Free download - Vinnova

Free download - Vinnova

Free download - Vinnova

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Swedish research for growth<br />

A VINNOVA MAGAZINE<br />

A NEW GENERATION CARS • STRONGER SWEDISH STEEL • MEET PROFESSOR MATHIAS UHLÉN<br />

VINNOVA INFORMATION VI 2005:08

Facts and figures about Sweden. Did you know that...?<br />

Sweden is recognized as one of the world’s most knowledgebased<br />

and innovative economies. Around 4 per cent of GDP<br />

is spent on R&D, of which the government accounts for 1<br />

per cent and industry the remaining 3 per cent.<br />

The Nobel Prize, which was founded by Alfred Nobel, the<br />

inventor of dynamite, is awarded every year for innovations<br />

and discoveries that have conferred “the greatest benefit<br />

on mankind” in physics, chemistry, medicine, literature and<br />

peace.<br />

ABB, AstraZeneca, Autoliv, Electrolux, Ericsson, Saab, Scania,<br />

Securitas, Sandvik, Tetra Pak, Volvo, IKEA and H&M are all<br />

wholly or partly owned Swedish multinational corporations.<br />

In 1959 Volvo introduced the 3-point safety belt, which is<br />

now saving a life every six minutes and is regarded as one of<br />

the most important road safety innovations ever. The curtain<br />

airbag and the Autoliv’s anti-whiplash system are other Swedish<br />

inventions.<br />

Swedish medical inventions include improvements in local<br />

anaesthesia, improvements in intravenous nutrition, the<br />

pacemaker, ultrasound, the gamma knife, beta blockers and<br />

Losec, the anti-ulcer drug. In recent years Losec has been<br />

the world’s best-selling pharmaceutical product.<br />

85 per cent of the population of Sweden had access to 3G<br />

services in January 2005, the highest figure in Europe. The<br />

NMT, GSM, GPRS, WCDMA and Bluetooth wireless standards<br />

all originated in Sweden.<br />

Sweden came third (after the US and Finland) in the World<br />

Economic Forum’s 2004 world ranking, both in terms of<br />

international competitiveness and growth prospects.<br />

The Swedish corporate tax rate, 28 per cent, is low by international<br />

comparison and significantly lower than the rates in<br />

most other European countries.<br />

Sweden is one of the world’s largest recipients of foreign direct<br />

investment. In the last ten years the number of foreignowned<br />

companies has risen from 2,500 to 10,000. The<br />

largest foreign investors during the last five years were the<br />

UK, Germany, the US, Finland, the Netherlands and Norway.<br />

Swedish exports account for nearly 50 per cent of GDP.<br />

Traditional industries such as forest products, mining and<br />

engineering (including the automotive industry, electrical<br />

goods and telecom) account for a substantial proportion of<br />

export revenues.<br />

Håkan Lans is a Swedish inventor. His inventions include the<br />

computer colour graphics and the GP & C satellite navigation<br />

system, which is the international standard in shipping and<br />

civilian aviation today.<br />

VINNOVA, the Swedish Governmental Agency<br />

for Innovation Systems, integrates research,<br />

development and innovation.<br />

VINNOVA’s mission is to promote sustainable<br />

growth by funding needs-driven research<br />

and developing effective innovation systems.<br />

Through its activities in this field, VINNOVA<br />

aims to make a significant contribution to<br />

Sweden’s development into a leading knowledge<br />

based economy.<br />

Postal address:<br />

VINNOVA, SE-101 58 Stockholm, Sweden<br />

Street address:<br />

Mäster Samuelsgatan 56<br />

Phone: +46 8473 3000<br />

Fax:+46 8473 3005<br />

E-mail: VINNOVA@VINNOVA.se<br />

www.VINNOVA.se<br />

Publisher: Per Eriksson, GD<br />

Editor-in-chief: Ylva Sjönell<br />

Editor: Sanna Berg<br />

Copy: Håkan Borgström, Andreas Nilsson,<br />

Per Westergård<br />

Form & Layout: Mårten Pien<br />

Production: Capito AB<br />

Printed by: EO print<br />

Printed on environment-friendly paper<br />

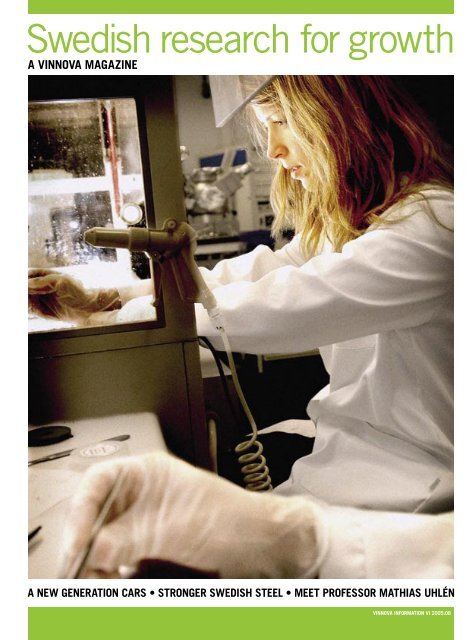

Cover: Advanced production of nanothreads<br />

in semiconductor materials could<br />

generate new Swedish export successes.<br />

Mikael Björk and Ann Persson have<br />

made path-breaking discoveries that may<br />

result in new electronic components and<br />

medical sensors.<br />

Cover photograph and page 23: Marcus Erixson<br />

Other photographs: Pressens bild: page 5, 14, 24.<br />

Anette Andersson: page 6, 7, 10, 11, 12, 13, 14.<br />

Niclas Kindahl, Acreo AB: page 21. Per Westergård:<br />

page 8, 15, 16, 26, 27, 28. Diamorph Magnetic:<br />

page 15. Martinson Group AB: page 17. Scandlines:<br />

page 20. Gunnar Ledfelt, KTH: page 21.<br />

Håkan Lindgren, KTH: page 22.<br />

ISSN 1650-3120<br />

2 | V I N N O V A M A G A Z I N E

4<br />

4<br />

6<br />

7<br />

9<br />

12<br />

14<br />

15<br />

Small country – strong research<br />

Mathias Uhlén<br />

The art of commercializing research<br />

Swedish research is the key to growth<br />

Three examples<br />

How to become a leader in the vehicle safety industry<br />

Whiplash research has generated billions of euros in<br />

socioeconomic benefits<br />

Cooperation promotes high-tech primary industries<br />

Sweden’s mines, steelworks and paper mills are among the most<br />

technologically advanced in the world<br />

Interdisciplinary collaboration produces sensitive sensors<br />

Gas sensors will make diesel engines cleaner by measuring emissions<br />

in the hot exhaust gases themselves<br />

The branding of a nation<br />

By Simon Anholt, regarded as a leading specialist in creating<br />

brand strategies for countries, cities and regions<br />

Smooth cooperation at ABB<br />

Charlotte Brogren, Vice President of Technology at ABB Robotics<br />

15<br />

contents<br />

16<br />

26<br />

Towards the future<br />

Three examples of strategic areas<br />

16<br />

17<br />

18<br />

19<br />

22<br />

