VERIFICATION OF INDEX MEMBRANES FOR HITCHINS NEW ...

VERIFICATION OF INDEX MEMBRANES FOR HITCHINS NEW ...

VERIFICATION OF INDEX MEMBRANES FOR HITCHINS NEW ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>VERIFICATION</strong><br />

<strong>OF</strong> <strong>INDEX</strong> <strong>MEMBRANES</strong><br />

<strong>FOR</strong><br />

<strong>HITCHINS</strong><br />

<strong>NEW</strong> ZEALAND LTD<br />

May 2005<br />

JN:6420<br />

Joyce Group Limited<br />

Page 1

<strong>VERIFICATION</strong> <strong>OF</strong><br />

<strong>INDEX</strong> <strong>MEMBRANES</strong> <strong>FOR</strong><br />

<strong>HITCHINS</strong> <strong>NEW</strong> ZEALAND LTD<br />

___________________________________________________<br />

1. INTRODUCTION<br />

2. TECHNICAL and SPECIFICATIONS<br />

3. HANDLING and STORAGE<br />

4. DESIGN IN<strong>FOR</strong>MATION<br />

5. BUILDINGS to NZBC ACCEPTABLE SOLUTION E2/AS1 FEBRUARY 2005<br />

6. SPECIFICALLY DESIGNED BUILDINGS<br />

7. STRUCTURE<br />

8. DURABILITY<br />

9. MAINTENANCE<br />

10. OUTBREAK of FIRE<br />

11. SPREAD of FIRE<br />

12. EXTERNAL MOISTURE<br />

13. INTERNAL MOISTURE<br />

14. INSTALLATION IN<strong>FOR</strong>MATION<br />

15. SYSTEM INSTALLATION<br />

16. WARRANTIES<br />

17. HEALTH and SAFETY<br />

Joyce Group Limited<br />

Page 2

18. BUILDING REGULATIONS<br />

19. QUALITY<br />

20. APPENDICES<br />

1. Product Performance Warranties.<br />

2. Quality Control Schedule.<br />

3. Installation Details.<br />

Joyce Group Limited<br />

Page 3

<strong>VERIFICATION</strong> <strong>OF</strong><br />

<strong>INDEX</strong> <strong>MEMBRANES</strong><br />

1.0 INTRODUCTION<br />

1.1 SCOPE<br />

The Managing Director of Hitchins New Zealand Ltd has commissioned the Joyce Group<br />

Limited to review the performance of the product “<strong>INDEX</strong> Membrane” and prepare a<br />

verification report identifying compliance with the NZ Building Code for the following clauses.<br />

Clause B2 Durability<br />

Clause E2 External Moisture<br />

1.2 <strong>VERIFICATION</strong> REPORT<br />

The report considers the data provided by Hitchins New Zealand Ltd and the manufacturer<br />

of <strong>INDEX</strong> Membranes and product appraisals carried out by leading Testing Authorities<br />

throughout the world.<br />

2.0 TECHNICAL SPECIFICATION<br />

2.1 Product Information<br />

<strong>INDEX</strong> modified reinforced bituminous membranes are manufactured by <strong>INDEX</strong><br />

Construction Products Spa of Italy under stringent quality control to standards set by<br />

UEATC (European Union of Agreement) and marketed to over 100 countries worldwide.<br />

2.2 The Technical Specification<br />

<strong>INDEX</strong> Systems are designed for application to concrete, plywood and compressed sheet<br />

substrates.<br />

<strong>INDEX</strong> Membranes General<br />

These are polymer-bitumen torch-on membranes.<br />

extensive to provide.<br />

The <strong>INDEX</strong> range of membranes is<br />

Vapour barrier/shield layer.<br />

Venting base sheet.<br />

Cap or finishing sheet.<br />

Specialised membranes.<br />

Joyce Group Limited<br />

Page 4

<strong>INDEX</strong> or finishing membranes are either mineral surfaced, (do not require protection<br />

coating) or plain with a painted finish.<br />

The system can be single layered, double reinforced membrane, two layered or multi<br />

layered<br />

This verification report specifically covers a double layered system including a base sheet of<br />

either Testudo 20P or Autotene and Nova P plain and coated.<br />

Autotene Base sheet is a 3.0mm thick torch-on membrane.<br />

The underside of Autotene Base is coated with a special heat-activated adhesive. When the<br />

membrane is laid on the insulating panel and the silicone film that protects the self-adhesive<br />

face is removed, it is sufficient to have the indirect heat generated by torching of the<br />

subsequent layer to produce simultaneous adhesion also of the base layer in contact with<br />

the polystyrene foam.<br />

With the energy necessary for laying one layer, using Autotene Base glues two, limiting the<br />

emission of fumes and odours, avoiding solvent emissions and the production of<br />

problematic waste materials, and avoid the use of an additional layer, with the added benefit<br />

of using a type of thermal insulation that is economically advantageous. Moreover,<br />

eliminating one heating phase halves the amount of time the installer is exposed to heat,<br />

which is a significant advantage, particularly in the summer.<br />

Autotene P Base sheet can be installed directly to the primed substrate of either plywood or<br />

concrete. The primer is Indever E.<br />

Autotene Base is a waterproofing membrane composed of distilled bitumen, selected for<br />

industrial use, with a high content of elastomeric and plastomeric polymer additives to obtain<br />

a phase inversion compound whose continuous phase is formed by polymers in which the<br />

bitumen is dispersed.<br />

The performance of the bitumen is therefore incremented along with durability and<br />

resistance to high and low temperatures, while the already optimum adhesive and<br />

waterproofing qualities of the bitumen remain unchanged.<br />

Autotene P Base sheet incorporates a rot-proof composite reinforcement composed of a<br />

non woven polyester fabric stabilised with fibreglass, which combines the stability of the<br />

glass with the elastically and resistance of the polyester fibre.<br />

Testudo P20 Base sheet.<br />

Testudo membranes are manufactured from distilled bitumen selected for industrial use<br />

modified with high content to elastocene polyester and reinforcement of high grammage, rotproof,<br />

single strand spot bond polyester, isotropic, thermally stabilise non-woven 200 gram<br />

fabric to produce an extremely strong, puncture and tear resistant membrane.<br />

