PDF (6.5 MB) - GEA Group

PDF (6.5 MB) - GEA Group

PDF (6.5 MB) - GEA Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

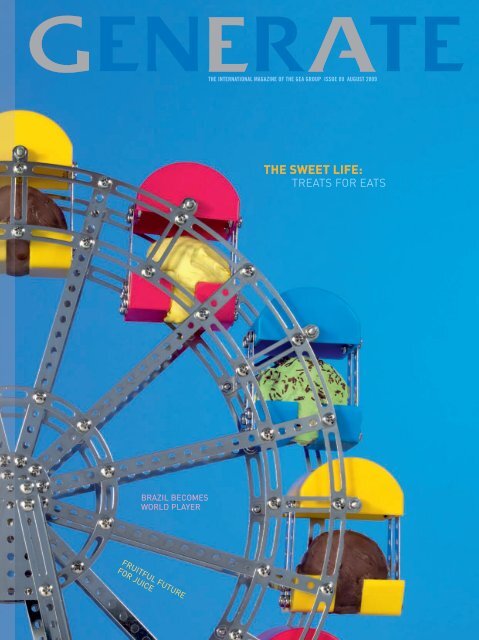

The international magazine of the <strong>GEA</strong> <strong>Group</strong> Issue 09 August 2009<br />

THE SWEET LIFE:<br />

TREATS FOR EATS<br />

Brazil becomes<br />

world player<br />

Fruitful future<br />

for juice

GENERATE is published by the <strong>GEA</strong> <strong>Group</strong><br />

Aktiengesellschaft, a globally successful<br />

technology group with more than 250<br />

companies in 50 countries.<br />

Listed on MDAX stock index, the company<br />

focuses on specialty mechanical engineering –<br />

especially process engineering and equipment.<br />

<strong>GEA</strong> <strong>Group</strong> technologies are applied in the<br />

food, chemical and petrochemical industries,<br />

the energy sector, air treatment and<br />

shipbuilding as well as the pharmaceutical<br />

and cosmetic industries. The <strong>GEA</strong> <strong>Group</strong> is one<br />

of the world`s market and technology leaders<br />

in 90 per cent of its businesses.<br />

In 2008 the group employed more than 21,000<br />

people who generated sales of more than<br />

EUR 5 billion.<br />

AIR TREATMENT<br />

Welcome to the ninth issue of GENERATE,<br />

published by the <strong>GEA</strong> <strong>Group</strong> Aktiengesellschaft.<br />

