Centralized Lubrication Chassis Systems for Trucks, Buses or Off ...

Centralized Lubrication Chassis Systems for Trucks, Buses or Off ...

Centralized Lubrication Chassis Systems for Trucks, Buses or Off ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8029 b<br />

Overview Product Range<br />

A contribution to reduce operating expense <strong>f<strong>or</strong></strong> fleet owners<br />

<strong>Centralized</strong> <strong>Lubrication</strong> <strong>Chassis</strong> <strong>Systems</strong><br />

<strong>f<strong>or</strong></strong> <strong>Trucks</strong>, <strong>Buses</strong> <strong>or</strong> <strong>Off</strong>-Road Equipment<br />

VOGEL<br />

<strong>Centralized</strong> <strong>Lubrication</strong> will :<br />

You, too, can save money!<br />

• reduce wear and tear<br />

• cut down maintenance costs<br />

• reduce susceptibility to repair<br />

• increase bearing life<br />

• reduce downtime of operating equipment<br />

• reach all lubrication points, even those not<br />

easily accessible<br />

• offer quick return on investment<br />

vo0F.1:1 .<br />

<strong>Centralized</strong><br />

<strong>Lubrication</strong><br />

Am<strong>or</strong>tization time : 1 year<br />

Z030a832(J0<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

VOGEL centralized lubrication systems are used by m<strong>or</strong>e<br />

and m<strong>or</strong>e fleet owners -truck, bus, construction, utility<br />

<strong>Lubrication</strong> systems lower operating<br />

expenses, they keep on saving after<br />

they have earned their keep .<br />

Our lubrication systems operate<br />

during your operating time - unlike<br />

your grease gun in your garage .<br />

The time of am<strong>or</strong>tization <strong>f<strong>or</strong></strong> our<br />

systems is one year, sometimes even<br />

less!<br />

Our systems are rugged and designed<br />

<strong>f<strong>or</strong></strong> rough service .<br />

No cheap lightweight construction .<br />

Quality w<strong>or</strong>kmanship .<br />

No compromise in quality.<br />

That is why our systems have passed<br />

all tests carried out by Mercedes-Benz,<br />

M•A•N, IVECO-Magirus and many other<br />

O E M'S .<br />

They recommend and install our<br />

systems with full warranty .<br />

We supply systems <strong>f<strong>or</strong></strong> the full range<br />

of lubricants, <strong>f<strong>or</strong></strong> every vehicle .<br />

F<strong>or</strong> any weather.<br />

Manually, semi-automatic, <strong>or</strong> fully<br />

automatic, the installation is SIMPLE .<br />

YOU CHOOSE :<br />

Installation by us -<br />

Installation by your own staff and<br />

training by us -<br />

Installation in many auth<strong>or</strong>ized<br />

w<strong>or</strong>kshops and branch offices of the<br />

OEM distribution chain -<br />

<strong>or</strong> OEM installed systems .<br />

We can supply systems as preassembled<br />

installation kits with tube<br />

layout and assembly instructions <strong>f<strong>or</strong></strong><br />

fast installation .<br />

VOGE["<br />

<strong>Centralized</strong><br />

<strong>Lubrication</strong><br />

will pay off your investment within one year<br />

2 2030583201<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

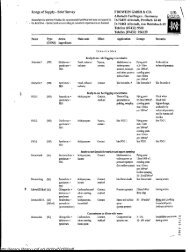

A customized VOGEL centralized lubrication system<br />

<strong>f<strong>or</strong></strong> every type of vehicle<br />

electrically <strong>or</strong> pneumatically operated<br />

~<br />

ro`•~o~<br />

o 0 0 0 0<br />

Lubricants<br />

ki~o<br />

0.4ju-sw<br />

FOa -M<br />

Types of pumps Types of pumps Types of pumps Types of pumps'<br />

Fluid greases KFU 2 PEU-98 KFM 3 KFU 2 PEU-98/S14<br />

NLGI grades 000, 00 KFU 6 PEU-99 KFU 6 KFMA 3<br />

Singlec<br />

KFG1 grease KFG1 KFG1<br />

reases<br />

NLGI grades 0 , 1 , 2 PFP-298 fitting PFP-298 PFP-298<br />

feeder<br />

system *)<br />

*1 The single-grease fitting feeder system <strong>f<strong>or</strong></strong> fluid greases and greases can be installed on all types of vehicles .<br />

