Trends In Unconventional Gas - Halliburton

Trends In Unconventional Gas - Halliburton

Trends In Unconventional Gas - Halliburton

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

D r i l l i n g & Pr o d u c t i o n<br />

in the rock matrix. <strong>Gas</strong>-content determination<br />

is largely independent of the<br />

core porosity and permeability, but is a<br />

function of methane adsorption within<br />

the coal macerals.<br />

Prospectors may tend to rely on<br />

nonspecific seam lithotypes and assumed<br />

values for adsorption isotherms.<br />

<strong>Gas</strong> contents are calculated with assumed<br />

isotherms, reservoir pressures,<br />

and gross seam thickness. Although<br />

these estimates are appropriate during<br />

early prospect evaluation, they must be<br />

validated through direct-core measurement<br />

in Phase 2. A complete coal-seam<br />

anatomy can be obtained and applied to<br />

the macroscale reservoir.<br />

3. Well logging. Significant technical<br />

breakthroughs in well logging<br />

have been developed specific to CBM.<br />

Perhaps the greatest advances involve<br />

log-processing methods and core-log<br />

integration techniques. Table 2 provides<br />

recommended log suites for projects in<br />

Phases 2 through 5.<br />

Electric microimaging (EMI) logging<br />

may provide the closest thing to a continuous<br />

core as currently possible. It can<br />

be integrated with the whole core so<br />

that grayscale levels can be correlated to<br />

discrete core lithology. Such integration<br />

can be performed in one well and applied<br />

across the field or basin that lacks<br />

core information.<br />

4. Cleat permeability determination. Three<br />

technologies are potentially available<br />

for cleat permeability determination<br />

and are applied predominantly through<br />

Phases 2 and 3:<br />

• Openhole discrete-seam drillstem<br />

testing (DST).<br />

• <strong>In</strong>terference testing and injection<br />

fall-off.<br />

• G-function derivative analysis.<br />

DST technology can enable the highgrading<br />

of discrete seams for subsequent<br />

production during the corehole<br />

process. Multiwell interference testing<br />

can enable the acquisition of far-field<br />

regional cleat permeability and permeability<br />

anisotropy. G-function analysis,<br />

primarily used for comparing regional<br />

variations, can enable near-field qualitative<br />

cleat permeability information to<br />

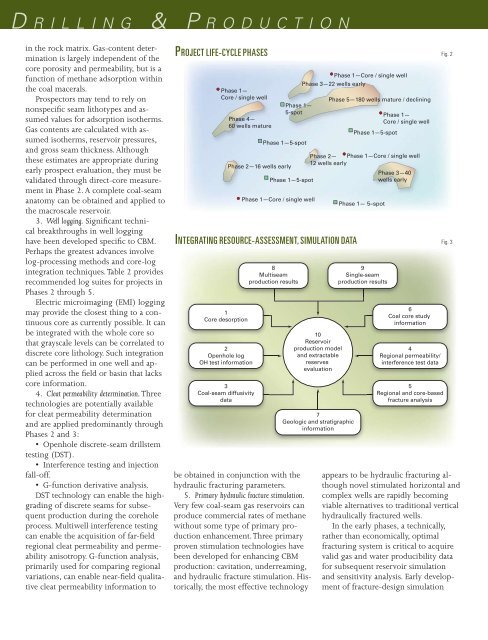

PROJECT LIFE-CYCLE PHASES Fig. 2<br />

Phase 1—<br />

Core / single well<br />

Phase 4—<br />

60 wells mature<br />

Phase 1—<br />

5-spot<br />

Phase 1—5-spot<br />

Phase 1—Core / single well<br />

be obtained in conjunction with the<br />

hydraulic fracturing parameters.<br />

5. Primary hydraulic fracture stimulation.<br />

Very few coal-seam gas reservoirs can<br />

produce commercial rates of methane<br />

without some type of primary production<br />

enhancement. Three primary<br />

proven stimulation technologies have<br />

been developed for enhancing CBM<br />

production: cavitation, underreaming,<br />

and hydraulic fracture stimulation. Historically,<br />

the most effective technology<br />

Phase 1—Core / single well<br />

Phase 3—22 wells early<br />

Phase 5—180 wells mature / declining<br />

Phase 1—5-spot<br />

Phase 2— Phase 1—Core / single well<br />

12 wells early<br />

Phase 2—16 wells early<br />

Phase 3—40<br />

Phase 1—5-spot<br />

wells early<br />

2 x 2<br />

Phase 1— 5–spot<br />

Phase 1—<br />

Core / single well<br />

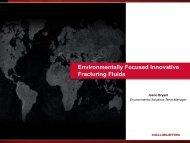

INTEGRATING RESOURCE-ASSESSMENT, SIMULATION DATA Fig. 3<br />

1<br />

Core desorption<br />

2<br />

Openhole log<br />

OH test information<br />

3<br />

Coal-seam diffusivity<br />

data<br />

8<br />

Multiseam<br />

production results<br />

10<br />

Reservoir<br />

production model<br />

and extractable<br />

reserves<br />

evaluation<br />

7<br />

Geologic and stratigraphic<br />

information<br />

2 x 2.5<br />

9<br />

Single-seam<br />

production results<br />

6<br />

Coal core study<br />

information<br />

4<br />

Regional permeability/<br />

interference test data<br />

5<br />

Regional and core-based<br />

fracture analysis<br />

appears to be hydraulic fracturing although<br />

novel stimulated horizontal and<br />

complex wells are rapidly becoming<br />

viable alternatives to traditional vertical<br />

hydraulically fractured wells.<br />

<strong>In</strong> the early phases, a technically,<br />

rather than economically, optimal<br />

fracturing system is critical to acquire<br />

valid gas and water producibility data<br />

for subsequent reservoir simulation<br />

and sensitivity analysis. Early development<br />

of fracture-design simulation<br />

No. z080121OGJdwy02.eps<br />

No. z080121OGJdwy03.eps