FARM Technologies<br />

THERMAL ENGINEERING<br />

Emission Control<br />

REFRIGERATION<br />

PROCESS Equipment<br />

MECHANICAL Separation<br />

PROCESS ENGINEERING<br />

PHARMA SYSTEMS<br />

Contact<br />

<strong>GEA</strong> <strong>Group</strong> Aktiengesellschaft<br />

Dorstener Straße 484<br />

44809 Bochum<br />

Tel: +49-(0)234-980-0<br />

Fax: +49-(0)234-980-1087<br />

www.geagroup.com<br />

Dear Readers,<br />

One of <strong>GEA</strong>’s fundamental strengths<br />

is that much of our technology plays a<br />

key role in the engineering processes<br />

of the products we continuously<br />

consume on a daily basis, like, for<br />

instance, energy, food and beverages.<br />

But what you may not know is that<br />

our products are also used to help<br />

create some of life’s little luxuries,<br />

like coffee, chocolate, candy bars and<br />

ice cream. And when times are tough,<br />

as they currently are in many of the<br />

world’s economies, sales figures from<br />

the confectionery industry suggest<br />

that people are more inclined to buy<br />

chocolate to cheer themselves up.<br />

It stands to reason: when you can’t<br />

afford life’s big luxuries, you tend to<br />

settle for the little ones. Our special<br />

feature in this issue is all about the<br />

luxury treats that delight taste buds<br />

all over the world.<br />

Historically, <strong>GEA</strong> has positioned itself<br />

in countries and markets where we<br />

believe there will be growth. In this<br />

issue, there is a feature on Latin<br />

America, focussing in particular on<br />

Brazil. Brazil is probably the least<br />

talked about of the so-called BRIC<br />

quartet of dynamic economies, but<br />

many commentators believe it is now<br />

the most likely to meet the predicted<br />

growth forecasts. Brazil has a lot going<br />

for it in terms of natural resources<br />

and a stable democracy and we hope<br />

our businesses based in the country<br />

will continue to play a role in its<br />

development as a regional superpower.<br />

Also, read in this issue how <strong>GEA</strong><br />

expertise is helping Ricola, a famous<br />

Swiss throat lozenge company, stay<br />

true to its roots by using only herbs<br />

grown in Switzerland but making the<br />

most of modern processing technology<br />

to make its production more efficient.<br />

You can also find out about how<br />

the modern consumers’ thirst for<br />

new products is enabling the juice<br />

industry to venture into new fields with<br />

innovative drinks that also happen<br />

to be good for us.<br />

At <strong>GEA</strong>, we always work hard to<br />

maintain the spirit of innovation that<br />

drives our business forward. We were<br />

one of the biggest exhibitors at the<br />

ANUGA FoodTec and ACHEMA trade<br />

fairs, where we showcased a wide<br />

variety of products, and we will also<br />

be present at drinktec, the world’s<br />

most important event for the beverage<br />

and liquid food technology industries<br />

later this year.<br />

Jürg Oleas<br />

Chairman of the Executive Board<br />

<strong>GEA</strong> <strong>Group</strong> Aktiengesellschaft

FEATURE STORY<br />

Life’s little luxuries<br />

The food and drinks that<br />

sweeten people’s lives<br />

Climate House<br />

The world’s weather comes<br />

together – under one roof<br />

LIFESTYLE<br />

Juice industry presses ahead<br />

HOW TO DO IT<br />

Making orange juice<br />

Going with the flow<br />

at drinktec 2009<br />

<strong>GEA</strong> showcases products at<br />

world fair for beverage and<br />

liquid food technology<br />

Q&A<br />

A Welsh dairy farmer talks about<br />

the health of the industry<br />

Nature’s remedy<br />

Swiss mountain plants are key<br />

to a famous herbal product<br />

Latin spirit<br />

Brazil flexes its<br />

economic muscles<br />

A DAY IN THE LIFE<br />

Lutz Wolf thinks big in the US<br />

ART IN ENGINEERING<br />

LAST WORD<br />

Global news from <strong>GEA</strong><br />

GENERATE MAGAZINE ISSUE 09 1

Low<br />

1023<br />

1020<br />

1000<br />

1032<br />

1008<br />

A unique attraction in Bremerhaven, Germany,<br />

lets you go globe-trotting without even<br />

having to leave the building.<br />

1008<br />

1012<br />

1016<br />

1004<br />

Low<br />

2

High<br />

LOw<br />

Some 600,000 people a year are expected<br />

to flock to the climate house for a<br />

chance to travel the world and experience<br />

different climate zones – including extreme<br />

heat and cold – in just one day and place.<br />

rainy day in the north German town<br />

of Bremerhaven nine years ago inspired<br />

the creation of a unique climate<br />

theme center. The downpour prompted<br />

Dr Carlo Petri, from Europe’s leading<br />

leisure specialists Petri & Tiemann, to<br />

consider the phenomena of weather<br />

patterns and atmospheric conditions.<br />

As the center’s website acknowledges,<br />

Petri is the brains behind Klimahaus ®<br />

Bremerhaven 8° Ost, which opened to the<br />

public in June 2009. Some 600,000 people<br />

a year are expected to flock to the climate<br />

house for a chance to travel the world<br />

and experience different climate zones –<br />

including extreme heat and cold – in just<br />

one day and place.<br />

The ‘journey’ takes visitors around the globe<br />

along the eighth line of longitude. Starting<br />

and finishing at Bremerhaven, it takes in the<br />

Blümlisalp glacier in Switzerland, Sardinia,<br />

the Niger desert region, a rain forest in<br />

Cameroon, then on to Antarctica, Samoa,<br />

Alaska and the island of Hallig Langeness in<br />

the North Sea.<br />

the sophisticated fan and air conditioning<br />

technology, there is no danger to health and<br />

no risk of catching a cold.”<br />

Klimahaus ® Bremerhaven 8° Ost covers a<br />

total of 11,500 square meters of exhibition<br />

area. In addition to the journey round the<br />

world, there are two other sections entitled<br />

‘elements’ and ‘perspectives’.<br />

The elements area explains the physical<br />

and meteorological principles underlying<br />

the phenomena of weather and climate.<br />

A large cylinder containing the four<br />

elements – fire, water, earth and air –<br />

enables people to experiment with the<br />

weather inside the Klimahaus. You can<br />

even create your own thunderstorm.<br />

Earth' past and future is the focus of<br />

the perspectives section and there’s an<br />

opportunity to forecast the weather.<br />

Finally, visitors can find out how much CO 2<br />

they produce daily and learn practical ways<br />

of reducing it.<br />

All-in-all a good day out – whatever the<br />

weather in Bremerhaven.<br />

Simulating, in one 5,000 square meter<br />

exhibition area, cool, high-altitude, alpine<br />

temperatures, the furnace-like heat of<br />

North Africa, the bitter cold Antarctic and<br />

rain forest humidity is a triumph of modern<br />

air treatment technology. More specifically,<br />

the fan coil units supplied by <strong>GEA</strong> Air<br />

Treatment – <strong>GEA</strong> fan coil units, with volume<br />

ratings of 535 to 1,305m3/h and cooling<br />

ratings of 1.45 to 4.73 kW – realistically<br />

create cool and windy climate zones and<br />

also provide the required climate control of<br />

the building zones.<br />

Go globe trotting in one day: at the Klimahaus ® Bremerhaven 8˚ Ost.<br />

A total of 31 <strong>GEA</strong> Power-Gekos and<br />

seven <strong>GEA</strong> Flex-Gekos were installed<br />

in collaboration with specialists from<br />

ventilation and air conditioning contractors<br />

Axima Deutschland.<br />

Amazingly, even in the cold sections visitors<br />

don’t have to wrap up like arctic explorers.<br />

As Roland Wiemann, Director of the Eastern<br />

Sales Region of <strong>GEA</strong> Happel Klimatechnik,<br />

explains: “Even though visitors experience<br />

very realistic climate extremes, they don’t<br />

need to dress especially warmly. Thanks to<br />

Jurassic theme park<br />

<strong>GEA</strong> Air Treatment is an experienced supplier of air handling and conditioning equipment<br />

to the leisure industry. Three of the company's systems are helping to recreate the earth’s<br />

climate as it was millions of years ago when dinosaurs ruled the world.<br />

Gondwana – the Prehistorium, a dinosaur theme park in Landsweiler-Reden, Germany,<br />

opened in December 2008. It takes visitors on a trip through the Silurian, Jurassic and<br />

Cretaceous periods in a 4,000 square meter complex.<br />

Two of the <strong>GEA</strong> Air Treatment units filter and pre-adjust the air temperature in the entrance<br />

and exhibit halls, creating realistic conditions for visitors as they explore prehistoric oceans<br />

and get close to dinosaurs like the infamous Tyrannosaurus Rex. The units use the thermal<br />

energy from the exhaust air to regulate the air temperature, saving energy and conserving<br />

resources. A third smaller, extra-flat, unit provides good air exchange in the adjacent rooms.<br />

