Development of Miniature Specimen Test Techniques

Development of Miniature Specimen Test Techniques

Development of Miniature Specimen Test Techniques

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNOLOGY-13<br />

ADDITIONAL INFORMATION<br />

The concept <strong>of</strong> specimen miniaturization has its origin in the nuclear industry, where because <strong>of</strong> expensive and limited<br />

irradiation space, specimen sizes were miniaturized for experimental irradiation programmes in reactors. The miniature<br />

specimen test techniques can be broadly classified into the following categories: (a) <strong>Test</strong>s, which are based on<br />

miniaturization or scaling down <strong>of</strong> conventional specimen size (like miniature tensile, fatigue, impact and fracture<br />

toughness tests) (b) <strong>Test</strong>s that are based on novel techniques using disk sized specimens <strong>of</strong> approximately 0.3 mm<br />

thickness (like disk bend tests, shear punch / small punch tests). (c) <strong>Techniques</strong> based on ball-indentation (BI) testing.<br />

GENERAL EXPLANATION RELATED TO THE DESCRIPTION<br />

The small specimen test techniques like disk specimen tests (shear punch,<br />

small punch) and ball-indentation tests do not have equivalent<br />

conventional counterparts. These novel test techniques need to be first<br />

validated and benchmarked before being effectively put to use. The<br />

methodology adopted at IGCAR is to first carry out experiments which<br />

involve performing both conventional and small specimen tests on various<br />

simulated heats <strong>of</strong> widely ranging microstructures and mechanical<br />

properties prepared from the alloy <strong>of</strong> interest. The data from the small<br />

specimen test technique is analyzed, compared and correlated with the<br />

corresponding conventional test properties. For an unknown condition <strong>of</strong><br />

the alloy, using the small specimen test and the correlations derived, the<br />

conventional properties <strong>of</strong> the bulk material are obtained.<br />

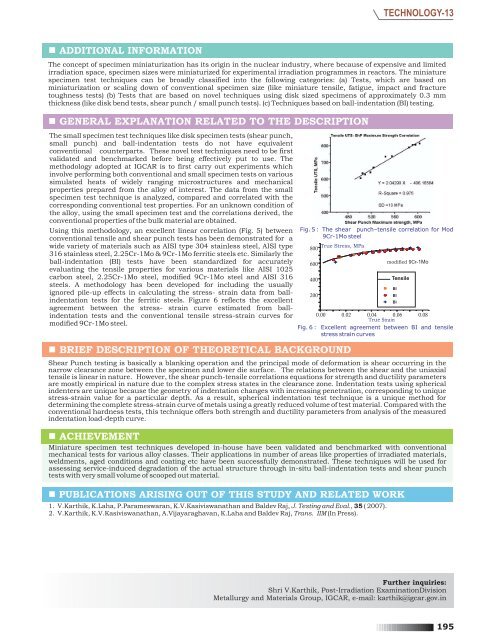

Using this methodology, an excellent linear correlation (Fig. 5) between Fig. 5 : The shear punch–tensile correlation for Mod<br />

conventional tensile and shear punch tests has been demonstrated for a<br />

9Cr-1Mo steel<br />

wide variety <strong>of</strong> materials such as AISI type 304 stainless steel, AISI type 800<br />

True Stress, MPa<br />

316 stainless steel, 2.25Cr-1Mo & 9Cr-1Mo ferritic steels etc. Similarly the<br />

ball-indentation (BI) tests have been standardized for accurately 600<br />

modified 9Cr-1Mo<br />

evaluating the tensile properties for various materials like AISI 1025<br />

carbon steel, 2.25Cr-1Mo steel, modified 9Cr-1Mo steel and AISI 316 400<br />

Mod 9Cr- Tensile<br />

1Mo<br />

steels. A methodology has been developed for including the usually<br />

Tensile<br />

BI<br />

ignored pile-up effects in calculating the stress- strain data from ballindentation<br />

tests for the ferritic steels. Figure 6 reflects the excellent<br />

BI<br />

200<br />

BI<br />

BI<br />

agreement between the stress- strain curve estimated from ballindentation<br />

tests and the conventional tensile stress-strain curves for 0.00 0.02 0.04 0.06 0.08<br />

True Strain<br />

modified 9Cr-1Mo steel.<br />

Fig. 6 : Excellent agreement between BI and tensile<br />

stress strain curves<br />

BRIEF DESCRIPTION OF THEORETICAL BACKGROUND<br />

Shear Punch testing is basically a blanking operation and the principal mode <strong>of</strong> deformation is shear occurring in the<br />

narrow clearance zone between the specimen and lower die surface. The relations between the shear and the uniaxial<br />

tensile is linear in nature. However, the shear punch-tensile correlations equations for strength and ductility parameters<br />

are mostly empirical in nature due to the complex stress states in the clearance zone. Indentation tests using spherical<br />

indenters are unique because the geometry <strong>of</strong> indentation changes with increasing penetration, corresponding to unique<br />

stress-strain value for a particular depth. As a result, spherical indentation test technique is a unique method for<br />

determining the complete stress-strain curve <strong>of</strong> metals using a greatly reduced volume <strong>of</strong> test material. Compared with the<br />

conventional hardness tests, this technique <strong>of</strong>fers both strength and ductility parameters from analysis <strong>of</strong> the measured<br />

indentation load-depth curve.<br />

ACHIEVEMENT<br />

<strong>Miniature</strong> specimen test techniques developed in-house have been validated and benchmarked with conventional<br />

mechanical tests for various alloy classes. Their applications in number <strong>of</strong> areas like properties <strong>of</strong> irradiated materials,<br />

weldments, aged conditions and coating etc have been successfully demonstrated. These techniques will be used for<br />

assessing service-induced degradation <strong>of</strong> the actual structure through in-situ ball-indentation tests and shear punch<br />

tests with very small volume <strong>of</strong> scooped out material.<br />

PUBLICATIONS ARISING OUT OF THIS STUDY AND RELATED WORK<br />

1. V.Karthik, K.Laha, P.Parameswaran, K.V.Kasiviswanathan and Baldev Raj, J. <strong>Test</strong>ing and Eval. , 35 ( 2007).<br />

2. V.Karthik, K.V.Kasiviswanathan, A.Vijayaraghavan, K.Laha and Baldev Raj, Trans. IIM (In Press).<br />

Further inquiries:<br />

Shri V.Karthik, Post-Irradiation ExaminationDivision<br />

Metallurgy and Materials Group, IGCAR, e-mail: karthik@igcar.gov.in<br />

195