FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

FluClean Fluidized Bed Cleaning System PERFECT ... - Gobizkorea

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

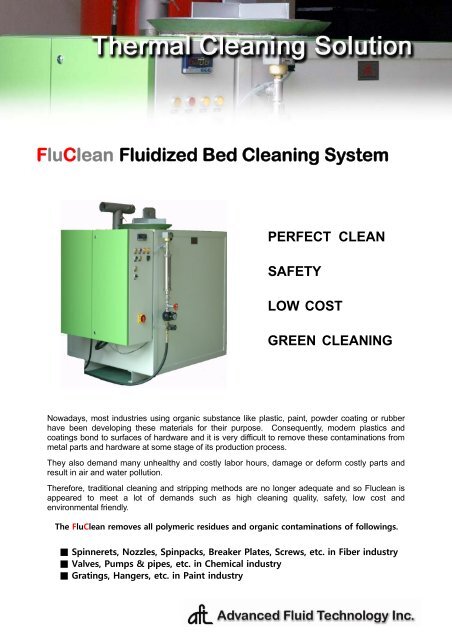

<strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> <strong>Cleaning</strong> <strong>System</strong><br />

<strong>PERFECT</strong> CLEAN<br />

SAFETY<br />

LOW COST<br />

GREEN CLEANING<br />

Nowadays, most industries using organic substance like plastic, paint, powder coating or rubber<br />

have been developing these materials for their purpose. Consequently, modern plastics and<br />

coatings bond to surfaces of hardware and it is very difficult to remove these contaminations from<br />

metal parts and hardware at some stage of its production process.<br />

They also demand many unhealthy and costly labor hours, damage or deform costly parts and<br />

result in air and water pollution.<br />

Therefore, traditional cleaning and stripping methods are no longer adequate and so Fluclean is<br />

appeared to meet a lot of demands such as high cleaning quality, safety, low cost and<br />

environmental friendly.<br />

The <strong>FluClean</strong> removes all polymeric residues and organic contaminations of followings.<br />

■ Spinnerets, Nozzles, Spinpacks, Breaker Plates, Screws, etc. in Fiber industry<br />

■ Valves, Pumps & pipes, etc. in Chemical industry<br />

■ Gratings, Hangers, etc. in Paint industry

PRINCIPLE<br />

<strong>FluClean</strong> Basic Scheme <strong>Fluidized</strong> <strong>Bed</strong> Technology employs<br />

pyrolysis to decompose coatings from the<br />

metal substrates.<br />

The cleaning process starts instantly.<br />

The <strong>FluClean</strong> Fluid <strong>Bed</strong> <strong>System</strong> consists<br />

of a cleaning furnace with a retort and an<br />

afterburner.<br />

The retort is filled with aluminum oxide<br />

fluidized by compressed air and the typical<br />

cleaning temperature for thermal oxidizing<br />

process can be adjusted between 420 °C<br />

and 520°C depends on the characteristic<br />

of polymer.<br />

The parts to be cleaned are placed into a<br />

special basket and immersed into the<br />

retort.<br />

The conversion of carbon to carbon dioxide takes place within the retort during the process.<br />

With the inherent operating characteristics of <strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> Furnaces, limiting oxygen is<br />

present in the fluidized bed for controlled carbon conversion.<br />

Under set temperature and the oxygen of the fluidization air, the contaminations are oxidized and<br />

removed as off-gas. The off-gas is exhausted and sent to the afterburner.<br />

The carbon remained in small capillaries is changed into carbon dioxide and exhausted.<br />

After cleaning process, the operator can find the bright parts and the parts are sent to the postcleaning<br />

process, if needed.<br />

The function of aluminum oxide as fluidized medium is for only heat transfer and never makes any<br />

abrasion or damage to the parts. The aluminum oxide still lasts and used for a long time.<br />

The average cleaning cycle is an order of magnitude shorter than traditional ovens due to the<br />

superior heat transfer characteristics of the fluid bed.<br />

ADVANTAGES<br />

<strong>PERFECT</strong><br />

SAFETY<br />

LOWEST<br />

GREEN<br />

OTHERS<br />

100% cleaning result at every batch<br />

Absolutely safe to operator<br />

Low operation & maintenance cost<br />

Environmentally-friendly technology with state-of-the-art Afterburner<br />

Short cleaning cycles<br />

No damage to parts due to homogenous heat dispersion<br />

Easy to operate<br />

The patented <strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> Technology makes the perfect cleaning quality, short cleaning<br />

cycle, operator safety & friendliness, absolutely no damage to parts and clean environment without<br />

air pollution possible. It could be the first and very surprised experience.