1032<br />

1012<br />

GENERATE MAGAZINE ISSUE 09 3

ooking at the rows upon rows of fruit<br />

juices on our supermarket shelves it<br />

would be easy to think that this readymade<br />

superfood had been around for<br />

centuries; but you’d be wrong. while it’s<br />

probably true that mankind has been<br />

enjoying fruit juice throughout recorded<br />

history, its fragile chemical nature has<br />

meant that until comparatively recently it<br />

was impossible to keep it fresh for more<br />

than a few days.<br />

GENERATE eXaMines whY,<br />

for TodaY’s Modern JUiCe<br />

ManUfaCTUrers and healTh-<br />

ConsCioUs CUsToMers, The<br />

JUiCe is worTh The sQUeeze.<br />

New technology<br />

it is said that in the case of orange juice,<br />

overproduction of oranges in California<br />

way back in the early 1900s prompted the<br />

creation of the fruit juice industry we know<br />

today. at that time almost all the crop was<br />

sold as solid fruit and the juice industry, in<br />

the days before home refrigerators, was<br />

practically non-existent.<br />

The producers had become overburdened<br />

by a glut of fruit that nobody knew what<br />

to do with, and the industry faced the<br />

possibility of having to destroy around 30<br />

per cent of its trees. fortunately it was<br />

around this time that new pasteurization<br />

techniques were coming onstream and<br />

the growers hit on the idea of turning the<br />

fruit into juice at source, using the new<br />

technology to preserve its shelf life. at the<br />

same time the new national railway network<br />

was completed, allowing easy access to<br />

america’s big cities and eager consumers.<br />

a new industry had been born.<br />

4

The Us has now slipped from being the<br />

world’s largest producer of orange juice,<br />

having been overtaken by the Brazilian<br />

state of são paolo in the 1980s. Brazil now<br />

accounts for almost 50 per cent of the total<br />

world production, with the Us delivering<br />

around 37 per cent* (read more about<br />

Brazil on pages 24-27).<br />

Global industry<br />

surprisingly, while the basic techniques for<br />

producing good quality fruit juice had been<br />

known for many years it was not until after<br />

the second world war that the industry<br />

really took off throughout the world. and<br />

it wasn’t until the 1980s that the present<br />

bewildering range of exotic juices started to<br />

appear on supermarket shelves. at last the<br />

world could enjoy the tastes and textures<br />

of unfamiliar fruits from every corner of the<br />

earth simply by taking a carton from the<br />

fridge and pouring the contents into a glass.<br />

although orange juice still remains the<br />

world’s favorite, the imagination of the<br />

juice manufacturers knows no bounds.<br />

exotic cocktails, made from fruits like<br />

papaya, mango, pomegranate and passion<br />

fruit presented in equally exotic cartons,<br />

compete for our attention, all promising<br />

good health and well being for the<br />

discerning customer.<br />

Health benefits<br />

papaya, for example, seems to have<br />

particularly beneficial qualities due to<br />

its high levels of vitamin C, magnesium,<br />

luterein, betacryptoxanthin and beta<br />

carotene, which – as any nutritionist worth<br />

his salt will know – helps keep skin healthy,<br />

eyes clear, and is even said to protect<br />

against certain types of cancer. Cranberry<br />

juice, on the other hand, is said to help<br />

people suffering from cystitis and can<br />

also prevent the formation of kidney and<br />

bladder stones.<br />

drinking pomegranate juice has been<br />

shown to stabilize the levels of men's<br />

antigen prostate level, or psa. it is also<br />

thought that pomegranate juice increases<br />

blood flow to the heart in people with<br />

ischemic coronary heart disease.<br />

The list is seemingly endless and the<br />

amazing thing is that, unlike most foods that<br />

are good for us, fruit juices actually taste<br />

nice as well.<br />

Juicy trends<br />

with all these apparent health benefits<br />

it’s not surprising that the relatively<br />

new phenomenon of the ‘Juice Bar’ is<br />

gaining in popularity, with pioneers of the<br />

trade offering ready-made franchises to<br />

entrepreneurs keen to get a foothold in the<br />

market. in high streets and shopping malls<br />

from sydney to new York the brightly lit<br />

bars create tempting concoctions of every<br />

kind of juice imaginable.<br />

during the last decade designer juices<br />

like naked, which has become part of<br />

the giant pepsiCo group, and innocent,<br />

now part-owned by rival Coca-Cola, have<br />

made massive inroads into the traditional<br />

juice market by introducing super-quality<br />

smoothies and other premier health-drink<br />

products. This highly profitable section<br />

of the juice market is aimed squarely at<br />

the well-heeled, health-conscious, gymsubscribing<br />

customer, as well as those<br />

simply looking for an occasional treat.<br />

with the increase in public awareness of the<br />

benefits of healthy eating it is likely that this<br />

premier section of the market will continue<br />

to flourish despite the current economic<br />

downturn. highly populated developing<br />

countries like China and india will provide<br />

enormous potential markets for both<br />

mainstream and premier fruit juice<br />

products in the future.<br />

They say that necessity is the mother of<br />

invention, but when those early Californian<br />

orange growers came up with a solution to<br />

the problem of their unwanted fruit, they<br />

could never have imagined shelves full of<br />

vanilla, banana and acai berry smoothies.<br />

*BBC news Channel website http://news.bbc.co.uk<br />

GENERATE MAGAZINE ISSUE 09 5

making orange juice<br />

orange juice, sometimes described<br />

as packaged sunshine, is the<br />

world’s citrus juice of choice. The<br />

technology used for processing<br />

the raw products into juice is<br />

similar across the world. oranges<br />

are grown on commercial farms<br />

across the world but orange juice<br />

production is dominated by Brazil<br />

and the Us. here are the landmark<br />

stages in the oranges’ journey from<br />

the tree to the breakfast table.<br />

HarvestiNG<br />

farms generally grow varieties of oranges<br />

that mature at different times to enable<br />

them to produce a steady supply of fruit.<br />

ripened, the oranges are hand-picked and<br />

delivered to industrial processing facilities<br />

where they undergo quality control checks<br />

before industrial processing begins.<br />

CleaNiNG/CrusHiNG<br />

The fruit is washed and cleaned and sorted<br />

according to size. Jets of water spray the<br />

oranges as they pass along conveyor belts.<br />

despite being washed, their sweet citrus<br />

scent remains. no two oranges are exactly<br />

the same but on average an orange is 43 per<br />

cent juice and 57 per cent peel and pulp.<br />

JuiCe extraCtioN<br />

Traditionally, oranges have been pressed<br />

manually to separate solids and liquids but<br />

automatic processing, allied with gentler ways<br />

of treating the oranges to produce more juice,<br />

have helped facilitate the industry’s widespread<br />

growth. oranges are fed into huge juicing<br />

machines (known as extractors) and the juice is<br />

extracted from fruit as well as separated from<br />

the peel and oil in a series of processes. There<br />

are two main extraction methods: one cuts the<br />

fruit in half and the juice is extracted by rotating<br />

squeezing heads and the second uses circular<br />

cutters to extract juice by cutting through<br />

the top and bottom of the oranges, which are<br />

placed in cup-shape holders. The pulp content<br />

is adjusted by centrifugal technology according<br />

to the individual requirements. a range of Gea<br />

technology and equipment including separators<br />

and decanters (see panel, right) are used in<br />

these processes. Juice is then ready for<br />

concentration or pasteurization.<br />

6<br />

extractOr<br />

pump<br />

FiNisher<br />

hYDrOcYcLONe<br />

cLariFier<br />

ceLLs<br />

cOLLectOr<br />

taNk<br />

saND/sOLiDs puLp

pasteurizatioN oF NFC JuiCe<br />

when the orange juice is not concentrated<br />

but sold as nfC (not from concentrate) juice,<br />

it has to be pasteurized (heated rapidly for a<br />

short time) to kill any harmful bacteria. This<br />

process also extends the products’ shelf live.<br />

The industry is constantly striving for ways to<br />

make pasteurized orange juice look and taste<br />

like its freshly squeezed equivalent.<br />

paCkaGiNG/traNsportatioN<br />

The product can now begin its journey<br />

to customers across the world. it is<br />

either bottled on site, using state-ofthe-art<br />

bottling technology, or stored<br />

in refrigeration tanks before being<br />

loaded into tankers, driven to ports<br />

and transported around the world<br />

in specially refrigerated ships.<br />

CoNCeNtratioN<br />

The majority of the world’s orange<br />

juice is manufactured for export so<br />

turning the juice into concentrated<br />

juice gives it a better stability for<br />

storage and transport and makes<br />

it more cost-effective. To make<br />

concentrated juice, the juice passes<br />

through evaporators, which draw off<br />

the water through heat to produce<br />

a juice that is five times more<br />

concentrated than freshly squeezed<br />

juice. This concentrated orange juice<br />

is frozen for transportation and is<br />

then reconstituted in the country it is<br />

exported to through defrosting and the<br />

addition of water and flavorings.<br />

Citrus oil reCoverY<br />

essential oils are a valuable byproduct<br />

of the citrus juice production<br />

process, especially oils from lemons<br />

and grapefruit but also from oranges.<br />

The oil itself is in the citrus fruit’s<br />

peel. it is released during pressing<br />

in the extractors and washed off. The<br />

oil in the peel wash water is then<br />

concentrated by separators in a twostage<br />

separation process.<br />

Juice<br />

pump<br />

buFFer<br />

taNk<br />

heater<br />

cONceNtrate<br />

buFFer<br />

taNk<br />

pump<br />

evapOratOr<br />

Gea eNGiNeeriNG FOr the Juice iNDustrY<br />

Various <strong>GEA</strong> <strong>Group</strong> companies are involved in all the key stages of the citrus juicing<br />

industry including production, bottling and refrigeration.<br />

Leading the way in beverage technology expertise is <strong>GEA</strong> Westfalia Separator<br />

Process, part of <strong>GEA</strong>’s Mechanical Separation Division. <strong>GEA</strong> Westfalia Separator has<br />

been the market leader in centrifugal separation technology for over 100 years and<br />

its range of separators, decanters and membrane filtration help manufacturers to<br />

ensure maximum yield and the highest product quality. <strong>GEA</strong> Westfalia Separator’s<br />

range of separators and decanters are used in the extraction process, resulting in<br />

higher product yields and consistently high quality juice and oil. <strong>GEA</strong> Hovex, also<br />

part of the Mechanical Separation Division, supplies desanding cyclones to protect<br />

the downstream equipment from the erosive effect of the sand.<br />

A number of companies from <strong>GEA</strong> Process Engineering are also involved in the<br />

production process. <strong>GEA</strong> Niro’s freeze-drying technology improves juices’ shelf life<br />

and reduces storage and transportation costs. <strong>GEA</strong> Wiegand’s evaporation<br />

technology (taking out water from solids by thermal energy) is used to concentrate<br />

juices. By extracting the flavors from the thin juices to create a thick concentrate,<br />

the juice can be reconstituted close to the fruit’s original flavor after transportation<br />

and storage. <strong>GEA</strong> Filtration technology is used for reclaiming CIP (Clean In Place)<br />

chemicals for reuse in the CIP process.<br />

<strong>GEA</strong> Procomac, which is also part of the Process Engineering Division, is a<br />

specialist in cutting-edge bottling and packaging technology. It designs,<br />

manufactures and services complete cold aseptic and ESL (Extended Shelf Life)<br />

filling lines for juices in PET (Polyethylene terephthalate) bottles. Its customers<br />

include Tropicana, one of the US’s biggest juice manufacturers.<br />

Finally, <strong>GEA</strong>’s Refrigeration Division, in the shape of Grasso and Grenco, is involved<br />

in the refrigeration of juice. The product is transported in ‘juice carriers’, specially<br />

designed bulk vessels that can hold up to half a million refrigerated liters of juice.<br />

GENERATE MAGAZINE ISSUE 09<br />

7

8<br />

This September the eyes<br />

of the world’s beverage<br />

industry will be turned<br />

on Munich for drinktec 2009.

