PDF (433 KB)

PDF (433 KB)

PDF (433 KB)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

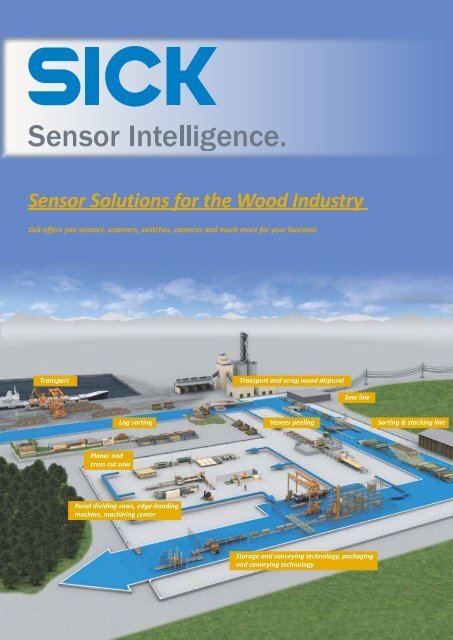

Sensor Solutions for the Wood Industry<br />

Sick offers you sensors, scanners, switches, cameras and much more for your business<br />

Transport<br />

Transport and scrap wood disposal<br />

Saw line<br />

Log sorting<br />

Veneer peeling<br />

Sorting & stacking line<br />

Planer and<br />

cross cut saw<br />

Panel dividing saws, edge-banding<br />

machine, machining center<br />

Storage and conveying technology, packaging<br />

and conveying technology

Report<br />

Achieving More With<br />

Intelligent Sensors<br />

Product identification<br />

Pallet tracking<br />

reliably rule out risks to employees from<br />

hazardous machines.<br />

In the logistics automation segment,<br />

Sick offers solutions for the automatic<br />

identification of bar codes and 2-D codes,<br />

as well as for the identification of objects in<br />

logistical systems through the use of RFID<br />

systems. This application segment also includes<br />

the detection of height, shape and<br />

volume with laser measurement systems,<br />

that can be calibrated if necessary.<br />

Barcode reading<br />

As a leading developer and manufacturer<br />

of intelligent sensor technology worldwide,<br />

Sick plays a major role in enhancing<br />

process optimization throughout the industrial<br />

arena. On both a large and small scale,<br />

their sensor solutions contribute to making<br />

all production steps safer, quicker and more<br />

cost-effective. Risks and sources of error<br />

are systematically eliminated, and individual<br />

production steps or complete processes<br />

are accelerated significantly.<br />

With their extensive automation expertise,<br />

they are able to provide reliable<br />

solutions for all phases of the production<br />

process. The manufacturer looks for areas<br />

to create efficiency, down to the smallest<br />

detail – enabling the highest possible productivity<br />

levels.<br />

Track & trace - data management & identification<br />

Factory automation includes products<br />

and solutions for automation and safety<br />

technology. The control of production<br />

processes and quality assurance are the<br />

most important areas of use of the noncontact<br />

sensors for automation technology.<br />

Sick sensors ensure maximum efficiency<br />

in almost all sectors. The open standard<br />

IO Link for the fieldbus-neutral pointto-point<br />

dialogue between sensors and<br />

controllers, initiated by the company and<br />

supported by numerous sensor producers,<br />

underlines the company’s technological<br />

leadership.<br />

The products, complete solutions and<br />

services of the Industrial Safety Systems<br />

Division ensure effective accident prevention<br />

and personal protection in order to<br />

In process automation, Sick is the<br />

brand name for components and complete<br />

system solutions for gas analyses,<br />

dust measurement technology, throughflow<br />

measurement, water and liquid analyses<br />

and filling level measurement technology.<br />

Whether planning, engineering,<br />

production or quality assurance – a variety<br />

of measurement principles from a single<br />

source are combined to create total turnkey<br />

concepts for a number of measurement<br />

tasks in analysis and process measurement<br />

technology to ensure that the<br />

measurement technology matches the<br />

production plant.<br />

With openness toward more<br />

quality of life<br />

Thus, sensor technology is open to all<br />

worlds – that also applies to automation<br />

technology for interface variants, fieldbus<br />

connections, and communications proto-<br />

The activities of the German company<br />

focuses on sensors and sensor solutions<br />

for industrial applications. The company,<br />

founded in 1946 and with more than 40 international<br />

and national subsidiaries, numerous<br />

representatives and several participations,<br />

is a technology and market<br />

leader in factory, logistics and process automation.<br />

Sick employs 5,800 employees.<br />

Path measurement<br />