24<br />

26<br />

27<br />

Security research creates growth<br />

Research in this area promotes Swedish exports of<br />

security products<br />

Wood – a high-tech sunrise industry<br />

Wood is processed in order to produce higher-value<br />

products<br />

Knowledge-based biotechnology industry<br />

Collaboration between central government, higher<br />

education and trade unions<br />

Good ideas receive support<br />

Producing packaging from waste<br />

A camera that sees through the skin<br />

Air streams conquer the world<br />

The cradle of Swedish growth<br />

High-quality research – an essential condition<br />

for growth<br />

Global market for small enterprises<br />

Encouraging SMEs’ research activites<br />

Small country – large car industry<br />

Building a new hybrid ethanol-electric car<br />

Useful contacts<br />

V I N N O V A M A G A Z I N E | 3

EDITORIAL<br />

SMALL COUNTRY – STRONG RESEARCH<br />

Sweden has developed a strong<br />

research system over the years<br />

which has played an important part<br />

in our growth and prosperity. As a<br />

small country we have to trade in<br />

the international marketplace in order<br />

to survive. Close public-private<br />

partnership is a tradition in Sweden.<br />

This is one of the reasons for<br />

our high economic growth and our<br />

ability to develop large companies<br />

that play a major role in a globalized<br />

world.<br />

The last ten years have seen a<br />

shift in Sweden from a public-private<br />

partnership to a public-privateuniversity<br />

partnership, i.e. “triple<br />

helix cooperation”. This is also what<br />

drives VINNOVA, the Swedish Governmental<br />

Agency for Innovation<br />

Systems. Our mission is to invest in<br />

problem-oriented research and the<br />

development of effective innovation<br />

systems. We do this through a<br />

systematic approach to research,<br />

innovation and growth.<br />

This magazine offers some examples<br />

of the kind of research and<br />

innovation being done in Sweden<br />

with VINNOVA’s support and of how<br />

these activities promote present<br />

and future growth in Sweden. The<br />

examples show that we are active<br />

partners in various types of triple<br />

helix projects whose aim is to<br />

strengthen R&D based on effective<br />

innovation systems.<br />

Per Eriksson<br />

Director-General<br />

Karin Markides,<br />

Vice Director-General<br />

The art of<br />

commercializing<br />

research<br />

He is one of Sweden’s leading researchers<br />

and is making history by mapping human<br />

proteins. At the same time Mathias Uhlén<br />

is very keen on commercializing his<br />

ideas – a recipe for exports and growth.<br />

THERE IS OF COURSE nothing to say<br />

that a person cannot be both an outstanding<br />

researcher and a successful<br />

entrepreneur. Nonetheless, very few<br />

people make the grade in both fields.<br />

In both cases you have to be among the<br />

best if you are going to get anywhere.<br />

Mathias Uhlén is the kind of citizen<br />

that every country dreams about.<br />

He has been engaged in world-class<br />

research for two decades now and has<br />

also started a number of successful<br />

biotechnology companies. The project<br />

he is leading at the moment comprises<br />

both these activities: he is carrying out a<br />

comprehensive mapping of human proteins.<br />

The project is being carried out<br />

at the Royal Institute of Technology,<br />

Stockholm. He has himself developed<br />

and commercialized many of the tools<br />

that make this gigantic task possible.<br />

Several groups of young researchers<br />

are working on different stages of the<br />

mapping process in Mathias Uhlén’s<br />

well-lit laboratory. They manage about<br />

10 proteins a day.<br />

– Within the space of a few fleeting<br />

years we will be revealing<br />

some of the most basic<br />

information about human<br />

beings. Being involved in<br />

this is absolutely fascinating<br />

and to us medical researchers<br />

it is like landing<br />

on the moon.<br />

Sweden has a long<br />

tradition of successful<br />

protein research. Swedish<br />

technology is used for about half the<br />

protein analysis done all over the world.<br />

Mathias Uhlén has contributed to this.<br />

He took out his first patent as a young<br />

research student over 20 years ago and<br />

has created protein analysis tools that<br />

generate Swedish export earnings worth<br />

tens of millions of euros every year.<br />

Mathias Uhlén often has the pleasant<br />

task of trying to explain to admiring<br />

colleagues or research funders why Sweden<br />

has so many successful companies.<br />

– There is a high level of knowhow<br />

here and we are receptive to new<br />

technologies. This sets its stamp on<br />

both research and industry. For several<br />

decades, moreover, Sweden has had<br />

political leaders who have realized the<br />

importance of serious investment in<br />

research and education generally.<br />

There is keen international competition,<br />

however. Mathias Uhlén says that<br />

he is eagerly following the world’s two<br />

strongest economies: the USA, which<br />

is becoming increasingly cautious when<br />

it comes to publishing biotechnology<br />

research findings, and China, which<br />

is driven by<br />

boundless<br />

confidence in<br />

the future. The<br />

The mapping of the<br />

body’s building blocks<br />

is based on small antibodies<br />

that can capture<br />

and identify specific<br />

proteins in tissue samples.<br />

4 | V I N N O V A M A G A Z I N E

Swedish protein research proved to be a great commercial success. Mathias Uhlén regards collaboration between industry and academia as an<br />

essential condition for growth. Here Mathias demonstrates a detail to Swedish Minister for Education, Research and Culture Leif Pagrotsky.<br />