2030583202<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

<strong>Centralized</strong> fluid grease lubrication <strong>f<strong>or</strong></strong> all rolling stock<br />

with pneumatically operated piston pump PEU-98 <strong>or</strong> PEU-99 and VKR distribut<strong>or</strong>s<br />

These systems are suitable <strong>f<strong>or</strong></strong> almost all trucks, buses,<br />

construction equipment, etc . equipped with compressed<br />

air.<br />

The pneumatically operated piston pumps PEU-98 <strong>or</strong><br />

PEU-99 deliver approx. 50 cm3 (3 cu Inch) per pump<br />

stroke, sufficient <strong>f<strong>or</strong></strong> centralized lubrication systems of<br />

standard size trucks, buses and trailers .<br />

Reservoir capacities : 4 <strong>or</strong> 3 liters .<br />

Usable lubricants are : Fluid greases of NLGI grades<br />

000, 00 .<br />

The pump is activated by a solenoid valve .<br />

Using the Impulse counter DSWM 21-2iS1, the pneumatically<br />

operated piston pumps adapt also to systems <strong>f<strong>or</strong></strong><br />

trailer lubrication . See page 8.<br />

PEU-98<br />

The 2-, 4-and 6-p<strong>or</strong>ted VKR piston distribut<strong>or</strong>s distribute<br />

and meter the iubricantfed by the pump . They pass the<br />

lubricant premetered to the lubrication points .<br />

Piston distribut<strong>or</strong>s feed lubricant while driving ; the<br />

friction areas are moving and the bearings are capable<br />

to receive new lubricant .<br />

The IG 433-3 controller allows <strong>f<strong>or</strong></strong> timed on-off period<br />

cycle control of the solenoid and pump action and<br />

rep<strong>or</strong>ts any faults via an indication lamp mounted on<br />

the dashboard In the driver's cab .<br />

VKR distribut<strong>or</strong> systems may also operate with 12 V <strong>or</strong><br />

24 V, using the electrically operated gear pump unit<br />

KFU 2 <strong>or</strong> KFU 6 and the IC 433-4 control unit that<br />

monit<strong>or</strong>s the on and off time of the gear pump unit .<br />

See also page 6 .<br />

PEU-99<br />

piston distribut<strong>or</strong>s VKR,<br />

2-, 4- and 6-p<strong>or</strong>ted<br />

4<br />

<strong>Centralized</strong><br />

<strong>Lubrication</strong><br />

will pay off your investment within one year<br />

2430583203<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

piston pump PEU-99<br />

mounted to a semitrailer<br />

control unit IC 433 .3<br />

x<br />

5<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

<strong>Centralized</strong> fluid grease lubrication , especially <strong>f<strong>or</strong></strong> tract<strong>or</strong>-trailer<br />

combinations <strong>or</strong> semitrailers, with the electrically operated gear pump unit<br />

KFU 2 <strong>or</strong> KFU 6 and VKR distribut<strong>or</strong>s (trailer secondary)<br />

Truck-trailer combinations, tract<strong>or</strong>s and semitrailers,<br />

special vehicles with complex superstructures have<br />

many lubrication points and long tube runs, too many<br />

<strong>f<strong>or</strong></strong> a centralized lubrication system activated by only<br />

one pneumatically operated piston pump . Two pumps<br />

should be installed .<br />

The electrically operated piston pump units KFU 2 <strong>or</strong><br />

KFU 6, however, can handle every size of system with<br />

one pump only .<br />

If, <strong>f<strong>or</strong></strong> instance, tract<strong>or</strong> and trailer will be separated<br />

rarely <strong>or</strong> never, the lubrication of the entire truck-trailer<br />

combination can be effected by one unit only (trailer<br />

secondary) .<br />

The trailer <strong>or</strong> supp<strong>or</strong>ted trailer will be connected<br />

hydraulically with a coupling to the truck <strong>or</strong> tract<strong>or</strong> .<br />

The supply of the trailer <strong>or</strong> supp<strong>or</strong>ted trailer will be<br />

effected by the unit and controller of the tract<strong>or</strong> .<br />

The economic advantage of this system layout Is considerable,<br />

as no extra pump is required <strong>f<strong>or</strong></strong> .the trailer .<br />

