Exercise 2: PROFIBUS - Universität Stuttgart

Exercise 2: PROFIBUS - Universität Stuttgart

Exercise 2: PROFIBUS - Universität Stuttgart

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Universität <strong>Stuttgart</strong><br />

Institute of Industrial Automation and Software Engineering<br />

Prof. Dr.-Ing. Dr. h.c. P. Göhner<br />

Introduction:<br />

<strong>Exercise</strong> 2: <strong>PROFIBUS</strong><br />

The <strong>PROFIBUS</strong> (PROcess FIeld BUS) was developed in the years 1987-1991 in a joint<br />

project by several companies and research institutes. <strong>PROFIBUS</strong> was designed primarily for<br />

fast data transmission on the actuator-sensor-level. But it also offers many powerful services,<br />

which make it suitable for the connection of intelligent control devices in a decentralized<br />

automation system.<br />

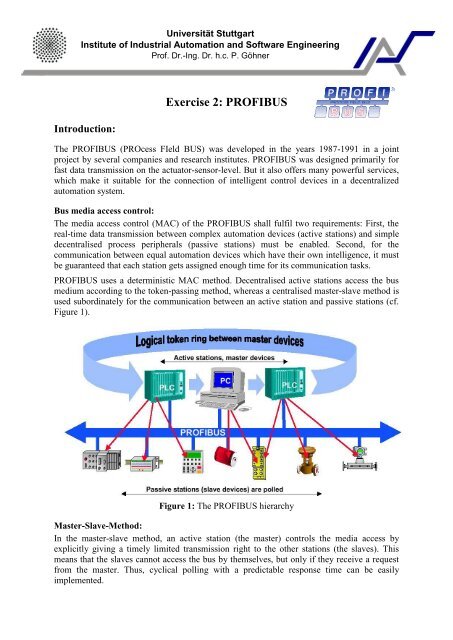

Bus media access control:<br />

The media access control (MAC) of the <strong>PROFIBUS</strong> shall fulfil two requirements: First, the<br />

real-time data transmission between complex automation devices (active stations) and simple<br />

decentralised process peripherals (passive stations) must be enabled. Second, for the<br />

communication between equal automation devices which have their own intelligence, it must<br />

be guaranteed that each station gets assigned enough time for its communication tasks.<br />

<strong>PROFIBUS</strong> uses a deterministic MAC method. Decentralised active stations access the bus<br />

medium according to the token-passing method, whereas a centralised master-slave method is<br />

used subordinately for the communication between an active station and passive stations (cf.<br />

Figure 1).<br />

Figure 1: The <strong>PROFIBUS</strong> hierarchy<br />

Master-Slave-Method:<br />

In the master-slave method, an active station (the master) controls the media access by<br />

explicitly giving a timely limited transmission right to the other stations (the slaves). This<br />

means that the slaves cannot access the bus by themselves, but only if they receive a request<br />

from the master. Thus, cyclical polling with a predictable response time can be easily<br />

implemented.

Industrial Automation Systems Theory <strong>Exercise</strong> 2: Profibus 12<br />

Token-Passing Method:<br />

In order to achieve the coordination between the active stations (master devices), a tokenmessage<br />

(special data frame) is passed on from one active station to the next (in order of the<br />

ascending addresses). The active station, which possesses the token at the moment, has the<br />

right to access the bus and to communicate with passive stations (slaves) or with other active<br />

stations. When it has finished its communication tasks, it passes on the token to the next<br />

station.<br />

In order to guarantee that each station can send data in any case after a maximum period of<br />

time, it is necessary to set a maximum period of time during which the token must have<br />

completely passed once through the logical ring. For this purpose, the target rotation time T TR<br />

is set during the configuration of the bus system. When a station receives the token, it<br />

compares the target rotation time with the measured real rotation time T RR . The station is<br />

allowed to send messages as long as the target rotation time is not exceeded. In any case the<br />

station has the right to send one message with high priority. Figure 2 depicts the message<br />

processing algorithm.<br />

reception of<br />

token<br />

T RR = real rotation time<br />

T TR<br />

= target rotation time<br />

yes<br />

T RR<br />

>T TR<br />

?<br />

no<br />

yes<br />

exists a message<br />

with high priority ?<br />

no<br />

yes<br />

exists a message<br />

with high priority ?<br />

no<br />

process 1<br />

message with<br />

high priority<br />

process<br />

message with<br />

high priority<br />

yes<br />

exists a message<br />

with low priority ?<br />

no<br />

no<br />

T RR<br />

>T TR<br />

?<br />

yes<br />

process<br />

message with<br />

low priority<br />

no<br />

T RR<br />

>T TR<br />

?<br />

yes<br />

pass on token<br />

Structure of data frames and data services:<br />

Figure 2: Message processing algorithm<br />

In order to increase the security of the transmission, <strong>PROFIBUS</strong> uses the data representation<br />

of the UART standard, i.e. one information byte is transmitted with 11 bit:<br />

ST 2 0 2 1 2 2 2 3 2 4 2 5 2 6 2 7<br />

ST: start bit (always logical „0“)<br />

P SP

Industrial Automation Systems Theory <strong>Exercise</strong> 2: Profibus 13<br />

2 0 - 2 7 : information- bytes<br />

P: parity bit<br />

SP: stop bit (always logical „1“)<br />

Data transmission of the <strong>PROFIBUS</strong> is based on a standardized data frame formats. They are<br />

presented in the following:<br />

Data frame without data field<br />

SD1<br />

DA<br />

Data frame with fixed data field<br />

. .<br />

length<br />

.<br />

SD3 DA SA FC data field<br />

. . .<br />

FCS<br />

(8 bytes)<br />

Data frame with variable data field length<br />

. . .<br />

SD2 LE LEr SD2 DA SA FC data field FCS<br />

. . .<br />

(max. 246 bytes)<br />

Token frame<br />

SD4<br />

DA<br />

SA<br />

SA<br />

FC<br />

FCS<br />

ED<br />

ED<br />

ED<br />

SD1...SD4: Start Delimiter<br />

LE: Length<br />

LEr: Length (repetition)<br />

DA: Destination Address<br />

SA: Source Address<br />

FC: Frame Control<br />

FCS: Frame Check Sequence<br />

ED: End Delimiter<br />

<strong>PROFIBUS</strong> uses two services to transmit the data between master and slave devices. With the<br />

SDN service (Send Data with No acknowledge) the master can send data to the slave without<br />

waiting for a response (cf. Figure 3a). The SRD service (Send and Request Data with reply) is<br />

used to request data from a slave (cf. Figure 3b). The request frame can either contain data to<br />

be send to the slave or a data frame without data field can be used if data should be polled<br />

only.<br />

master<br />

slave<br />

master<br />

slave<br />

data frame<br />

request frame<br />

response frame<br />

immediate<br />

reply<br />

Figure 3a: SDN-service<br />

Figure 3b: SRD-service<br />

Bus length and baud rate:<br />

The maximum value of the permissible bus length of the <strong>PROFIBUS</strong> depends on the chosen<br />

baud rate:<br />

baud rate [kbit/s] 9.6 – 93.75 500 1500 12000<br />

max. bus length [m] 1200 400 200 100<br />

(Bibliography: Klaus Bender (Hrsg.): „Profibus, Der Feldbus für die Automation“, Hanser<br />

Verlag, 1990)