147 mar/apr 2010 - Odebrecht Informa

147 mar/apr 2010 - Odebrecht Informa

147 mar/apr 2010 - Odebrecht Informa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ODEBRECHT<br />

#<strong>147</strong> • vol XXXVII • <strong>mar</strong>/<strong>apr</strong> <strong>2010</strong><br />

English Edition<br />

I N F O R M A<br />

Welcome<br />

The story of Braskem’s acquisition of Quattor and Sunoco

today<br />

Rio de Janeiro<br />

The campus of Rio de Janeiro State University (UERJ) and Maestro Antonio Carlos Jobim<br />

International Airport (Galeão) are projects that symbolize a period of major development<br />

for Rio de Janeiro and Brazil. They are sources of pride for a city that holds a special place<br />

in the hearts of all Brazilians. A place of “a thousand delights” according to the lyrics<br />

of André Filho, it celebrated its 445th anniversary on March 1, <strong>2010</strong>.<br />

ODEBRECHT ARCHIVES américo vermelho

04<br />

Having 5,000 members from 35 countries presents <strong>Odebrecht</strong> Libya<br />

with a major challenge: maintaining cultural unity<br />

ODEBRECHT<br />

I N F O R M A<br />

07<br />

08<br />

A professional education program for farm machine operators<br />

grooms multifunctional professionals trained to preserve the environment<br />

ETH and Brenco merge to form the world's largest sugarcane<br />

bioenergy producer<br />

09<br />

10<br />

14<br />

Its 2009 fundraising campaign enables the Tribute to the Future<br />

Program to benefit over 8,000 people through 12 projects<br />

The CCR Project is the largest investment made in Argentina’s oil<br />

refining industry in the last 10 years<br />

The result of the first PPP for Brazil's sanitation sector, the<br />

<strong>mar</strong>ine outfall project in Salvador, Bahia, is nearing completion<br />

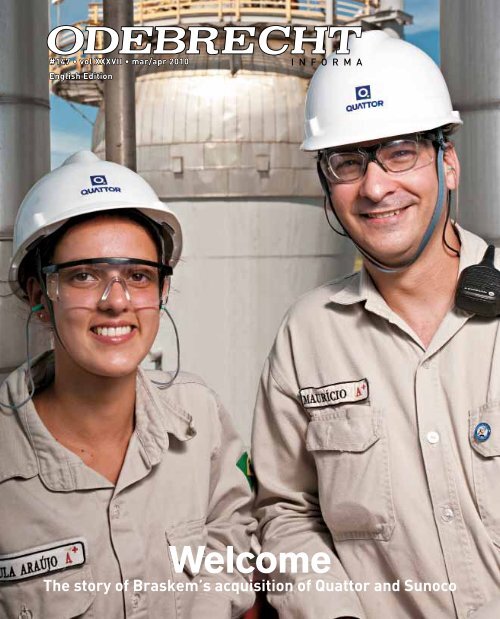

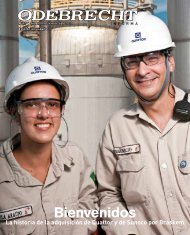

Ana Paula Bezerra<br />

de Araújo and<br />

Maurício Ostroer:<br />

members of<br />

Quattor.<br />

Photo by Edu Simões<br />

16<br />

The DUARTE CORRIDOR project in the Dominican Republic will solve<br />

traffic problems in downtown Santo Domingo<br />

19<br />

20<br />

26<br />

30<br />

32<br />

The <strong>Odebrecht</strong> Foundation <strong>mar</strong>ks its 45th anniversary<br />

by reaffirming its commitment to helping build stronger families<br />

The acquisition of Quattor and Sunoco moves Braskem up from 12th<br />

to 8th place in the global petrochemical rankings<br />

At the 2009 Annual Meeting, <strong>Odebrecht</strong> leaders analyze past<br />

achievements and plan the Group’s future<br />

<strong>Odebrecht</strong> Knowledge Communities are consolidated as a<br />

permanent forum of exchange and debate for the Group’s members<br />

A TV program featuring members at the jobsites is among the<br />

winners of the 2009 Highlight Awards<br />

sections<br />

03<br />

12<br />

24<br />

25<br />

35<br />

48<br />

in the loop<br />

interview<br />

profile<br />

people<br />

newsroom notes<br />

argument<br />

34<br />

38<br />

40<br />

42<br />

44<br />

46<br />

In Salvador, Bahia, 161 members receive medals for 25 years of<br />

service at <strong>Odebrecht</strong><br />

Dredging the Port of Rio Grande’s access channel makes the<br />

facility even more strategic for Mercosur<br />

The Rio de Janeiro Metro officially opens its first station in<br />

Ipanema, carrying over 80,000 passengers per day<br />

Equipment for Braskem’s green ethylene plant arrives at the<br />

Triunfo Petrochemical Complex via the Port of Rio Grande<br />

OOG grooms young and seasoned professionals for growth in an<br />

industry <strong>mar</strong>ked by technological advances<br />

Schools In Action, a volunteer-based project, is being expanded<br />

in Macaé, Rio de Janeiro State

02<br />

Industrial growth<br />

This issue of <strong>Odebrecht</strong> <strong>Informa</strong> was supposed to be 32 pages long, but<br />

due to the large number of accomplishments <strong>Odebrecht</strong>’s teams have made<br />

in the last two months, it has grown to 48 pages so we can inform our readers<br />

about the most important milestones that took place during that period.<br />

The Group is growing organically in all its business areas. However, in the<br />

last 60 days, the most significant events occurred in the industrial sector. The<br />

highlights are the acquisition of Quattor Petroquímica in Brazil and Sunoco<br />

Chemicals in the United States. Aimed at making the Brazilian petrochemical<br />

industry one of the strongest in the world, these acquisitions have moved<br />

Braskem up from third to first place in the production of thermoplastics in the<br />

Americas, and from twelfth to eighth in the global petrochemical rankings.<br />

The news about major investments in the industrial sector also includes<br />

ETH Bioenergy. <strong>Odebrecht</strong>’s bioenergy subsidiary and Brenco – Companhia<br />

Brasileira de Energia Renovável have announced a merger that created the<br />

world’s largest producer of ethanol and electricity from sugarcane.<br />

These land<strong>mar</strong>k events attest that <strong>Odebrecht</strong> has firmly established its<br />

presence in the industrial sector. Although the Group started out as a service<br />

provider, its industrial operations have grown vigorously since it began<br />

investing in petrochemicals in 1979. This growth got a major boost in the<br />

last decade through the establishment of Braskem in 2002 and the creation<br />

of ETH in 2007.<br />

During <strong>Odebrecht</strong>’s Annual Meeting in December 2009 (also featured in this<br />

issue of <strong>Odebrecht</strong> <strong>Informa</strong>), Marcelo <strong>Odebrecht</strong>, President and CEO of <strong>Odebrecht</strong><br />

S.A., presented the Group’s Vision for 2020. The acquisition of Quattor and<br />

Sunoco and the merger of ETH and Brenco have made a decisive contribution<br />

to ensuring that this will be a highly promising decade.<br />

www.odebrechtonline.com.br<br />

Videoreporters<br />

> Works at sea for the Salvador<br />

Marine Outfall<br />

> Social programs in São Roque<br />

do Paraguaçu<br />

> Caia na Rede: digital inclusion<br />

for workers and local communities<br />

> ETBE: the bioadditive that fuels<br />

environmental gains<br />

Online archives<br />

> Read back issues of <strong>Odebrecht</strong><br />

<strong>Informa</strong>, the <strong>Odebrecht</strong> S.A. Annual<br />

Report since 2002, the <strong>Odebrecht</strong><br />

Group’s Annual Meetings since 2002<br />

and milestone publications (Special<br />

Issue on Social Programs, 60 years<br />

of the <strong>Odebrecht</strong> Group, 40 Years<br />

of the <strong>Odebrecht</strong> Foundation and<br />

10 Years of Odeprev)<br />

ODEBRECHT<br />

Founded in 1944, the <strong>Odebrecht</strong><br />

Group is a Brazilian organization<br />

made up of diversified businesses<br />

with global operations and<br />

world-class standards of quality.<br />

Its 92,000 members are present<br />

in the Americas, the Caribbean,<br />

Africa, Asia and Europe.<br />

Responsible for Corporate Communication<br />

at Construtora Norberto <strong>Odebrecht</strong> S.A. Márcio Polidoro<br />

Responsible for Editorial Programs<br />

at Construtora Norberto <strong>Odebrecht</strong> S.A. Karolina Gutiez<br />

Business Area Coordinators<br />

Nelson Letaif Chemicals & Petrochemicals • Miucha Andrade Ethanol & Sugar • José Cláudio Grossi Oil &<br />

Gas • Daelcio Freitas Environmental Engineering • Sergio Kertész Real Estate Developments<br />

• Coordinator at <strong>Odebrecht</strong> Foundation Vivian Barbosa<br />

Editorial Coordination Versal Editores<br />

Editor-in-Chief José Enrique Barreiro • Executive Editor Cláudio Lovato Filho • English Translation by H.<br />

Sabrina Gledhill • Art/Graphic Production Rogério Nunes • Photo Editor Holanda Cavalcanti<br />

• Infographics Adilson Secco • Illustrations Gilberto Marchi • Electronic Publishing Maria Celia Olivieri<br />

Printing 1,800 copies • Pre-Press/Printing by Pancrom<br />

Editorial Offices: Rio de Janeiro +55 21 2239-1778 • São Paulo +55 11 3641-4767<br />

versal@versal.com.br<br />

Originally published in Portuguese. Also available in Spanish.