Joyce Group Limited<br />

Page 5

Nova Mineral is a 4.00mm torch-on membrane.<br />

The Nova membranes are made up of distilled bitumen, selected for industrial use, with<br />

elastomeric and plastomeric polymers added to obtain a phase inversion compound whose<br />

continuous phase is formed by polymers in which the bitumen is dispersed, where the<br />

characteristics are determined by the polymeric matrix and not by the bitumen even though<br />

this is the most consistent ingredient.<br />

The performance of the bitumen is therefore increased along with the durability and the<br />

resistance to high and low temperatures while the already optimum adhesive and<br />

impermeable qualities of the bitumen remain unchanged.<br />

The membranes are reinforced with high weight, isotropic, thermally fixed, rot-proof, “nonwoven”<br />

single strand Spunbond polyester 180gram/m2 fabric. The reinforcement is very<br />

strong, has a notable ultimate elongation and an optimal resistance to puncture and tearing.<br />

Mineral Nova P is reinforced with a composite, high weight, rot-proof, “non-woven”<br />

polyester 160gram/m2 fabric, stabilized with fibreglass 60gram/m² mat. This reinforcement<br />

has a high tensile strength, is flexible and has optimal dimensional stability in hot conditions<br />

which reduces the problems of the banana effect and the retraction of head lap joints as it is<br />

2 to 3 times more stable than normal reinforcements in “non woven” polyester fabric.<br />

Indever Primer is a bituminous primer made up of a compound of solvents and oxidized<br />

bitumens. The primer produces a film with a strong anchorage on every type of substrate<br />

without any degree of superficial stickiness.<br />

Indever Primer is a bituminous primer with a higher concentrate of oxidised bitumen and<br />

plasterciser to produce a resin rich film on the substrate to provide a stronger anchorage on<br />

all types of substrates.<br />

Ideal for regions or building designs that could experience strong winds.<br />

3.0 HANDLING AND STORAGE<br />

3.1. Handling and storage of all materials whether on or off site is under the strict control of the<br />

Hitchins New Zealand Ltd trained installers.<br />

Dry storage must be provided. The rolls should always be stored in an upright position on a<br />

smooth, flat surface.<br />

Joyce Group Limited<br />

Page 6

4.0 DESIGN IN<strong>FOR</strong>MATION<br />

4.1. Typical <strong>INDEX</strong> Roofing Protection systems comprise the following principal elements:<br />

Load bearing structure that may be made of:<br />

Concrete (site-cast concrete or a mixture of concrete tiles and prefabricated concrete<br />

panels). This may be lined with a lightened cementitious cope of variable thickness used to<br />

create the minimum incline necessary for the downflow of rainwater on flat roofs; timber,<br />

planking or various types of wood compound panels; Metal, in ridged sheeting.<br />

4.2. Vapour barrier or vapour shield, which is generally made of a polymer bitumen membrane<br />

in the roofing if there is also thermal insulation. Its function is to protect the insulation from<br />

humidity originating internally.<br />

4.3. Waterproof covering made from overlapping polymer bitumen membranes, which protect<br />

the roof from inclement weather. It is used for flat roofs but is necessary for inclined roofs<br />

lined with tiles or other discrete elements.<br />

4.4 Roofing protection is not strictly necessary nor always utilised but if a flat roof is used as a<br />

terrace and subject to foot traffic, some kind of pavement must be put down on top of the<br />

covering. Likewise if the roof is used for parking. Often, a layer of gravel is used even if this<br />

increases the costs of the load-bearing structure and so is becoming less common.<br />

Such systems are known as “heavy protection”. Often, however, the waterproof covering is<br />

itself uncovered (an open covering) and can be painted or the membrane may incorporate a<br />

slate chip protection known as “protected” membranes. <strong>INDEX</strong> products of this nature are<br />

found in the Mineral range.<br />

4.5. Other features: perimeter walls, skylights, rainwater drain holes, guttering, cornices etc.<br />

which are fundamental for a roof to do its job properly which should be carefully designed<br />

and constructed.<br />

Different but associated layers in the same roofing system interact as they contract and<br />

expand with fluctuations in temperature. It is essential that these movements are restricted<br />

by careful design, correct construction of the points of connection and through careful choice<br />

of the system components. The different natures of the various layers affect the mechanical<br />

resistance of the adjacent layers.<br />

4.6 Plywood must comply with AS/NZS 2269 and be H3.1 treated. LOSP treated plywood must<br />

not be used under any circumstances.<br />

It must be CD Grade Structural Plywood with sanded C face upwards. It must comply with<br />

NZ Building Code Acceptable Solution E2/AS1 February 2005.<br />

Joyce Group Limited<br />

Page 7

4.7 Resistance to foot traffic<br />

The membranes can accept, without damage, the limited foot traffic and light commercial<br />

loads associated with installation and maintenance operations. Where traffic in excess of<br />

this is envisaged, additional protection to the membrane, in accordance with the marketing<br />

company’s instructions must be provided. Reasonable care is required, however, to avoid<br />

puncture by sharp objects.<br />

5.0 BUILDINGS TO NZBC ACCEPTABLE SOLUTION E2/AS1 FEBRUARY 2005<br />

5.1 Substrate<br />

5.2 Existing concrete substrate if infected with mould, apply Hitchins Mosskill. Leave for 3<br />

days and water-blast clean. Leave to dry and carry out any repairs required using Hitchins<br />

Formcrete F.<br />

5.3 New concrete should be clean and free from defects, cured at a minimum of 14 days,<br />

preferably 28 days, incorporating fillets to upstands, with sufficient falls and outlets. Dense<br />

concrete needs to be etched or abraded and pre-sealed with thinned down primer.<br />

5.4 Plywood shall be 17.5mm tanalised CD grade structural plywood over joists and noggins at<br />

600mm centres shall be glued and fixed with stainless steel screws approximately 55mm<br />

length at 150mm centres on perimeter and 200mm centres throughout the sheet. Plywood<br />

to be laid in a brick-like pattern with face grain running in one direction at right angles<br />

(across) purlins or joists. Falls to be a minimum of 1 in 50.<br />

5.5 Compressed sheet shall be 20mm thick over joists and noggins at 400mm centres, which<br />

will be glued and fixed with 55mm to 60mm x 10 gauge stainless steel Pozidrive Comsheet<br />

screws at 200mm centres. Sheets must be laid across the joist and falls to be 1.50mm<br />

minimum. The sheet installation shall also follow the manufacturer’s specific instructions.<br />