nyone who has ever attended the<br />

Oktoberfest will tell you that the<br />

city of Munich really knows how to<br />

throw a party.<br />

It therefore seems appropriate that the<br />

Bavarian capital should also play host to<br />

drinktec 2009, the biggest event for the<br />

world beverage and liquid food technology<br />

industries. Held every four years at the<br />

New Munich Trade Fair Center, drinktec is<br />

widely regarded in the sector as the premier<br />

platform for launching new products on the<br />

global market.<br />

For six days, September 14 – 19, drinktec<br />

will be the hottest ticket in town, attracting<br />

70,000 visitors from more than 160<br />

countries. And, despite the recession,<br />

the twelve exhibition halls have been fully<br />

booked for months. This year there will<br />

be 1,500 exhibitors from 60 countries,<br />

showcasing the latest technology for<br />

producing, filling and packaging and liquid<br />

foods. It’s also the only drinks trade fair to<br />

feature entire production chains that can<br />

be demonstrated in action.<br />

This year, for the first time, the spotlight<br />

will be on milk and milk-based drinks,<br />

with the presentation of Dairy Technology<br />

Awards and a dedicated lecture program.<br />

The awards will recognize technical<br />

innovation in the European dairy and food<br />

industry in the categories of: process<br />

and automation, packaging and filling,<br />

environment and sustainability, process<br />

management and IT, logistics and food<br />

safety. A survey by the fair’s organizers<br />

showed that nearly half of the exhibitors<br />

were also aiming their product range at<br />

the milk and liquid food segments.<br />

The <strong>GEA</strong> <strong>Group</strong> is in no doubt about the<br />

impact that attending drinktec can have on<br />

business and eleven of its companies will<br />

be represented. Dr Stefan Pecoroni, Head<br />

of the Business Unit Beverage Technology<br />

at <strong>GEA</strong> Westfalia Separator, underlines this.<br />

“Even in a tougher business environment,<br />

investment is continuing in the global<br />

beverages industry,” he says. “Information<br />

and communication between suppliers<br />

and customers are essential for making<br />

investment decisions of this kind. For <strong>GEA</strong>,<br />

drinktec is the top market place for this.<br />

Our strong presence again demonstrates<br />

how highly we rate this fair.”<br />

This year <strong>GEA</strong> Westfalia Separator is<br />

celebrating its 100th anniversary in the<br />

field of beer separation. Since its first<br />

separator was used to clarify beer at a<br />

Vienna brewery in 1909, the company has<br />

led the way in centrifugal technology.<br />

And the revolution continues with the new<br />

GSC 250 separator which will be on show<br />

at drinktec. With a capacity of up to 800<br />

hectoliters per hour, the machine is the<br />

largest brewery centrifuge featuring <strong>GEA</strong><br />

Westfalia Separator hydrostop. This special<br />

and patented ejection system produces<br />

maximum yield with minimum beer losses.<br />

In addition to brewing, <strong>GEA</strong> Westfalia<br />

Separator also offers an extensive range<br />

of decanters, separators and mechanical<br />

separation lines for the beverage, food,<br />

chemical, pharmaceutical and renewable<br />

resources industries.<br />

<strong>GEA</strong> Brewery Systems was formed by the<br />

merger of the two internationally renowned<br />

companies Huppmann and Tuchenhagen<br />

Brewery Systems. With the combination of<br />

hot and cold process area in one company,<br />

<strong>GEA</strong> Brewery Systems is a globally-unique<br />

competence center for breweries. At<br />

drinktec it will be presenting its extensive<br />

know-how and vast engineering experience<br />

in brewing technology and the manufacture<br />

of brewery equipment. Engineering experts<br />

and sales managers will be available at the<br />

stand to give visitors competent advice.<br />

Bottling specialist <strong>GEA</strong> Procomac is<br />

presenting a guided path through INSIDE<br />

ASEPTIC, which showcases the technologies<br />

for sterilizing containers and caps.<br />

A fifth generation of Unibloc Spin carousel<br />

with wet PAA (peracetic acid) sterilization<br />

system, which can reduce the total cost<br />

of ownership, will be on display, along<br />

with a carousel from the <strong>GEA</strong> Procomac<br />

VHP (vaporized hydrogen peroxide)<br />

sterilization technology. In addition, <strong>GEA</strong><br />

Procomac presents the new STERILBEAM<br />

caps sterilizer unit, going beyond the<br />

Chemical AGE, which uses energy-based<br />

technology. <strong>GEA</strong> Procomac Packaging is<br />

showing POLARIS, its layer preparation<br />

system suitable for medium to high<br />

speed production.<br />

Visitors to the <strong>GEA</strong> Wiegand section<br />

of the stand will be shown a model of<br />

an evaporation plant which is used to<br />

concentrate a variety of products within<br />

the food industry. The company is a<br />

leading designer, manufacturer and<br />

supplier of evaporation plants, distillation<br />

plants and membrane filtration plants.<br />

It also supplies systems for the chemical<br />

and pharmaceutical industries and for<br />

environmental application.<br />

Heat exchangers are an important part of<br />

beverage and liquid food manufacture and<br />

<strong>GEA</strong> will have three companies represented<br />

in this field at drinktec. Dairy specialist <strong>GEA</strong><br />

TDS is exhibiting its range of VARITUBE<br />

heat exchangers for heating, cooling,<br />

pasteurizing and ultra heat treating<br />

a variety of products. <strong>GEA</strong> PHE Systems<br />

will have its NT 50 and VT 20 plate heat<br />

exchangers and <strong>GEA</strong> EcoServe will highlight<br />

its servicing credentials for all makes of<br />

plate heat exchangers.<br />

<strong>GEA</strong> Tuchenhagen will have valves, cleaning<br />

devices and pumps on display. In particular,<br />

the new T-smart valves offer a cost-effective<br />

shut-off device during clean-in-place<br />

operations. This cuts down on cleaning<br />

cycles so that the production process can<br />

run more economically. The VARIPURE<br />

cleaners require fewer chemical cleaners<br />

and less energy and also produce less waste<br />

water, providing an environmentally-friendly<br />

solution while lowering costs.<br />

Accuracy and reliability are the key<br />

selling points of electromagnetic flow<br />

metering technology which will be the main<br />

feature of the <strong>GEA</strong> Diessel exhibits. The<br />

company, which has been developing and<br />

manufacturing flow meters for more than<br />

40 years, provides complete plants and units<br />

for liquid processing, along with testing and<br />

prequalification services.<br />

<strong>GEA</strong> Niro Soavi, which specializes in<br />

dynamic high pressure homogenization<br />

technology, will be showing its new Ariete<br />

5315 homogenizer.<br />

Finally, keeping cool is another important<br />

factor in the manufacture of beverages<br />

and liquid foods. This is where <strong>GEA</strong><br />

Refrigeration comes in. It is a leading<br />

manufacturer of compressors for industrial<br />

refrigeration, offering state-of-the-art<br />

technology for all stages of production<br />

and storage. On show will be the Grasso<br />

V 1100 (piston compressor) and other<br />

new products.<br />

Come and see us in hall A4, stand 314.<br />

GENERATE MAGAZINE ISSUE 09 9

CHampaGNe, CHoColate, iCe Cream,<br />

CoFFee aND CaNDY – Just a FeW oF<br />

tHe little iNDulGeNCes eNJoYeD<br />

arouND tHe WorlD. JuLie MitcHeLL<br />

looks at HoW luxurY FooD aND<br />

DriNk sWeeteN people’s lives.<br />

pHotoGrapHY: Will tHom<br />

stYliNG: saBriNa JarD<br />

GENERATE MAGAZINE ISSUE 09 11

Despite its souND<br />

NutritioNal<br />

CreDeNtials, tHe<br />

HumBle spiNaCH is<br />

Never GoiNG to Be<br />

First CHoiCe For a<br />

tastY sNaCk or a<br />

reWarDiNG treat.<br />

pinach is good for you according to<br />

health experts. it’s packed with vitamins,<br />

essential minerals such as iron and<br />

copper, antioxidants and dietary fiber. in<br />

the famous popeye cartoons spinach is a<br />

nutritional powerhouse, providing the sailor<br />

hero with super-human strength for fighting<br />

the bad guys and rescuing olive oyl.<br />

But, even though many children – and adults<br />

– have been wowed by popeye’s antics,<br />

they’ve not been inspired to blaze a trail to<br />

the vegetable counter. far from it. in fact the<br />

parental exhortation to “eat your greens” is<br />

almost universally met with defiance. But<br />

offer children chocolate, candy, potato chips<br />

or ice cream and it’s a different story.<br />

despite its sound nutritional credentials,<br />

the humble spinach is never going to be first<br />

choice for a tasty snack or a rewarding treat.<br />

similarly, the english mantra of “an apple a<br />

day keeps the doctor away” hasn’t deterred<br />

trips to the candy store.<br />

it seems that some foods, for all their<br />

goodness, are not what you would consider<br />

‘fun’. look at it this way: you won’t find<br />

spinach – or any other vegetable or fruit for<br />

that matter – on sale at a fairground. apples<br />

may put in an appearance but only under a<br />

coating of toffee. what you are most likely to<br />

find are ice cream and cotton candy.<br />

also known as candy floss in the Uk and fairy<br />