03<br />

Acervo odebrecht<br />

REPRODUCTION<br />

Maritime terminal completed in Peru<br />

Begun in August 2006, construction of the Maritime Terminal for the LNG<br />

(liquefied natural gas) Export Plant for Perú LNG, on the border between<br />

the Peruvian provinces of Chincha and Cañete, was completed in March.<br />

Thanks to this terminal, run by the CBD Melchorita Consortium (formed by<br />

<strong>Odebrecht</strong>, ENI, Saipem and Jan de Nul), Peru is now a natural gas exporter.<br />

Located 170 km south of Lima, the nation’s capital, the terminal was built<br />

by 2,000 workers. It can produce up to 4.4 million tonnes of LNG per year<br />

and handle ships capable of carrying up to 170,000 cu.m of gas. The first<br />

shipment of LNG will leave the port by early June <strong>2010</strong>.<br />

Angolan leaders in the making<br />

Signed in 2007, a partnership agreement between <strong>Odebrecht</strong> and the Government<br />

of Angola has enabled 10 young Angolans to study Civil Engineering and Architecture<br />

at Universidade Salvador (Unifacs) in the Brazilian state of Bahia. The goal<br />

of this partnership with <strong>Odebrecht</strong> is to prepare strategic Angolan members to<br />

work in their home country. On January 14, at <strong>Odebrecht</strong> Angola’s headquarters in<br />

Luanda, the students familiarized themselves with the performance of the entire<br />

Group and the company’s operations in their country, talked with members of the<br />

People and Organization program, reported on their experiences in Brazil and<br />

expressed their hopes and expectations. The students will graduate between 2011<br />

and 2012, after which they will join <strong>Odebrecht</strong> Angola. Two of them are already<br />

taking part in a compulsory internship at the company.<br />

Book launch in Venezuela<br />

Grooming<br />

teams in<br />

Mozambique<br />

The first class of mobile<br />

equipment operators for<br />

the Moatize Coal Project in<br />

Mozambique graduated in<br />

December. Eighty members<br />

were certified to operate<br />

mobile equipment such as<br />

wheel loaders, excavators<br />

and bulldozers. The professional<br />

education program<br />

that resulted in their training<br />

and certification aimed<br />

to improve the workers’ performance<br />

and make operations<br />

safer and more efficient.<br />

“There was a palpable<br />

feeling of recognition and<br />

professional development in<br />

the air when the certificates<br />

were presented,” says Paulo<br />

Avena, the <strong>Odebrecht</strong> officer<br />

Responsible for People<br />

in Mozambique. “We are<br />

more motivated now,” says<br />

Backhoe Operator Salvador<br />

Mulaphiha.<br />

<strong>Odebrecht</strong> Venezuela in December launched a book about the past and present<br />

of one of Venezuela’s largest indigenous peoples, the Wayuus, titled Los<br />

Wayuu – Na Wayuukana. Published in Spanish and Wayuunaiki, the Wayuu<br />

language, the book was written by educator, author and translator Jorge<br />

Enrique Pocaterra González. This is the first work <strong>Odebrecht</strong> has published<br />

in an indigenous language. The photos are by Américo Vermelho and Andrés<br />

Manner. The Wayuu people were the chief beneficiaries of the Maracaibo<br />

Plain Socialist Agrarian Project, an expansion of the El Diluvio-Pal<strong>mar</strong> Irrigation<br />

Project, which <strong>Odebrecht</strong> built in the Maracaibo region. “Our aim was<br />

to produce an ethnographic record of high quality in terms of information<br />

and esthetics. I believe we have achieved it,” says the officer Responsible for<br />

Planning, Administration & Finance at <strong>Odebrecht</strong> Venezuela, José Cláudio<br />

Daltro, the general editor of the book.

04 libya<br />

A culture and<br />

universal language<br />

odebrecht informa

In Libya, <strong>Odebrecht</strong> is taking on the challenge of maintaining the<br />

