Glossary and Abbreviations - Unido

Glossary and Abbreviations - Unido

Glossary and Abbreviations - Unido

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Jam thermometers<br />

This is a special thermometer that has readings up to 120 o C <strong>and</strong> is strengthened to<br />

withst<strong>and</strong> sudden changes in temperature. It is inserted into boiling jam <strong>and</strong> the reading is<br />

used to determine when to stop boiling (Section 4.6). There are no spare parts or<br />

maintenance required. The thermometer should be cleaned by wiping it with a cloth when<br />

cool, <strong>and</strong> rinsing it in clean water. It should be stored in its protective casing.<br />

Label applicators<br />

A platform holds a stack of labels below an opening in the table, with the top label level with<br />

the surface. Glue is applied to the label <strong>and</strong> a round container is rolled over the opening <strong>and</strong><br />

the label is picked up <strong>and</strong> pressed onto the container. The guide rails ensure that the label is<br />

applied in the same position on every container. There is no maintenance <strong>and</strong> it should be<br />

wiped clean with a damp cloth after use.<br />

Laboratory glassware/equipment<br />

The laboratory equipment includes glass beakers, flasks <strong>and</strong> a burette. Glassware should<br />

be cleaned with detergent <strong>and</strong> bottle brushes, rinsed with clean water <strong>and</strong> then rinsed<br />

again with distilled water (distilled water can be obtained from vehicle servicing <strong>and</strong> spares<br />

companies, where it is used to top up batteries). There are no routine maintenance or<br />

spares required.<br />

Mills<br />

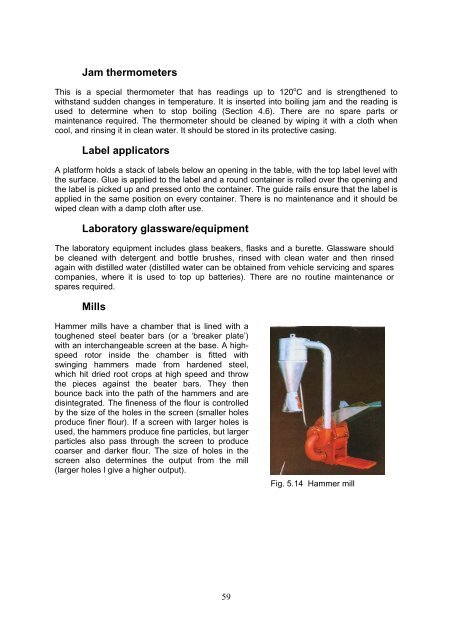

Hammer mills have a chamber that is lined with a<br />

toughened steel beater bars (or a ‘breaker plate’)<br />

with an interchangeable screen at the base. A highspeed<br />

rotor inside the chamber is fitted with<br />

swinging hammers made from hardened steel,<br />

which hit dried root crops at high speed <strong>and</strong> throw<br />

the pieces against the beater bars. They then<br />

bounce back into the path of the hammers <strong>and</strong> are<br />

disintegrated. The fineness of the flour is controlled<br />

by the size of the holes in the screen (smaller holes<br />

produce finer flour). If a screen with larger holes is<br />

used, the hammers produce fine particles, but larger<br />

particles also pass through the screen to produce<br />

coarser <strong>and</strong> darker flour. The size of holes in the<br />

screen also determines the output from the mill<br />

(larger holes l give a higher output).<br />

Fig. 5.14 Hammer mill<br />

59