floss in australia, this is a confection made<br />

from spinning colored sugar into a soft, fluffy<br />

mass which resembles a large cotton wool<br />

ball. it is widely believed that cotton candy<br />

made its debut to a wide audience in 1904<br />

at the st louis world’s fair and it has been<br />

synonymous with fairs ever since. The Us<br />

has even designated a national Cotton Candy<br />

day on december 7.<br />

like cotton candy at the fair, certain<br />

snacks and confectionery are considered<br />

to be part of the quintessential experience<br />

of a particular activity or event – popcorn at<br />

the movies, for example, hot dogs at the ball<br />

game or chocolate eggs at easter.<br />

More than a fuel<br />

The desire for tasty treats demonstrates<br />

the complex relationship that humans<br />

have with food. doctors and nutritionists<br />

will tell you that a balanced diet of protein,<br />

carbohydrate, fat, vitamins and minerals<br />

is important for maintaining a healthy<br />

body. But, as civilizations have developed,<br />

eating has become more than a means of<br />

fuelling the body’s needs – it’s inextricably<br />

linked to entertainment. That is why food<br />

and drink are so often central to cultural<br />

and religious festivals, carnivals and social<br />

gatherings. Birthdays, weddings, Christmas,<br />

Thanksgiving, ramadan, the hindu festival<br />

diwali, to name but a few, all have specific<br />

culinary associations.<br />

Throughout history feasts and banquets<br />

have been the cornerstone of a multitude of<br />

celebrations. in many instances they’ve been<br />

an occasion to show off power and wealth.<br />

12

treats CaN Be BotH a reWarD WHeN<br />

tHiNGs Have GoNe Well aND a ComFort<br />

aFter a BaD DaY.<br />

what we normally class as luxury food and<br />

drinks are mainly the preserve of those with<br />

a large bank balance. The rarity value of<br />

goods such as vintage wines, Beluga caviar,<br />

kobe beef and white truffles gives them a<br />

high price tag and therefore an exclusivity<br />

that underlines the status of those lucky<br />

enough to afford them. on the other hand<br />

there are products once considered luxuries<br />

– coffee for instance – which, thanks to mass<br />

production lowering their price, are now<br />

widely available.<br />

World of treats<br />

There are many and varied affordable treats<br />

served up around the world. vienna has<br />

sachertorte and Belgium and switzerland<br />

are famed for their chocolate. There are<br />

rice crackers from Japan, caramelized<br />

sorghum kernels in Burkino faso and<br />

koba ravina (made from rice flour, brown<br />

sugar and ground peanuts) in Madagascar.<br />

Many snacks and confections are enjoyed<br />

worldwide. But there are others, such as the<br />

deep-fried spiders loved by Cambodians, with<br />

limited global appeal.<br />

Considerable time, energy, money and<br />

resources go into making products which,<br />

you could argue, are non-essential food and<br />

drink. we wouldn’t starve without them,<br />

particularly as most have little or no real<br />

nutritional value. we don’t need to be hungry<br />

and thirsty to enjoy a glass of wine, a cup of<br />

coffee, chocolates, ice cream, salted nuts<br />

or potato chips. we consume them because<br />

they simply taste great and make us feel<br />

good. Treats can be both a reward when<br />

things have gone well and a comfort after<br />

a bad day.<br />

The comfort value of chocolate and other<br />

confectionery soars during periods of crisis<br />

which is why these industries are widely<br />

seen as recession-proof. and it would seem<br />

that they are continuing to buck the trend<br />

during the current global downturn. while<br />

businesses in other industries are struggling<br />

to stay afloat and cutting jobs, chocolate<br />

and candy manufacturers are reporting<br />

increased sales.<br />

Cadbury’s profits were up 30 per cent in<br />

2008 and nestlé’s grew by more than ten<br />

per cent. spanish cocoa and chocolate<br />

specialist natra reported a 50 per cent<br />

increase in sales during 2008 while lindt<br />

& sprüngli achieved above average organic<br />

growth of 5.8 per cent in local currencies.<br />

london department store selfridges so far<br />

this year sold 80 per cent more chocolate<br />

than in 2008, and sales of other confectionery<br />

were up 30 per cent. ><br />

2008 Wins!<br />

cAdBurY’s<br />

Profits 30%<br />

nAtrA's<br />

sALes 50%<br />

Lindt & sPrÜnGLi<br />

GroWtH 5.8%<br />

GENERATE MAGAZINE ISSUE 09 13

TASTY TREATS FACT FILE<br />

Food is the main ingredient at festivals and<br />

celebrations throughout the world. Here’s a<br />

taste of some of the well-known events, plus a<br />

few unusual ones, as well as some interesting<br />

facts and figures about treats.<br />

CANADA CONSUMPTION<br />

8.7l<br />

3kg<br />

UK CONSUMPTION<br />

6l<br />

10kg<br />

FINLAND CONSUMPTION<br />

14l<br />

6.6kg<br />

05<br />

USA CONSUMPTION<br />

18.3l<br />

SWITZERLAND CONSUMPTION<br />

10.1kg<br />

06<br />

08<br />

5.5kg<br />

02<br />

04<br />

10<br />

01<br />

ITALY CONSUMPTION<br />

9.2l<br />

11<br />

3.3kg<br />

Snack favorite the potato chip<br />

was invented by accident at<br />

Moon’s Lake House restaurant<br />

near Saratoga Springs, New York,<br />

in 1853. According to legend a<br />

customer kept complaining that<br />

his fried potatoes were too thick<br />

and soggy so the chef, George<br />

Crum, decided to get his own back<br />

by making them so thin and crispy<br />

that they couldn’t be eaten with a<br />

fork. And the rest is history.<br />

CHILE CONSUMPTION<br />

5.6l<br />

BRAZIL CONSUMPTION<br />

1.1kg<br />

03<br />

The biggest sundae was made<br />

in California in 1985. It was<br />

3.6 meters high and used<br />

17,666 liters of ice cream.<br />

14

Belgian chocolate manufacturer Guylian<br />

has given new meaning to the term ‘extra<br />

large eggs’. The company is listed in the<br />

Guinness Book of World Records for making<br />

the biggest ever Easter egg. It took 26<br />

chocolatiers 525 hours to make the 8.32<br />

meter high egg, using 1,950 kilograms<br />

of chocolate bars.<br />

TASTY TREATS KEY<br />

Cocoa growing regions<br />

Average consumption of ice cream<br />

(per person, per year)<br />

Source: Canadian Dairy Info Centre<br />

Average consumption of chocolate<br />

(per person, per year)<br />

Source: CAOBISCO<br />

'Did you know' fact<br />

Festivals of food (See key below)<br />

CHINA CONSUMPTION<br />

MALAYSIA CONSUMPTION<br />

2l<br />

1.9l<br />

0.1kg<br />

07<br />

JAPAN CONSUMPTION<br />

0.01l<br />

1.9kg<br />

01 Easter eggs – the Greeks dye hard-boiled eggs<br />

red as part of the Easter celebrations. Traditionally<br />

people tap their egg against someone else’s. The<br />

person whose egg is the last to crack gets a year<br />

of good luck.<br />

02 Know your onions – in the US the Vidalia onion is<br />

the state vegetable of Georgia. It is celebrated with<br />

eating contests, cook-offs, dancing and a rodeo.<br />

03 Oyster delight – in May Randburg’s Brightwater<br />

Commons in Johannesburg is transformed into<br />

food-lover’s paradise for the two-day Oyster, Wine<br />

& Food Festival.<br />

04 La Tomatina – held in Bunõl, Spain in August where<br />

people honor tomatoes by throwing more than 100<br />

tonnes of them at each other.<br />

05 Foodies delight – every August Preuvenemint-<br />

Maastricht in the Netherlands hosts an international<br />

food tasting festival.<br />

06 Envies Culinaires – is a four-day gourmet<br />

extravaganza in Lille, France. Delights on offer<br />

include fresh lobster, nougat, waffles, wine tasting<br />

and cookery demonstrations.<br />

07 Mooncake – an essential part of China’s<br />

Mid-Autumn Festival, one of the country’s most<br />

important events. The mooncake consists of a thick<br />

paste, usually made from lotus seeds, enclosing<br />

a salted egg yolk to symbolize the moon.<br />

08 Oktoberfest – Munich’s world famous beer festival<br />

in October when visitors drink their way through five<br />

million liters of beer over 16 days.<br />

If you thought making a car was<br />

a piece of cake – you’d be right.<br />

A team of bakers made a life-size<br />

replica of a Skoda Fabia for a<br />

television advertising campaign,<br />

using cakes, sweets, chocolate<br />

and marzipan.<br />

09<br />

AUSTRALIA CONSUMPTION<br />

18l<br />

5.7kg<br />

09 Yum In My Tum – is a food festival for children,<br />

held in Perth, Australia. Youngsters learn about<br />

food production and try their hands at cooking –<br />

and tasting.<br />

10 Truffle Festival – held in Alba, Italy to celebrate the<br />

white truffle season. Famous chefs from all over the<br />

world are invited to attend a truffle auction where<br />

the most exotic specimens sell at more than EUR<br />

1,500 a kilogram.<br />

11 Noche de Rábanos – sculptures made from radishes<br />

are displayed in the main plaza of Oaxaca city in<br />

Mexico on December 23. The radishes are specially<br />

grown and can weigh up to three kilograms and<br />

measure 50 centimeters in length.<br />

GENERATE MAGAZINE ISSUE 09 15

ICE DREAM<br />

Legend has it that the ice cream cone was invented<br />

accidentally. During the St Louis World’s Fair in 1904<br />

the ice cream seller ran out of cardboard dishes. A<br />

waffle seller at the next stall came to the rescue by<br />

rolling up waffles into cones to hold the ice cream.<br />

Whatever the truth of this the ice cream cone is a<br />

ubiquitous feature around the world, especially on<br />