cultural unity of 5,000 company members from 35 different countries<br />

written by Leonardo Maia / photos by Américo Vermelho<br />

After just three years in Libya,<br />

<strong>Odebrecht</strong> has built a virtual Tower<br />

of Babel in this Arab nation. There<br />

are over 5,000 members from 35<br />

nationalities working here, building<br />

two of the nation’s largest infrastructure<br />

projects: the expansion of Tripoli<br />

International Airport and the Third<br />

Ring Road in the nation’s capital.<br />

Made up of people from five continents,<br />

many of whom have joined the<br />

Group for the first time, <strong>Odebrecht</strong><br />

Libya is creating an opportunity to<br />

groom a new generation. The biggest<br />

challenge is maintaining cultural unity<br />

in a unique environment.<br />

When hiring and mobilizing teams<br />

to work in Libya, <strong>Odebrecht</strong> decided<br />

to bet on diversity and youth. At the<br />

moment, 87 expats under the age of<br />

30 are taking on their first challenges<br />

in northern Africa. They come from<br />

13 different countries, 40% are working<br />

on their first job in the Group,<br />

and virtually all of them were born<br />

in non-Muslim countries. They are<br />

working alongside seasoned professionals<br />

from countries as vastly different<br />

as Canada, Vietnam, Ecuador<br />

and Egypt.<br />

“Libya is an incredible laboratory<br />

for grooming this new generation<br />

with the support of Knowledgeable<br />

People in leadership positions.<br />

This environment contains many of<br />

the elements that are required to<br />

accelerate young people’s personal<br />

and professional growth,” explains<br />

Daniel Villar, <strong>Odebrecht</strong>’s CEO for<br />

Libya. Alexandre Del Sálvio, a young<br />

engineer from southern Brazil who<br />

has been in Tripoli since the projects<br />

began, agrees: “Things happen much<br />

faster here. It makes you mature<br />

faster. One year in Libya is like three<br />

or four in Brazil.”<br />

Alexandre’s wife, Janaíne, who works<br />

in the People and Organization area for<br />

the Third Ring Road project, already<br />

feels that she has adapted to Libyan<br />

culture, but she can still cite a few of<br />

Among the 35 nationalities of<br />

<strong>Odebrecht</strong> members in Libya,<br />

the most numerous is Thai (more<br />

than 1,800 people), followed<br />

by Libyan and Vietnamese.<br />

Opposite, Alexandre Del Sálvio with<br />

colleagues Khiria Mohamed (left)<br />

and Ebtihal Salem at the Tripoli<br />

Third Ring Road jobsite; right, Sara<br />

Fathi O<strong>mar</strong>, Janaíne Del Sálvio,<br />

Kholod Mohamed Bajagni and Farida<br />

Kadah: investing in diversity<br />

odebrecht informa

In the Arab world it is<br />

common for most of the<br />

operational staff to come from<br />

other countries. <strong>Odebrecht</strong><br />

prioritizes local Arabs for<br />

technical positions and jobs<br />

requiring college degrees.<br />

For Libyans, rejecting<br />

food is considered rude.<br />

During the period of fasting<br />

called Ramadan, Westerners<br />

should avoid eating in front<br />

of Arabs.<br />

Iraqui member Hussein Al Khashab (green jacket) with his workmates:<br />

“Sometimes I can’t tell the Brazilians and Arabs apart”<br />

the challenges she faces. “The concept<br />

of leisure and recreation is different<br />

here. Alcohol is banned, and there are<br />

no night clubs, large shopping malls<br />

or shows. It also feels strange to work<br />

Saturdays and Sundays and only get<br />

Fridays off,” she adds. She has received<br />

some taunts for going out without a<br />

headscarf. “We have to respect the<br />

local culture and not wear short skirts<br />

in public, for example. But then again,<br />

if someone wore a burkah in Passo<br />

Fundo [a rural town in Rio Grande do<br />

Sul, Brazil], everybody there would find<br />

that weird too.”<br />

According to Hussein Al Khashab,<br />

an Iraqi who joined <strong>Odebrecht</strong> in 2003<br />

and previously worked in the United<br />

Arab Emirates and Djibouti, the<br />

Brazilians are adapting quickly. “I can’t<br />

help noticing that some people are<br />

struggling with the language, but the<br />

influence of Arab immigration to Brazil<br />

helps a lot. Sometimes I can’t tell the<br />

Brazilians and Arabs apart. They look<br />

very much alike.” Fadel Eswedi, 28, is<br />

working on the Tripoli Airport project.<br />

He, too, believes the Brazilians will<br />

soon fit right in: “I think that the best<br />

way to understand someone else’s<br />

culture is by talking to them. The<br />

Brazilians are curious and are always<br />

asking questions.”<br />

Disseminating the concepts and values<br />

of the <strong>Odebrecht</strong> Entrepreneurial<br />

Technology (TEO) has been a big<br />

challenge in Libya, due to the large<br />

number of recently hired members.<br />

The pursuit of cultural unity involves<br />

programs such as the Introduction to<br />

the <strong>Odebrecht</strong> Culture and Routes of<br />

Knowledge, which have groomed over<br />

350 expats. Foreigners also receive<br />

plenty of reading materials on Libya<br />

before they arrive. Now, the plan is to<br />

ensure that local members also have<br />

fast-track access to TEO. “Libyans<br />

who are leaders and speak English are<br />

taking part in the same development<br />

programs as the expats, and have<br />

assimilated our philosophy in a natural<br />

and positive way. When it comes to<br />

mid-level and operational members,<br />

for whom Arabic is required, we are<br />

training a local member to help us<br />

imbue them with TEO,” says Ciro<br />

Barbosa, the officer Responsible for<br />

Planning, Administration and Finance.<br />

Based on his experience of people<br />

development programs in Djibouti,<br />

Hussein Al Khashab feels that initiatives<br />

like these are important.<br />

“<strong>Odebrecht</strong> has an exceptional environment<br />

and values that few other<br />

companies share. At our company, we<br />

take a person’s culture into account,<br />

along with their skills and experience.”<br />

Alexandre Del Sálvio, who took part<br />

in the Introduction to the <strong>Odebrecht</strong><br />

Culture Program in 2008, believes that<br />

TEO is catching on. “Members with<br />

years of experience are being mobilized,<br />

and now we are seeing TEO in<br />

practice. One of the points that most<br />

attracted my attention is the identification<br />

of one’s replacement. It’s a different<br />

kind of mindset that invests in<br />

younger people,” he observes.<br />

But the biggest challenge of all may<br />

be influencing the Libyans to take on<br />

life and career plans with the company.<br />

According to the local culture, work<br />

is just the fourth priority for many,<br />

after religion, family and friends.<br />

Some, like Fadel Eswedi, are showing<br />

signs of change. “If I got a job offer<br />

from another company, I’d give it a lot<br />

of thought. But I believe that I have<br />

more opportunities at <strong>Odebrecht</strong>. I’ve<br />

learned to deal and live with different<br />

cultures. Major projects like the Tripoli<br />

Airport expansion are rare in Libya. I<br />

have to make the most of it.”<br />

odebrecht informa

professional education<br />

07<br />

Driven to succeed<br />

A course for farm equipment operators creates growth opportunities<br />

for professionals in the ethanol and sugar industry<br />

written by Guilherme Oliveira / photo by Sérgio Alberti<br />

Rony Wilton: "We're being<br />

groomed for leadership"<br />

“I’m going to operate a machine<br />

like that one day,” thought Rony<br />

Wilton Santana when he came across<br />

a sugarcane harvester on his first<br />

day on the job in May 2008. He was<br />

planting sugarcane manually at ETH<br />

Bioenergy’s Santa Luzia Unit in Nova<br />

Alvorada do Sul, in the Brazilian state<br />

of Mato Grosso do Sul. Seven months<br />

later, he was assigned to operate a<br />

planting machine. “I’d heard that there<br />

were classes and jobs available, so I<br />

worked hard to get myself noticed,”<br />

he recalls. In January <strong>2010</strong>, Rony<br />

became one of the 206 students taking<br />

ETH Bioenergy’s five-month Farm<br />

Equipment Operators’ Training Course.<br />

After 500 class hours, he will become<br />

a Harvester Operator at the Santa<br />

Luzia Unit.<br />

The company has invested roughly<br />

BRL 150,000 in this program, which<br />

offers professional education programs<br />

for tractor drivers and planter and<br />

harvester operators. “They will be outstanding<br />

multi-functional professionals<br />

who are aware of safety and environmental<br />

issues. Their studies go beyond<br />

operations to include the mechanics of<br />

these machines,” observes Luiz Antonio<br />

Borges, the Unit’s Agricultural Manager.<br />

The course covers several different<br />

areas, ranging from planting to harvesting<br />

sugarcane. “Investments like this<br />

are essential to keep pace with ETH’s<br />

growth and become even more competitive,”<br />

says Luiz Antonio. “It’s a complex<br />

program that motivates and challenges<br />

people. It is a fantastic opportunity for<br />

students and hugely beneficial for the<br />

company, because it reduces maintenance<br />

costs and raises safety awareness<br />

to prevent accidents, among other<br />

things,” he adds.<br />

At the Rio Claro Unit in Caçú, Goiás,<br />

another group of 40 students is taking<br />

a similar course. This is just the first<br />

step in the company’s schedule of people<br />

development programs, which produced<br />

1,170 trained members in 2009<br />

through courses for Farm Equipment<br />

Operators, Industrial Operators and<br />

Maintenance Technicians. Rony Wilton<br />

is already planning the next steps in<br />

his career. “We will be better qualified<br />

and able to work in different areas. We<br />

have a career now, and we’re being<br />

groomed for leadership,” says the<br />

student, who will reap in June what he<br />

sowed in 2008.<br />

odebrecht informa

808<br />

bioenergy<br />

ODEBRECHT ARCHIVES<br />

Philippe Reichstul, President of Brenco (left), and José Carlos Grubisich:<br />

optimistic and prepared to take on major challenges<br />

World leadership<br />

The merger of ETH and Brenco results in the creation of the world's biggest<br />