Package ejector<br />

Board detection<br />

Flexible automation - presence detection & measurement<br />

14<br />

No. 4 · October 2012

Report<br />

cols. The areas of use are myriad: without<br />

sensors, the fridge would remain empty,<br />

as there would be no bottling of beverages<br />

or packaging of food, and none of the<br />

items would reach the supermarket. Only<br />

the openness of sensor technology to be<br />

able to communicate with any machine<br />

and to recognize any barcode makes the<br />

everyday lives easier.<br />

Safe control solution<br />

Hazardous area protection<br />

Cars, furniture, clothing, prefabricated<br />

houses – barely any product can be manufactured<br />

economically without refined automation.<br />

No matter whether the issue is<br />

initial installation or retrofitting – the decisive<br />

point is just how much easier a photoelectric<br />

switch or scanner makes life for<br />

the site engineer or for service personnel.<br />

In this context, it is sensor intelligence that<br />

facilitates things – e.g. through cyclical<br />

monitoring of functions, parameter memories<br />

in the connecting plug, uniform installation<br />

technology, simple user interfaces<br />

– and through openness to systems, as<br />

the sensor is capable of working with any<br />

machine control.<br />

Sick provides technology to respond<br />

to the tasks involved in industrial automation:<br />

measuring, detecting, monitoring<br />

and controlling, protecting, networking<br />

and integrating, identifying, positioning.<br />

The development and industry experts<br />

continually create innovations to<br />

solve these tasks.<br />

Enabling and safe locking<br />

saw mill, engineered wood, veneer and<br />

furniture industries. Sick offers a variety<br />

of products and complete system solutions,<br />

which lead to optimized production<br />

results:<br />

For log sorting by height measuring,<br />

diameter detection and 3-D log measurement,<br />

for cant measurement, board detection<br />

and cant detection in saw lines,<br />

for lumber sorting, distance measurement<br />

and fine positioning in storage and conveying<br />

technology up to technology for<br />

transport and scrap wood disposal.<br />

Distance measurement<br />

Quality determination<br />

Access protection<br />

Safety - access guarding & area guarding<br />

Volume determination<br />

Transport and scrap wood disposal<br />

Innovative solutions for the wood<br />

industry<br />

The demands on the wood industry<br />

are diverse and sophisticated. Fast, safe<br />

and efficient production processes are indispensable<br />

for high productivity in the<br />

Log measurement<br />

³ ³ Flexible Automation: Reliable detection<br />

with all types of sensors for tasks<br />

such as leading edge detection, profile<br />

detection, double detection, empty<br />

detection, level detection, etc. support<br />

stable and efficient processes<br />

and boost performance. Maximum<br />

Wane measurement<br />

Quality control - inspection & verification<br />

throughput depends on the perfect<br />

tuning of all sensor tasks in the process<br />

– and Sick provides optimum solutions<br />

for all of these.<br />

³ ³ Safety: Flexible processes and the interaction<br />

between man and machine present<br />

special challenges for safety technology<br />

in the wood industry. SICK offers<br />

the widest portfolio of safety solutions:<br />

marked by a high degree of integration<br />

in its controls and accompanied<br />

by an extensive range of services that<br />

includes consulting, commissioning,<br />

training and additional education.<br />

³ ³ Quality Control: Displacement sensors<br />

for precise measurement of components,<br />

vision sensors to identify components<br />

and 3-D vision systems for highend<br />

testing. This ensures that the high<br />

quality level demanded is achieved.<br />

³ ³ Track & Trace: With IDpro stationary<br />

code reading and systems, bar code<br />

scanners, hand-held scanners and RFID<br />

interrogators with transponders, Sick<br />

offers a complete portfolio for your<br />

identification needs.<br />

www.sick.de<br />

No. 4 · October 2012 15