Trends In Unconventional Gas - Halliburton

Trends In Unconventional Gas - Halliburton

Trends In Unconventional Gas - Halliburton

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

D r i l l i n g & Pr o d u c t i o n<br />

be efficiently fractured independently<br />

by:<br />

• Using coiled tubing or tubulars<br />

with hydrojetting techniques.<br />

• Using dynamic diversion techniques<br />

for either vertical or horizontal<br />

placement.<br />

• Or, incorporating completion mechanical<br />

downhole assemblies featuring<br />

stimulation sleeves and swellable<br />

elastomer packers to enable stimulation<br />

of multiple zones without use of bridge<br />

plugs to isolate intervals to be treated.<br />

These pinpoint stimulation<br />

techniques offer operators<br />

cost-effective methods to<br />

stimulate multiple zones in<br />

one rig-up.<br />

Fluid treatment<br />

Ultralow permeability<br />

is the primary challenge in<br />

shale formations. Fracturing<br />

fluids that are nondamaging<br />

and that enhance load<br />

recovery is essential in shale<br />

formations with very limited<br />

permeability. A combination<br />

of specialized chemistries<br />

delivers maximum effective<br />

fractures and preserves the<br />

formation’s existing permeability<br />

to gas, contributing<br />

significantly to the shaleproduction<br />

success. Components of the<br />

fracture fluids include:<br />

• Special friction reducers formulated<br />

to reduce potential fracture-face<br />

damage caused by long-chain polymers,<br />

without compromising their capability<br />

to reduce friction pressure.<br />

• Microemulsion surfactant that<br />

helps reduce capillary pressure, releasing<br />

imbibed treatment water and<br />

improving gas permeability. It also<br />

provides significant safety and environmental<br />

benefits by replacing methanol<br />

in water-block treatments.<br />

• Fracture-cleaning enhancer and<br />

conductivity enhancer for accelerating<br />

fracture cleanup and flowback of treatment<br />

fluids.<br />

Together, these components create a<br />

synergistic fluid treatment solution designed<br />

to help optimize gas production<br />

from formations with ultralow native<br />

permeability. The system provides workable,<br />

cost-efficient solutions for shale<br />

productivity programs from beginning<br />

to end—from analysis and planning to<br />

drilling, fracturing, early production,<br />

long-term production, and ultimate<br />

recovery/abandonment.<br />

The ability rapidly to fracture<br />

multiple independent zones yields a<br />

significant decrease in completion time.<br />

The components of the system work<br />

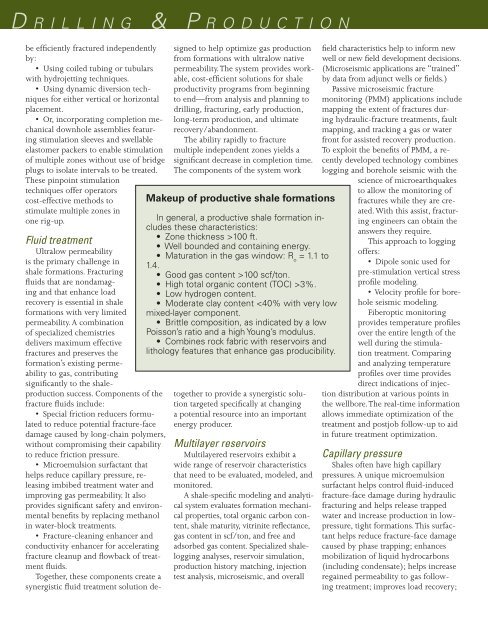

Makeup of productive shale formations<br />

<strong>In</strong> general, a productive shale formation includes<br />

these characteristics:<br />

• Zone thickness >100 ft.<br />

• Well bounded and containing energy.<br />

• Maturation in the gas window: R o<br />

= 1.1 to<br />

1.4.<br />

• Good gas content >100 scf/ton.<br />

• High total organic content (TOC) >3%.<br />

• Low hydrogen content.<br />

• Moderate clay content