producer of ethanol and electricity from sugarcane<br />

written by Miucha Andrade<br />

February 18, a Thursday, is a<br />

watershed date in the history of<br />

ETH Bioenergy. Following extensive<br />

negotiations and four months after<br />

the memorandum of understanding<br />

was signed, ETH and the Brazilian<br />

renewable energy company Brenco<br />

– Companhia Brasileira de Energia<br />

Renovável announced a merger that<br />

has resulted in the creation of the<br />

world’s largest producer of ethanol<br />

and electricity from biomass (in this<br />

case, sugarcane).<br />

By 2012, ETH will have increased<br />

its production capacity to 3 billion<br />

liters of ethanol. It will also be generating<br />

2,700 GWh of electric power,<br />

the equivalent of the Brazilian state<br />

of Paraíba’s consumption, including<br />

216 counties and 3 million people<br />

served. Thanks to a total investment<br />

of BRL 7.3 billion, the new company<br />

will reach the <strong>mar</strong>k of 10,000 members<br />

by 2012, adding 2,400 people to<br />

its payroll compared with <strong>2010</strong>.<br />

According to the merger agreement,<br />

<strong>Odebrecht</strong> S.A., in partnership<br />

with Sojitz, now owns 65% of ETH<br />

Bioenergy, and Brenco’s shareholders<br />

own 35%.<br />

Before the event was officially<br />

announced in the press, all ETH<br />

members received a letter and<br />

a video with the following message<br />

from ETH CEO José Carlos<br />

Grubisich: “This is a joyous occasion<br />

for all of us to celebrate. This process<br />

has speeded up our growth plans<br />

and established us in the <strong>mar</strong>ket so<br />

we can take on fresh challenges.”<br />

The optimistic tone of this statement<br />

demonstrates that there is a<br />

lot of work to be done. It includes<br />

the priority of getting two new units<br />

online by the end of <strong>2010</strong> and two<br />

more in 2011 in the states of Goiás,<br />

Mato Grosso and Mato Grosso do<br />

Sul, while staying on budget and<br />

schedule.<br />

Questions about the next stages<br />

of the merger were answered at an<br />

event held on February 18, involving<br />

leaders of both companies. The<br />

message was clear: “Let’s start<br />

working together as of tomorrow. If<br />

you need to make a decision, take it<br />

and don’t wait, because there’s no<br />

time to lose,” José Carlos said, adding<br />

a final word of thanks: “I would<br />

like to thank all of you for your drive,<br />

determination and commitment of<br />

time and energy. We only managed<br />

to complete this operation because<br />

you have done an outstanding job and<br />

demonstrated the quality of our management<br />

and our assets.”<br />

odebrecht informa

Growing contributions to the Tribute to the Future Program make it<br />

possible to carry out 12 projects that will benefit over 8,000 people<br />

written by Gabriela Vasconcellos / photo by Diego Costa<br />

corporate social responsibility<br />

Making dreams come true<br />

09<br />

The total figures for the Tribute<br />

to the Future's performance during<br />

its last campaign over the course of<br />

2009 include 1,620 investors and BRL<br />

2,374,765.62 in funds raised. That<br />

amount will make it possible to carry<br />

out 12 projects that will benefit 8,243<br />

people. The highlight for the year was<br />

the increased participation of Group<br />

members (see infographic). Miguel<br />

Gradin, CEO of <strong>Odebrecht</strong> Óleo e Gás<br />

(OOG), the Group’s Oil & Gas business<br />

area, is emphatic: “Leaders must raise<br />

their team members’ awareness that<br />

corporate social responsibility is a mission<br />

that all of us share and is fully in<br />

line with our culture.”<br />

Paul Altit, CEO of <strong>Odebrecht</strong><br />

Realizações (OR), the Group’s Real<br />

Estate arm, believes that activities like<br />

contributing to Tribute to the Future<br />

should be part of each Group member’s<br />

life and career plan. “We have the<br />

<strong>Odebrecht</strong> Foundation, which is prepared<br />

to identify projects to which we can contribute,<br />

so this presents us with a unique<br />

opportunity. Tribute to the Future is an<br />

effective way to align our professional<br />

and personal responsibilities and help<br />

improve the quality of life of underprivileged<br />

people in our country.”<br />

The feature that sets this program<br />

apart, in the opinion of Braskem<br />

Technology and Innovation Director Luis<br />

Fernando Cassinelli, is its organization.<br />

“I’ve seen several initiatives aimed at<br />

improving access to education in lowincome<br />

communities, but none are as<br />

disciplined as this one, nor do they get<br />

such impressive results.”<br />

In 2009, the Conpar joint venture,<br />

which is expanding and upgrading the<br />

Presidente Getúlio Vargas Refinery<br />

(REPAR) in the state of Paraná, took<br />

the lead with 356 investors. Antônio<br />

Costa, the <strong>Odebrecht</strong> Project Director<br />

for REPAR, observes: “That outcome<br />

is down to everyone’s involvement and<br />

awareness of the importance of this program,<br />

and thanks to our team’s strong<br />

spirit of social commitment.” Clovis<br />

Faleiro, who is responsible for running<br />

the program, believes that Tribute to the<br />

Future’s strategy has ensured that its<br />

activities have a capillary effect. “Leaders<br />

and team members perceive the results<br />

and adopt the program. This explains<br />

the number of investors and signals that<br />

much remains to be done.”<br />

to find out more about the<br />

PROJECTS that will be sponsored in<br />

<strong>2010</strong> (in Portuguese) visit:<br />

www.tributoaofuturo.org.br<br />

Young people participating in <strong>Odebrecht</strong> Foundationbacked<br />

programs in the Southern Bahia Lowlands<br />

odebrecht informa

10<br />

retranca argentina<br />

The Ensenada Industrial Complex in La Plata, where YPF’s CCR plant will be built: cleaner fuel<br />

A national bench<strong>mar</strong>k<br />

Under construction in La Plata, YPF’s plant is the outcome of the<br />

biggest investment in oil refining in the last decade<br />

written by Cláudio Lovato Filho / photos by Guilherme Afonso<br />

This is a special time in the history<br />

of the Argentine oil industry.<br />

The first continuous catalyst regeneration<br />

reformer (CCR) is under<br />

construction in that country. This<br />

new facility will convert exportable<br />

surpluses of naphtha, normally of<br />

little commercial value, into higherquality<br />

fuels for which there is a<br />

growing demand in Argentina. The<br />

plant is being built for YPF S.A. at<br />

its Ensenada Industrial Complex<br />

in the city of La Plata, 60 km from<br />

Buenos Aires. It will not only benefit<br />

the <strong>mar</strong>ket but be a plus for the<br />

environment, because it will make<br />

it possible to produce cleaner fuel.<br />

Scheduled for completion by<br />

July 2012, this unit represents<br />

the biggest investment made in<br />

Argentina’s oil refining industry in<br />

the last 10 years: USD 348 million.<br />

It will produce 200,000 tonnes (metric<br />

tons) per year of aromatic compounds<br />

that will be combined with<br />

naphtha as additives. As a result,<br />

production of super and premium<br />

naphtha will grow by an additional<br />

900 million liters per year.<br />

<strong>Odebrecht</strong> is building the project,<br />

which began in November 2009.<br />

At the moment, the company’s<br />

teams are engaged in the detailed<br />

engineering in Buenos Aires and<br />

São Paulo and managing the procurement<br />

of equipment on a global<br />

scale. Meanwhile, the surveying<br />

work is underway in La Plata. In<br />

Buenos Aires, <strong>Odebrecht</strong> and YPF<br />

members are sharing the same<br />

office. More than that, they are<br />

working as one team.<br />

“This project is creating a bench<strong>mar</strong>k<br />

in this country,” says <strong>Odebrecht</strong><br />

Project Director Pablo Brottier. “The<br />

new unit will make it possible to<br />

increase fuel quantity and quality. We<br />

believe that it will also serve as an<br />

incentive for other companies in this<br />

industry, which will have to keep up<br />

with YPF’s leadership position.”<br />

"This project is creating a bench<strong>mar</strong>k in this country" [ Pablo Brottier ]<br />