recipe for Europe is to develop an effective<br />

research funding system that can<br />

meet a variety of requirements.<br />

– We need to go in for breadth, so as<br />

to have a broad scientific base, and for<br />

excellence, so that we can support largescale<br />

projects that require a concentration<br />

of resources. No country can afford<br />

not to support applied research today. All<br />

investment in this sector pays off handsomely<br />

in our export earnings.<br />

Apart from breadth, excellence and<br />

applied research there is, according to<br />

Mathias Uhlén, a fourth component in<br />

European growth – support for innovations.<br />

Sweden has an advantage here<br />

compared with many other countries,<br />

MAPPING THE BODY’S BUILDING BLOCKS<br />

since researchers in Sweden can take<br />

out patents on their innovations. The<br />

result is a very simple and unbureaucratic<br />

system, says Mathias Uhlén.<br />

HE HAS HIMSELF been involved in<br />

about 70 patent applications and has set<br />

up companies in fields as different as<br />

DNA sequencing and research into the<br />

biology and biochemistry of trees. One<br />

thing about commercializing research<br />

findings that he has learned over the<br />

years is the vital importance of picking<br />

the right product.<br />

– The crucial thing is to position<br />

yourself so that you are best in the<br />

world. It is not enough for a Swedish<br />

Human Protein Resource is a unique<br />

scientific project that involves mapping<br />

human proteins. The researchers<br />

in Stockholm are investigating the<br />

22,000 proteins that represent the<br />

body’s building blocks and improving<br />

our basic understanding of the biology<br />

of the human body.<br />

The objective of the project is to create<br />

an atlas of all the proteins that are<br />

active in human cells. This information<br />

is published continuously on the Internet<br />

and made available to researchers<br />

all over the world. About 800 proteins<br />

and half a million tissue images are<br />

added to the database every six months.<br />

All in all, the project is expected to<br />

produce about three million images<br />

company to be as good as an American<br />

competitor, since the USA is an enormous<br />

domestic market. You simply have<br />

to find a niche where you are unique.<br />

He considers Sweden a good country<br />

for research-intensive companies.<br />

– Swedes are good at teamwork, although<br />

we are sometimes a little too dependent<br />

on consensus, which can hold<br />

up decisions. But we are loyal co-workers<br />

and this is something that you really<br />

need in research-intensive companies.<br />

There is also a very laid-back relationship<br />

between universities and companies,<br />

just as there is in the USA. This is<br />

a great advantage for knowledge-driven<br />

growth.<br />

covering over 700 different types of<br />

body tissues. The proteins control<br />

the life processes in the cells, and<br />

knowledge about them can be used<br />

to improve our understanding of the<br />

progress of diseases and make the key<br />

to the development of new drugs. The<br />

project is funded by the Knut and Alice<br />

Wallenberg Foundation.<br />

V I N N O V A M A G A Z I N E | 5

SWEDISH RESEARCH IS THE KEY TO GROWTH<br />

It is no longer merely a question of statistics.<br />

More and more examples show<br />

that funds allocated to research and<br />

development stimulate growth in society<br />

as a whole. Research is a growth factor<br />

of strategic importance to industry. But<br />

smooth cooperation between academia<br />

and industry is also an important factor<br />

for the development of society as a<br />

whole.<br />

The Whiplash research carried out<br />

at Chalmers University of Technology<br />

in Gothenburg is one example of how<br />

basic research – conducted in cooperation<br />

with industry and public actors<br />

– saves many millions of euros in<br />

public spending.<br />

The shift towards sustainable development<br />

is one of the great challenges<br />

of our time. It could prove a powerful<br />

driver of growth, either by boosting environmental<br />

engineering or by encouraging<br />

energy conservation. The ProcessIT<br />

project is a good example of this. Better<br />

process monitoring, integration of IT<br />

systems and a number of other functions<br />

create economic growth.<br />

The project has built up a world-class research<br />

and innovation environment that<br />

is based on close interaction between<br />

academia, industry and public actors.<br />

The solutions it produces will be used in<br />

a variety of sectors, such as the chemical<br />

industry, paper manufacturing and<br />

engineering industries. One successful<br />

subproject is concerned with optimizing<br />

mining infrastructure, which should<br />

save millions of euros every year.<br />

Innovation, entrepreneurship and<br />

generation of new knowledge are important<br />

factors for growth. Sweden is<br />

among the biggest investors in research<br />

and development and is also one of the<br />

countries with the highest innovative<br />

capacity. The aim of these investments is<br />

to create new products and companies.<br />

The road to success usually starts with<br />

research strategies that focus on the<br />

interaction between academia and industry.<br />

One example is S-SENCE, the Swedish<br />

Sensor Centre in Linköping. This<br />

centre represents one of the first Swedish<br />

efforts to establish a strong research environment<br />

in which industry’s needs and<br />

interests play an important part.<br />

Here follows a more detailed presentation<br />

of the above three examples<br />

of how research stimulates growth in<br />

Sweden.<br />

6 | V I N N O V A M A G A Z I N E

INNOVATIVE THINKING<br />

Sweden became a world leader in neck<br />

injury research after new theories were<br />

presented in the mid-1980s about the way<br />

whiplash injuries are caused. This research<br />

is currently led by Professor Per Lövsund<br />

at Chalmers University of Technology.<br />

How to become a leader in<br />

the vehicle safety industry<br />

Whiplash research has generated billions of euros in<br />

socioeconomic benefits. In addition, Swedish companies have<br />

achieved great success in the export market for these products.<br />

ONE COLD WINTER day in Stockholm<br />

Gunilla Sogell was on her way home<br />

from work as usual. Her car suddenly<br />

skidded on Lidingö bridge outside<br />

Stockholm and crashed into the bridge<br />

railing at 70 kph. Her head flew backwards<br />

and forwards like a whiplash. The<br />

neck is exposed to enormous forces in<br />

such a collision. It can be stretched by<br />

as much as 5 centimetres. Vertebrae can<br />

be dislocated, discs slipped and ligaments<br />

stretched and ruptured. Most of<br />

these injuries are more or less invisible.<br />

The years following the accident were<br />

a nightmare. At most, she was taking<br />

23 painkillers a day, apart from sleeping<br />

medicine and anti-inflammatory and<br />

anti-depressive pills.<br />

– Two years after the accident I didn’t<br />

want to live any more. I was so frustrated<br />

at not being able to work as usual.<br />

You see, there are no visible signs that<br />

you are injured, she says.<br />

A MEDICAL MYSTERY<br />

Per Lövsund, Professor of Traffic Safety<br />

at Chalmers University of Technology,<br />

has studied whiplash injuries for many<br />

years. He says that about 2,000 people<br />

are disabled every year in Sweden as a<br />

result of neck injuries. These injuries are<br />

on the increase and cost society several<br />

million euros every year, mostly in compensation<br />

for loss of income.<br />

But there is hope. Today, Sweden is a<br />

world leader in the field of neck injury<br />

research, for which Per Lövsund is now<br />

responsible.<br />

– Rather modest public investment<br />

has yielded a good return, he says.<br />

According to Per Lövsund, this<br />

success is largely due to cooperation<br />

between industry, research and society.<br />

His research team has already achieved<br />

remarkable results. For example, not a<br />

V I N N O V A M A G A Z I N E | 7

‘ The industry has even been enthusiastic about our<br />

long-term research, which is not so common in a<br />

world where everyone wants to see results fast.’<br />

single car is produced today without<br />

airbags, curtain airbags or specially<br />

designed seats.<br />

– The whiplash protection that has<br />

been built into all Volvo and Saab cars<br />

since 1997 has reduced the risk of neck<br />

injuries by at least 50 per cent in connection<br />

with serious accidents, he says. This<br />

is the result of many years’ research.<br />

– We have gone all the way from basic<br />

to applied research. The industry has<br />

even been enthusiastic about our longterm<br />

research, which is not so common<br />

in a world where everyone wants to see<br />

results fast.<br />

ADVANCED IMPACT DUMMY<br />

The results of neck injury research<br />

include the development of a very<br />

advanced impact dummy that has been<br />

used in many studies. It can measure<br />

the stress on different joints in connection<br />

with a collision.<br />

The research team has also developed<br />

a mathematical model corresponding<br />

to the female anatomy. The reason for<br />

this is that women are injured more<br />

seriously than men in connection with<br />

rear-end collisions.<br />

– We do not know yet why this is.<br />

There is a theory that it has something<br />

to do with differences in muscle mass<br />

and nerves. We hope that new studies<br />

STUDY QUANTIFIES THE BENEFITS OF NECK INJURY RESEARCH<br />

Vehicle safety research has generated<br />

more than 500 million euro in socioeconomic<br />

benefits in the form of lower<br />

medical costs, reduced loss of income<br />

and less suffering.<br />

VINNOVA (the Swedish Governmental<br />

Agency for Innovation Systems) and its<br />

predecessor have supported neck injury<br />

research at Chalmers University of<br />

Technology ever since 1985. A vehicle<br />

research programme has enabled<br />

researchers to collaborate with Volvo<br />

and Saab and other companies on ways<br />

and means of making vehicles safer.<br />

Needs-based research has given safety<br />

developers in these companies the<br />

knowledge they need to develop new<br />

products. A study has now been made<br />

of the achievements of this research.<br />

– We ourselves were surprised at the<br />

will point us in the right direction, says<br />

Per Lövsund.<br />

– Later on, a completely new dummy<br />

will be built so that we can study angle<br />

collisions from the rear and from the<br />

front.<br />

results. The studies of collisions and<br />

injuries indicated without any doubt that<br />

serious injuries can be reduced by 50<br />

per cent. This is a direct result of measures<br />

taken as a result of the research<br />

done at Chalmers University of Technology,<br />

says Knut Sandberg Eriksen of the<br />

Institute of Transport Economy, Oslo,<br />

one of the authors of the study.<br />

The study, which was carried out in<br />

cooperation with Møre Research in<br />

Molde, Norway, found that this research<br />

benefits society in two different<br />

ways. First, it benefits ordinary citizens<br />

by making vehicles safer in connection<br />

with rear-end collisions. Second, it<br />

benefits Swedish industry by increasing<br />

exports of these products or vehicles<br />

that include them.<br />

8 | V I N N O V A M A G A Z I N E

INNOVATIVE THINKING<br />

SVENSK INDUSTRIS INNOVATIVA FRAMSTEG<br />

Cooperation promotes hightech<br />

primary industries<br />

Sweden’s mines, steelworks and paper mills are among the most<br />

technologically advanced in the world. But they must become<br />

even more efficient if they are to be profitable in the future.<br />

HERE IS A SUCCESSFUL example in the<br />

north of Sweden of how primary industries<br />

can collaborate with universities to<br />

secure economic growth and create new<br />

jobs in small technology-based companies.<br />

Ore mining in the LKAB Group’s<br />

mines in Kiruna and Malmberget is carried<br />

out nowadays by means of remotecontrolled<br />

machinery about 1 kilometre<br />

underground. The cost per tonne of<br />

ore mined has been reduced by 3 per<br />

cent per year in the last few decades.<br />

As a result, twice as much ore is now<br />

mined by only half as many employees,<br />

and LKAB is one of the country’s most<br />

profitable groups with profits exceeding<br />

1 billion euro and constantly increasing<br />

turnover.<br />

– If this trend is to continue, we will<br />

have to develop our processes even further<br />

so that we can extract more from<br />

the raw materials while controlling production<br />

so as to avoid bottlenecks. This<br />

will require integration of IT systems,<br />

better process monitoring and other<br />

improvements, explains Lars-Eric Aaro,<br />

Director of Research and Development.<br />

LKAB’s head office is in the centre of<br />

Luleå. The inhabitants of this prosperous<br />

city are the wealthiest in Sweden<br />

V I N N O V A M A G A Z I N E | 9

A winner of the VINNVÄXT award. Competitive companies and new jobs are the top priority for Anders OE Johansson of Luleå University<br />

