Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

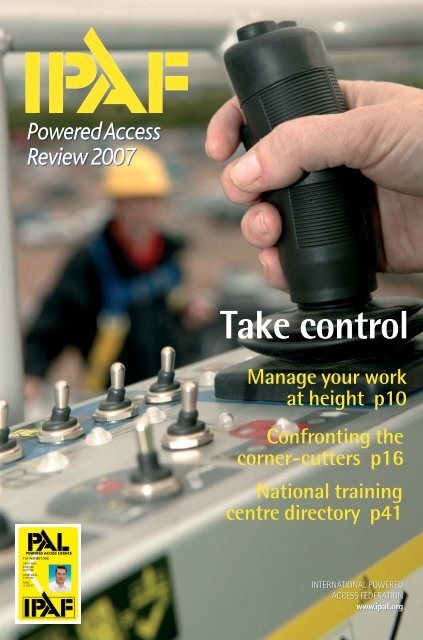

Powered Access<br />

Review 2007<br />

Take control<br />

Manage your work<br />

at height p10<br />

Confronting the<br />

corner-cutters p16<br />

National training<br />

centre directory p41<br />

INTERNATIONAL POWERED<br />

ACCESS FEDERATION<br />

www.ipaf.org

The boom is definitely back.<br />

NEVER THINK SMALL.<br />

Snorkel doesn’t claim to be the industry giant.<br />

But if you want aerial equipment big in capabilities,<br />

big in quality and big in value, Snorkel more<br />

than measures up.<br />

From spec’ing your equipment to building it, we<br />

take the time to do things right. So you get a<br />

better-made lift that operates easily, works hard<br />

and lasts long. A lift customized with everything<br />

you need and nothing you don’t.<br />

You also get the assurance of Snorkel’s on-time<br />

delivery – a standard of service in which we lead<br />

the industry.*<br />

For all your aerial jobs, go ahead and think big.<br />

Snorkel can handle it.<br />

*Details on request.<br />

USA | Australia | New Zealand | Europe | Asia<br />

800.255.0317 | snorkelusa.com

CONTENTS<br />

Powered Access<br />

Review 2007<br />

Produced by:<br />

Supplement editor: Paul Howard<br />

Features editor: Will Mann<br />

Group production editor: Russell Cox<br />

Chief sub editor: Nick Shepherd<br />

Layout sub editor: Hayley Pink<br />

<strong>IPAF</strong> news editor:<br />

Take control<br />

Manage your work<br />

at height p10<br />

Confronting the<br />

corner-cutters p16<br />

National training<br />

centre directory p41<br />

INTERNATIONAL POWERED<br />

ACCESS FEDERATION<br />

www.ipaf.org<br />

Berlinda Nadarajan<br />

<strong>IPAF</strong> Head Office, Bridge End Business<br />

Park, Milnthorpe LA7 7RH, UK<br />

T +44 (0)15395 62444<br />

F +44 (0)15395 64686<br />

E info@ipaf.org<br />

W www.ipaf.org<br />

Further contact details on p50<br />

Reed Business Information: Quadrant House,<br />

The Quadrant, Sutton, Surrey SM2 5AS, UK.<br />

Tel: +44(0)20 8652 4642<br />

Fax: +44(0)20 8652 8958<br />

Welcome – 4<br />

<strong>IPAF</strong> managing director Tim Whiteman wants you to<br />

help raise safety awareness.<br />

News – 7<br />

The latest news from <strong>IPAF</strong> and the world of powered<br />

access.<br />

Height aware debate – 10<br />

<strong>IPAF</strong>, the HSE and contractors discuss awareness of<br />

the risks associated with working at height.<br />

President in profile – 16<br />

<strong>IPAF</strong> president Andrew Reid talks tough.<br />

Training faces – 19<br />

Meet the people who benefit from <strong>IPAF</strong>’s training.<br />

Rentals – 23<br />

<strong>IPAF</strong>’s Rental+ logo is a sure sign of the highest<br />

industry standards being met.<br />

Did you know? – 27<br />

Open your eyes to new ways of using powered access.<br />

Stay on course – 30<br />

Three new courses will soon be available from <strong>IPAF</strong><br />

training centres.<br />

Strap yourself in – 31<br />

When and where to wear harnesses.<br />

Mastclimbers – 33<br />

Details of <strong>IPAF</strong>’s revamped training course.<br />

MEWPs for managers – 36<br />

All managers need to know about work at height.<br />

Member benefits – 38<br />

Why becoming an <strong>IPAF</strong> member makes good sense.<br />

International – 39<br />

A round-up of news from around the world.<br />

Training Centre directory – 41<br />

A full listing of <strong>IPAF</strong>-approved centres in the UK<br />

and abroad.<br />

Manufacturers directory – 49<br />

Find manufacturers who are <strong>IPAF</strong> members.<br />

Key contacts – 50<br />

Contact details for <strong>IPAF</strong>’s board, council, committees,<br />

and offices.<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007<br />

3

WELCOME<br />

Save a life today!<br />

“Powered access is<br />

one of the safest<br />

ways of working at<br />

height and yet every<br />

year people die for<br />

want of wearing a<br />

harness on boom<br />

type platforms.”<br />

www.sed.co.uk<br />

WEAR A FULL BODY HARNESS<br />

WITH A SHORT LANYARD IN<br />

BOOM TYPE PLATFORMS<br />

For full information about the correct use of harnesses in platforms, please<br />