odebrecht informa

A native of Mendoza, the home<br />

of the finest Argentine wines, civil<br />

engineer Pablo Brottier has been<br />

with <strong>Odebrecht</strong> for three years.<br />

His relationship with the company<br />

began when he was based in São<br />

Paulo. He is pleased and motivated<br />

to have been given an opportunity to<br />

work for a company where he feels<br />

at home while taking part in a project<br />

that is important for Argentina’s<br />

growth. Last January, Pablo got<br />

a chance to revisit São Paulo and<br />

participate in an important event<br />

for the execution of the CCR plant<br />

project.<br />

At a workshop tailored specifically<br />

for the project and organized<br />

by <strong>Odebrecht</strong>, over 40 participants,<br />

including company experts<br />

working in Brazil on similar<br />

projects, exchanged information<br />

and experiences with <strong>Odebrecht</strong><br />

Argentina and YPF. The day-long<br />

event was enhanced by a site visit<br />

to <strong>Odebrecht</strong>’s projects at the<br />

Presidente Getúlio Vargas Refinery<br />

(REPAR) in Araucaria, Paraná,<br />

and the Henrique Lage Refinery<br />

(REVAP) in São José dos Campos,<br />

São Paulo. “It was a highly synergistic<br />

experience that will enable us<br />

to harness <strong>Odebrecht</strong>’s knowhow to<br />

make any improvements the project<br />

requires,” observes Pablo Brottier.<br />

One of the workshop participants<br />

was electrical engineer Marcelo<br />

Broccoli, Project and Construction<br />

manager for YPF’s Engineering<br />

Directorate. Working alongside<br />

Pablo, he is leading the implementation<br />

of the new unit, taking<br />

on challenges such as the installation<br />

of massive structures (see<br />

infographic) in a fully operational<br />

industrial complex with limited<br />

La Plata: 60 km from Buenos Aires, the city has a population of 550,000<br />

space, while retrofitting five other<br />

plants and installing the connections<br />

between them. “We have an<br />

integrated team here that shares a<br />

THE NEW UNIT'S MAIN FEATURES<br />

common objective and has complementary<br />

skills. We are going to<br />

make the CCR plant a model for<br />

Argentina.”<br />

The CCR plant’s main equipment includes two 11-MW<br />

centrifugal compressors, a four-chamber furnace with a<br />

35-million kcal/h capacity, a regeneration module, a PSA<br />

(purification unit for the hydrogen produced), a reactor and a<br />

plate heat exchanger. The project also includes a 115-m-high<br />

flare and existing units will be retrofitted: a Naphtha<br />

Hydrotreatment Unit, an Aromatics Extraction Unit and an<br />

Aromatics Fractionating Unit, all of which will be interconnected.<br />

The plant will have a production capacity of 120 cu.m/hour of<br />

reformed naphtha (used to increase gasoline octane) and 1,000<br />

lb/h of catalytic regeneration (for hydrogen purification).<br />

odebrecht informa

12 interview<br />

<strong>Odebrecht</strong> <strong>Informa</strong> – What’s it like to<br />

be a dam builder?<br />

José Bonifácio Pinto Júnior – It’s<br />

a nomadic life, but very gratifying,<br />

because I can see the results of the<br />

work of a terrific team from the beginning<br />

to end of every hydro we build.<br />

I’d taken part in numerous projects in<br />

several states before I went back to<br />

Rondônia to build the Santo Antônio<br />

plant, which is the biggest I’ve ever<br />

worked on. In the 1980s, I helped<br />

build the Samuel hydroelectric plant<br />

on the Ja<strong>mar</strong>i River, a tributary of<br />

the Madeira, near Porto Velho. My<br />

wife, Luce, is from Guajará-Mirim,<br />

Rondônia. I have two daughters,<br />

Alessandra and Rebeca. The eldest,<br />

Alessandra, has a degree in business<br />

administration and was born in Porto<br />

Velho. Rebeca was born in Guayaquil,<br />

Ecuador, when I was working on the<br />

Chagón Cerecita irrigation project.<br />

A go-getter<br />

Born in the Brazilian state of Pernambuco, engineer José Bonifácio<br />

Pinto Júnior has set up camp in various parts of the country and now<br />

leads the army of more than 10,000 workers building the Santo Antônio<br />

hydroelectric plant in Porto Velho, Rondônia. Bonifácio completed 33<br />

years with the Group in January. An <strong>Odebrecht</strong> CEO and the officer<br />

Responsible for the hydro plant project, he received on December 22<br />

the Marshal Rondon Order of Merit Medal from Governor Ivo Cassol in<br />

recognition of his work and the company’s efforts on behalf of the state<br />

of Rondônia. Energy, jobs, development and quality of life are some<br />

of the benefits the project is bringing to the region. Bonifácio sees the<br />

tribute he received as a reflection of the local community’s support<br />

for the hydro – one of <strong>Odebrecht</strong>’s goals since the preliminary stages<br />