5.6 On large structures involving steel trusses, purlin and noggins (spacing greater than 800mm<br />

centres) and involving tongue and groove plywood. <strong>INDEX</strong> Autotene or Kontabit Bandage<br />

must be laid over plywood sheets and mechanically fixed on one edge of strip. This<br />

provides a slip membrane to stress points.<br />

5.7 Before any primer is applied or membrane installed, carry out an inspection to ensure that<br />

all preliminaries have been carried out satisfactorily, including formation of falls, timber fillets<br />

to the corners, gutters, outlets, vents, upstands, fascias, balustrades and any other<br />

protrusions, sky lights, ducting, rebates to walls and expansion joints if required. Ensure the<br />

plywood is free of defects, smooth, clean and dry.<br />

5.8 Priming<br />

5.8.1 If possible, pre-prime sheets before installation or as soon as practical after sheets have<br />

been installed.<br />

Joyce Group Limited<br />

Page 8

5.8.2 To dry surface apply Hitchins Indever primer at 5m² to all sheet faces and edges, including<br />

fillets. Leave to dry.<br />

5.9 Roof Drainage<br />

5.9.1 Roofs must be constructed so that falls and drainage comply with Paragraph 8.5.6 of NZBC<br />

Acceptable Solution E2/AS1 February 2005. Roof must be constructed with 1:50 minimum<br />

falls, and gutters must be constructed with 1:25 minimum falls, with no seams in the gutters<br />

closer than 1 metre to an outlet.<br />

5.10 Junctions and Penetrations<br />

5.1.1 Junctions of the roof to walls must comply with paragraph 8.5.8 of<br />

NZBC Acceptable Solution E2/AS1 February 2005, and penetrations must comply with<br />

paragraph 8.5.9.<br />

6.0 SPECIFICALLY DESIGNED BUILDINGS<br />

6.1 Concrete Substrates<br />

6.1.1 Concrete substrates must be to a specific engineering design to meet the requirements of<br />

NZBC.<br />

6.2 Plywood Substrates<br />

6.2.1 Plywood substrates must be supported by a framing system meeting the requirements of the<br />

NZ Building Code and the specifications of the plywood manufacturer. Plywood must be of<br />

a thickness and grade to meet specific structural design requirements.<br />

Plywood must be secured to the structure to resist wind uplift and all other forces acting on<br />

the roof, such as deflection from gravity and incidental live loads.<br />

In high wind regions, the design of the building must provide maximum protection against<br />

wind up-lift forces on the membrane and its installation will incorporate adequate mechanical<br />

fixing of the base sheet at parapet and perimeter of the roof.<br />

The membrane system shall be able to with stand uplift to wind loads as specified in NZS<br />

3604:1999, Timber Framed Buildings or AS/NZS 1170.2. 2002 Structural Design Actions –<br />

wind Actions or AS 4055-1992 Wind Load for Housing or other Constructions.<br />

6.3 Roof Drainage Junctions and Penetrations<br />

A specific weathertightness design must be undertaken for each roof for roof drainage,<br />

junctions and penetrations to meet the requirements of the NZ Building Code.<br />

Joyce Group Limited<br />

Page 9

STRUCTURE<br />

7.1 The Load-Bearing Structure<br />

This is the surface on which the roofing protection system rests. Its function is to resist<br />

deformation from the permanent load of its own weight and by temporary loads imposed by<br />

the use to which it is put, maintenance and weather conditions such as snow, rain, wind etc.<br />

7.2 The Laying Surfaces and Inclination<br />

The load-bearing structure also creates the laying surface for the layers above which,<br />

except in particular cases, are layers of constant thickness.<br />

It is the load-bearing structures function to ensure there is sufficient incline for the downflow<br />

of rainwater.<br />

This is not a problem for sloping roofs or for roofs made from timber or metal, but for<br />

cementitious flat roofs another solution is required.<br />

A lightweight concrete cope is laid over the load-bearing structure in variable thicknesses<br />

and is divided into a series of areas no greater than 500 m² each and with variable inclines.<br />

Each area has its own water drainage system proportional in section to the area of roof it<br />

serves.<br />

The laying surface must be smooth and on a cementitious surface. There should be no<br />

depressions greater than 1 cm under a 2m. straight-edge laid on the surface, or greater than<br />

3 mm using a 20cm rule. Variations in level between timber planks should not exceed 2mm.<br />

Edging lines between prefabricated panels are covered with bridging strips to insulate them.<br />

7.3. Structural movement of the substrate must be adequately allowed for, and movement joints<br />

provided. The configuration and location of the joints in the substrate should be carefully<br />

considered. Conventional construction and movement (including seismic) joint details may<br />

be used.<br />

The BRANZ Good Roofing Membrane Practice gives guidance in this area.<br />

7.4. The membrane needs to be considered as part of the total roof design, and as such will<br />

need to be stopped at formed waterproof construction and structural movement control<br />

joints where these are installed. Construction/control joints must be constructed in<br />

accordance with the details of the current Technical Literature for the <strong>INDEX</strong> Roofing<br />

Membranes.<br />

In common with any roof membrane system, the ability of the product to resist structural<br />

movement will decrease with age.<br />

Joyce Group Limited<br />

Page 10

As a result, premature failure may occur at structural movement joints if these are not<br />

designed and installed correctly.<br />

7.5 Large roof structures require expansion joints to be designed and constructed at 10 metre<br />

centres or at stress points such as change of direction or corridors abutting the main<br />

building, (Refer appendix 3 for details).<br />

7.6 Ventilation to the roof cavity must allow for airflow throughout the cavity. The number of<br />

airvents required will depend on the depth of the cavity and whether soffit vents are<br />

installed. Therefore the ratio of air vents can very from 1 in 20m² to 1 in 40m².<br />

