Contents / General Description / Carter WGD 2

Contents / General Description / Carter WGD 2

Contents / General Description / Carter WGD 2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6B-12 1955 PONTIAC SHOP MANUAL<br />

PUMP JET CLUSTER<br />

BODY TO FLANGE ATTACHING SCREWS<br />

VACUMETER SPRING<br />

METERING ROD JETS<br />

EXHAUST GAS PASSAGE<br />

THROTTLE SHAFT ARM<br />

BODY TO FLANGE SCREWS<br />

SCREW<br />

Fig. 6B-21<br />

Carburetor Bowl Assembly-<strong>Carter</strong><br />

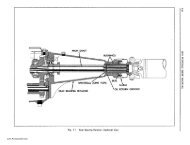

Fig. 6B-22<br />

Throttle Flange Assembly-<strong>Carter</strong><br />

DISASSEMBLY OF THROTTLE FLANGE<br />

1. Remove four throttle flange attaching screws<br />

to separate the carburetor body from flange, and remove<br />

gasket (fig. 6B-22).<br />

2. Remove idle mixture adjusting screws and<br />

springs.<br />

NOTE: Under normal service the carburetor flange<br />

may be cleaned without further disassembly. If complete<br />

disassembly is necessary, perform the remaining<br />

operations.<br />

3. Remove throttle shaft arm attaching screw,<br />

washer and throttle shaft arm (Fig. 6B-22).<br />

4. File off staked ends of throttle valve attaching<br />

screws and remove screws and throttle valves.<br />

5. Remove shaft from throttle flange.<br />

CLEANING AND INSPECTION OF PARTS<br />

Dirt, gum, water or carbon contamination in or on<br />

the exterior moving parts of a carburetor are often<br />

responsible for unsatisfactory performance. For this<br />

reason, efficient carburetion depends upon careful<br />

cleaning and inspection while servicing.<br />

1. Thoroughly clean carburetor castings and all<br />

metal parts in clean cleaning solvent. CAUTION:<br />

Composition and plastic parts such as thermostatic<br />

coil housing and pump plunger should not be immersed<br />

in solvent. DO NOT SOAK AIR HORN<br />

ASSEMBLY IN CLEANER OR SOLVENT FOR<br />

MORE THAN ONE HALF HOUR IF CHOKE<br />

PISTON HOUSING HAS NOT BEEN REMOVED.<br />

2. Blowout all passages in castings with compressed<br />

air and blow off all parts so they are free<br />

of solvent. CAUTION: Do not use drills or wire to<br />

clean out jets or parts as this may enlarge the<br />

opening and affect carburetor operation.<br />

3. Carefully inspect parts for wear and replace<br />

those which are worn. Check the following specific<br />

points:<br />

a. Carefully note the condition of slots in the<br />

choke piston cylinder. If they are found to be<br />

carbonized, remove Welch plug in the bottom of the<br />

climatic control housing by piercing center with a<br />

small pointed instrument and prying outward. Care<br />

should be exercised so that damage will not result<br />

to the casting when removing this plug. Before installing<br />

new plug, carbon present in piston cylinder<br />

slots should be removed and the Welch plug seat<br />

should be carefully cleaned.<br />

b. Remove carbon from bores of flange with sandpaper;<br />

never use emery cloth.<br />

c. Remove carbon from hot air passage in base<br />

of flange (Fig. 6B-22) and from mating holes in<br />

intake manifold.<br />

d. See if needle or seat is worn; if so, both must<br />

be replaced.<br />

www.PontiacSafari.com