OFF-GAS CLEANING IN AFTERBURNER<br />

According to air pollution laws and regulations, no off gas is allowed to be exhausted to the<br />

atmosphere before being treated.<br />

The burnt off-gas coming from the cleaning furnace contains organic and inorganic substances<br />

and so the off-gas is sent to the thermal afterburner via cyclone. The off gas is burnt again at<br />

combustion chamber of afterburner by a constant flame (above 650°C) and its temperature can be<br />

reached to around 1000°C.<br />

During the process, the off gas can be cracked completely and cooled down again around 80°C<br />

by water cooler for operator safety and comes out to the air by exhaust blower.<br />

After thermal afterburner, operator does not need to afraid of any air pollution.<br />

APPLICATIONS<br />

SYNTHETIC FIBER INDUSTRY<br />

Spinnerets, Nozzles, Spinpacks, Breaker Plates, Screws, etc.<br />

CHEMICAL INDUSTRY<br />

Molds, extrusion screws, polymer pumps, filters, dies, breaker<br />

plates, mixing trays, valves, pumps, pipes, etc.<br />

PAINT INDUSTRY<br />

Hooks, frames, jigs, grates, reject parts, and baskets etc.

MODEL AND TECHNICAL DATA<br />

<strong>FluClean</strong> <strong>Fluidized</strong> <strong>Bed</strong> <strong>Cleaning</strong> Furnace is available in 2 different designs in retort to fully comply<br />

with your particular cleaning demands.<br />

AFR Series has rectangular retort and AFC Series has cylindrical retort.<br />

Model<br />

Retort<br />

mm<br />

Bath<br />

load<br />

L<br />

Air consumption<br />

Nm³/hr<br />

Electrical consumption<br />

KW<br />

connection operation heat-up operation<br />

External dimensions<br />

mm<br />

AFR 1 300 x 300 x 400 14 420 160 8 4 1000 x 650 x 1000<br />

AFR 2 300 x 500 x 400 24 700 260 10 7.2 1000 x 850 x 1000<br />

AFR 3 300 x 700 x 400 34 970 370 12 9.6 1000 x 1050 x 1000<br />

AFC 121 φ 300 x 400 11 18.7 7.6 6 4.8 700 x 1000 x 1100<br />

AFC 122 φ 300 x 600 17 18.7 7.6 7.2 5.8 700 x 1000 x 1300<br />

AFC 163 φ 400 x 750 38 33.1 13.4 10.8 8.7 890 x 1190 x 1450<br />

AFC 164 φ 400 x 1000 50 33.1 13,4 14.4 11.6 890 x 1190 x 1700<br />

AFC 203 φ 500 x 750 59 52.4 21.3 18 14.4 1050 x 1350 x 1450<br />

AFC 204 φ 500 x 1000 78 52.4 21.3 24.3 19.5 1050 x 1350 x 1700<br />

AFC 243 φ 600 x 750 85 75.6 30.7 25.2 20.2 1150 x 1450 x 1460<br />

AFC 244 φ 600 x 1000 113 75.6 30.7 32.4 25.9 1150 x 1450 x 1710<br />

AFC 245 φ 600 x 1200 136 75.6 30.7 36.0 28.8 1150 x 1450 x 1910<br />

AFC 283 φ 700 x 750 115 101.5 41.3 27.9 22.4 1280 x 1580 x 1460<br />

AFC 284 φ 700 x 1000 154 101.5 41.3 36.0 28.8 1280 x 1580 x 1710<br />

AFC 285 φ 700 x 1200 184 101.5 41.3 42.0 33.6 1280 x 1580 x 1910<br />

AFC 323 φ 800 x 750 151 136.0 55.4 32.4 25.9 1350 x 1650 x 1460<br />

AFC 324 φ 800 x 1000 200 136.0 55.4 43.2 34.6 1350 x 1650 x 1710<br />

AFC 325 φ 800 x 1200 240 136.0 55.4 52.8 42.3 1350 x 1650 x 1910<br />

AFC 364 φ 900 x 1000 254 172.0 69.8 54.0 43.2 1500 x 1800 x 1850<br />

AFC 365 φ 900 x 1200 305 172.0 69.8 63.6 50.4 1500 x 1800 x 2050<br />

Specifications may be changed for improvement without prior notice. Others on request.<br />

Just <strong>FluClean</strong> system is the Global Standard in Thermal cleaning !<br />

address<br />

231-5, Mae San-Ri, Opo-Eup,<br />

Kwang Ju-Si, Gyeong Gi-Do,<br />

KOREA 464-893<br />

phone :<br />

fax<br />

web<br />

e-mail<br />

+ 82 (0)31 768 0741<br />

+ 82 (0)31 768 0740<br />

www.aftinc.co.kr<br />

aft@aftinc.co.kr<br />

Representative