technology report 04

technology report 04

technology report 04

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Research & Development<br />

Materials need to<br />

be understood<br />

Development workers with material analysis competence<br />

In order to promote materials development and optimize<br />

the properties of materials, the materials must be understood,<br />

starting from the atoms and working up to the<br />

macroscopic scale. „Our Technology Center offers diverse<br />

possibilities with its motivated team, laboratories and<br />

technical centers, as well as different material-specific<br />

analysis and testing methods,“ says Annette Lukas, Head<br />

of the Heraeus Technology Center at the Hanau site. „With<br />

this technical equipment, we assist our customers in<br />

developing and optimizing tailored products, and support<br />

them in solving material-specific problems or analyzing<br />

damage.“<br />

The service areas for material testing include surface<br />

analytics, a bonding laboratory for testing bonding wires<br />

and substrates for the automotive and microelectronics<br />

industries, and metallography. Further areas include gas<br />

analysis in solid materials, destructive and non-destructive<br />

tests on materials, as well as melting and heat-treatment<br />

technologies. All departments work together very closely,<br />

and materials being tested sometimes go through almost<br />

all the departments before being approved for use by the<br />

customer. „The wide range of analytical methods and<br />

our materials competence allow us not only to supply our<br />

customers with maximum quality and quality assurance,<br />

but also to assist them with advisory services,“ concludes<br />

Annette Lukas.<br />

Surface analytics: SEM, EDX and SAM give deep insights<br />

One of the most important industrial catalysis processes<br />

is the chemical reaction of ammonia to nitric acid for the<br />

fertilizer industry, using large catalytic gauzes made of<br />

platinum-rhodium alloys. The catalytic effect of the gauzes<br />

has continuously improved over recent decades. In order<br />

to improve the catalytic surface activity of the gauzes,<br />

developers from Heraeus utilize state-of-the-art techniques<br />

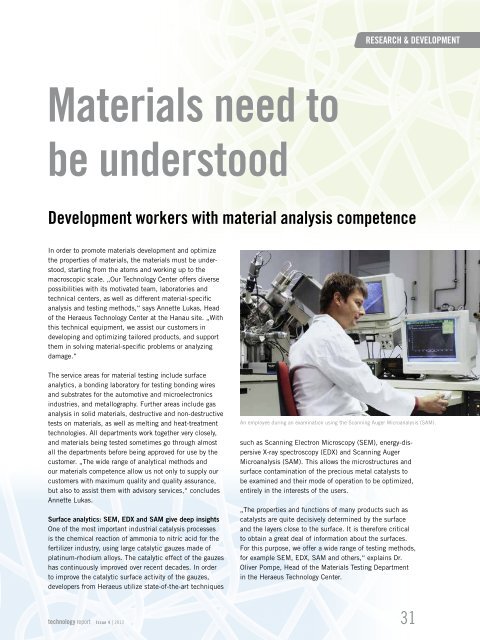

An employee during an examination using the Scanning Auger Microanalysis (SAM).<br />

such as Scanning Electron Microscopy (SEM), energy-dispersive<br />

X-ray spectroscopy (EDX) and Scanning Auger<br />

Microanalysis (SAM). This allows the microstructures and<br />

surface contamination of the precious metal catalysts to<br />

be examined and their mode of operation to be optimized,<br />

entirely in the interests of the users.<br />

„The properties and functions of many products such as<br />

catalysts are quite decisively determined by the surface<br />

and the layers close to the surface. It is therefore critical<br />

to obtain a great deal of information about the surfaces.<br />

For this purpose, we offer a wide range of testing methods,<br />

for example SEM, EDX, SAM and others,“ explains Dr.<br />

Oliver Pompe, Head of the Materials Testing Department<br />

in the Heraeus Technology Center.<br />

<strong>technology</strong> <strong>report</strong> Issue 4 | 2013<br />

31