These gear pump units do neither require any compressed<br />

air valves n<strong>or</strong> compressed air lines .<br />

The electrically operated gear pump units KFU 2 and<br />

KFU 6 do not supply lubricant "in p<strong>or</strong>tions", but continuously<br />

until also the metering chambers of those<br />

distribut<strong>or</strong>s which are faraway from the pump are<br />

filled . Only then the pump wiii be switched off .<br />

KFU 6<br />

KFU 2<br />

gear pump units KFU 2, KFU 6<br />

output:140 cm3imin<br />

reservoir capacities : 2 .7 <strong>or</strong> 6 liters<br />

lubricant:<br />

fluid grease NLOI grades 000, 00<br />

<strong>Centralized</strong><br />

<strong>Lubrication</strong><br />

will pay off your investment within one year<br />

2030583205<br />

6<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

2-, 4 and 6-p<strong>or</strong>ted piston distribut<strong>or</strong>s with metering The electronic control unit IG 433-4, which is part of the<br />

quantities from 0.1 to 0 .4 cm3 distribute and meter system, will initiate after an adjustable interval time a<br />

here, too, the lubricant fed by the unit . pump operation and will control and monit<strong>or</strong> this w<strong>or</strong>k<br />

cycle .<br />

7<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

Independent trailer lubrication<br />

with the pneumatically operated piston pump PEU-98/S14<br />

<strong>or</strong> with the electrically operated compact unit KFMA3<br />

F<strong>or</strong> trucks and trailers which are frequently separated <strong>or</strong><br />

coupled to other tract<strong>or</strong>s, It is recommended to fit the trailer<br />

with its own system. With combined systems (trailer secondary),<br />

there would otherwise be the risk that with frequent<br />

opening and closing of the lubricant coupling dirt, moisture <strong>or</strong><br />

air may enter the main line and thus cause malfunctions .<br />

The pneumatically operated piston pump PEU-98/S14 is mainly<br />

designed <strong>f<strong>or</strong></strong> huge trailers with m<strong>or</strong>e than 18 lubrication<br />

points .<br />

The pump will be actuated by an adjustable impuise counter .<br />

This counts the number of brake actuations and will initiate a<br />

pump stroke after a certain number.<br />

F<strong>or</strong> trailers with up to 18 lubrication<br />

points, the electrically operated<br />

compact unit KFMA 3 is an economic<br />

solution.<br />

The pump mot<strong>or</strong> will run, with every<br />

brake actuation, <strong>f<strong>or</strong></strong> 1, 2, <strong>or</strong> 3 seconds<br />

(adjustable), thus supplying all<br />

connected lubrication points in<br />

sequence .<br />

Single-grease fitting feeder system<br />

if a complete centralized lubrication system is too costly <strong>f<strong>or</strong></strong><br />

you, you will still not have to do without a system .<br />

Decide in fav<strong>or</strong> of a single-grease fitting feeder system .<br />

There is only one central lubrication point at an easily accessible<br />

position on the vehicle. From this point, lines are laid to<br />

the lubrication points . <strong>Lubrication</strong> will be effected by means of<br />

a grease gun <strong>or</strong> drum pump .<br />

To limit the grease quantity (greases Of NLGI grades 0, 1, 2), a<br />

pre-metering unit may be used . it will prevent overiubrication<br />

and lubricant waste .<br />

Automating the above is simple by instaiiing a suitable pump<br />

and controller at any time.<br />

I<br />

<strong>Centralized</strong><br />

<strong>Lubrication</strong><br />

will pay off your investment within one year<br />

20300583207<br />

8<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

<strong>Centralized</strong> fluid grease lubrication<br />

<strong>f<strong>or</strong></strong> light and medium-size vehicles<br />

with the space-saving compact unit KFM 3<br />

Light and medium size utility vehicles have many maintenance-free<br />

bearings - but some lubrication points<br />

remain : <strong>f<strong>or</strong></strong> instance, the king pins .<br />

F<strong>or</strong> reasons of ign<strong>or</strong>ance <strong>or</strong> negligence, these lubrication<br />

points will be easily <strong>f<strong>or</strong></strong>gotten during regular maintenance<br />

Inspections . This will result in extended repair<br />

and spare part costs . This is not necessary!<br />

F<strong>or</strong> light trucks, transp<strong>or</strong>ters and minibuses, VOGEL<br />

developed a"tail<strong>or</strong>-made' centralized fluid grease lubrication<br />

system. (Greases of NLGI grades 000, 0fl) .<br />

The electrically operated compact unit KFM 3 comprises<br />

an 1 .5 I reservoir as well as the control electronics. The<br />

reservoir capacity is sufficient<strong>f<strong>or</strong></strong> not less than one year .<br />