of Technology, Lars-Eric Aaro, Director of Research and Development at LKAB and Mayor Karl Petersen.<br />

north of Stockholm. Mayor Karl Petersen<br />

has no doubts about the reasons for<br />

its success.<br />

– The universities and heavy industry<br />

are the backbone of the region.<br />

BROADER RESEARCH<br />

The challenges that Luleå faces are<br />

the same as in the north of Sweden as<br />

a whole – the primary industries must<br />

produce more at ever lower cost, and at<br />

the same time new, highly qualified jobs<br />

are needed. Sweden’s two northernmost<br />

counties are now cooperating within<br />

the framework of the ProcessIT project<br />

in order to achieve this goal. Anders<br />

OE Johansson of Luleå University of<br />

Technology is the project leader:<br />

GROWTH PROGRAMMES IN THE REGION<br />

The aim of the VINNVÄXT programme<br />

(Growth in regions by R&D and effective<br />

Innovation Systems) is to promote<br />

sustainable growth and international<br />

competitiveness in regions by means<br />

of needs-driven research. Another aim<br />

is to develop the innovation system so<br />

that it attains an internationally competitive<br />

level in a specific growth area.<br />

The ProcessIT project is a VINNOVA<br />

project implemented within the VINN-<br />

VÄXT framework. The participants are<br />

the authorities and universities in Umeå<br />

– We have long experience of dedicated,<br />

needs-driven research. LKAB<br />

and other industrial companies realize<br />

that they must go a step further and engage<br />

in broader research together with<br />

the universities. One of the aims of the<br />

ProcessIT project is to produce generic<br />

lessons. It must be possible to apply the<br />

technological solutions not only in mining,<br />

but also in the chemical industry,<br />

paper manufacturing and engineering<br />

industries.<br />

This opens the door for new cooperation<br />

projects in which the industries<br />

concerned support small local researchbased<br />

companies at the cutting edge of<br />

technological development. With the<br />

primary industries as customers, they<br />

and Luleå and the following companies:<br />

LKAB, Boliden, SSAB, Kappa Kraftliner<br />

and SCA.<br />

Lorentz Andersson, governor of Västerbotten<br />

county, chairs the board of<br />

the ProcessIT project.<br />

– Our aim is, together with our neighbouring<br />

county, to support cooperation<br />

between large companies and the universities.<br />

Today, the technological level<br />

in the primary industries is at least as<br />

high as in the telecom industry.<br />

Lorentz Andersson is looking even<br />

will be able to grow and create new<br />

jobs. The ProcessIT project started by<br />

carrying out an analysis of the region’s<br />

companies and their production. This<br />

generated a hundred proposals for<br />

improvements, including measurement<br />

data that will make it possible to control<br />

production chains, which are often<br />

complex, more efficiently.<br />

Close collaboration is the motto<br />

for the ProcessIT project, a winner of<br />

the VINNVÄXT award. Competitive<br />

companies and new jobs are the top<br />

priority for Mayor Karl Petersen, Lars-<br />

Eric Aaro, Director of Research and<br />

Development at LKAB, and Anders<br />

OE Johansson of Luleå University of<br />

Technology.<br />

further afield and would like to expand<br />

cooperation to the Gulf of Bothnia<br />

region as a whole.<br />

– A large proportion of Europe’s<br />

suppliers of raw materials, i.e. iron ore,<br />

steel, forest products, oil, natural gas<br />

etc., are to be found in this region.<br />

Successful companies are not only crucial<br />

to regional growth, but competitive<br />

primary industries in the north are vital<br />

to Europe as a whole.<br />

1 0 | V I N N O V A M A G A Z I N E

INNOVATIVE THINKING<br />

From steel pellets<br />

to meatballs<br />

Small balls of iron ore are one reason why the Swedish<br />

production chain from iron ore to finished quality<br />

steel is the most profitable and efficient in the world.<br />

Using pellets instead of ordinary ore makes steel<br />

production more reliable and less energy-consuming.<br />

THE CONVEYOR BELT trundles at the<br />

rate of a few metres per second towards<br />

the top of Furnace 3 at SSAB. Several<br />

thousand tonnes of ore pellets, coke and<br />

lime are poured into the 40 metre high<br />

furnace every day. After eight hours at<br />

a temperature of 2,000° C the iron minerals<br />

are converted into liquid pig iron<br />

that can be tapped from the bottom of<br />

the furnace and be worked into quality<br />

steel.<br />

THE KEY TO SUCCESS<br />

The ore pellets with a diameter of one<br />

centimetre that constitute the raw<br />

material are the key to SSAB’s success.<br />

The process in the blast furnace is<br />

complicated. It requires great precision<br />

to produce high-quality pig iron with<br />

the minimum of energy. Using pellets of<br />

a consistent quality rather than lumps<br />

of ore makes it easier to control the<br />

process, although the size and quality of<br />

the ore pellets must be checked, too.<br />

– But when we get the results of the<br />

day’s slow test the ore is already in the<br />

furnace and it is too late to change the<br />

After eight hours at a temperature<br />

of 2,000° C the iron minerals are<br />

converted into liquid pig iron.<br />

mixture of pellets, coke and slag-forming<br />

materials, explains Robert Johansson,<br />

who is a development engineer.<br />

With the help of the ProcessIT<br />

cooperation project the aim is now to<br />

measure the properties of the pellets at<br />

the same time as the furnace is charged,<br />

thus optimizing the quantity of coke in<br />

relation to the size of the pellets.<br />

– This could save several million euros<br />

a year if we were able to avoid using too<br />

much coke – having too low a temperature<br />

in the furnace might otherwise<br />

mean that we would have to stop production.<br />

John Erik Larsson is the man<br />

who will make this possible. He used to<br />

be a researcher at Luleå University of<br />

Technology and runs an optical metrology<br />

business called MBV Systems.<br />

– Using high-speed measurements<br />

we can create high-resolution threedimensional<br />

images of the pellets while<br />

they are on the conveyor belt. Advanced<br />

calculation methods then tell us the size<br />

distribution and roundness deviations,<br />

which give an indication of the quality<br />

of the pellets.<br />

Iron pellets are a rapidly growing product<br />

that is profitable both for mining and<br />

steel companies. Work is in progress on the<br />

development of a laser-based method for<br />

measuring deviations in the quality of the<br />

small pellets.<br />

FLEXIBLE SYSTEMS<br />

The ore pellets, which consist of finely<br />

ground grains of ore and various binders,<br />

are easy to handle and reduce the<br />

need for treatment steps at the steel<br />

works, explains Lars-Eric Aaro, Director<br />

of Research and Development at<br />

LKAB.<br />

– Ten years ago we only made one<br />

kind of pellet. Nowadays pellets account<br />

for more than 80 per cent of<br />

sales and we have a range of seven<br />

different types that have all been<br />

developed to meet the requirements of<br />

various customers, he says.<br />

John Erik Larsson mentions the<br />

breadth of the ProcessIT project.<br />

– The technology we develop should<br />

not be restricted to the needs of a single<br />

customer. My system can measure<br />

and monitor the quality of everything<br />

from wood chips in heating plants and<br />

pulp plants to meatballs!<br />

V I N N O V A M A G A Z I N E | 1 1

INNOVATIVE THINKING<br />

Interdisciplinary<br />

collaboration produces<br />

sensitive sensors<br />

A product no larger than a fingertip – the result of a decade of<br />

research – has the potential to break into the world auto market.<br />

The gas sensor will make diesel engines cleaner by measuring<br />

emissions in the hot exhaust gases. The tiny sensor is one result<br />

at S-SENCE, a VINNOVA-supported Competence centre.<br />

SENSORS CAN BE USED for many industrial<br />

applications. They are useful for<br />

measuring gases and liquids in many<br />

different areas, such as the food industry,<br />

water treatment, medical diagnostics and<br />

Sensors are important in a wide range of<br />

industries, from process industries to<br />

medical diagnostics, according to Tina<br />

Krantz-Rülcker.<br />

process and environmental engineering.<br />

S-SENCE has taken advantage of<br />

this. Close cooperation takes place at<br />

this Competence centre at Linköping<br />

University between researchers at the<br />

university and the development departments<br />

of the participating companies.<br />

VINNOVA is contributing 623 000 euro<br />

per year for a period of 10 years, and<br />

these funds are being matched by corresponding<br />

contributions from industry<br />

and the university. The director, Tina<br />

Krantz-Rülcker, has noted many advantages<br />

as a result of close collaboration<br />

with industry.<br />

– Companies gain access to advanced<br />

and successful research findings related<br />

to their business areas and researchers<br />

like us get the opportunity to work on<br />

topics that interest us. Thanks to our<br />

collaboration at S-SENCE we can test<br />

our research findings directly in the<br />

company’s processes!<br />

WINNING COLLABORATION<br />

Higher education benefits, too. Doctoral<br />

students may be employed by<br />

the university and work at one of the<br />

companies affiliated to the Competence<br />

centre. At the same time, industrial<br />

doctoral students who are employed by<br />

the companies can visit the academic<br />

environment, so that both groups benefit<br />

from this collaboration.<br />

One concrete example is Helena<br />

Wingbrant, who recently became the<br />

20th student at the centre to obtain her<br />

PhD. She has now completed the last<br />

tests of a new gas sensor based on heatresistant<br />

silicon carbide. It is designed<br />

to measure the hot exhaust gases in<br />

a diesel engine in order to optimize<br />

exhaust emission control.<br />

– It has been stimulating to work<br />

so close to the product development<br />

side. I have carried out measurements<br />

with sensors in the test laboratories at<br />

both Volvo in Gothenburg and Ford in<br />

Detroit.<br />

MULTIMILLION EURO AGREEMENT<br />

Per Holmberg, development manager<br />

at AppliedSensor, which paid for some<br />

of Helena Wingbrant’s research at S-<br />

SENCE, says that they are now going<br />

ahead with the patented sensor.<br />

– This demonstrates how our collaboration<br />

works – the researchers are<br />

ahead of us, but they are not in our way.<br />

We believe that the sensor has great potential<br />

in view of future stringent exhaust<br />

emission standards, for example in the<br />

USA. Now we are involved in discussions<br />

with several car manufacturers. This<br />

1 2 | V I N N O V A M A G A Z I N E

The sensor developed by researcher Helena Wingbrant, which measures exhaust emissions,<br />

has the potential to conquer the world auto market. It is the result of successful research collaboration<br />

between Linköping University and industry at the S-SENCE Competence centre.<br />