a hot summer day. As the mercury rises, so do ice<br />

cream sales. Of course ice cream is still enjoyed<br />

year round, particularly in Finland which has the<br />

highest consumption in Europe. Other big consumers<br />

are the US, Australia and New Zealand. NASA even<br />

commissioned a freeze-dried variety in the late 60s<br />

so that the Apollo astronauts could enjoy ice cream<br />

in outer space.<br />

Ice cream has been around for centuries. Originally<br />

it was made with ice, collected from frozen lakes<br />

and mountains, flavored with honey and fruits.<br />

What we recognize as ice cream – a combination<br />

of milk, cream, eggs and sugar – was invented<br />

much later. It remained a rare and expensive treat<br />

reserved for special occasions until industrial<br />

refrigeration arrived in the 20th century and made<br />

mass production possible. Since then ice cream<br />

parlors have sprung up around the globe and there’s<br />

a mind-boggling choice of flavors available from the<br />

humble vanilla and strawberry to the more exotic<br />

rocky road and chocolate chip cookie dough. The US<br />

manufacturer Baskin-Robbins has created more than<br />

1,000 varieties.<br />

Interestingly, former British Prime Minister Margaret<br />

Thatcher has a place in the ice cream revolution.<br />

Before she became a politician she was part of a<br />

chemical research team that discovered a way of<br />

doubling the amount of air in ice cream to produce a<br />

lighter texture and reduce manufacturing costs. This<br />

proved popular with consumers and vendors who<br />

could more easily fill a cone from a tap.<br />

Fast forward to today and <strong>GEA</strong> Niro Soavi has<br />

developed high pressure homogenization and valve<br />

technology that makes ice cream even softer and<br />

lighter. It comprises a homogenizer that blends the<br />

ice cream ingredients into a stable and uniform<br />

emulsion. The NanoVALVE then effectively<br />

disperses the emulsion, reducing the size of the ice<br />

crystals. The finished mixture contains more air,<br />

enhancing the flavor and making it smoother and<br />

easier to digest.<br />

FOOD OF THE GODS<br />

No food stimulates the senses quite like chocolate.<br />

It’s the ultimate affordable luxury. Its versatility<br />

makes it a sought-after ingredient the world over<br />

for snacks, candies, desserts, cookies and ice cream.<br />

You can also drink it, on its own or as flavored milk.<br />

Chocolates make desirable gifts and, molded into<br />

a variety of shapes, chocolate is an integral part of<br />

many festivals – as Easter eggs, coins for Hanukkah<br />

or heart-shaped candies for Valentine’s Day.<br />

Until the 16th century, chocolate was unknown<br />

outside Central and South America. The name<br />

derives from the Aztec word xocolatl, which means<br />

bitter water. Initially chocolate was purely a drink<br />

until mechanization made it possible to extract the<br />

cocoa butter from the solids.<br />

Today, cocoa beans are grown in many parts of the<br />

world, with Ivory Coast, Ghana, Indonesia, Brazil,<br />

Nigeria, Cameroon, Malaysia, Equador and Papua<br />

New Guinea being the main producers.<br />

There are three main types of chocolate: the dark<br />

variety comprises varying proportions of cocoa solids<br />

and cocoa butter and is often sweetened with sugar.<br />

Milk chocolate is sweetened and has added milk<br />

powder or condensed milk. White chocolate is made<br />

from cocoa butter, sugar and milk.<br />

Dark chocolate containing a minimum of 70 per cent<br />

cocoa solids is growing in popularity. Particularly<br />

as doctors have found that cocoa powder contains<br />

antioxidants that reduce the formation of harmful<br />

free radicals and also lower blood pressure and<br />

cholesterol levels.<br />

Zotter, the Austrian chocolate manufacturer, has<br />

gone a step further by using a <strong>GEA</strong> Westfalia<br />

Separator CD 305 decanter to reduce the fat content<br />

in the cocoa mass. As one of the new key components<br />

in the center of the production chain, the decanter<br />

obtains cocoa mass which has the right consistency<br />

for conching. Here, the fat content, as well as the<br />

grain size distribution, are key aspects. Conching is<br />

where the cocoa and sugar particles are refined to<br />

give the finished chocolate its flavor and smooth feel.<br />

In the past the consistency of the cocoa mass had to<br />

be adjusted by adding sugar, which generally had a<br />

limiting effect on the production of dark chocolate.<br />

<strong>GEA</strong> Niro contributes to the chocolate industry,<br />

supplying a range of agglomeration systems for<br />

making chocolate powder for hot chocolate drinks.<br />

Flower power<br />

It seems appropriate that Mexico, the country that<br />

gave chocolate to the world, should also be the origin<br />

of vanilla, one of the most sought-after spices.<br />

Vanilla extract is used in a wide range of food and<br />

drinks and it’s the most popular ice cream flavor.<br />

The Spanish conquistador Hernán Cortés is widely<br />

credited with introducing vanilla to Europe in the<br />

1520s. Vanilla, which is Spanish for ‘little pod’, is<br />

the only edible orchid. Most of the world’s vanilla<br />

production is concentrated in Madagascar, Mexico,<br />

parts of South America and Tahiti.<br />

Harvesting the pods is very labor-intensive which<br />

is why vanilla is the second most expensive spice<br />

in the world.<br />

Saffron, another flower derivative, claims the top<br />

spot in the exclusive category. It comes from the<br />

stigma of the saffron crocus, which is native to<br />

South West Asia. Each flower has three stigmas,<br />

so collecting them is a painstaking process. Saffron<br />

is used to flavor and add a distinctive yellow color<br />

to a variety of dishes.<br />

In Mexico the<br />

incidence of diabetes<br />

is predicted to rise<br />

40 per cent by 2012.<br />

16

the foods and drinks we consume<br />

for pleasure are multi-billion<br />

dollar industries that create jobs<br />

and make a huge contribution to<br />

the global economy.<br />

Big business<br />

Sadly, while people in the developed world<br />

happily satisfy their cravings for treats, nearly<br />

one billion people in poorer countries go<br />

hungry every single day. For them a treat is<br />

enough food and clean water.<br />

The richer countries are not blind to their<br />

plight and efforts are being made by the UN,<br />

governments, aid agencies and charities to<br />

alleviate poverty and hunger in the developing<br />

world. Mass fund-raising campaigns, such<br />

as the Live8 concert held in London in 2005<br />

and, more recently, the Professional Football<br />

Against Hunger match weekend in Europe in<br />

March 2009, are helping to make a difference.<br />

Money raised from these events finances<br />

projects to enable poor communities to grow<br />

and produce their own food.<br />

It’s worth noting, in this context, that the<br />

foods and drinks we consume for pleasure<br />

are multi-billion dollar industries that create<br />

jobs and make a huge contribution to the<br />

global economy. According to the World<br />

Cocoa Foundation the livelihoods of 50<br />

million people depend on cocoa from which<br />

chocolate is made. And, around two-thirds<br />

of the world’s cocoa is grown in West Africa.<br />

Coffee is another big global employer, from<br />

the farmers in Africa and South and Central<br />

America to the people working in coffee bars.<br />

Traditionally trade tends to discriminate<br />

against poorer producers but, thanks to the<br />

efforts of the World Fair Trade Organization,<br />

farmers and workers in developing countries<br />

are getting a better deal on exports to<br />

developed countries. To achieve a Fair Trade<br />

certification companies must be committed<br />

to paying no less than market prices. Certain<br />

brands of coffee, tea, wine, cocoa and nuts<br />

are among the products bearing the Fair<br />

Trade mark.<br />

Not so sweet<br />

Although widespread snacking is good for<br />

business, there is a downside. It’s often<br />

said that the foods that taste the best are<br />

the ones that are bad for you. Sadly, most<br />

treats are loaded with fat and sugar and, if<br />

you consume them in large quantities, you<br />

will likely gain weight.<br />

Obesity rates are soaring in the developed<br />

world and so too are the associated health<br />

problems of heart disease and diabetes. In<br />

Mexico the incidence of diabetes is predicted<br />

to rise 40 per cent by 2012, killing 100,000<br />

people in that year. The fact that Mexico tops<br />

the league table for cola consumption is<br />

believed to be a contributing factor.<br />

Growing rates of obesity-related diabetes<br />

in the UK prompted a Scottish doctor to<br />

suggest that chocolate should be taxed.<br />

He warned that many people were eating<br />

their entire daily calorie quota in chocolate,<br />

in addition to normal meals. His comments<br />

made good headlines but such a tax is<br />

unlikely to be imposed.<br />

A major problem when trying to lose weight<br />

is combating the craving for tasty treats<br />

which, because of their high calorie content,<br />

are temporarily off your menu. Of course<br />

there are numerous low-fat or sugar free<br />

options to choose from. Maybe the best<br />

way is to think of tasty treats as just that –<br />

something you eat occasionally as part of<br />

a balanced diet.<br />

The <strong>GEA</strong> Niro Soavi NanoVALVE (see page 16) makes ice cream<br />

