Best Practices for the Reduction of Air Emissions From Construction ...

Best Practices for the Reduction of Air Emissions From Construction ...

Best Practices for the Reduction of Air Emissions From Construction ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

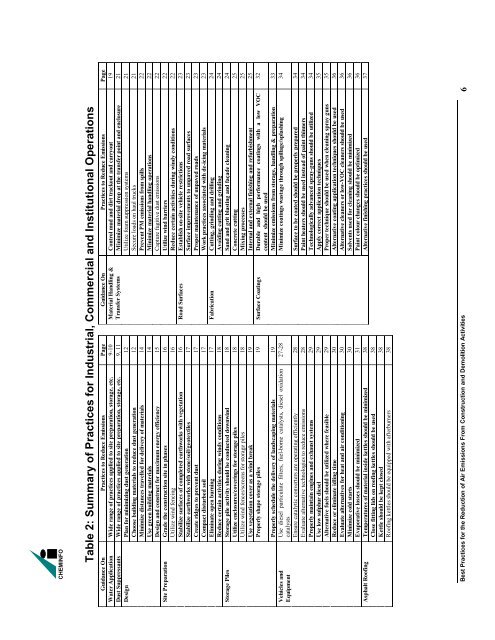

CHEMINFO<br />

Table 2: Summary <strong>of</strong> <strong>Practices</strong> <strong>for</strong> Industrial, Commercial and Institutional Operations<br />

Guidance On <strong>Practices</strong> to Reduce <strong>Emissions</strong> Page Guidance On <strong>Practices</strong> to Reduce <strong>Emissions</strong> Page<br />

Water Application Wide range <strong>of</strong> practices applied to site preparation, storage, etc. 9-10 Material Handling & Control mud and dirt trackout and carryout 19<br />

Dust Suppressants Wide range <strong>of</strong> practices applied to site preparation, storage, etc. 9, 11 Transfer Systems Minimize material drop at <strong>the</strong> transfer point and enclosure 21<br />

Design<br />

Plan <strong>for</strong> minimizing dust generation 12 Utilize foam suppression systems 21<br />

Choose building materials to reduce dust generation 12 Secure loads on haul trucks 21<br />

Minimize distances travelled <strong>for</strong> delivery <strong>of</strong> materials 14 Prevent PM emissions from spills 22<br />

Use green building materials 14 Minimize material handling operations 22<br />

Design and construct <strong>for</strong> maximum energy efficiency 15 Capture fugitive dust emissions 22<br />

Site Preparation Grade <strong>the</strong> construction site in phases 16 Utilize wind barriers 22<br />

Utilize wind fencing 16<br />

Reduce certain activities during windy conditions 22<br />

Stabilize surfaces <strong>of</strong> completed earthworks with vegetation 16 Road Surfaces<br />

Establish on-site vehicle restrictions 23<br />

Stabilize earthworks with stone/soil/geotextiles 17 Surface improvements to unpaved road surfaces 23<br />

Create ridges to prevent dust 17 Proper maintenance <strong>of</strong> unpaved roads 23<br />

Compact disturbed soil 17<br />

Work practices associated with de-icing materials 23<br />

Eliminate open burning 17 Fabrication<br />

Cutting, grinding and drilling 24<br />

Reduce certain activities during windy conditions 18 Avoiding cutting and grinding 24<br />

Storage Piles<br />

Storage pile activity should be conducted downwind 18 Sand and grit blasting and façade cleaning 24<br />

Utilize enclosures/coverings <strong>for</strong> storage piles 18 Concrete cutting 25<br />

Utilize wind fences/screens <strong>for</strong> storage piles 18 Mixing processes 25<br />

Use vegetation cover as a wind break 19<br />

Internal and external finishing and refurbishment 25<br />

Properly shape storage piles 19 Surface Coatings Durable and high per<strong>for</strong>mance coatings with a low VOC 32<br />

content should be used<br />

Properly schedule <strong>the</strong> delivery <strong>of</strong> landscaping materials 19 Minimize emissions from storage, handling & preparation 33<br />

Vehicles and<br />

Use diesel particulate filters, fuel-borne catalysts, diesel oxidation 27-28 Minimize coatings wastage through spillage/splashing 34<br />

Equipment<br />

catalysts<br />

Ensure catalytic converters are operating efficiently 28 Surface to be coated should be properly prepared 34<br />

Evaluate alternative technologies to reduce emissions 28 Paint heaters should be used instead <strong>of</strong> paint thinners 34<br />

Properly maintain engines and exhaust systems 29 Technologically advanced spray-guns should be utilized 34<br />

Use low sulphur diesel 29 Apply correct application techniques 35<br />

Alternative fuels should be utilized where feasible 29 Proper technique should be used when cleaning spray guns 35<br />

Reduce or eliminate idling time 30 Alternative coating application techniques should be used 36<br />

Evaluate alternatives <strong>for</strong> heat and air conditioning 30 Alternative cleaners or low-VOC cleaners should be used 36<br />

Minimize cold starts 30 Solvents used <strong>for</strong> cleaning should be minimized 36<br />

Evaporative losses should be minimized 31 Paint colour changes should be optimized 36<br />

Asphalt Ro<strong>of</strong>ing Temperatures <strong>of</strong> material inside kettles should be minimized 38<br />

Alternative finishing practices should be used 37<br />

Close fitting lids on ro<strong>of</strong>ing kettles should be used 38<br />

Kettle should be kept closed 38<br />

Ro<strong>of</strong>ing kettles should be equipped with afterburners 38<br />

<strong>Best</strong> <strong>Practices</strong> <strong>for</strong> <strong>the</strong> <strong>Reduction</strong> <strong>of</strong> <strong>Air</strong> <strong>Emissions</strong> <strong>From</strong> <strong>Construction</strong> and Demolition Activities 6