may lead to sales of millions<br />

of sensors, he says.<br />

The company has been<br />

successful in commercializing<br />

research results. A few<br />

years ago it signed an agreement<br />

with Texas Instruments<br />

worth over 50 million<br />

euro relating to another gas<br />

sensor. The sensor measures<br />

concentrations of noxious<br />

gases in vehicle ventilation systems.<br />

When these concentrations reach a<br />

certain level the sensor causes the air<br />

damper to close long before the driver<br />

has noticed anything.<br />

S-SENCE’s current success just goes<br />

to show how long the road from research<br />

to commercial product normally is.<br />

– Long-term funding has really paid<br />

off. It takes time to build up a research<br />

team with the right people and equipment.<br />

Working in a centre has also<br />

given us a strong team spirit, although<br />

we have very different backgrounds<br />

– from physics to chemistry to biology,<br />

explains Tina Krantz-Rülcker.<br />

She is now planning the future of the<br />

centre after the project in its present<br />

form comes to an end in mid-2006.<br />

Collaboration will continue in some<br />

form, and many new companies have<br />

‘Long-term funding has<br />

really paid off. It takes<br />

time to build up a research<br />

team with the right people<br />

and equipment.’<br />

joined as partners during the last year.<br />

They include NIBE, which produces<br />

heating systems, and the paper manufacturer<br />

Billerud, which apart from<br />

COMPETENCE CENTRE FOR SENSOR TECHNOLOGY<br />

S-SENCE is one of VINNOVA’s 28<br />

Competence centres for collaboration<br />

between industry and university. It is<br />

based on the Department for Applied<br />

Physics at Linköping University.<br />

S-SENCE focuses on gas and liquid<br />

sensors. These may be used to monitor<br />

processes in the food industry and<br />

rinsing water in household appliances,<br />

and also in connection with medical<br />

diagnostics and to detect narcotics<br />

and explosives. They may also be<br />

used to measure exhaust emissions<br />

the project at the centre also<br />

collaborates with Senset, a<br />

spin-off company on measurements<br />

of emissions from its<br />

paper mills.<br />

– Counter-financing from<br />

VINNOVA has naturally attracted<br />

these companies, since<br />

they have not had to pay for<br />

all the research themselves.<br />

The fact that several new<br />

partners have appeared, now that the<br />

product does not have long to go, is a<br />

sign that they believe that cooperation<br />

will continue in the future.<br />

and the quality of oil in vehicles.<br />

VINNOVA’s aim is to develop worldclass<br />

research resources at universities<br />

for the benefit of, and in cooperation<br />

with, industry. Asko Cylinda, Volvo,<br />

Ford, Billerud, AppliedSensor, Biacore,<br />

Biosensor Applications, NIBE,<br />

Senset and Tekniska Verken i Linköping<br />

AB all take an active part in the<br />

S-SCENCE Competence centre in<br />

the expectation of long-term benefits<br />

from cooperation.<br />

V I N N O V A M A G A Z I N E | 1 3

CHRONICLE<br />

THE BRANDING OF A NATION<br />

‘For a rich country,<br />

it can help update<br />

people’s perceptions,<br />

to communicate<br />

technological expertise,<br />

creativity and<br />

dynamism, alongside<br />

the images of heritage<br />

and tradition.’<br />

Nation branding is a phrase we hear<br />

very often today, and it isn’t surprising<br />

that places are trying to compete<br />

on the global market by building their<br />

brands. It’s the natural consequence<br />

of a crowded marketplace where competing<br />

‘products’ need to attract the<br />

attention of the ‘consumer’.<br />

I define nation branding as the<br />

process of aligning<br />

the policies,<br />

investments,<br />

innovations, behaviours<br />

and communications<br />

of a<br />

country around a<br />

clear strategy for<br />

achieving enhanced<br />

competitive<br />

identity.<br />

The process<br />

can add value<br />

to countries in<br />

many different<br />

ways. For a poor<br />

country, surviving on handouts and<br />

labouring under a negative ‘brand<br />

image’ of war, poverty, disease and<br />

corruption, nation branding can be<br />

a way of eliciting more than pity, of<br />

communicating that the country also<br />

offers attractive prospects for investment,<br />

export, tourism and cultural<br />

relations.<br />

For a rich country, it can help update<br />

people’s perceptions, to communicate<br />

technological expertise, creativity<br />

and dynamism, alongside the images<br />

of heritage and tradition.<br />

Whoever is doing it, true nation<br />

branding has little to do with slogans,<br />

logos or advertising.<br />

Most places ultimately<br />

get the reputation they<br />

deserve, and the only<br />

way to change it is by<br />

doing different things.<br />

This means creating<br />

a culture where every<br />

player in every sector,<br />

from policy-making to<br />

industry, from tourism<br />

to exports, strives to<br />

achieve constant innovation,<br />

implemented<br />

to impeccable international<br />

standards, but<br />

always in line with the national brand<br />

strategy. All these innovations have<br />

to prove the point about the way the<br />

country wishes to be perceived.<br />

When a country starts to practise<br />

innovation clearly guided by a common<br />

strategy, the media take notice:<br />

promotion becomes simpler and cheaper<br />

when there is always something<br />

new to say, when it is all part of the<br />

same compelling new story.<br />

The only way to acquire a reputation<br />

is by earning it, and brand strategy<br />

provides a good way of planning<br />

and aligning the change in national<br />

behaviour which ultimately leads to a<br />

better national reputation: one which<br />

is more fair, more true, and more useful<br />

to the country’s economic, social<br />

and political goals.<br />

© 2005 Simon Anholt<br />

Simon Anholt is one of the world’s leading specialists<br />

in creating brand strategies for countries,<br />

cities and regions. He is the British Government’s<br />

advisor on Public Diplomacy.<br />

Breast milk speeds up healing<br />

A refinement of an innovation at Sahlgrenska<br />

University Hospital has proved<br />

effective in speeding up wound healing<br />

and scarring. This innovation may<br />

even provide a solution to an unsolved<br />

problem that occurs in connection with<br />

operations on the abdomen. There is a<br />

risk after such operations of the intestines<br />

growing together with the healing<br />

surface. This restricts mobility in the<br />

abdomen and causes ileus, which is<br />

very painful. Breast milk may provide<br />

a solution to the problem. It contains<br />

lactoferrin, a protein that regulates and<br />

strengthens the immunological defence<br />

mechanisms of babies. A peptide (a<br />

string of amino acids) that helps operation<br />

wounds to heal has been identified<br />

and isolated. A group of entrepreneurs<br />

have refined this patented innovation<br />

and established a company called PharmaSurgics.<br />

A material with extreme properties<br />