lighter. The product is forced through a homogenizing valve under<br />

high density fluid-dynamic energy, breaking down the particles<br />

to nanometer size.<br />

<strong>GEA</strong> and luxury foods<br />

The wide availability of tasty treats and snacks,<br />

as with most other foods, could not be achieved<br />

without cutting-edge engineering, processing and<br />

refrigeration that enable manufacturers to make,<br />

store and distribute products across the world.<br />

<strong>GEA</strong> is one of the leaders in supplying innovative<br />

equipment and expertise throughout the food and<br />

beverage production chain.<br />

It’s more than likely that the ice cream in your<br />

freezer has been made with milk and cream that<br />

has had contact with <strong>GEA</strong>’s milking and processing<br />

equipment. The Farm Technologies Division is a<br />

world-class supplier of technical innovations and<br />

systems for all stages of the milk production process.<br />

Your ice cream may also have been frozen and<br />

stored by refrigeration equipment supplied by<br />

<strong>GEA</strong> Refrigeration Division companies. In addition<br />

to complete refrigeration systems and components,<br />

used throughout the food, brewing and beverage<br />

industries, they supply a wide range of spiral and<br />

tunnel freezers used in food processing. Refrigeration<br />

is also an important step in the production of<br />

candy bars.<br />

Mechanical separation is an important part of food<br />

and drink manufacture and another area in which<br />

<strong>GEA</strong> leads the way. <strong>GEA</strong> Westfalia Separator supplies<br />