8.0 DURABILITY<br />

8.1 Serviceable Life<br />

<strong>INDEX</strong> roofing membranes are expected to have a serviceable life of at least 15 years<br />

provided they are designed, used, installed and maintained in accordance with the technical<br />

literature of the manufacturer.<br />

8.2 Chemical Resistance<br />

Industrial air pollutants and wind-borne salt deposits should not significantly affect durability<br />

of the membranes.<br />

However, the long-term properties of the material may be affected by contact to petroleumbased<br />

products such as oils, greases and solvents.<br />

9.0 MAINTENANCE<br />

9.1 Preventive maintenance is very important to provide the long term performance of the<br />

membrane system<br />

9.2 After any structural alteration or the installation of plant or equipment, these membranes<br />

should be inspected by the installer and corrective work carried out.<br />

9.3 The membrane roof system must be regularly (at least 2 times per year) checked for<br />

damage, to remove rubbish or debris and to ensure gutter outlets do not become blocked.<br />

9.4 Moss or mould growth must be treated and surface cleaned and any plant growth removed<br />

when infestations occur.<br />

9.5 Care must be taken when inspecting the membrane system to ensure the continuing<br />

prevention of moisture ingress and repairs must be undertaken where required.<br />

Damage such as small punctures and tears must be repaired by an approved applicator.<br />

Protective coating shall be reinstated after seven years.<br />

Joyce Group Limited<br />

Page 11

10.0 OUTBREAK <strong>OF</strong> FIRE<br />

10.1 Separation or protection must be provided to the membranes and<br />

plywood substrate from heat sources such as flues and chimneys.<br />

10.2 NZBC Acceptable Solution C/AS1 Part 9 and Verification Method<br />

C/VM1 provide methods for separation and protection of combustible materials from heat<br />

sources.<br />

11.0 SPREAD <strong>OF</strong> FIRE<br />

11.1 The membranes may be used on roofs of buildings intended for all Purpose Groups,<br />

including SC and SD, subject to the requirements of NZBC Acceptable Solution C/AS1 Part<br />

7, Paragraph 7.11.1.<br />

11.2 The membranes may be used for cladding fire-rated roof construction, providing the roof<br />

construction complies with the requirements of NZBC Acceptable Solution C/AS1 Part 7.<br />

12.0 EXTERNAL MOISTURE<br />

12.1 <strong>INDEX</strong> Roofing Membranes, when installed in accordance with the Technical Literature, will<br />

provide a roof that will shed precipitated water and melted snow, and prevent the<br />

penetration of water that could cause undue dampness or damage to building elements.<br />

12.2 The membrane systems must be installed and maintained in a weatherproof state at a<br />

minimum recommended fall of 1:50. All membrane joints must be as detailed in the<br />

Technical Literature.<br />

12.3 At penetrations, the membrane must be raised to a level above that of any possible ponding<br />

that may be caused by blockage of roof drainage facilities.<br />

12.4 Side laps must be a minimum of 100mm and end laps must be a minimum of 150mm. All<br />

laps joints must be torch sealed and staggered.<br />

12.5 Provisions for Snow<br />

Specific weather tightness design for preventing the ingress of snow melt water is required<br />

in accordance with the requirements of NZBC Acceptable Solution E2/AS1 February 2005<br />

Paragraph 1.3.<br />

13.0. INTERNAL MOISTURE<br />

13.1 The impermeability of the membranes requires that consideration must be given to the<br />

effective control of moisture in the roof structure, and closed-in construction spaces under<br />

the membrane must have adequate ventilation to prevent the accumulation of moisture<br />

venting and vapour barrier requirements will depend on the level of moisture that is present<br />

in the construction at the time of the installation, the value of the ceiling/roof construction,<br />

and the type of occupancy.<br />

Joyce Group Limited<br />

Page 12

14.0 INSTALLATION IN<strong>FOR</strong>MATION<br />

14.1 Installation Skill Level Requirement.<br />

Installation of membranes must be completed by Hitchins New Zealand Limited trained and<br />

approved applicators.<br />

15.0 SYSTEM INSTALLATION<br />

15.1 Substrate Preparation<br />

All surfaces must be checked to ensure they are clean and dry, smooth and free from sharp<br />

edges, loose or foreign materials, oil, grease or other deleterious materials that may affect<br />

adhesion of the membranes or may damage the membranes.<br />

15.2 A concrete surface is acceptable if no bumps greater than 10mm are found under a 2m rule<br />

in any direction and no bumps greater than 3mm are found under a rule of 0.20m.<br />

The surface should be trowelled and all cracks and gaps should be filled with mortar.<br />

Any projections and site residue such as nails, sheeting, bits of wood etc. must be removed.<br />

15.3 17.5mm plywood must be fixed using glue and 55mm long stainless steel counter sink head<br />

screws only, at 150mm centres on perimeter and 300mm centres throughout the sheets.<br />

Sheets must have 3mm gaps between joints except where tongue-in-groove joints are used.<br />

Plywood must be laid in a brick bond pattern with the face grain at right angles to the main<br />

support forming with grain going in one direction.<br />

A 20mm triangular fillet shall be used at the base of any 90º upstand and external edges<br />

shall be chamfered with a minimum radius of 5mm.<br />

15.4 20mm compressed sheet must be fixed using glue and 55mm to 60mm x 10 gauge stainless<br />

steel Pozidrive Comsheet screws at 200mm centres. Sheets must be laid across the joists<br />

and the installation procedure shall be in accordance with the specific instruction of the<br />

manufacturer of the sheet.<br />

15.5 Plywood and framing at the time of membrane application must have a maximum moisture<br />

content of 20% or lower if specified by the plywood manufacturer.<br />

15.6 The relative humidity of the concrete must be 75% or less before laying the membrane.<br />

Concrete slabs can be checked for dryness by using a hygrometer.<br />

15.7 Priming<br />

Prior to the application of membrane all plywood sheet faces, edges and fillets must be<br />

primed at a rate of 5m² per litre. Concrete surfaces should also be primed.<br />