leading to the execution of this project.<br />

written by Luiz Carlos Ramos / photo by Roberto Rosa<br />

OI – What’s your relationship with<br />

Porto Velho like today?<br />

Bonifácio – It involves constant presence<br />

and attention. I spend all my time<br />

shuttling between three cities: I keep<br />

an eye on the works in Santo Antônio,<br />

I have an office in Rio de Janeiro, and<br />

spend the weekends with my family in<br />

Belo Horizonte. And, no, I haven’t forgotten<br />

my hometown, Recife: I’m a fan<br />

of the Náutico soccer club, which was<br />

unfortunately demoted to Series B of<br />

the Brazilian Leagues, but we’re sure<br />

that it’s just a temporary setback.<br />

OI – When did you begin dedicating<br />

your attention to the Santo Antônio<br />

project?<br />

Bonifácio – It all started back in 2001,<br />

long before we broke ground. Back<br />

then, Brazil was facing an energy crisis,<br />

but a lot of people didn’t think it was<br />

worthwhile to harness the potential<br />

odebrecht informa

of rivers in the Amazon to produce<br />

energy. The initial studies indicated<br />

that four plants should be built, and<br />

two were approved. The environmental<br />

license was issued in July 2007,<br />

and on December 10, Consórcio<br />

Madeira Energia, the consortium led<br />

by <strong>Odebrecht</strong> and Furnas, tendered the<br />

lowest average rate for energy generated<br />

and won the auction for the Santo<br />

Antônio Plant concession. The Santo<br />

Antônio Energia company was formed<br />

to operate the plant for 30 years. The<br />

Santo Antônio joint-venture contractor<br />

led by <strong>Odebrecht</strong>, and also including<br />

the Consórcio Santo Antônio Civil<br />

(<strong>Odebrecht</strong> and Andrade Gutierrez), is<br />

building it, along with Gicom – Grupo<br />

Industrial do Complexo do Rio Madeira<br />

(Alstom, Bardella, Voith Siemens,<br />

Andritz and Areva), which supplies the<br />

equipment, and <strong>Odebrecht</strong> Engineering<br />

& Construction, which is responsible for<br />

the electromechanical installation. We<br />

broke ground in September 2008, and<br />

the work has been going incredibly fast.<br />

OI – Is it going as quickly as originally<br />

expected?<br />

Bonifácio – Absolutely. As planned,<br />

the 44 bulb turbines should be ready<br />

by 2015. But by December 2011, it will<br />

already be possible to use the first turbine<br />

to generate energy, according to<br />

our advance delivery schedule.<br />

OI – How is the project going?<br />

Bonifácio – We are working on both<br />

banks of the river, prioritizing the<br />

powerhouse on the right bank, where<br />

the first turbines will go online by<br />

December 2011, while building the<br />

spillway on the left bank, which will<br />

ensure that the river is diverted by May<br />

2011. The entire infrastructure of the<br />

project has already been built, including<br />

the industrial kitchen, which serves<br />

"Since 2001, we have<br />

engaged in dialog<br />

with officials, the<br />

general public and the<br />

riverside communities"<br />

[ José Bonifácio ]<br />

21,000 meals a day, and the Worker<br />

Service Center (CAT), which includes 15<br />

hospital beds.<br />

OI – How did you overcome the initial<br />

resistance to the project?<br />

Bonifácio – Through dialog and a long<br />

process of awareness raising among all<br />

the different actors involved in the project.<br />

Since 2001, we at <strong>Odebrecht</strong> have<br />

engaged in dialog with officials, the<br />

general public and the riverside communities.<br />

We’ve demonstrated at public<br />

hearings and meetings that the environment<br />

will not suffer a major impact.<br />

Because we will be using bulb turbines,<br />

the dam will be lower, and therefore<br />

the area to be flooded will only cover<br />

217 sq.km, of which 164 sq.km include<br />

the riverbed. We offer compensation to<br />

families that live in areas affected by the<br />

works and make sure to preserve the<br />

local wildlife, plant life and history.<br />

OI – <strong>Odebrecht</strong> launched the Acreditar<br />

Program in Porto Velho in January<br />

2008 to offer job skills to local workers.<br />

How is that program going?<br />

Bonifácio – It’s been an exciting<br />

success. Of the 10,000 workers currently<br />

employed by this project, 83%<br />

are from Acreditar. They now have<br />

a new profession. And over 10% are<br />

women. The program was praised<br />

by President Luiz Inácio Lula da<br />

Silva and is now being replicated at<br />

The Santo Antônio Hydro under construction<br />

<strong>Odebrecht</strong> construction sites throughout<br />

Brazil.<br />

OI – And the program even had a “kid,”<br />

Acreditar Júnior.<br />

Bonifácio – Acreditar Júnior is designed<br />

for adolescents between the ages of 14<br />

and 17, the children of Consórcio Santo<br />

Antônio Civil members. More than 400<br />

teenage boys have received uniforms,<br />

backpacks and educational materials<br />

and are starting to take classes and<br />

undergo training, provided that they<br />

are at least in the sixth year of pri<strong>mar</strong>y<br />

school and don’t drop out. They receive<br />

half a minimum salary per month and<br />

take part in an exercise in citizenship.<br />

OI – What is the main lesson you’ve<br />

learned from this project and the others<br />

you’ve helped build in the last 33<br />

years?<br />

Bonifácio – I’ve learned the lesson<br />

of respecting human beings, which<br />

Mr. Norberto <strong>Odebrecht</strong> has taught<br />

to every generation in the Group. It is<br />

the lesson of trusting people and their<br />

desire to serve others and develop. I<br />

have fond memories of the time when<br />

I joined the company in 1977, through<br />

its subsidiary in Recife I started out as a<br />

trainee when I was in the fourth year of<br />

Civil Engineering School at the Federal<br />

University at Pernambuco (UFPE). I<br />

learned a lot from my leaders, particularly<br />

the late supervisor Claudionor.<br />

odebrecht informa

14 sanitation<br />

Challenges<br />

on land and sea<br />

As it nears completion,<br />

construction of the<br />

Boca do Rio Marine<br />

Outfall in Salvador,<br />

Bahia, enters a highly<br />

complex phase<br />

written by Rodrigo Vilar<br />

photos by Nilton Souza<br />

One of the most important sanitation<br />

works built in the northeastern<br />

Brazilian city of Salvador in recent<br />

decades, the Jaguaribe Ocean<br />

Disposal System is in its final stages<br />

of construction. <strong>Odebrecht</strong>’s teams<br />

in December sank the last section of<br />

the offshore pipeline and completed<br />

the onland section of the outfall.<br />

Better known as the Boca do Rio<br />

Marine Outfall, this project is an<br />

initiative of the Brazilian Federal<br />

Government and the State of Bahia<br />

through the state water company<br />

Empresa Baiana de Águas e<br />

Saneamento (EMBASA). It includes<br />

a 1.3-km onland tunnel, a pumping<br />

plant, a pressurized main, and a<br />

pre-treatment plant, as well as the<br />

3.6-km <strong>mar</strong>ine outfall per se. This is<br />

the first PPP (public-private partnership)<br />

project ever carried out through<br />

a public tender in Brazil’s sanitation<br />

sector. Foz do Brasil, an <strong>Odebrecht</strong><br />

subsidiary, is the concession company<br />

responsible for managing and<br />

exploiting the system for 15 years.<br />

Despite its size, during nearly two<br />

years of construction this massive<br />

project has gone almost unnoticed<br />

by the general public. The onland<br />

section has made little impact on<br />

odebrecht informa

the city’s routine thanks to the pipejacking<br />

equipment imported from<br />

Germany, considered the best in the<br />

world for this type of operation. It<br />

uses an automated system that drills<br />

with extremely low impact, automatically<br />

embedding concrete pipe. “We<br />

have drilled underneath streets and<br />

homes without interrupting traffic,<br />

interfering very little with people’s<br />

daily lives,” explains Jorge Oke, the<br />

officer Responsible for Production on<br />

this project.<br />

There has been no shortage of<br />

challenges. During the onland stage<br />

of drilling, for example, the drill’s<br />

The moment the last section of pipe<br />

was installed in the Bay of All Saints<br />

and, in the smaller photo, a detail<br />

of the materials used, made from<br />

high-density polyethylene<br />

progress was delayed by highly<br />

resistant rock. “Normally we could<br />

drill 50 to 80 mm per minute, but we<br />

slowed down to 8 to 10 mm because<br />

of the rock. As a result, there were<br />

continual delays and excessive wear<br />

to the cutting disks, which had to<br />

be replaced constantly,” says the<br />

Project Director. Despite the obstacles,<br />

the team’s 280 members managed<br />

to keep the project on schedule.<br />

“We have a mix of top-quality<br />

seasoned veterans and a new crop of<br />

young people with tremendous ability<br />

and a desire to learn,” says Roberto.<br />

Installing the final section of a<br />

total of four stretches of HDPE (highdensity<br />

polyethylene) pipe in the<br />

ocean was a highly complex operation.<br />

The pipe was manufactured<br />

and coupled together in the Bay of<br />

Aratu, inside the Bay of All Saints,<br />

where each section was pressurized<br />

and transported like a giant 900-m<br />

floating tube. The trip takes 24<br />

hours, on average, covering 52 km,<br />

a coordinated effort involving six to<br />

eight tugboats and five support vessels<br />

that can only be done at specific<br />

times, under the right sea and wind<br />

conditions. Based on his experience<br />

of installing five other outfalls,<br />

Roberto Santos explains, “Out on the<br />

water, we have to respect my friend<br />

Neptune, call the sea ‘sir’ and not try<br />

to be better than him. If he says you<br />

can’t work, don’t work. Fortunately,<br />

we completed the operation successfully.”<br />

According to EMBASA, when the<br />

outfall begins operations in April,<br />

as scheduled, sewage capacity will<br />

reach 90% in Salvador and Lauro de<br />

Freitas, in the state capital’s metropolitan<br />

region. This will ensure that<br />

