FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

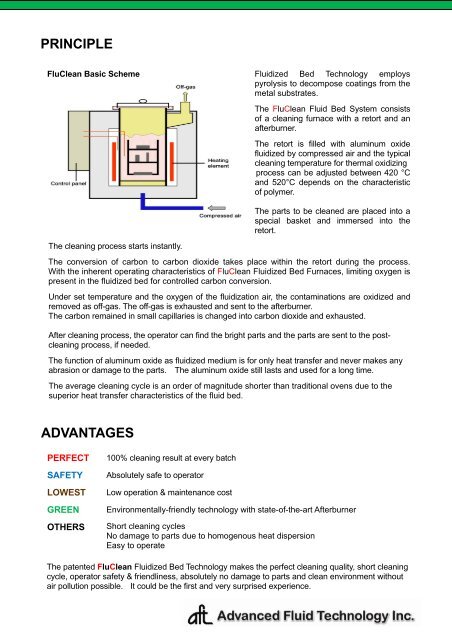

PRINCIPLE<br />

<strong>FluClean</strong> Basic Scheme <strong>Fluidized</strong> <strong>Bed</strong> Technology employs<br />

pyrolysis to decompose coatings from the<br />

metal substrates.<br />

The cleaning process starts instantly.<br />

The <strong>FluClean</strong> Fluid <strong>Bed</strong> <strong>System</strong> consists<br />

of a cleaning furnace with a retort and an<br />

afterburner.<br />

The retort is filled with aluminum oxide<br />

fluidized by compressed air and the typical<br />

cleaning temperature for thermal oxidizing<br />

process can be adjusted between 420 °C<br />

and 520°C depends on the characteristic<br />

of polymer.<br />

The parts to be cleaned are placed into a<br />

special basket and immersed into the<br />

retort.<br />

The conversion of carbon to carbon dioxide takes place within the retort during the process.<br />

With the inherent operating characteristics of <strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> Furnaces, limiting oxygen is<br />

present in the fluidized bed for controlled carbon conversion.<br />

Under set temperature and the oxygen of the fluidization air, the contaminations are oxidized and<br />

removed as off-gas. The off-gas is exhausted and sent to the afterburner.<br />

The carbon remained in small capillaries is changed into carbon dioxide and exhausted.<br />

After cleaning process, the operator can find the bright parts and the parts are sent to the postcleaning<br />

process, if needed.<br />

The function of aluminum oxide as fluidized medium is for only heat transfer and never makes any<br />

abrasion or damage to the parts. The aluminum oxide still lasts and used for a long time.<br />

The average cleaning cycle is an order of magnitude shorter than traditional ovens due to the<br />

superior heat transfer characteristics of the fluid bed.<br />

ADVANTAGES<br />

<strong>PERFECT</strong><br />

SAFETY<br />

LOWEST<br />

GREEN<br />

OTHERS<br />

100% cleaning result at every batch<br />

Absolutely safe to operator<br />

Low operation & maintenance cost<br />

Environmentally-friendly technology with state-of-the-art Afterburner<br />

Short cleaning cycles<br />

No damage to parts due to homogenous heat dispersion<br />

Easy to operate<br />

The patented <strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> Technology makes the perfect cleaning quality, short cleaning<br />

cycle, operator safety & friendliness, absolutely no damage to parts and clean environment without<br />

air pollution possible. It could be the first and very surprised experience.