Hydrogen phosphide as a fumigant for foods, feeds and processed ...

Hydrogen phosphide as a fumigant for foods, feeds and processed ...

Hydrogen phosphide as a fumigant for foods, feeds and processed ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

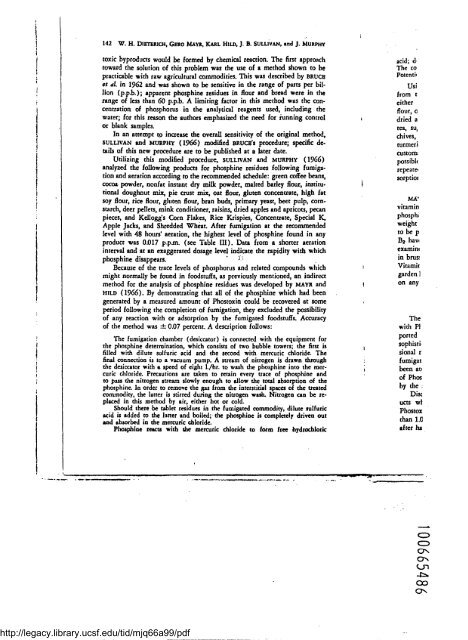

142 W. H. D1ErER1CH, GERO MAYR, KARL HILA, ) . B. SULLIVAN, <strong>and</strong> J . MURPHY<br />

toxic byproducts would be <strong>for</strong>med by chemical reaction . The first approach<br />

toward the solution of this problem w<strong>as</strong> the use of a method shown to be<br />

practicable with raw agricultural commodities. This w<strong>as</strong> described by BRUCE<br />

of al. in 1962 <strong>and</strong> w<strong>as</strong> shown to be sensitive in the range of parts per billion<br />

(p.p.b.) ; apparent phosphene residues in flour <strong>and</strong> bread were in the<br />

range of less than 60 p.p.b. A limiting factor in this method w<strong>as</strong> the concentration<br />

of phosphorus in the analytical reagents used, including the<br />

water; <strong>for</strong> this re<strong>as</strong>on the authors emph<strong>as</strong>ized the need <strong>for</strong> funning control<br />

or blank samples.<br />

In an attempt to incre<strong>as</strong>e the overall sensitivity of the original method,<br />

SULLIVAN <strong>and</strong> MURPHY (1966) modified BRUCE's procedure ; specific details<br />

of this new procedure are to be published at a later date .<br />

Utilizing this modified procedure, SULLIVAN <strong>and</strong> MURPHY (1966)<br />

analyzed the following products <strong>for</strong> phosphine residues following fumigation<br />

<strong>and</strong> aeration according to the recommended schedule : green coffee beans,<br />

cocoa powder, nonfat instant dry milk powder, malted barley flour, institu .<br />

tional doughnut mix, pie crust mix, oat flour, gluten concentrate, high fat<br />

soy flour, rice flour, gluten flour, bran buds, primary ye<strong>as</strong>t, beet pulp, cornstarch,<br />

deer pellets, mink conditioner, raisins, dried apples <strong>and</strong> apricots, pecan<br />

pieces, <strong>and</strong> Kellogg's Corn Flakes, Rice Krispies, Concentrate, Special K,<br />

Apple Jacks, <strong>and</strong> Shredded Wheat. After fumigation at the recommended<br />

level with 48 hours' aeration, the highest level of phosphine found in any<br />

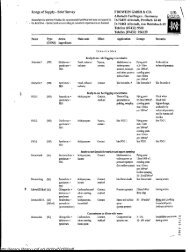

product w<strong>as</strong> 0 .017 p .p.m. (see Table III) . Data from a shorter aeration<br />

interval <strong>and</strong> at an exaggerated dosage level indicate the rapidity with which<br />

phosphine disappears .<br />

Because of the trace levels of phosphorus <strong>and</strong> related compounds which<br />

might normally be found in <strong>foods</strong>tuffs, <strong>as</strong> previously mentioned, an indirect<br />

method <strong>for</strong> the analysis of phosphine residues w<strong>as</strong> developed by MAYR <strong>and</strong><br />

HILD (1966). By demonstrating that all of the phosphine which had been<br />

generated by a me<strong>as</strong>ured amount of Phostoxin could be recovered at some<br />

period following the completion of fumigation, they excluded the possibility<br />

of any reaction with or adsorption by the fumigated <strong>foods</strong>tuffs. Accuracy<br />

of the method w<strong>as</strong> ± 0.07 percent . A description follows :<br />

The fumigation chamber (desiccator) is connected with the equipment <strong>for</strong><br />

the phosphine determination, which consists of two bubble towers; the first is<br />

filled with dilute sulfuric acid <strong>and</strong> the second with mercuric chloride . The<br />

final connection is to a vacuum pump. A stream of nitrogen is drawn through<br />

the desiccator with a speed of eight 1./fir. to w<strong>as</strong>h the phosphine into the mercuric<br />

chloride. Precautions are taken to retain every trace of phosphine <strong>and</strong><br />

to p<strong>as</strong>s the nitrogen stream slowly enough to allow the total absorption of the<br />

phosphine. In order to remove the g<strong>as</strong> from the interstitial spaces of the treated<br />

commodity, the latter is stirred during the nitrogen w<strong>as</strong>h . Nitrogen can be replaced<br />

in this method by air, either hot or cold .<br />

Should there be tablet residues in the fumigated commodity, dilute sulfuric<br />

acid is added to the latter <strong>and</strong> boiled; the phosphine is completely driven out<br />

<strong>and</strong> absorbed in the mercuric chloride .<br />

Phosphine reacts with the mercuric chloride to <strong>for</strong>m free hydrochloric<br />

M<br />

1<br />

i<br />

acid ; d-<br />

The co<br />

Potenti'<br />

Usi<br />

from t<br />

either<br />

flour, o<br />

dried a<br />

tea, su;<br />

chives,<br />

turmeri<br />

custom:<br />

possibh<br />

repeate,<br />

sorptio t<br />

MA'<br />

vitamin<br />

phosphi<br />

weight<br />

to be p<br />

Ba. haw<br />

examint<br />

in br<strong>as</strong>:<br />

Vitamit<br />

garden I<br />

on any<br />

The<br />

with P1<br />

ported<br />

sophisti,<br />

sional r<br />

fumigat<br />

been at'<br />

of Phos<br />

by the<br />

Disc<br />

ucts wl<br />

Phostox<br />

than 1 .0<br />

after ha<br />

http://legacy.library.ucsf.edu/tid/mjq66a99/pdf