a range of market-leading separators, decanters and<br />

mechanical separation lines to the dairy, beverage<br />

and food sector.<br />

<strong>GEA</strong> Process Equipment Division is another<br />

contributor to the dairy and beverage industries,<br />

offering a range of customized solutions, including<br />

heat exchangers, pasteurizers and homogenizers,<br />

plus top quality sanitary valves and pumps. Plate<br />

heat exchangers from <strong>GEA</strong> PHE Systems are used<br />

during the heating or cooling processes involved in<br />

the production of smoothies, ice cream and yogurts.<br />

So too is <strong>GEA</strong> Process Engineering Division. Led by<br />

<strong>GEA</strong> Niro, it provides complete process lines and<br />

products, including evaporators, spray dryers, fluid<br />

bed dryers, extraction plants and freeze dryers for the<br />

food, beverage and dairy industries.<br />

GENERATE MAGAZINE ISSUE 09 17

BEN LLEWELLIN seTs oUT<br />

The ChallenGes faCinG<br />

dairY farMers in The<br />

Uk and eXplains whY<br />

he reMains CoMMiTTed<br />

To The indUsTrY.<br />

pHotoGrapHY: CHris moYse<br />

18

GENERATE MAGAZINE ISSUE 09 19

lower house farm, in the heart of<br />

pembrokeshire in wales, has been in the<br />

llewellin family since the 1800s. Ben, the latest<br />

to follow in the family tradition, looks after the<br />

dairy herd with his wife nia and his parents<br />

George and anne. at a time when low milk<br />

prices are forcing many of the Uk’s dairy<br />

farmers out of the industry, Ben and his<br />

family have made a significant investment<br />

in new milking equipment.<br />

Q. Did you always plan to become a<br />

dairy farmer?<br />

A. Yes, i hoped to continue the business,<br />

although, at one stage, i considered<br />

becoming a vet. i wanted to go as far as<br />

i could with my education and i took a<br />

degree in agriculture. after graduating<br />

in 2004 i came back to the farm.<br />

Q. What is the size of your farm and how big<br />

is the herd?<br />

A. there are more than 120 hectares divided<br />

into grazing land, fields for growing maize<br />

to feed the cattle and grass silage for winter<br />

fodder. We also have woodland and streams<br />

for which we receive money to preserve them<br />

as wildlife habitat. the herd comprises 200<br />

Holstein cows and 130 heifers [young cows<br />

that have not yet calved]. in addition, when<br />

Nia and i married she brought ten Jersey<br />

cows to the farm plus 12 heifers.<br />

Q. isn’t it a lot of work for just four people?<br />

A. it’s very much a team effort – we all<br />

work as hard as each other, starting and<br />

finishing at the same time. milking times<br />

are 5.30am-9.30am and 4pm-7pm and the<br />

hours in between are spent on management<br />

of the herd, looking after the fields, and<br />

dealing with slurry. it would be lovely to take<br />

more weekends off but it’s just not possible<br />

because our profits depend on the work we<br />

put in. everything is streamlined to make the<br />

business as efficient as possible. We would<br />

love to employ someone but the way the<br />

industry is at the moment it’s very difficult<br />

to find someone who is willing and able to<br />

put in the effort.<br />

Q. What made you decide to reinvest in your<br />

farm at a time when the uk dairy industry<br />

is shrinking?<br />

A. two and a half years ago we were at a<br />

crossroads. the old milking parlor was<br />

taking far too long to collect milk and it<br />

was about to die on us. either we had to<br />

reinvest in new equipment or sell up and do<br />

something else with our lives. Nia and<br />

i wanted to continue the farm because we<br />

love the countryside and the lifestyle.<br />

We now have a herringbone parlor from Gea<br />

Westfalia surge. it holds 16 cows in each side<br />

so 32 cows can be milked at a time. From<br />

the parlor the milk goes through a filter and<br />

cooling system into a tank.<br />

20

Each cow wears a pedometer to measure<br />

their activity and, when they walk over a<br />

metal ring at the back of the parlor, the data<br />

is fed into the computer. If a cow shows high<br />

activity it means she’s on heat and ready to<br />

be inseminated.<br />

Q. Is it true that cows know when it’s time to<br />

be milked?<br />

A. Yes and they’ve also got used to listening<br />

to the radio while they’re being milked! If we<br />

don’t have the radio on, they’re distracted.<br />

Cows like to follow a routine – it’s amazing<br />

how often they will go into the same cubicles<br />

to sleep at night and when they’re kept in<br />

during the winter. The cows all have different<br />

personalities and we give each one a name<br />

which continues through the generations.<br />

Q. How much milk does your herd produce<br />

and where does it go?<br />

A. We sell to First Milk, which is the UK’s<br />

largest farmer-owned cooperative. The milk<br />

usually goes to a cheese factory down the<br />

road in Haverfordwest. But, if there’s a milk<br />

shortage, it will be taken to a bottling plant.<br />

We get 1.6 million liters of milk per year from<br />

the herd. On average a cow produces 8,500<br />

liters. Some cows will give you 6,000 liters<br />

and others 13,000 liters, even though they’ve<br />

been fed exactly the same – it’s all down to<br />

breeding. Improving the breeding to enable<br />

cows to be more efficient at producing milk<br />

is what interests me most. To achieve this we<br />

have to choose genetically elite bulls. Each<br />

bull has a list of approximately 25 different<br />

traits and we select those that can overcome<br />

our cows’ weak points.<br />

Q. What is the milk life of a cow and how<br />

often do they calve?<br />

A. Six and a half years is the national<br />

average and in that time they would have<br />

three to four calves, although we have one<br />

cow that is expecting her 12th. We try and<br />

alter the calving pattern to take advantage<br />

of higher milk prices in the autumn. But this<br />

can be difficult to maintain because they are<br />

kept inside during the winter so it costs<br />

more in feed.<br />

Q. There have been reports in the press<br />

about Welsh livestock being under threat<br />

from bovine TB. How big a problem is it?<br />

A. Bovine TB is crippling the industry in<br />

Wales because farms are prevented from<br />

selling stock, particularly bulls which are<br />

expensive to keep. We lost 22 cows last year<br />

– some of our best breeding stock – and<br />

two bulls.* Even though pasteurization kills<br />

any TB in the milk, the animals still have to<br />

be slaughtered.<br />

The disease was under control before<br />

badgers became a protected species.<br />

Because they no longer have any natural<br />

predators the balance has shifted and<br />

the badgers have multiplied. The Welsh<br />

Assembly has now authorized a pilot<br />

badger cull. Ideally we want a two-sided<br />

attack on the disease so that cows and<br />

wildlife can co-exist.<br />

Q. What other challenges does the UK dairy<br />

industry face?<br />

A. The biggest problem is that the milk<br />

price has been poor for so long that it is<br />

getting harder and harder to stay afloat.<br />

It’s not high enough to be able to reinvest<br />

and have a good living standard. At one<br />

time the collection and selling of milk<br />

was all done through the Milk Marketing<br />

Board. But this was deemed to be a<br />

monopoly and was broken up in the 1990s<br />

into three co-operatives. Then individual<br />

private companies came in, which gave<br />

supermarkets more choice about where<br />

they bought their milk and more<br />

bargaining power.<br />

Farmers in other EU countries have been<br />

sheltered from this because they have had<br />

government support to keep prices high.<br />

But now the price has collapsed in Europe<br />

and there’s an oversupply, compared to<br />

a shortage here. The recession and fall<br />

in the pound makes it more expensive<br />

to import. Hopefully this will encourage<br />

our Government to value the British dairy<br />

farmer. Another issue is that produce that<br />

is imported but packaged here can be<br />

advertised and sold as being British.<br />

There’s also more paperwork now. The dairy<br />

industry is much more heavily regulated –<br />

which is right really. It makes it easier for<br />

products to be traced back to the farms.<br />

Q. Are you confident for the future?<br />

A. The number of dairy farmers going out<br />

of business every year is frightening and<br />

very few young people are coming in – the<br />

average age of a dairy farmer is late 50s.<br />

If we can survive this exodus I believe that<br />

there is a future because the British public<br />

will always want fresh milk.<br />

* According to the Farmers Guardian more<br />

than 12,000 cattle infected with bovine TB were<br />

slaughtered in Wales in 2008 – 52 per cent more<br />

than the previous year.<br />

System provider for all farm sizes<br />

Wherever cows are being milked, <strong>GEA</strong> Farm Technologies<br />

is there, helping to produce a quarter of the world’s<br />

milk. Since 1926 the company has led the way in the<br />

development, production and delivery of system solutions<br />

for successful dairy production.<br />

Today <strong>GEA</strong>`s Farm Technologies Division, with its main<br />

office in Bönen, Germany, is a worldwide leading<br />

manufacturer of technical innovations, integrated<br />

product solutions and effective animal hygiene products<br />

for cost-efficient milk production. Manure technology<br />

and barn equipment round off the profile as a system<br />

provider for all farm sizes.<br />

Once the milk leaves the farm, its route to the<br />

consumer, as milk or other dairy products, is likely to<br />

go via equipment from <strong>GEA</strong>. The company’s Air<br />

Treatment, Emission Control, Refrigeration, Process<br />

Equipment, Mechanical Separation and Process<br />

Engineering divisions all play a role in the dairy market,<br />

providing a range of manufacturing equipment, process<br />

lines and storage solutions.<br />

GENERATE MAGAZINE ISSUE 09 21

tHeY saY Nature is tHe Best remeDY<br />

For HumaN ailmeNts aND, For more<br />

tHaN 70 Years, HerBal proDuCts<br />

From a FamilY-oWNeD sWiss CompaNY<br />

Have suCCessFullY sootHeD<br />

tHe tHroats oF GeNeratioNs oF<br />

CoNsumers. aND tHe seCret, it<br />

WoulD seem, is all iN tHe loCatioN.<br />

The Swiss mountain areas provide the ideal soil and climate for growing<br />

the herbs used in Ricola products.<br />

o grow and process the herbs for<br />

making ricola products anywhere but<br />

in switzerland you would have to move<br />

mountains – literally.<br />

for it’s the alpine soil and climate, together<br />

with organic cultivation and harvesting<br />

methods, that are essential to the flavor<br />

and give the brand its identity.<br />

ricola’s herbal candies, pastilles, drops<br />

and teas are renowned throughout the<br />

world for refreshing and soothing the<br />

mouth and throat. for this reason they are<br />

particularly popular among singers and<br />

actors – Madonna, Mariah Carey, placido<br />

domingo and Cate Blanchett are among<br />

many famous customers.<br />

Quality herbs<br />

every year 230 tonnes of dried herbs go into<br />

making the ricola range, all of which are<br />

grown in switzerland to strict national Biosuisse<br />

guidelines. no artificial fertilizers,<br />

herbicides or pesticides are used.<br />

“from the fields to finished candy, every<br />

process is documented and subject to strict<br />

guidelines and quality controls,” explains<br />

Thomas aeschlimann, ricola’s division<br />

Manager, herb Cultivation. “The quality of the<br />

herbs can’t be improved during processing<br />

which is why it’s important to get everything<br />

right from the start.”<br />

“Growing herbs is a difficult and complex<br />

business as each herb needs its special<br />

habitat, climate, fertilization and care. we<br />

deliberately use only certified, organic herbs<br />

which are cultivated in the swiss mountain<br />

areas. and the swiss mountains only exist in<br />

switzerland – nothing will ever change that!”<br />

There are over 100 independent farmers<br />

contracted to ricola, most of whom have<br />

between 15 and 25 years’ experience in herb<br />

cultivation. The relationship has advantages<br />

for both parties. ricola can keep tabs on<br />

regular delivery and quality and the farmers<br />

are guaranteed a regular income.<br />

Harvest time<br />

Because different parts of different<br />

plants are used – leaves, flowers or roots<br />

– harvesting is done at different times.<br />

so, for example, if only the leaves are<br />

required, there is no need to wait until the<br />

plant flowers to harvest it. also the duration<br />

of the cultures varies considerably: ribwort,<br />

for example, is grown on a year-to-year<br />

basis while the elder trees – from which<br />

the flowers are harvested – can live up<br />

to 25 years.<br />

after harvesting the herbs are carefully<br />

dried to retain their natural flavor. again,<br />

ricola applies strict criteria to the process.<br />

“each herb has its own specification,” says<br />

aeschlimann. “no ifs and buts – everything<br />

is defined.”<br />

The dried herbs are then transported to<br />

ricola where they are processed, stored<br />

and blended, before the ingredients are<br />

extracted. Traditionally, the liquid extracts<br />

were clarified by a filtering system. But<br />

then, three years ago, the company decided<br />

to switch to a more efficient method that<br />

would improve the quality of clarification at a<br />

reduced cost but without affecting the flavor.<br />

detlev Jüttner, Branch Manager for Gea<br />

westfalia separator switzerland, says that,<br />

following pre-tests at its subsidiary and a<br />

successful separation trial at the University<br />

of applied science in wädenswil, ricola<br />

acquired a Gea westfalia separator decanter<br />

for clarifying the liquid extracts. “Because<br />

the decanter is enclosed, it’s more hygienic<br />

and provides a better extraction process with<br />

no flavor lost,” he explains. “so it’s much<br />

more efficient for ricola.”<br />

aeschlimann agrees: “we achieved the<br />

aim of making the process more efficient<br />

and to our high quality standards.” he adds<br />

that ricola employees were fully involved in<br />

making the changes and that it was relatively<br />

easy to learn the new process. “Besides, the<br />

Gea westfalia separator suppliers were very<br />

friendly, highly qualified and proactive.”<br />

ricola was founded in the swiss town<br />

of laufen in 1930 by emil richterich. The<br />

name is formed from the first two letters<br />

of richterich & Compagnie, laufen, which<br />

was his original confectionery business set<br />

up in 1924.<br />

in 1940 richterich hit on the recipe for herb<br />

lozenges using a mixture of 13 natural swiss<br />

herbs, including peppermint, sage, thyme<br />

and cowslip. This original herb Cough drop<br />

is still being made today and the recipe<br />

remains a closely-guarded secret. over the<br />

years the company has expanded its range<br />

with new flavors, including lemon, cranberry,<br />