The unit can supply a maximum of 18 iubrication points<br />

with lubricant .<br />

Everyone of the max .18 metering pumps will be directly<br />

connected via a 4 mm tube to the appropriate lubrica•<br />

tion point. With every cycle, every lubrication point will<br />

receive a constant quantity of lubricant (0 .15 cm3 <strong>or</strong><br />

0 .08 cm3), depending on the buiid-in metering pumps .<br />

No separate lubrication distribut<strong>or</strong>s are required <strong>f<strong>or</strong></strong>this<br />

system .<br />

This unit also serves to lubricate vehicle options like<br />

hydraulic lifts, tipping devices, etc .<br />

Installation by your own staff! Sh<strong>or</strong>t installation times!<br />

2030583208<br />

9<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

i<br />

<strong>Centralized</strong> grease lubrication <strong>f<strong>or</strong></strong> all vehicles on- <strong>or</strong> off-road<br />

with electrically operated piston pump KFG 1<br />

<strong>or</strong> pneumatically operated piston pump PFP-298 and progressive feeders<br />

<strong>Centralized</strong> grease lubrication systems comprise - similar<br />

to fluid grease systems - pump with lubricant reservoir,<br />

distribut<strong>or</strong>s (feeders) with tubing and control unit<br />

Pump, feeders, tubing and fittings are designed <strong>f<strong>or</strong></strong> the<br />

feeding of greases and the high pressures associated<br />

with these systems .<br />

Greases of NLGI grades 0, 1, 2 are used, which will be fed<br />

via progressive feeders to the lubrication points .<br />

The electrically operated piston pump KFG 1 with a<br />

reservoir with 2 liters capacity is equipped with two outlets,<br />

allowing the distribution of the delivered lubricant<br />

quantity to the front end and to the rear of the vehicle .<br />

N<strong>or</strong>mally, two progressive feeders will thus be sufficient,<br />

one each <strong>f<strong>or</strong></strong> the front and rear axle region .<br />

By the electric drive, this pump Is independent of a<br />

vehicle-based compressed air system .<br />

The electronic control unit IG 471 <strong>or</strong> IG 472, <strong>f<strong>or</strong></strong>ming part<br />

of this system, activates after an adjustable intervai time<br />

the pump operation . The control unit IG 472 controls and<br />

monit<strong>or</strong>s the pump operation and rep<strong>or</strong>ts any faults via<br />

an indication lamp on the dashboard of the driver's<br />

cab.<br />

electrically operated piston pump KFG 1<br />

control unit IG 471<br />

10<br />

<strong>Lubrication</strong><br />

will pay off your investment within one year<br />

2030583209<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

,<br />

f<br />

The pneumatically operated piston pump PFP•298<br />

with an 1 .5 I reservoir is also equipped with two iubricant<br />

outiets .<br />

The appropriate electronic control unit IG 45 activates<br />

after an adjustable intervai time a pump operation and<br />

controls and monit<strong>or</strong>s this pump operation .<br />

pneumatically operated piston pump PFP-298<br />

control unit IC 45<br />

Progressive feeders VPKM :<br />

The Iubricant is fed by the pump to the lubrication<br />

points via the progressive feeders progressively, i .e. in<br />

fixed sequence.<br />

Metered quantity per cycle and outlet : 0.1-0 .25 cm3<br />

Number of outlets possible : 18.<br />

20"0 aS32i0<br />

„<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf

1k<br />

:VOGEr!<br />

will pay off your investment within one year<br />

Fact<strong>or</strong>y in Berlin<br />

Fact<strong>or</strong>yfn Dietzenbach<br />

VOGEL°<br />

WILLY VOGEL AKTIENGESELLSCHAFT<br />

Motzener Stra6e 35/37, Postfach 480149, D-1000 Berlin 48<br />

Tel . (030) 720 02-0 • Tx 183284 • Fax (030) 7 20 02-111 • Ttx 308142=Vogel<br />

Gottlieb-Daimler-Stra6e 7, Postfach 2088, D-6057 Dietzenbach<br />

Tel . (06074) 4096-0 • Tx 4197649 • Fax (06074) 4096-33<br />

2030583211<br />

N000„99<br />

http://legacy.library.ucsf.edu/tid/iux47e00/pdf