Joyce Group Limited<br />

Page 13

15.8 Membrane Installation<br />

The membrane must be installed in accordance with the technical literature of the<br />

manufacturer.<br />

The installation of the base sheet to buildings in high wind regions is over Indever E Primer<br />

and will incorporate mechanical fixing (large flat head fasteners) to parapet and perimeter of<br />

roof as per technical literature of the manufacture.<br />

Installation of the membrane is to commence at the lowest point working up the grade of the<br />

roof orderly.<br />

15.9 Bonding of torch-on sheets is achieved by melting the lower surface by torching and<br />

pressing the membrane down. Press the membrane to the surface with a broom or roll<br />

smooth carefully without forming wrinkles or air bubbles.<br />

Care must be taken to not overheat the coating. A bead of molten material must exude from<br />

all laps to indicate a satisfactory seal and should be leveled out using a heated rounded tip<br />

trowel.<br />

The sheet joints to the finish membrane shall be offset to the sheets of the base sheet.<br />

The membrane shall be torched down on the underside to fuse the membrane to the<br />

substrate for maximum adhesion.<br />

Form mould and weld additional layers of membrane to provide flashings to wall upturns,<br />

fascia down turns, into gutters, hip ridges, skylights, expansion joints, air vents, mechanical<br />

services pipes/ducts balustrade posts, rain water heads and other penetrations in<br />

accordance with detailed drawings (Refer Appendices 3).<br />

On joints of the mineral capping layer the exuded bead must have extra mineral chip applied<br />

while still hot.<br />

15.10 Coatings<br />

Where a coloured coating system is specified all debris and dexterous material must be<br />

removed from the surface and the surface must be dry and free from contaminants before<br />

application.<br />

The Hitchins acrylic coating in selected colour should be applied at the rate of 6m² per litre.<br />

Each coat must be allowed to dry for a period of 2 hours before application of the second<br />

coat.<br />

<strong>INDEX</strong> Solaris Plus, a bituminous aluminium coating, silver colour should be applied to a<br />

rate 7m² per litre coat. Each coat must be allowed to dry for a period of 3 hours before the<br />

application of the second coat.<br />

Joyce Group Limited<br />

Page 14

The approved applicator and building contractor must complete the Hitchins / <strong>INDEX</strong><br />

Quality Control Schedule for each project’ (Refer Appendix 2). The completed document<br />

is to be made available to the building owner at the completion of the contract.<br />

15.11 Inspections<br />

The technical literature must be referred to by Building Consent Authorities during the<br />

inspection of membrane applications.<br />

16.0 WARRANTIES<br />

Hitchins New Zealand Ltd will provide a written product performance warranty. The type of<br />

system will determine the duration of warranty period.<br />

Refer appendix 1.<br />

The installer of the <strong>INDEX</strong> Membrane System will provide a written workmanship warranty.<br />

Refer appendix 2.<br />

17.0 HEALTH AND SAFETY<br />

Safe use and handling procedures for the membrane systems is provided in the Technical<br />

Literature.<br />

18.0 BUILDING REGULATIONS<br />

18.1 In my opinion <strong>INDEX</strong> Roofing Membranes, if designed, used, installed and maintained in<br />

accordance with the statements and conditions of the manufacturer’s technical data and the<br />

conditions of this report, will meet or contribute to meeting the following provisions of the<br />

NZBC.<br />

Clause B2 Durability<br />

Performance B2.3.1(b) 15 years.<br />

<strong>INDEX</strong> Roofing membranes, meet this requirement. See paragraphs 8.1 and 8.2 of<br />

report.<br />

this<br />

Clause E2 External Moisture<br />

Performance E2.3.1 and E2.3.2. <strong>INDEX</strong> Roofing Membranes meet these requirements.<br />

See paragraphs 12.1 to 12.5 of this report.<br />

19.0 QUALITY<br />

19.1 The manufacture of the materials forming the system has not been examined in this<br />

assessment. An examination of the manufacturing practice and quality control procedures<br />

employed in the manufacture of the materials is subject to the ongoing validity of the current<br />

BBA (British Board of Agreement) and Bureau Veritas Control Reports.<br />

Joyce Group Limited<br />

Page 15

19.2 The quality of materials supplied by Hitchins NZ Ltd is the<br />

responsibility of Hitchins NZ Ltd.<br />

19.3 Quality on site is the responsibility of Hitchins NZ Ltd trained installers.<br />

A Quality Control Schedule will be completed for each project, (Refer appendix 2 for copy).<br />

19.4 Designers are responsible for the building design, and building<br />

contractors are responsible for the quality of construction of<br />

accordance with the instructions of Hitchins NZ Ltd.<br />

substrate systems in<br />

19.5 Building owners are responsible for the maintenance of the membrane systems in<br />

accordance with the instructions of Hitchins NZ Ltd.<br />

SOURCES of IN<strong>FOR</strong>MATION<br />

AS/NZS 2269: 1994 Plywood-Structural.<br />

Approved Document for New Zealand Building Code External Moisture Clause E2, Building<br />

Industry Authority, February 2005.<br />

NZ Building Code Handbook and Approved Documents, Building Industry Authority 1992.<br />

BRANZ Good Roofing Membrane Practice Reprint October 2003.<br />

Ron Thurlow<br />

JOYCE GROUP LIMITED<br />

Joyce Group Limited<br />

Page 16

Appendix 1<br />

PRODUCT PER<strong>FOR</strong>MANCE<br />

WARRANTIES

Hitchins New Zealand Limited<br />

P O B ox 40 -7 49 , Up per H ut t, W el li ngto n, New Z ea la n d Te l: 64 4 52 7 7248 Fa x: 64 4 528 4 8 13<br />

8 December 2004<br />

PRODUCER’S STATEMENT<br />

Covering<br />

PRODUCT PER<strong>FOR</strong>MANCE & WARRANTIES<br />

On<br />

<strong>INDEX</strong> <strong>MEMBRANES</strong><br />

<strong>INDEX</strong> modified reinforced bituminous membranes are manufactured by <strong>INDEX</strong> CONSTRUCTION PRODUCTS SPA of Italy<br />

under stringent quality control and marketed to over 100 countries worldwide. <strong>INDEX</strong> membranes have been appraised by<br />

leading testing authorities throughout the world and certified as suitable waterproof membrane for the building and<br />

construction industry, as such meets the E2 and B2 requirements.<br />

<strong>HITCHINS</strong> <strong>NEW</strong> ZEALAND LIMITED with an established history of marketing innovative and quality products is the<br />

distributing and promotional company for <strong>INDEX</strong> membranes throughout New Zealand and the Pacific Islands.<br />

