Drilling with high rpm compared to drilling with conventional speed

Drilling with high rpm compared to drilling with conventional speed

Drilling with high rpm compared to drilling with conventional speed

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

IACDS Bauma 2013 seminar 2013-04-19<br />

High <strong>rpm</strong> <strong>drilling</strong> <strong>to</strong>day<br />

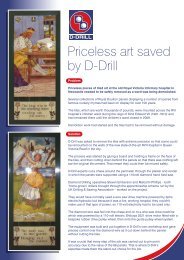

Why is 40 - 50 m/sec peripheral <strong>speed</strong> normal for a wall saw but not for a core drill?<br />

4.5 m/ second peripheral <strong>speed</strong> is<br />

often standard in Sweden,<br />

whereas some would consider this<br />

<strong>high</strong> <strong>speed</strong> <strong>drilling</strong>.<br />

Different manufacturers have<br />

different recommendations.<br />

Bohrmo<strong>to</strong>r Pentruder MDU mit Untersetzungsspindel SH<br />

Umfangsgeschwindigkeit m/s<br />

Stufe 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Drehzahl 320 400 480 560 640 720 800 880 960 1040 1120 1200 1280 1360 1440<br />

Ø 52 0,87 1,09 1,31 1,52 1,74 1,96 2,18 2,39 2,61 2,83 3,05 3,27 3,48 3,70 3,92<br />

Ø 62 1,04 1,30 1,56 1,82 2,08 2,34 2,60 2,86 3,11 3,37 3,63 3,89 4,15 4,41 4,67<br />

Ø 72 1,21 1,51 1,81 2,11 2,41 2,71 3,01 3,32 3,62 3,92 4,22 4,52 4,82 5,12 5,43<br />

Ø 82 1,37 1,72 2,06 2,40 2,75 3,09 3,43 3,78 4,12 4,46 4,81 5,15 5,49 5,84 6,18<br />

Ø 92 1,54 1,93 2,31 2,70 3,08 3,47 3,85 4,24 4,62 5,01 5,39 5,78 6,16 6,55 6,93<br />

Ø 102 1,71 2,14 2,56 2,99 3,42 3,84 4,27 4,70 5,12 5,55 5,98 6,41 6,83 7,26 7,69<br />

Ø 107 1,79 2,24 2,69 3,14 3,58 4,03 4,48 4,93 5,38 5,82 6,27 6,72 7,17 7,62 8,06<br />

Ø 112 1,88 2,34 2,81 3,28 3,75 4,22 4,69 5,16 5,63 6,10 6,56 7,03 7,50 7,97 8,44<br />

Ø 122 2,04 2,55 3,06 3,58 4,09 4,60 5,11 5,62 6,13 6,64 7,15 7,66 8,17 8,68 9,19<br />

Ø 132 2,21 2,76 3,32 3,87 4,42 4,97 5,53 6,08 6,63 7,18 7,74 8,29 8,84 9,39 9,95<br />

Ø 142 2,38 2,97 3,57 4,16 4,76 5,35 5,95 6,54 7,13 7,73 8,32 8,92 9,51 10,11 10,70<br />

Ø 152 2,55 3,18 3,82 4,45 5,09 5,73 6,36 7,00 7,64 8,27 8,91 9,55 10,18 10,82 11,45<br />

Ø 162 2,71 3,39 4,07 4,75 5,43 6,10 6,78 7,46 8,14 8,82 9,50 10,17 10,85 11,53 12,21<br />

Ø 172 2,88 3,60 4,32 5,04 5,76 6,48 7,20 7,92 8,64 9,36 10,08 10,80 11,52 12,24 12,96<br />

Ø 182 3,05 3,81 4,57 5,33 6,10 6,86 7,62 8,38 9,14 9,91 10,67 11,43 12,19 12,95 13,72<br />

Ø 192 3,22 4,02 4,82 5,63 6,43 7,23 8,04 8,84 9,65 10,45 11,25 12,06 12,86 13,67 14,47<br />

