). No reflow cycle before shear.<br />

Cpk = or >1.67 10<br />

(5 balls from a<br />

min. of 10<br />

devices)<br />

STRESS TEST Reference Test Conditions End Point<br />

Requirements<br />

TEST Freescale<br />

48A<br />

ESD<br />

(HBM)<br />

CLASSIFICATION<br />

ESD<br />

(CDM)<br />

CLASSIFICATION<br />

JESD22-<br />

A114<br />

JESD22-<br />

C101<br />

Pre- and Post Functional / Parametrics<br />

Test software shall meet requirements of AEC-<br />

Q100-007.<br />

Testing performed to the limits of device<br />

specification in temperature and limit value.<br />

ElectroStatic Discharge/<br />

Human Body Model Classification:<br />

Test @ 500 / 1000 / 1500 / 2000 / 2500<br />

Volts(FYI)<br />

See AEC-Q100-002 for classification levels.<br />

ElectroStatic Discharge/<br />

Charged Device Model Classification:<br />

Test @ 125 / 250 / 500 / 750 / 1000 Volts<br />

Timed RO of 96hrs MAX.<br />

LU JESD78 Latch-up:<br />

Test per JEDEC JESD78<br />

Ta= Operating Temperature Maximum (ROOM<br />

and HOT)<br />

ED AEC-Q100-<br />

009,<br />

Freescale<br />

48A spec<br />

Electrical Distribution/Drift Analysis<br />

(Pre and Post HTOL)<br />

NBTI Identify the speed pattern that drifts the most and<br />

create guardband if needed. (Two rdpts -<br />

TimeZero and at final NBTI readpoint). Serialized<br />

CONTROL /<br />

CORRELATION<br />

UNITS<br />

Freescale<br />

12MYS-<br />

62419B<br />

FG AEC-Q100-<br />

007<br />

units<br />

Correlation units are required for NBTI drift<br />

analysis.<br />

TEST @ RH<br />

2KV min.<br />

TEST @ RH<br />

500V min<br />

Minimum<br />

Sample Size<br />

0 Fails All All All<br />

3 units per<br />

Voltage level<br />

3 units per<br />

Voltage level<br />

3 0 Passed Generic Data:<br />

MPC5121, 516 TePBGA, 27 x 27<br />

mm, MSL3, 260C<br />

0/15 Cpk >= 1.67<br />

# of Lots Total Units Results<br />

LotID-(#Rej/SS)<br />

NA=Not applicable<br />

Comments<br />

1 0 Passed Generic Data:<br />

MPC5121e <strong>Consumer</strong><br />

0/3 @ 500V<br />

0/3 @ 1000V<br />

0/3 @ 1500V<br />

3/3 @ 2000V<br />

3/3 @ 2500V<br />

1 0 Passed Generic Data:<br />

MPC5121e <strong>Consumer</strong><br />

0/3 @ 125V<br />

0/3 @ 250V<br />

0/3 @ 500V<br />

3/3 @ 750V<br />

3/3 @ 1000V<br />

TEST @ RH 6 1 0 Passed Generic Data:<br />

MPC5121e <strong>Consumer</strong><br />

0/6<br />

TEST @ RHC<br />

Cpk = or > 1.67<br />

Fault Grading FG shall be = or ><br />

90% for qual units<br />

TEST GROUP E - ELECTRICAL VERIFICATION TESTS<br />

5 3 0 Passed Generic Data:<br />

MPC5121e <strong>Consumer</strong><br />

All Cpk > 1.67 except for<br />

ABIST_61 speed pattern on first<br />

qual lot. The Vt targets were<br />

changed for subsequent lots with<br />

a Cpk > 1.67.<br />

TEST @ RHC 70 3 0 Completed Generic Data:<br />

MPC5121e <strong>Consumer</strong><br />

NA 25 3 0<br />

FG%= TBD Production Test has higher %<br />

criteria; see AEC-Q100-007 for<br />

details