Installation of <strong>INDEX</strong> membranes is through approved Hitchins’ Gunac applicator firms with experienced and trained<br />

personnel working within the recommended application procedures set down by <strong>INDEX</strong> and Hitchins New Zealand Limited, in<br />

keeping with good trade practices.<br />

<strong>INDEX</strong> membranes installed over sound clean and primed substrates, built to the Revised Building Code and in keeping<br />

within the guidelines of Hitchins’ Quality Control Sheet and substrate recommendations.<br />

<strong>HITCHINS</strong> <strong>NEW</strong> ZEALAND LIMITED will provide a written Product Performance Warranty as follows:-<br />

* Twenty (20) Years<br />

* * Protea Duo P 4mm triple reinforced single layer membrane finished in a Mineral Chip or Plain (Texflamina<br />

surface) over-coated with an approved Hitchins’ coating.<br />

* * A double layer fully bonded <strong>INDEX</strong> membrane system (6 to 7½mm) finished in a Mineral Chip or over-coated<br />

with an approved Hitchins’ coating.<br />

* Fifteen (15) Years<br />

* * A single layer <strong>INDEX</strong> Plain membrane 4.5Kg (4.5mm) finished in Mineral Chip.<br />

* * A single layer <strong>INDEX</strong> Plain membrane (3mm to 4mm) finished in an approved Hitchins’ coating.<br />

* Ten (10) Years<br />

* * Single layer <strong>INDEX</strong> Plain membrane (3mm to 4mm) left uncoated.<br />

* * Single layer <strong>INDEX</strong> Plain membrane (3mm to 4mm) re-sheathed over an existing membrane.<br />

Within the above Product Performance Warranty, design, expansion joints, venting, adequate falls, outlets and flashing<br />

requirements must be to a high standard, including the installation work. Regular and adequate cleaning maintenance (moss<br />

or mould treatment if and when required) must be carried out including reinstatement of the protective coating every 7 years<br />

approximately. Maintenance requirement is covered under the Hitchins' Product Performance Warranty document.<br />

Hitchins New Zealand Limited Product Performance Warranty must be accompanied by the applicator workmanship<br />

warranty, thus providing the client with a comprehensive overall performance warranty.<br />

For and on behalf of<br />

Hitchins New Zealand Limited<br />

Jim Gerbes<br />

MANAGING DIRECTOR

MARKETING <strong>OF</strong> QUALITY PRODUCTS<br />

The following resume covers Hitchins New Zealand Limited in association with <strong>INDEX</strong> Constructions Products Spa to<br />

provide the market with quality bitumen membrane products.<br />

<strong>INDEX</strong> Construction Products Spa within its first division is a world leader in the production and marketing of polymer<br />

bitumen waterproof membranes in various locations around the world with marketing associated companies in 110<br />

countries.<br />

<strong>INDEX</strong> invests extensively in research and development to supply products of advanced technology and unique<br />

properties including various for specific uses. All products are produced to a high standard under BVQI (Bureau<br />

Veritas Quality International) an ISO-9001 accreditation.<br />

<strong>INDEX</strong> product documentation covering company profile, waterproofing composition and analysis of roofing protection<br />

systems, application manuals, product Data Specs, technical specifications and sales brochures are of an exceptional<br />

standard and composition. <strong>INDEX</strong> back-up support and service is of the same calibre.<br />

Coupled with Hitchins New Zealand Limited extensive history of service within the building and construction industry,<br />

marketing quality products under a Performance Warranty, together with <strong>INDEX</strong> Construction Products Spa, we are<br />

able to provide:<br />

* Quality products through an extensive range.<br />

* Unique products for specific uses.<br />

* High standard of technical support and service.<br />

* Products covered by Performance Warranty.<br />

Unique products for a specific use<br />

The <strong>INDEX</strong> Torch-On Membranes brochure depicts the range of products Hitchins New Zealand Limited market and<br />

you will note the unique properties and functions some of these membranes have, such as:<br />

* Protea Duo P, 3mm - Triple reinforced multi-layer bitumen and finished with Texflamina to produce the highest specification<br />

membrane on the New Zealand market.<br />

* Testudo P 20, 3mm - A high quality SBS bitumen rich reinforced but flexible membrane for tanking, gutters.<br />

* Firestop P, 4.5 kg - The flame-retardant properties provide an ideal membrane for public amenity buildings.<br />

* Defend H, 4 mm - An anti-root protective and waterproof membrane for garden areas.<br />

* Nova Biamarto Plain and Mineral – Double-reinforced APP bitumen membrane; quality is above the industry standard.<br />

* Elastocene P, 3mm - Flexible modified bitumen membrane for all year round installation and detailed work.<br />

* Fidia P, Biamarto 3mm - An APP modified bitumen membrane with excellent weather-ability, durability and high quality<br />

finish.<br />

* Perfobase - Used in conjunctions with air vents to provide base sheet to ventilate the substrate in a double layered system.<br />

* Roll Base - For use over timber or deteriorated bitumen screeds in a double layered system.<br />

* Autotene P –Fully bonded Base Sheet in a double-layer system.<br />

<strong>INDEX</strong> products are marketed through approved Hitchins’ Gunac applicators for installation on projects throughout<br />

New Zealand and the Pacific Islands.<br />

Hitchins New Zealand Limited through the <strong>INDEX</strong> Club provides incentives and financial support for applicator training<br />

at the <strong>INDEX</strong> Training Auditorium in Italy. This is a unique and comprehensive scheme and there is nothing like it on<br />

the New Zealand market. Further we hold training seminars at our Upper Hutt facilities and other locations around<br />

New Zealand.<br />

With training, application manuals, Health and Safety guides provided, plus onsite inspections and guidance we<br />

believe that collectively, our applicator network will provide a high standard of workmanship.<br />

Hitchins produce and market quality coatings, many of which have the reputation of providing long term performance.<br />

Simply, they have stood the test of time.<br />

With high U.V. rays in New Zealand, Hitchins New Zealand Limited's policy is that other than mineral finishes, all other<br />

membranes should be coated with one of our proven coatings.<br />

<strong>INDEX</strong>, Hitchins and the Gunac applicator network providing quality products installed to a high level of finish.