A fantastic new material – MAX – can be<br />

used instead of gold in the manufacture of<br />

electrical components. MAX has low friction,<br />

low resistance, high heat resistance<br />

and high abrasive resistance, which makes<br />

it suitable as an alloy. Apart from that, it<br />

is cheap: gold costs 12,500 euro per kg,<br />

while MAX costs 36 euro per kg.<br />

Thin film made from MAX has been<br />

produced by the Impact Coatings company<br />

in Linköping in cooperation with ABB,<br />

Sandvik Kanthal, Uppsala University and<br />

Linköping University. The role of Impact<br />

Coatings was to scale up laboratory experiments<br />

and develop a mass production<br />

process.<br />

The object of the project was to industrialize<br />

a completely new nanomaterial<br />

consisting of three elements (titanium,<br />

silicon and carbon). In no time at all this<br />

work has made Sweden a leader in this<br />

field. The whole value chain is here, from<br />

basic materials science to know-how<br />

1 4 | V I N N O V A M A G A Z I N E

INTERVIEW<br />

Smooth cooperation<br />

at ABB<br />

No country with such a small population<br />

has produced so many complex<br />

products.<br />

– It’s not that we are smarter than<br />

anybody else. Sweden’s advantage<br />

is that we have long experience of<br />

developing technical systems, says<br />

Charlotte Brogren, Vice President of<br />

Technology at ABB Robotics.<br />

– But competition in a globalized<br />

world is becoming keener all the time.<br />

That is why Sweden must concentrate<br />

on areas where we already possess<br />

advanced know-how.<br />

ABB’s product portfolio is full of robots<br />

and power transmission products.<br />

Superficially, it looks like old technology,<br />

but the customers’ constantly<br />

changing wishes create an environment<br />

of continuous change. In order<br />

to succeed, ABB is engaged in close<br />

cooperation with researchers at many<br />

universities all over the world.<br />

– It is thanks to our contacts with<br />

The Linköping and Lund universities<br />

of technology that we are successful<br />

robot manufacturers today.<br />

CORE AREAS<br />

According to Charlotte Brogren, cooperation<br />

with Swedish researchers is<br />

smooth, direct and unbureaucratic. But<br />

relations with some foreign universities<br />

are more complicated, and regulations<br />

make it more difficult to conduct joint<br />

research projects with them.<br />

Although ABB only sells 3 per cent of<br />

its products in Sweden, almost a third<br />

of all research is done in this country.<br />

– We continuously evaluate where<br />

we can get the best value for our<br />

research grants. So far, our Swedish<br />

partners hold their own. But we cannot<br />

live on our past successes. Sweden’s<br />

future growth lies in our core areas,<br />

automation and power transmission,<br />

but also in the telecom, vehicle and<br />

process industries. All these areas<br />

require broad experience of technically<br />

complicated system solutions.<br />

about processes and production equipment<br />

to finished applications. Apart from<br />

having a market worth many millions of<br />

euros for its thin film processes using<br />

MAX, the company also intends to sell<br />

complete production plants.<br />

A new superglass<br />

Innovations are not always planned.<br />

Diamorph in Stockholm started with a<br />

failed experiment. This gave rise to a new<br />

superglass that is extremely hard, impactresistant<br />

and with a refraction index on a<br />

par with diamonds. Saeid Esmaeilzadeh<br />

is a researcher at the Department of Inorganic<br />

Chemistry at Stockholm University.<br />

Two years ago he was studying silicon<br />

nitride ceramics. Silicon nitride and<br />

additives were melted in his experiments<br />

at high temperature and were then set to<br />

cool at a controlled rate so that crystals<br />

were formed from the melt. But one<br />

night something unforeseen occurred.<br />

They usually work with melts at a<br />

temperature of 1,500 to 2,000° C and<br />

always keep the coolant connected to<br />

the kilns. In the middle of the night the<br />

cooling system broke down, the kiln was<br />

automatically shut down and the melt<br />

cooled much faster than usual. When<br />

Saeid examined the sample it was not<br />

crystalline but glass, with very interesting<br />

properties. It was the hardest silicate<br />

glass that has ever been produced. In<br />

addition, it has an extremely high refraction<br />

index, virtually the same as that<br />

for diamonds. It can be endowed with<br />

magnetic properties by adding high concentrations<br />

of various metals. Apart from<br />

all this, it can be produced by means of<br />

a simple process technology. The innovation<br />

has got to the commercialization<br />

stage and discussions are in progress<br />

with several cooperation partners.<br />

Award-winning high-performance<br />

processes<br />

ECPR (ElectroChemical Pattern Replication)<br />

is a completely new method for<br />

manufacturing conductor patterns on<br />

certain types of electronic chips. It has<br />

reduced 6 steps of the 10-step fabrication<br />

process to just one. The fabrication<br />

time has been cut from two hours to 2 or<br />

3 minutes! The innovation was developed<br />

in connection with a degree project<br />

in Lund and the company Replisurus<br />

is now located in Kista. The company<br />

has won a number of awards, including<br />

VINNOVA’s VINN NU competition.<br />

V I N N O V A M A G A Z I N E | 1 5

TOWARDS THE FUTURE<br />

Key measures are required at various<br />

levels to achieve long-term growth. In<br />

order to know where these measures<br />

should be taken we need analyses of<br />

future needs and strategies. These may<br />

relate to education, research, innovation<br />

and interplay between actors.<br />

VINNOVA (the Swedish Governmental<br />

Agency for Innovation Systems) has<br />

identified a number of areas in which<br />

such key measures can promote growth<br />

in Sweden.<br />

One example is Sweden’s national<br />

strategy for security research, which<br />

includes a plan for making better use<br />

of knowledge and skills to produce<br />

products, processes and services.<br />

Another example is the national<br />

innovation and research strategy for<br />

biotechnology. This strategy focuses on<br />

areas where there are good prospects<br />

of high growth and international competitiveness.<br />

Structures are identified<br />

in industry and in clusters of biotechnology,<br />

pharmaceutical and medical<br />

technology companies in various<br />

Swedish regions.<br />

A third example is wood manufacturing.<br />

Swedish sawmills, construction<br />

companies and researchers are collaborating<br />

on the development of rational<br />

wood processing. And they are well<br />

on the way to success. Here follows<br />

a more detailed presentation of the<br />

above three examples of how research<br />

stimulates growth in Sweden.<br />

Security research creates growth<br />

Sweden needs a programme for security research. This would enhance preparedness for<br />

all kinds of threats and disasters and promote Swedish exports of security products.<br />