Salvador stays on the list of cities<br />

with the best sanitation ratings in<br />

Brazil.<br />

“Initiatives aimed at forming<br />

public-private partnerships should<br />

be preceded by extensive studies to<br />

determine the priority and need for<br />

the works involved, and whether it<br />

is convenient to build them through<br />

a PPP. It is important to know that<br />

we can count on Foz do Brasil, particularly<br />

after the positive experience<br />

we are having on the SDO Jaguaribe<br />

project,” observes Abelardo de<br />

Oliveira Filho, President and CEO of<br />

EMBASA.<br />

According to Raul Ribeiro, Director<br />

of Foz do Brasil–Jaguaribe, the company<br />

responsible for operating the<br />

system: “Through this public-private<br />

partnership, we will transform experience<br />

and complementary skills into<br />

benefits for the community.”<br />

odebrecht informa

16 dominican republic<br />

Adios and good<br />

riddance<br />

The Duarte Corridor road system will cut down<br />

on traffic jams in downtown Santo Domingo<br />

written by Humberto Werneck / photos by Holanda Cavalcanti<br />

Opposite page, Daniel<br />

de los Santos: traffic jams<br />

in the city center are a major<br />

headache. In this photo, Duarte<br />

Corridor roadworks: traffic<br />

is well organized during the<br />

construction phase<br />

The owner of a van that is his main<br />

source of income, Daniel de los Santos<br />

lives 14 km from downtown Santo<br />

Domingo. On weekends, when traffic<br />

is light, it takes him no more than 20<br />

minutes to drive there. But on weekdays,<br />

the trip can take an hour and a<br />

half. The problem, he explains, is the<br />

tapones, or traffic jams. But Daniel’s<br />

headaches will soon be over thanks<br />

to the Duarte Corridor road system,<br />

which <strong>Odebrecht</strong> and its partner<br />

Ingeniería Estrella are building in the<br />

center of the Dominican Republic’s<br />

capital city.<br />

This USD 204-million project, including<br />

USD 100 million from Brazil’s<br />

National Bank for Economic and Social<br />

Development (BNDES), involves the<br />

construction of six overpasses and<br />

three tunnels. Ground was broken in<br />

July 2009, and the first two overpasses<br />

will be delivered by May. According<br />

to Daniel, that alone will shave 30<br />

minutes off his night<strong>mar</strong>e commute.<br />

“When the entire project is finished by<br />

the end of next year, motorists will be<br />

able to get from the airport to the city<br />

center – a 30-km trip – almost without<br />

a single stop light,” says Project<br />

Director Luiz Sérgio Ferraz da Costa.<br />

<strong>Odebrecht</strong>’s first project in the capital<br />

of the Dominican Republic, where<br />

it has been present since 2002, the<br />

Duarte Corridor is also the first public<br />

works contract the company has won<br />

in that country through an international<br />

public tender. It runs from East<br />

to West, and consists of two routes:<br />

Kennedy Avenue, for traffic coming in<br />

from Santiago, the country’s secondlargest<br />

city, which will get four new<br />

overpasses; and 27 de Febrero Avenue,<br />

where two 500-meter overpasses will<br />

be built.<br />

Building urban roadworks of this<br />

magnitude in an area traveled by<br />

200,000 vehicles per day involves<br />

major challenges. To surmount them,<br />

the joint-venture contractor led by<br />

<strong>Odebrecht</strong> has adopted procedures<br />

never before seen in that country. It<br />

hired a traffic consulting firm, Tectran,<br />

from Belo Horizonte, Brazil, and mobilized<br />

an information campaign. In addition<br />

to publishing ads, the company sent<br />

teams out into the streets to answer<br />

questions, hand out fliers and engage<br />

the public in dialog, since the local community<br />

was naturally concerned about<br />

odebrecht informa

how the roadworks would affect their<br />

daily lives. Signs and signaling have also<br />

been installed to guide motorists while<br />

the works are in progress.<br />

It is working like a charm. “Traffic is<br />

better organized in the vicinity of the<br />

roadworks than in other parts of the<br />

city,” observes Manuel Estrella, the<br />

owner of the construction firm that<br />

bears his name, which was a concrete<br />

supplier for the company before it<br />

became an <strong>Odebrecht</strong> partner. “I’m<br />

learning a lot,” says Estrella, who says<br />

his first surprise was the amount of<br />

time his Brazilian colleagues devoted<br />

to planning the project. One of his<br />

younger co-workers, engineer Victor<br />

Collado, 25, the officer Responsible<br />

for the Production Program for the<br />

Duarte Corridor project, announces:<br />

“One of my goals is to encapsulate<br />

<strong>Odebrecht</strong>’s culture and work philosophy<br />

and take them to Estrella.” Victor<br />

Díaz Rúa, the Minister of Public Works<br />

and Communications, whose ministry<br />

is the client for this project, notes:<br />

“The thing that makes <strong>Odebrecht</strong> an<br />

admired company in the Dominican<br />

Republic is quality, not just in construction<br />

but in how the project is<br />

handled. It is characterized by high<br />

standards of organization and safety.”<br />

Marcos Machado, the Project<br />

Director responsible for winning the<br />

tender and mobilizing the project,<br />

says that for <strong>Odebrecht</strong> the challenge<br />

it faced in the Duarte Corridor project<br />

was more about image than technology.<br />

The company is involved in other<br />

initiatives that are also helping burnish<br />

<strong>Odebrecht</strong>’s public image, such as<br />

restoring part of the Juan Pablo Duarte<br />

Olympic Center, built for the 2003<br />

Pan-American Games. An agreement<br />

between the Public Works and Sports<br />

ministries has made it possible for the<br />

odebrecht informa

joint venture to set up its campsite in a<br />

small part of the center’s grounds. In<br />

return, the contractor will restore 14<br />

basketball and indoor soccer courts,<br />

as well as a baseball diamond in<br />

the area. “We have already delivered<br />

four,” observes <strong>Odebrecht</strong>’s Humberto<br />

Sampaio, the Administration and<br />

Finance Manager. The company has<br />

also refurbished the Military Security<br />

Department’s barracks, which stand<br />

next door to the playing courts.<br />

Cláudio Medeiros, the officer<br />

Responsible for the Administrative-<br />

Financial Program on CEO Marco<br />

Cruz’s team is running the program<br />

that provides professional education<br />

and job skills to local workers. Since<br />

2005, the company has been prospecting<br />

with a fine sieve for young professionals,<br />

including engineer Jensson<br />

Nina, the officer Responsible for<br />

Production, who was one of the first<br />

to join <strong>Odebrecht</strong> through the Young<br />

Partners program. “Here you are<br />

encouraged to gain the independence<br />

and autonomy to make decisions,”<br />

says Jensson.<br />

<strong>Odebrecht</strong> currently has 52 Young<br />

Partners in the country (seven of<br />

whom are working on the Duarte<br />

Corridor), all of whom are Dominicans.<br />

Engineer Analie García Pena, 22, is<br />

working in the Planning area of the<br />

Duarte Corridor project. In her assessment,<br />

“At this company, our colleagues<br />

are interested in sharing knowledge.”<br />

During the most recent selection<br />

process, begun in October 2009, the<br />

company chose 327 candidates for<br />

the program and may hire 21 of them.<br />

“The selection process is the seed we<br />

are planting, and soon we will harvest<br />

the fruits,” says Cláudio Medeiros,<br />

who is clearly enthusiastic about the<br />

prospects.<br />

Mobilizing aid to Haiti<br />

As soon as they heard about the<br />

earthquake that hit Haiti on January<br />

12, <strong>Odebrecht</strong> teams mobilized<br />

aid for that nation’s people. Based<br />

in the Dominican Republic, which<br />

shares the Island of Hispaniola<br />

with Haiti, <strong>Odebrecht</strong> joined forces<br />

with the local government and the<br />

Brazilian Embassy. The company<br />

provided five hydraulic excavators,<br />

three wheeled loaders and a tractor<br />

trailer that were sent to Haiti to help<br />

rescue earthquake victims, as well<br />

as medicine, 25 large tents, a thousand<br />

blankets, 565 plastic tarps, 14<br />

gallons of helicopter fuel and tanker<br />

trucks to distribute treated water.<br />

Coordinated by Project Director<br />

Marcos Machado, these efforts also<br />

included helping the aid committee<br />

set up by the Brazilian Embassy<br />

in Santo Domingo with pricing and<br />

logistics for the materials and the<br />

loan of furniture for Brazil’s foreign<br />

ministry staff.<br />

In Miami, Gilberto Neves,<br />

<strong>Odebrecht</strong>’s CEO for the United<br />

States, coordinated an operation<br />

<strong>Odebrecht</strong> equipment in<br />

Port-au-Prince: making a contribution<br />

that made it possible to repair the<br />

facilities at Port-au-Prince Airport<br />

in just three weeks through a joint<br />

effort with American Airlines,<br />

which took charge of transporting<br />

people, equipment and materials<br />

there from Florida, the Dominican<br />

Republic and Puerto Rico. A cargo<br />

terminal that had suffered less<br />

damage was converted into an<br />

arrivals terminal, with customs,<br />

immigration, baggage handling systems<br />

and an administrative system.<br />

Another structure that was still<br />

reasonably intact – a three-story<br />

building – became the departure<br />

terminal. In addition to the people<br />

the company had brought in from<br />

other countries, <strong>Odebrecht</strong> had 30<br />

Haitian professionals on its team,<br />

some of whom had been trained at<br />

a workshop the company set up at<br />

the airport site. By February 19, the<br />

efforts of <strong>Odebrecht</strong>’s teams had<br />

made it possible for commercial<br />

flights to resume to and from Haiti<br />

for the first time since the tragedy<br />

struck.<br />

odebrecht informa

memory<br />

19<br />

The spirit of the times<br />

The <strong>Odebrecht</strong> Foundation turns 45 and reaffirms its belief in the<br />