P O B ox 4 0 -74 9 , Uppe r H utt, W elli n gto n, New Zea la n d Te l: 64 4 52 7 724 8 Fa x: 64 4 528 4 8 13<br />

Durability Statement<br />

<strong>INDEX</strong> Construction Products Spa manufactures a wide range of bitumen membranes, one of which is Fidia Biamarto.<br />

Double Fidia Biamarto is an App modified double reinforced bitumen membrane. The App modified bitumen provides<br />

durability and U.V. resistance. The double reinforcement comprises of spunbound polyester for strength and glass<br />

fibre layer for stability.<br />

Technical specifications of Fidia Biamarto are covered in the product Data Spec. Properties of Fidia Biamarto are<br />

durability, mould and workability, flexibility yet trafficable and the ability to achieve a professional finish. Fidia Biamarto<br />

weathers to a Grey, exposing the fine fibreglass fibres that provide improved adhesion of the coating.<br />

Fidia Biamarto coated with <strong>INDEX</strong> Solaris or Hitchins' Traffigard will provide improved weather resistance U.V.<br />

protection and heat reduction thus ensuring the membrane remains stable and performs satisfactorily over an<br />

extended period. The coatings themselves will perform as required under the New Zealand Building Code.<br />

Warrantees are addressed under the project contract documentation and Hitchins New Zealand Limited Product<br />

Performance Warrantees as covered in their Producer's Statement.<br />

Product performance, particularly durability is dependent on the maintenance requirement during the warranty period<br />

and beyond. The coated membrane should receive regular inspections and maintenance work (when required) carried<br />

out, being:<br />

(1) Check to ensure all outlets are free of foreign or vegetative matter.<br />

(2) If moss or mould growth appears, treat and waterblast clean at low pressure. If no infestation wash down<br />

every 2-3 years.<br />

(3) Any fault found in the membrane, the applicator firm (installer) or in their absence Hitchins New Zealand<br />

Limited advised, so those repairs can be carried out promptly. Time is of the essence. Repair work (if required)<br />

within the Warranty period will be at no cost to the client.<br />

(4) The protective coating needs to be reinstated when required, usually every 7 years. This is at the client's cost.<br />

Given that the maintenance requirements are carried out as above, including any repair work (if and when required) by<br />

an approved Gunac applicator, then Fidia Biamarto membrane will meet the durability requirements as under the New<br />

Zealand Building Code.<br />

For and on behalf of<br />

Hitchins New Zealand Limited<br />

Jim Gerbes<br />

MANAGING DIRECTOR<br />

3 July 2001

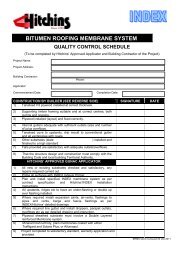

Appendix 2<br />

QUALITY CONTROL SCHEDULE

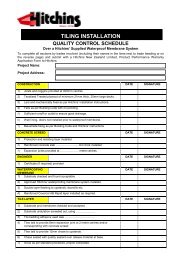

BITUMEN RO<strong>OF</strong>ING MEMBRANE SYSTEM<br />

QUALITY CONTROL SCHEDULE<br />

(To be completed by Hitchins’ Approved Applicator and Building Contractor of the Project)<br />

Project Name:<br />

Project Address:<br />

Building Contractor:<br />

Phone:<br />

Applicator:<br />

Commencement Date:<br />

Completion Date:<br />

CONSTRUCTION BY BUILDER (SEE REVERSE SIDE) SIGNATURE DATE<br />

1) Tanalised H3 plywood installed at correct thickness.<br />

2) Supporting timber framing suitable and at correct centres, both<br />

purlins and noggins.<br />

3) Plywood installed (layout) and fixed correctly.<br />

4) Internal gutters adequate with sufficient outlets (size and number<br />

of) plus overflows.<br />

5) Tanalised cove to upstands, drip mould to conventional gutter<br />

and all vents/pipes with cowels.<br />

6) Other substrates (state ) installed and<br />

finished to a high standard.<br />

7) Falls as per Building Code, minimum 1:50 roof and 1:25 gutters.<br />

<strong>HITCHINS</strong>’ APPROVED GUNAC APPLICATOR<br />

1) All new or existing substrates checked and satisfactory, any<br />

repairs required carried out.<br />

2) Prime all surfaces with <strong>INDEX</strong> Indever Primer.<br />

3) Plan and install specified <strong>INDEX</strong> membrane system as per<br />

contract specification and Hitchins’/<strong>INDEX</strong> Installation<br />

Instructions.<br />

4) All upstands, ridges etc to have an under-flashing or double up<br />

over flashing installed.<br />

5) Where required install expansion joints, air-vents, flashings to<br />

pipes and vents, barge and fascia flashings as per<br />

<strong>INDEX</strong>/Hitchins’ detailed drawings.<br />

6) Where required line gutter and install droppers, parapet outlets,<br />

overflows etc as per detailed drawing and instruction.<br />

7) Mineral finish left tidy, plain membranes coated with either<br />

Traffigard and Solaris Plus, or Alumasol.<br />

8) Project completed to satisfactory standard, warranty application and<br />

provided.

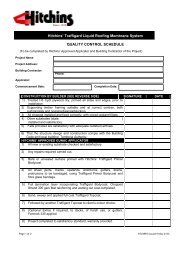

<strong>INDEX</strong> BITUMEN RO<strong>OF</strong>ING MEMBRANE SYSTEM<br />

The following is provided by Hitchins New Zealand Limited to assist the building contractor to provide a substrate<br />

suitable for the installation of <strong>INDEX</strong> reinforced modified bitumen membranes. The contract documents, New Zealand<br />

