Netherlands: high-tech fastening for high-speed track ... - Hilti

Netherlands: high-tech fastening for high-speed track ... - Hilti

Netherlands: high-tech fastening for high-speed track ... - Hilti

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Magazine Fall/Winter 2005<br />

Engineering<br />

Page 19<br />

tile. “At the planning stage, <strong>for</strong><br />

safety reasons, we had to conservatively<br />

reduce the resulting coefficient<br />

of friction from the measured<br />

0.4 to a value of 0.1 in order to account<br />

<strong>for</strong> vertical dynamic effects,”<br />

continues Peter Meijvis. After<br />

reducing friction in this way,<br />

90% of the load is taken up by the<br />

dowels. “The total of 13 dowels in<br />

each concrete slab – 9 in the center<br />

section and 2 at each end – is<br />

capable of taking up this load with<br />

the required <strong>high</strong> safety factor. In<br />

theory, a lower number of dowels<br />

would have been adequate, but we<br />

decided on a redundant system because<br />

even just a scratch in one of<br />

the round bars could be enough to<br />

initiate a fatigue fracture.”<br />

Drawings of the entire stretch of<br />

<strong>track</strong> hang along the walls of the<br />

long corridor leading to Peter Meijvis’s<br />

office. Although he knows<br />

the details on the drawings by<br />

heart, he’s still amazed to see how<br />

this light-colored strip of concrete<br />

is taking shape as it progresses<br />

through the Dutch countryside. Peter<br />

Meijvis and his colleagues will<br />

almost certainly be sitting in one of<br />

the very first trains. All of their<br />

planning and problem-solving will<br />

then seem to whiz past in a kind of<br />

time-lapse playback as they travel<br />

along the <strong>track</strong> at <strong>high</strong> <strong>speed</strong>.<br />

<strong>Hilti</strong> Concrete Dowels proved<br />

their load-beaning capacity and<br />

reliebility in extensive tests.<br />

Read more on page 20.<br />

The new<br />

railway pioneers<br />

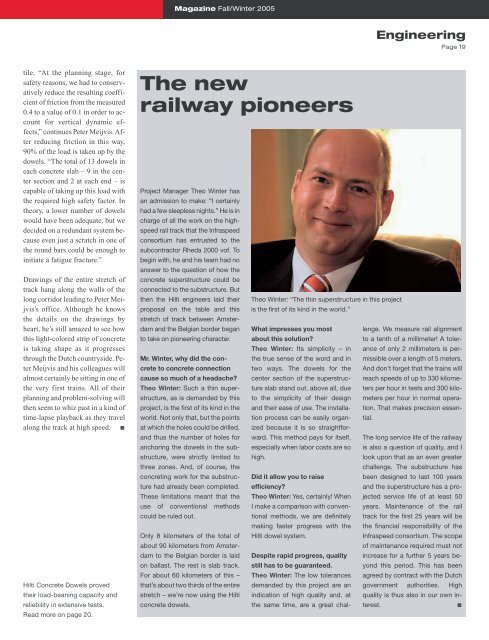

Project Manager Theo Winter has<br />

an admission to make: “I certainly<br />

had a few sleepless nights.” He is in<br />

charge of all the work on the <strong>high</strong><strong>speed</strong><br />

rail <strong>track</strong> that the Infra<strong>speed</strong><br />

consortium has entrusted to the<br />

subcontractor Rheda 2000 vof. To<br />

begin with, he and his team had no<br />

answer to the question of how the<br />

concrete superstructure could be<br />

connected to the substructure. But<br />

then the <strong>Hilti</strong> engineers laid their<br />

proposal on the table and this<br />

stretch of <strong>track</strong> between Amsterdam<br />

and the Belgian border began<br />

to take on pioneering character.<br />

Mr. Winter, why did the concrete<br />

to concrete connection<br />

cause so much of a headache?<br />

Theo Winter: Such a thin superstructure,<br />

as is demanded by this<br />

project, is the first of its kind in the<br />

world. Not only that, but the points<br />

at which the holes could be drilled,<br />

and thus the number of holes <strong>for</strong><br />

anchoring the dowels in the substructure,<br />

were strictly limited to<br />

three zones. And, of course, the<br />

concreting work <strong>for</strong> the substructure<br />

had already been completed.<br />

These limitations meant that the<br />

use of conventional methods<br />

could be ruled out.<br />

Only 8 kilometers of the total of<br />

about 90 kilometers from Amsterdam<br />

to the Belgian border is laid<br />

on ballast. The rest is slab <strong>track</strong>.<br />

For about 60 kilometers of this –<br />

that’s about two thirds of the entire<br />

stretch – we’re now using the <strong>Hilti</strong><br />

concrete dowels.<br />

Theo Winter: “The thin superstructure in this project<br />

is the first of its kind in the world.”<br />

What impresses you most<br />

about this solution?<br />

Theo Winter: Its simplicity – in<br />

the true sense of the word and in<br />

two ways. The dowels <strong>for</strong> the<br />

center section of the superstructure<br />

slab stand out, above all, due<br />

to the simplicity of their design<br />

and their ease of use. The installation<br />

process can be easily organized<br />

because it is so straight<strong>for</strong>ward.<br />

This method pays <strong>for</strong> itself,<br />

especially when labor costs are so<br />

<strong>high</strong>.<br />

Did it allow you to raise<br />

efficiency?<br />

Theo Winter: Yes, certainly! When<br />

I make a comparison with conventional<br />

methods, we are definitely<br />

making faster progress with the<br />

<strong>Hilti</strong> dowel system.<br />

Despite rapid progress, quality<br />

still has to be guaranteed.<br />

Theo Winter: The low tolerances<br />

demanded by this project are an<br />

indication of <strong>high</strong> quality and, at<br />

the same time, are a great challenge.<br />

We measure rail alignment<br />

to a tenth of a millimeter! A tolerance<br />

of only 2 millimeters is permissible<br />

over a length of 5 meters.<br />

And don’t <strong>for</strong>get that the trains will<br />

reach <strong>speed</strong>s of up to 330 kilometers<br />

per hour in tests and 300 kilometers<br />

per hour in normal operation.<br />

That makes precision essential.<br />

The long service life of the railway<br />

is also a question of quality, and I<br />

look upon that as an even greater<br />

challenge. The substructure has<br />

been designed to last 100 years<br />

and the superstructure has a projected<br />

service life of at least 50<br />

years. Maintenance of the rail<br />

<strong>track</strong> <strong>for</strong> the first 25 years will be<br />

the financial responsibility of the<br />

Infra<strong>speed</strong> consortium. The scope<br />

of maintenance required must not<br />

increase <strong>for</strong> a further 5 years beyond<br />

this period. This has been<br />

agreed by contract with the Dutch<br />

government authorities. High<br />

quality is thus also in our own interest.