Many Swedish ideas about security solutions<br />

are more advanced than those in the<br />

USA, says Svante Bergh, director at<br />

Ericsson Microwave Systems.<br />

THE MAIN THREAT today is not an<br />

invasion by a foreign power. Nowadays,<br />

the threats and risks that we must watch<br />

out for are the spread of serious infection,<br />

acts of terrorism, natural disasters<br />

that put essential infrastructure out of<br />

action and technical breakdowns in<br />

power, telecom and IT systems.<br />

According to the study ‘Knowledge<br />

for Safety’s Sake. Proposals for a national<br />

security research strategy’, which<br />

was conducted by VINNOVA, strategic<br />

changes are needed.<br />

Several members of the study group<br />

speak in terms of transformation from<br />

a society that is capable of meeting<br />

military threats alone to a society that<br />

can deal with all types of threats.<br />

– We must build a system in which<br />

our response is geared to the needs, regardless<br />

of whether this involves sending<br />

combat units to other countries or<br />

dealing with power failures in different<br />

parts of the country. In some cases the<br />

armed forces can operate under police<br />

command, while in others a fireman<br />

could be the key person, says Svante<br />

Bergh, the Confederation of Swedish<br />

Enterprise representative.<br />

According to the authors of the study,<br />

about 300 companies and institutes in<br />

Sweden may benefit from research programmes<br />

in order to develop new civil<br />

security products. The main sectors are<br />

complex IT systems, simulation and IT<br />

security, followed by mobile solutions,<br />

sensor technology, physical transports,<br />

NBC technology and the arms industry.<br />

– Sweden is already in the forefront in<br />

many areas, both in research and in the<br />

SWEDISH SECURITY RESEARCH STRATEGY<br />

VINNOVA presents the following proposals:<br />

• Invest 15,5–20,7 million euro per<br />

year on security research.<br />

• Make the Swedish Emergency Management<br />

Agency responsible for<br />

coordinating security research.<br />

• Set up a four-year national R&D<br />

programme to promote research in the<br />

EU.<br />

• Facilitate participation in US security<br />

research programmes.<br />

corporate sector. This gives us an excellent<br />

starting-point in the nascent international<br />

market for civil security products, says<br />

Head of Department Eva Lindencrona at<br />

VINNOVA, who led the study team.<br />

But there is no time to lose. The<br />

European Commission plans to improve<br />

protection against terrorism,<br />

serious organized crime and natural<br />

disasters in the EU. The EU is to spend<br />

375 million euro on space and security<br />

research during the period 2007‒2013.<br />

– We must be on that train, and<br />

preferably among the leaders, says<br />

Svante Bergh.<br />

He also says that many Swedish<br />

ideas about security solutions are more<br />

advanced than those in the USA, despite<br />

the fact that America spends vast<br />

sums on research into civil security.<br />

• Create innovative capacity for the<br />

security sector by enhancing public<br />

authorities’ purchasing capacity and developing<br />

common technical standards.<br />

The group included representatives of<br />

VINNOVA, the Swedish Emergency Management<br />

Agency, the Swedish Armed<br />

Forces, the Defence Materiel Administration,<br />

the Swedish Defence Research<br />

Agency, the Swedish National Defence<br />

College and the Confederation of Swedish<br />

Enterprise.<br />

1 6 | V I N N O V A M A G A Z I N E

STRATEGIES FOR THE FUTURE<br />

Wood<br />

Manufacturing<br />

– a high-tech<br />

sunrise industry<br />

Wood is beautiful, practical and strong,<br />

and it has more uses than people<br />

realize. In addition, it has such good<br />

environmental properties that<br />

using more wood instead of other<br />

materials would lower atmospheric<br />

carbon dioxide concentrations.<br />

A beautiful air control tower in Skellefteå, in the north of Sweden. The<br />

facade is made of glulam panel and is assembled in whole lengths.<br />

WE ARE NOT TALKING about a magic<br />

new material, but about ordinary wood,<br />

albeit subjected to high-tech processes<br />

in which its functional, aesthetic and environmental<br />

properties are improved in<br />

order to produce higher-value products.<br />

Nowadays wood research is conducted<br />

at most universities of technology,<br />

often in close cooperation with<br />

the timber industry and wood research<br />

institutes such as SP Trätek. VINNOVA<br />

has identified wood manufacturing as a<br />

fast-growing industry and contributes<br />

research funding to it. Two sectors that<br />

are considered to have growth potential<br />

are the interior industry and woodbased<br />

construction.<br />

Martinsons is a family firm that was<br />

founded in 1939. In those days it was just<br />

an ordinary sawmill.<br />

Laminated wood (glulam) was the first<br />

processed wood material. Nowadays it is<br />

often used for structural beams in many<br />

different types of buildings. Another<br />

processed product on the market is<br />

called solidwood. It consists of crossglued<br />

laminated timber that can be<br />

used for beams and other load-bearing<br />

structures. The technology ensures a<br />

strong, dimensionally stable and very<br />

light material. Solidwood can have a<br />

free span of up to 12 metres, but is only<br />

a quarter the weight of concrete.<br />

Martinsons, a company in the village<br />

of Bygdsiljum in northern Sweden, has<br />

conducted intensive research in order to<br />

develop the new products glulam and<br />

solidwood.<br />

– We have laid a good foundation for<br />

a successful business with excellent export<br />

opportunities, says Lars Martinson,<br />

the managing director.<br />

– The new products are important,<br />

but at the moment we are concentrating<br />

on developing effective and efficient<br />

system solutions. So we are designing<br />

standard modules that can be used in<br />

flexible applications. Building a wooden<br />

house should not be any more difficult<br />

than building one with Lego, says Lars<br />

Martinson. Martinson is very keen on<br />

the idea of building large apartment<br />

blocks of wood. A long-term research<br />

project has been started to produce finished<br />

modules with all the installations<br />

made at the factory. The buildings could<br />

then easily be assembled on the building-site.<br />

Five six-storey apartment blocks<br />

of wood with a total of 96 apartments<br />

have just been completed in Sundsvall,<br />

a seaside town in the north of Sweden.<br />

All those involved in the project were<br />

pleasantly surprised by the result.<br />

A SUNRISE INDUSTRY<br />

– We were worried that noise might be<br />

a problem in these buildings, says Lars<br />

Martinson. But our newly developed<br />

patented sound-absorption system<br />

works better than we expected.<br />

The residents agree that the buildings<br />

are quiet. The sounds that can be<br />

heard are soft and less invasive than in a<br />

building built of hard materials.<br />

Japan is the company’s largest export<br />

market at present. There is such great<br />

demand for glulam that a new production<br />

line has been built to meet it. One<br />

of the reasons why glulam is so popular<br />

nowadays is that it is both stronger<br />

and lighter than steel. The company’s<br />

Japanese customers have realized that<br />

wooden buildings offer a better chance<br />

of surviving an earthquake.<br />

V I N N O V A M A G A Z I N E | 1 7

STRATEGIES FOR THE FUTURE<br />

Knowledgebased<br />

biotechnology<br />

industry<br />

Swedish life science<br />

companies have achieved<br />

great success and improved<br />

many people’s lives.<br />

Sweden can continue to create innovative products thanks to collaboration between higher<br />