Building Code and the plywood manufacturer’s installation recommendations should be adhered to. If there is a<br />

conflict of instructions, the building contractor is to resolve with the architect or client, ensuring that Hitchins’<br />

recommendations (or improved standard) is adhered to as we know our product’s capabilities and limitations. The<br />

application or installation process is to be carried out by an approved Gunac applicator. These terms are a prerequisite<br />

to obtaining a Hitchins’ Product Performance Warranty.<br />

CONCRETE<br />

To be at least 28 days old, minimum falls of 1:50 with no ponding, clean and dry. Large structures to have expansion<br />

joints incorporated. Uncured or damp concrete is to have an <strong>INDEX</strong> Vented Base Sheet to allow moisture vapour to<br />

dissipate out.<br />

PLYWOOD<br />

1. Plywood is to be tanalised H3 and of minimum CPD grade, arrive on site dry and kept dry until fixed. Prepriming<br />

recommended.<br />

2. All plywood primed with <strong>INDEX</strong> Indever Primer.<br />

3. Supporting timber spacing to be at the following centres:-<br />

21mm plywood at 800mm centres<br />

17.5mm plywood at 600mm centres<br />

15mm plywood at 400mm centres<br />

4. Centres being both ways, i.e. purlins and noggins (blocking) every third noggin to be full depth of purlin or any<br />

other construction system that ensures the purlins will not twist.<br />

5. All plywood laid in one direction across the purlins (right angles) as per the plywood manufacturer’s<br />

instructions.<br />

6. Plywood laid in an offset brick like pattern. Vital!<br />

7. Fixing by twist nails or screws is to be at a minimum of 150mm centres at sheet perimeter and 300mm<br />

throughout the sheet.<br />

8. Minimum length of nails or screws to be three times the thickness of plywood e.g. 18mm requires 54mm or<br />

larger fixers.<br />

9. For improved performance apply a bead of adhesive to supporting timber prior to installing plywood.<br />

10. If Tongue and Groove plywood is used for improved performance glue in the Tongue.<br />

11. Plywood laid with approximately 2mm gap except on large roof structures where expansion joints must be<br />

designed and built in. See expansion joints.<br />

12. Roofs to have a built in fall of minimum 1 in 50 and gutter 1 in 25.<br />

13. If Tongue and Groove plywood is used where all plywood sheets are not supported, then plywood joints are to<br />

be bandaged using Hitchins’ Kontabit or <strong>INDEX</strong> Autotene, which is a self adhesive flexible elastomeric<br />

membrane.<br />

14. Alternatively the roof is to be sheathed with a double (Base and Cap Sheet) membrane system.<br />

15. If the roof cavity is required to be vented, it must be designed and built to provide airflow to all cavities. See<br />

venting.<br />

16. Expansion joints designed and constructed as per Hitchins’ recommendations (see detailed drawings in mini<br />

manual) and as per plans and specifications.<br />

17. Built in gutters, outlets and overflows to be adequate in size and number to shed water under all conditions.<br />

18. All upstands to have tanalised timber fillets installed.<br />

19. Barge ends, drip edge detail to gutter, etc to be installed.<br />

20. All pipes, vents etc to have metal coves installed so that <strong>INDEX</strong> membranes are flushed up and under.<br />

21. <strong>INDEX</strong> membrane flashing installed prior to wall lining installation, ditto skylights which then also have metal<br />

over-flashing.<br />

22. Concrete, block or brick to provide a chase for <strong>INDEX</strong> membrane to be flashed into and sealed with bead of<br />

sealant.<br />

23. In general, provide a sound substrate for the installation of <strong>INDEX</strong> membranes.<br />

24. Install Hitchins’ supplied <strong>INDEX</strong> membranes as specified over fresh Indever Primer as per manufacturer’s<br />

recommended procedures and good sound trade practices, including double up flashings.<br />

25. If required install air-vents, within the <strong>INDEX</strong> membrane system on raised platform, well flashed and sealed.<br />

See Hitchins’ details.<br />

10. Finally, the Hitchins’ supplied <strong>INDEX</strong> membranes are protected by the building contractors or client during<br />

the remaining construction period; then checked over at completion and any repairs or resurfacing carried out<br />

at their cost.

Appendix 3<br />

INSTALLATION DETAILS

<strong>HITCHINS</strong>’ <strong>INDEX</strong> DETAIL DRAWINGS<br />

INTRODUCTION<br />

The following drawings have been produced to assist specifiers and applicators.<br />

They clearly show what is required not only in installation, but in the finishes.<br />

For clarity we have produced the drawings in colour as per the codes below:-<br />

<strong>INDEX</strong>’ Membrane<br />

<strong>INDEX</strong>’ Accessories<br />

Substrates - Plywood<br />

Supporting Structure<br />

Metal Roof<br />

Joint Sealant

Appendix 4<br />

CURRICULUM VITAE<br />

of<br />

RONALD FREDERICK THURLOW<br />

and<br />

TERRENCE HUGH O’CONNER

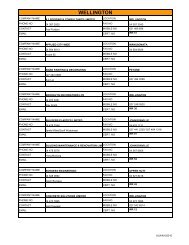

Appendix 4 (continued)<br />

WELLINGTON CITY COUNCIL

For further information please contact -<br />

<strong>NEW</strong> ZEALAND LIMITED EW LI<br />

<strong>FOR</strong> FULL<br />

Technical Support<br />

PLUS<br />

Quality Product Supply<br />

AND<br />

Friendly, helpful service!<br />

CONTACT<br />

WELLINGTON AUCKLAND AUCKLAND<br />

Jim Gerbes – Managing Director<br />

Phone No: 04 527 7248<br />

Facsimile No: 04 528 4813<br />

Jim’s Mobile No: 021 490 590<br />

Email Address: jim@hitchins.co.nz<br />

Wade Brown – Technical Consultant<br />

Mobile No: 021 22 111 22<br />

Email: office@hitchins.co.nz<br />

P O Box 40-749, Upper Hutt<br />

7/15 Masefield Street, Upper Hutt<br />

Jason Gerbes – Auckland Regional Manager<br />

Phone No: 09 360 3246<br />

Facsimile No: 09 360 5081<br />

Jason’s Mobile No: 021 527 667<br />

Jason’s Email: jason@hitchins.co.nz<br />

P O Box 46 018, Herne Bay, Auckland<br />

300 Richmond Road, Grey Lynn, Auckland<br />

Rick Mumford – Technical Consultant<br />

Phone No: 09 360 3246<br />

Facsimile No: 09 360 5081<br />

Mobile No: 021 318 021<br />

Email Address: office@hitchins.co.nz<br />

P O Box 46 018, Herne Bay, Auckland<br />

300 Richmond Road, Grey Lynn, Auckland<br />

<strong>HITCHINS</strong> <strong>NEW</strong> ZEALAND LIMITED<br />

C\Winwood\Joyce Group Report on <strong>INDEX</strong> Membranes/28 July 2005/Fliss