Glossary and Abbreviations - Unido

Glossary and Abbreviations - Unido

Glossary and Abbreviations - Unido

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

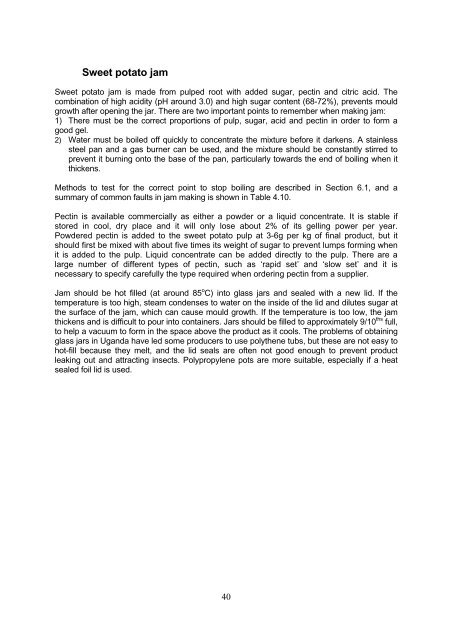

Sweet potato jam<br />

Sweet potato jam is made from pulped root with added sugar, pectin <strong>and</strong> citric acid. The<br />

combination of high acidity (pH around 3.0) <strong>and</strong> high sugar content (68-72%), prevents mould<br />

growth after opening the jar. There are two important points to remember when making jam:<br />

1) There must be the correct proportions of pulp, sugar, acid <strong>and</strong> pectin in order to form a<br />

good gel.<br />

2) Water must be boiled off quickly to concentrate the mixture before it darkens. A stainless<br />

steel pan <strong>and</strong> a gas burner can be used, <strong>and</strong> the mixture should be constantly stirred to<br />

prevent it burning onto the base of the pan, particularly towards the end of boiling when it<br />

thickens.<br />

Methods to test for the correct point to stop boiling are described in Section 6.1, <strong>and</strong> a<br />

summary of common faults in jam making is shown in Table 4.10.<br />

Pectin is available commercially as either a powder or a liquid concentrate. It is stable if<br />

stored in cool, dry place <strong>and</strong> it will only lose about 2% of its gelling power per year.<br />

Powdered pectin is added to the sweet potato pulp at 3-6g per kg of final product, but it<br />

should first be mixed with about five times its weight of sugar to prevent lumps forming when<br />

it is added to the pulp. Liquid concentrate can be added directly to the pulp. There are a<br />

large number of different types of pectin, such as ‘rapid set’ <strong>and</strong> ‘slow set’ <strong>and</strong> it is<br />

necessary to specify carefully the type required when ordering pectin from a supplier.<br />

Jam should be hot filled (at around 85 o C) into glass jars <strong>and</strong> sealed with a new lid. If the<br />

temperature is too high, steam condenses to water on the inside of the lid <strong>and</strong> dilutes sugar at<br />

the surface of the jam, which can cause mould growth. If the temperature is too low, the jam<br />

thickens <strong>and</strong> is difficult to pour into containers. Jars should be filled to approximately 9/10 ths full,<br />

to help a vacuum to form in the space above the product as it cools. The problems of obtaining<br />

glass jars in Ug<strong>and</strong>a have led some producers to use polythene tubs, but these are not easy to<br />

hot-fill because they melt, <strong>and</strong> the lid seals are often not good enough to prevent product<br />

leaking out <strong>and</strong> attracting insects. Polypropylene pots are more suitable, especially if a heat<br />

sealed foil lid is used.<br />

40