importance of the family for building a better society<br />

written by Gabriela Vasconcellos / photos by Eduardo Moody<br />

The <strong>Odebrecht</strong> Foundation is<br />

<strong>mar</strong>king its 45th anniversary in <strong>2010</strong><br />

by reaffirming its mission – educating<br />

young people for life through work on<br />

the basis of values and limits – with a<br />

consolidated vision of the future: becoming<br />

the administrator of non-reimbursable<br />

resources and establishing a<br />

model for agricultural, ecological and<br />

sustainable tourism called Agro-Eco<br />

Tourism in the Pratigi Environmental<br />

Protection Area (APA) in the Southern<br />

Bahia Lowlands in northeastern Brazil.<br />

Since 2003, the Foundation has<br />

focused on transforming a stagnant,<br />

underprivileged rural area into a<br />

prosperous and dynamic place by<br />

harnessing its environmental potential<br />

and thereby encouraging young<br />

people to stay in the countryside.<br />

Through investments of over BRL 130<br />

million, the Program for the Integrated<br />

and Sustainable Development of the<br />

Mosaic of APAs in the Southern Bahia<br />

Lowlands has made a major contribution<br />

to creating work opportunities and<br />

increasing local families’ incomes. The<br />

aim is to create a rural middle class.<br />

According to Norberto <strong>Odebrecht</strong>,<br />

Chairman of the Board of Trustees<br />

of the <strong>Odebrecht</strong> Foundation, helping<br />

develop a family-based population<br />

has been the main focus for 45 years.<br />

“Our mission is to offer support to<br />

families that will help raise new<br />

generations that are structured and<br />

prepared for growth,” he explains.<br />

Now at the peak of its maturity, the<br />

Foundation is looking to the future.<br />

“People imbued with the spirit of<br />

the times never look at themselves<br />

or backward: they look forward and<br />

work as a team for the benefit of the<br />

community,” underscores Norberto<br />

<strong>Odebrecht</strong>.<br />

Group of beneficiaries of one<br />

of the Foundation’s projects in the<br />

Southern Bahia Lowlands: helping<br />

create a rural middle class<br />

odebrecht informa

20 competitiveness<br />

Meet Brazil’s new<br />

petrochemical sector<br />

Braskem acquires Quattor<br />

and Sunoco Chemicals and<br />

becomes the number-one<br />

producer of thermoplastic<br />

resins in the Americas<br />

written by Thereza Martins<br />

photos by Edu Simões<br />

odebrecht informa

Quattor unit<br />

in Duque de<br />

Caxias, Rio<br />

de Janeiro:<br />

expansion plans<br />

Braskem’s acquisition of Quattor<br />

Petroquímica in Brazil and Sunoco<br />

Chemicals in the United States has<br />

brought the company to a new level of<br />

competitiveness and size. It has gone<br />

from third to first place among thermoplastic<br />

producers in the Americas.<br />

And in the global rankings for petrochemicals,<br />

it has moved up from<br />

twelfth to eighth place. “The acquisition<br />

of Quattor is part of Braskem's<br />

strategic drive to form a broad alliance<br />

with Petrobras to make the Brazilian<br />

petrochemical industry one of the<br />

strongest in the world,” says Braskem<br />

Entrepreneurial Leader (CEO) Bernardo<br />

Gradin. “As for Sunoco, it represents<br />

our first opportunity to operate outside<br />

Brazil.”<br />

After nearly seven months of negotiations,<br />

the acquisition of Quattor<br />

was finalized in January through an<br />

agreement that, among other things,<br />

will change Braskem’s corporate<br />

structure. <strong>Odebrecht</strong> and Petrobras<br />

will share the company’s strategic<br />

decisions, and <strong>Odebrecht</strong> will have a<br />

50.1% share of its voting stock. The<br />

agreement also involves the creation of<br />

a holding company, BRK Investimentos<br />

Petroquímicos, which will own all of<br />

Braskem’s common stock. Carried<br />

out in stages, the merger with Quattor<br />

will be submitted to the Council for<br />

Economic Defense (CADE), Brazil's<br />

antitrust agency, for approval.<br />

Engineer Luiz de Mendonça has<br />

been assigned to head Quattor. He has<br />

been a Braskem member since 2002,<br />

the year the company was founded,<br />

and his last position with the company<br />

was Vice President responsible for the<br />

Polymers Unit. Mendonça now faces<br />

the challenge of leading the consolidation<br />

of Quattor’s business culture and<br />

practices with Braskem’s philosophical<br />

principles. The first step was holding a<br />

number of open meetings with teams<br />

at the industrial plants in Duque de<br />

Caxias, Rio de Janeiro, the ABC region<br />

of São Paulo, and Camaçari, Bahia, as<br />

well as the São Paulo office, to discuss<br />

the merger of Quattor and Braskem<br />

and the role that Quattor’s teams will<br />

play in Braskem’s growth, while introducing<br />

them to Braskem’s strategic<br />

vision and culture.<br />

To analyze Quattor’s processes<br />

and become fully familiarized with its<br />

operations as quickly as possible, work<br />

fronts have been organized to identify<br />

synergies and best practices that<br />

can and should be shared. Braskem<br />

members will work at Quattor and vice<br />

versa. Some areas will also be consolidated<br />

to better harness the potential of<br />

both companies.<br />

Quattor has units and investments<br />

undergoing expansion that are ready<br />

to go online, which will add 200,000<br />

tonnes per year of ethylene to its<br />

production capacity, possibly as early<br />

as May of this year. Others will add<br />

200,000 tonnes per year of polyethylene.<br />

Rio Polímeros (RioPol) is<br />

expected to go onstream at full capacity<br />

in <strong>2010</strong>, when Petrobras’s Plangás<br />

begins operations.<br />

odebrecht informa

Control room in Duque de<br />

Caxias: Quattor owns nine<br />

industrial plants<br />

According to Otávio Carvalho, a director<br />

of the MaxiQuim consulting firm,<br />

Braskem has chosen the right way to<br />

take on the competition and expand its<br />

<strong>mar</strong>ket. It has decided to bolster the<br />

industry in Brazil and internationalize<br />

its operations by acquiring petrochemical<br />

companies, as well as carrying out<br />

projects from scratch by prospecting for<br />

raw materials and building factories.<br />

Braskem is already studying several such<br />

initiatives, known as greenfield projects,<br />

in Mexico, Peru, Venezuela and Bolivia.<br />

The first steps have already been taken<br />

in Mexico. Braskem and Idesa, a Mexican<br />

petrochemical firm, are partners in a joint<br />

venture controlled by Braskem (65%).<br />

The aim of this partnership is to develop<br />

an integrated petrochemical project to<br />

produce ethylene the polyethylene in<br />

that country using natural gas feedstock.<br />

Capable of producing up to a million<br />

tonnes of polyethylene per year, these<br />

new plants will begin operations by 2015.<br />

Otávio Carvalho observes that one of<br />

the main features of the petrochemical<br />

industry is its global, competitive <strong>mar</strong>ket.<br />

Now that the nation’s economy is<br />

The main numbers...<br />

... for Braskem through the<br />

acquisition of Quattor:<br />

• 5,510 million tonnes/year of plastic<br />

resins: polyethylene (3,035 t),<br />

polypropylene (1,965 t) and PVC (510 t);<br />

• BRL 26 billion in annual earnings;<br />

• 26 production plants; and<br />

• 6,300 Members.<br />

• BRL 700 million – acquisition<br />

value of Quattor.<br />

... for Sunoco Chemicals:<br />

• 950,000 tonnes/year of polypropylene;<br />

• 3 industrial units;<br />

• 1 technology center; and<br />

• 360 Members.<br />

• Acquisition value of Sunoco:<br />

USD 350 million.<br />

odebrecht informa

ooming and consumption is high, doing<br />

business in Brazil has become attractive<br />

to producers from several countries.<br />

“China, India and Middle Eastern countries,<br />

for example, are moving in our<br />

direction,” he says, adding: “Although<br />

Braskem is the only producer in Brazil,<br />

it is not the only seller. Global distributors<br />

are active in this country, and<br />

international companies with plants in<br />

Argentina, Colombia and the US have<br />

established commercial bases here and<br />

are vying for the nearly 11,000 clients in<br />

this country’s plastics industry.”<br />

A long-term partner in projects at<br />

the Triunfo Petrochemical Complex<br />

in Rio Grande do Sul and the Paulínia<br />

Unit in São Paulo State, Petrobras has<br />

chosen Braskem to increase its stake in<br />

the petrochemical industry, “due to its<br />

expertise, and management, technical<br />

and commercial capacity,” according to<br />

Paulo Roberto Costa, the state-owned<br />

oil giant’s Downstream Director. “These<br />

characteristics have given us the peace<br />

of mind to play a more active role and<br />

increase our stake in its corporate<br />

structure.”<br />

Carlos Fadigas, Braskem’s Vice<br />

President for Finance and Investor<br />

Relations, observes: “The consolidation of<br />

the oil and petrochemical supply chains<br />

adds value and competitive advantages<br />

to every link in those chains: extraction,<br />

refining, the production of raw materials<br />

for the petrochemical industry and their<br />

conversion into resins.” Another important<br />

aspect of this partnership with Petrobras<br />

is the fact that the oil company shares<br />

a long-term view of the business with<br />

<strong>Odebrecht</strong>. “The petrochemical industry is<br />

a capital-intensive sector that requires a<br />

long-term outlook. One or two years of low<br />

tide won’t daunt partners who have been<br />

in this <strong>mar</strong>ket for decades, are familiar<br />

with the ups and downs and know how to<br />

plan for growth,” says Fadigas.<br />

The plastics industry’s reaction to<br />

the acquisition of Quattor was one<br />

of “hope and confidence,” according<br />

to Alfredo Schmitt, Chairman of the<br />

Brazilian Association for the Plastic<br />

Packaging Industry (ABIEF). “As business<br />

leaders, we understand the world<br />

trend in the petrochemical industry,<br />

which is verticalizing and consolidating<br />

to compete on the global playing field,<br />

and we hope the resulting gains in<br />

scale will be felt throughout the plastics<br />

supply chain.”<br />

odebrecht informa

24<br />

profile<br />

A true Carioca<br />

written by Júlio Cesar Souza / photo by Américo Vermelho<br />

Marcos Vidigal do A<strong>mar</strong>al could add “Botafogo” to his<br />

surname. A Carioca (native of Rio) born in the Botafogo<br />

district, he is an impassioned fan of the soccer club<br />

of the same name that gave the world one of the<br />

sport’s greatest stars, Mané Garrincha. The 47-yearold<br />

engineer has played an important role in major<br />

infrastructure projects in his hometown. He has<br />

worked on construction and retrofitting projects for<br />

stadiums, subways, educational centers, outfalls,<br />

roads and penitentiaries.<br />

Looking back on his 19 years with <strong>Odebrecht</strong>, Vidigal<br />

says the last four have been the most intense. “We<br />

work with experienced, committed teams, but the projects<br />

were highly complex and the schedules were very<br />

demanding, requiring tremendous dedication. There<br />

was zero room for error.” He cites examples like the<br />

retrofitting of Maracanã Stadium and construction of João<br />

Havelange Olympic Stadium for the 2007 Pan-American<br />

Games, and construction of the Ipanema Metro (see article<br />

on page 40 of this issue). “They were public challenges that<br />

had to be met.”<br />

Vidigal joined <strong>Odebrecht</strong> in 1991 when the company was<br />

building the access road to the Metro’s Cantagalo Station in<br />

Copacabana. Today he is responsible for two projects: the<br />

expansion of Line 1 of the Rio Metro and the infrastructure<br />

facilities for the Complexo do Alemão slum district. Vidigal<br />

knows that these works represent valuable opportunities to<br />