education, the health services and industry.<br />

THE LIFE SCIENCE industry is the fastest<br />

growing in Sweden. World-class<br />

innovations such as ulcer drugs, other<br />

pharmaceutical products and dialysis<br />

equipment, the pacemaker and other<br />

medical technology are the result of<br />

collaboration between enterprises and<br />

Swedish universities.<br />

– The new knowledge about our<br />

genes and basic body functions offers<br />

the industry new challenges. It is<br />

important, in order to take advantage<br />

of the commercial opportunities, the<br />

cutting edge of science, says Harriet<br />

Wallberg-Henriksson, President of<br />

the Karolinska Institute in Stockholm,<br />

which is one of the world’s leading<br />

medical universities.<br />

TRADITION<br />

A long tradition of outstanding research<br />

and close collaboration with the Swedish<br />

health service, with its large proportion<br />

of researcher physicians, is one of<br />

the main reasons why the Swedish biotechnology<br />

industry has a world-class<br />

reputation. However, it is an extremely<br />

competitive industry. Developing new<br />

products is very costly and takes a long<br />

time.<br />

– But this is Sweden’s comparative<br />

advantage, explains Per-Erik Sandlund,<br />

CEO of SwedenBIO. Sweden’s topclass<br />

– and cost-effective – know-how<br />

is what enables it to compete. Swedish<br />

biotechnology enterprises are streamlined<br />

and flat, and there are no hierarchical<br />

obstacles in the industry, he says.<br />

NEW JOBS<br />

Furthermore, Sweden has an efficient<br />

system of patient records and bio banks,<br />

and it is a relatively simple matter<br />

to carry out clinical studies of drugs,<br />

compared with the situation in the USA<br />

and Asia.<br />

VINNOVA has formulated a national<br />

biotechnology strategy with a view to<br />

strengthening the industry. In addition,<br />

the government is discussing these issues<br />

with representatives of the industry,<br />

higher education and trade unions. The<br />

goal is to create new jobs and increase<br />

export earnings, even though the industry<br />

already accounts for a quarter of<br />

Successful medical research is important<br />

to ensure that the Swedish biotechnology<br />

industry is a growth industry, says<br />

Harriet Wallberg - Henriksson, President<br />

of the Karolinska Institute.<br />

Sweden’s exports. Among other things,<br />

there are plans to set up a national<br />

programme for researchers who wish to<br />

divide their time between academia and<br />

industry. The government is also examining<br />

the possibility of aiding companies<br />

that have a large R&D budget.<br />

Interesting areas for the future mentioned<br />

by Harriet Wallberg-Henriksson<br />

include individualized medicine,<br />

with tailor-made treatments for small<br />

groups of people on the basis of genetic<br />

information. This would be a completely<br />

new approach for pharmaceutical<br />

companies.<br />

– There is also great potential for<br />

combining medical and technological<br />

research, for example in the form<br />

of nanomedicine and new sensors for<br />

different types of IT solutions for telemedicine<br />

and self-tests.<br />

PROFITABLE OPERATIONS<br />

In the longer term, biotechnology may<br />

also play an important part in transforming<br />

traditional industries such as<br />

food, forestry and chemicals.<br />

– It is clearly profitable to support<br />

medical research, says Harriet<br />

Wallberg-Henriksson. According to<br />

American studies, there is a 10-dollar<br />

return on each dollar invested. Per-Erik<br />

Sandlund agrees.<br />

– Developing the life science sector is<br />

one of our great challenges. Apart from<br />

generating export profits for enterprises<br />

and creating new jobs, it could also<br />

reduce healthcare expenses.<br />

1 8 | V I N N O V A M A G A Z I N E

GOOD IDEAS<br />

RECEIVE SUPPORT<br />

Maria Gröndahl and Lisa Eriksson with their new packaging material.<br />

PRODUCING PACKAGING FROM WASTE<br />

Waste can really turn to gold. The<br />

Xylophane company has invented a new<br />

packaging material. Maria Gröndahl, a<br />

doctoral student of biopolymer technology<br />

at Chalmers University of Technology,<br />

succeeded a few years ago in producing<br />

a thin film of the renewable material<br />

xylane. This biopolymer is present in<br />

grain, straw and wood, but until recently<br />

it was regarded as a residue without any<br />

economic value.<br />

– We have produced a film from this<br />

material that can be used in environmentally<br />

sound packages instead of aluminium<br />

and other non-renewable materials,<br />

she says. She collaborated on this<br />

project with her colleague Lisa Eriksson,<br />

who has a degree in engineering biology.<br />

– We discovered that the films we<br />

developed are an excellent barrier<br />

against oxygen. They are very useful in<br />

the packaging industry, which uses large<br />

quantities of oxygen barriers to protect<br />

sensitive products such as food and<br />

drugs, she says.<br />

Developing alternative packaging,<br />

whether for juice, fast food or headache<br />

pills, is a timely idea. The EU Packaging<br />

Directive regulates the design of the<br />

packages of the future. It stipulates,<br />

Many good ideas are created in<br />

Sweden. VINNOVA supports innovative<br />

ideas with growth potential, thus<br />

promoting the establishment of new<br />

technology-based companies. The<br />

VINN NU competition provides funding<br />

for small companies at an early stage,<br />

thus creating opportunities for them<br />

to realize their ideas. Here are three<br />

examples of projects that have been<br />

supported in this way.<br />

among other things, that packaging must<br />

be environmentally sounder in future.<br />

Xylophane is also the name of the product<br />

developed by the two engineers together<br />

with Paul Gatenholm, a professor<br />

at Chalmers University of Technology.<br />

– We are already in touch with the<br />

packaging industry with a view to scaling<br />

up our laboratory results to a larger<br />

pilot scale, says Maria Gröndahl.<br />

The product has raised great expectations,<br />

and she mentions that the<br />

company has also established international<br />

contacts.<br />

A CAMERA THAT SEES THROUGH THE SKIN<br />

Our skin is often used to study the<br />

safety of all sorts of products from<br />

cosmetics to drugs. A company called<br />

WheelsBridge has developed a system,<br />

for which a patent has been applied<br />

for, that makes such tests simpler and<br />

more effective.<br />

– The camera that we have developed<br />

can see “through” the outer<br />

layers of skin and photograph the blood<br />

circulation in the deeper skin layers. It<br />

may detect signs of inflammations or<br />

allergic reactions to an ointment, for<br />

example, explains Gert Nilsson.<br />

He is Professor of Medical Technology<br />

at Linköping University and runs the<br />

company together with others, including<br />

a dermatologist. Their customers<br />

are manufacturers of skincare products<br />

and drugs who need to test the safety<br />

of their products.<br />

– Sometimes the aim may be to<br />

measure the effectiveness of a product,<br />

such as a product designed to increase<br />

blood circulation.<br />

At present, dermatologists assess<br />

red spots subjectively. The camera can<br />

provide more accurate values and also<br />

monitor the development of a reaction<br />

in the skin over time. The technology is<br />

based on the changes that take place<br />

in polarized light when it strikes red<br />

blood cells in the skin. Development is<br />

complete and the product will soon be<br />

launched on the market.<br />

– We have gone from development to<br />

marketing in order to sell the product.<br />

The money from VINN NU will help us<br />

to establish a distribution network in<br />

Europe.<br />

V I N N O V A M A G A Z I N E | 1 9

GOOD IDEAS<br />

RECEIVE SUPPORT<br />

AIR STREAMS<br />

CONQUER<br />

THE WORLD<br />

A new, revolutionary cooling technology<br />

offers completely new heat transfer<br />

possibilities. The method is silent and<br />

extremely effective. It can make existing<br />

cooling systems better and cheaper,<br />

as well as offering new ways of cooling<br />

electronic and industrial equipment of<br />

various kinds.<br />

– One problem connected with the<br />

cooling of materials is that air is a very<br />

poor conductor of heat. A fan can be<br />

used to blow away hot air to accelerate<br />

the cooling process, but the material<br />

always retains a thin layer of air around<br />

itself that slows down the heat transfer,<br />

explains Anna Borgström.<br />

Together with her colleague Roderick<br />

Barrett she has developed the cooling<br />

technology used by Aureola Swedish<br />

Engineering. The method is based on<br />

fundamental physical phenomena that<br />

the two Royal Institute of Technology<br />

students use in a new way.<br />

– We can manipulate air molecules<br />