Ø 200 3,35 4,19 5,02 5,86 6,70 7,54 8,37 9,21 10,05 10,89 11,72 12,56 13,40 14,23 15,07<br />

Ø 225 3,77 4,71 5,65 6,59 7,54 8,48 9,42 10,36 11,30 12,25 13,19 14,13 15,07 16,01 16,96<br />

Ø 250 4,19 5,23 6,28 7,33 8,37 9,42 10,47 11,51 12,56 13,61 14,65 15,70 16,75 17,79 18,84<br />

Ø 300 5,02 6,28 7,54 8,79 10,05 11,30 12,56 13,82 15,07 16,33 17,58 18,84 20,10 21,35 22,61<br />

Ø 350 5,86 7,33 8,79 10,26 11,72 13,19 14,65 16,12 17,58 19,05 20,51 21,98 23,45 24,91 26,38<br />

Ø 400 6,70 8,37 10,05 11,72 13,40 15,07 16,75 18,42 20,10 21,77 23,45 25,12 26,79 28,47 30,14<br />

Ø 450 7,54 9,42 11,30 13,19 15,07 16,96 18,84 20,72 22,61 24,49 26,38 28,26 30,14 32,03 33,91<br />

Ø 500 8,37 10,47 12,56 14,65 16,75 18,84 20,93 23,03 25,12 27,21 29,31 31,40 33,49 35,59 37,68<br />

Ø 550 9,21 11,51 13,82 16,12 18,42 20,72 23,03 25,33 27,63 29,93 32,24 34,54 36,84 39,15 41,45<br />

Ø 600 10,05 12,56 15,07 17,58 20,10 22,61 25,12 27,63 30,14 32,66 35,17 37,68 40,19 42,70 45,22<br />

Ø 650 10,89 13,61 16,33 19,05 21,77 24,49 27,21 29,93 32,66 35,38 38,10 40,82 43,54 46,26 48,98<br />

Ø 700 11,72 14,65 17,58 20,51 23,45 26,38 29,31 32,24 35,17 38,10 41,03 43,96 46,89 49,82 52,75<br />

Ø 750 12,56 15,70 18,84 21,98 25,12 28,26 31,40 34,54 37,68 40,82 43,96 47,10 50,24 53,38 56,52<br />

Standard-Bohrkronen mit optimaler Umfangsgeschwindigkeit 2-4 m/s<br />

High-Speed Bohrkronen mit erhöhter Umfangsgeschwindigkeit 4-6 m/s<br />

• More difficult <strong>to</strong> cool drill bit.<br />

• More difficult <strong>to</strong> remove slurry.<br />

• Lower price Lower quality of Core<br />

drill, Drill rig and Core bit<br />

• Price pressure Difficult for <strong>to</strong>ol<br />

manufacturers <strong>to</strong> produce the optimal<br />

drill bit.<br />

Bauma 2013<br />

Munich seminar<br />

Bauma 2013<br />

Munich seminar<br />

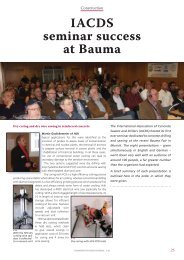

Our thesis – Higher <strong>speed</strong>s Faster <strong>drilling</strong><br />

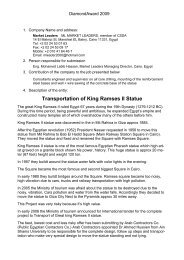

High <strong>speed</strong> <strong>drilling</strong> – Important criteria for success<br />

Power = Constant<br />

Peripheral <strong>speed</strong> x 2 Concrete removal rate x 2<br />

<strong>rpm</strong><br />

Powerful core drill<br />

Adjustment of <strong>rpm</strong><br />

Rigidity of drill<br />

system<br />

Drill bit<br />

Sufficient cooling<br />

Concrete<br />

removal<br />

rate<br />

Skilled opera<strong>to</strong>r<br />

Bauma 2013<br />

Munich seminar<br />

Bauma 2013<br />

Munich seminar<br />

2