obtain technical guidance note H1 from <strong>IPAF</strong>. Tel: 015395 62444 www.ipaf.org<br />

Free with this magazine is a little sticker<br />

that could save a life. It says: “Wear a<br />

harness on boom type platforms.”<br />

This is a very simple message, but it’s<br />

one that we need your help to get across<br />

to the right people. Powered access is<br />

one of the safest ways of working at<br />

height and yet every year people die<br />

for want of this simple message. If you<br />

work with platforms or have them on<br />

your site, help us to make sure that this<br />

message gets to the right people.<br />

So who are those people? They are the<br />

operators of all boom type platforms.<br />

Some of them will have been using the<br />

equipment for years without a harness,<br />

and will tell you so.<br />

But those are exactly the kind of people<br />

we need to reach before it’s too late.<br />

Others will be new to the business and<br />

will be happy for you to tell them that it<br />

is standard safety practice to wear a full<br />

body harness with the lanyard set short<br />

in boom type platforms (for scissor<br />

lifts other rules apply, but it is not<br />

normally necessary to wear a harness).<br />

The industry’s policy on this was<br />

set by a joint team of the International<br />

Powered Access Federation and the<br />

Construction Plant-hire Association,<br />

working together with the Health &<br />

Safety Executive. Its advice is summarised<br />

on a simple, pocket-sized<br />

leaflet called <strong>IPAF</strong> H1. You can get<br />

free copies from us by calling 015395<br />

62444 or you can download it free from<br />

www.ipaf.org.<br />

So what should you do if you have<br />

platforms working on your site? First<br />

of all, be happy that you are using one<br />

of the safest and most effective ways of<br />

working at height – and one that the<br />

HSE has specifically endorsed during<br />

the introduction of the Work at Height<br />

Regulations (WAHRs), but secondly,<br />

make sure the equipment is being used<br />

safely by trained operators. Think about<br />

going on a short course to ensure you<br />

can fulfil your responsibilities under the<br />

WAHRs and read more about what the<br />

HSE expects of you on page 10 of this<br />

magazine.<br />

But on a very practical note, think<br />

about what you can do with that little<br />

sticker. Stick it next to the controls of a<br />

boom type machine – you really could<br />

save a life.<br />

Tim Whiteman<br />

Managing director<br />

International Powered Access Federation<br />

www.ipaf.org<br />

PS: Our thanks to the team at SED for<br />

printing the stickers and supporting this<br />

campaign. You can order extra stickers<br />

and download free copies of <strong>IPAF</strong>’s<br />

H1 leaflet on the use of harnesses at<br />

www.ipaf.org.<br />

4<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

Your powered<br />

access expertise<br />

+<br />

<strong>IPAF</strong> membership<br />

=<br />

Greater market<br />

opportunity<br />

<strong>IPAF</strong> membership can bring<br />

you major benefits, whatever<br />

your involvement with the<br />

powered access industry.<br />

First of all, it tells your<br />

customers a lot about you. It lets<br />

them know you have the highest<br />

professional standards – and<br />

reassures them that you are on<br />

top of today’s health and safety<br />

standards.<br />

Because of our lobbying at<br />

national and international<br />

levels, you have a stronger<br />

voice in all those issues that<br />

affect your business – from<br />

health and safety legislation<br />

to the introduction of worldwide<br />

standards and how they are<br />

implemented country by country.<br />

• Our advice line, publications<br />

and bulletins help keep you in<br />

touch with everything that is<br />

going on – and make sure you<br />

know how to respond to<br />

technical, practical, commercial<br />

and legal developments.<br />

• Our operator training is second<br />

to none – and recognised by the<br />

MCG. Only <strong>IPAF</strong> members can<br />

offer this market leading<br />

training – now becoming<br />

essential for the use of powered<br />

access equipment.<br />

Our <strong>IPAF</strong> Rental+ award<br />

is only available to <strong>IPAF</strong><br />

rental company members.<br />

This ensures that your<br />

customers can identify<br />

you as a specialist in<br />

powered access rental –<br />

and that you have been<br />

independently audited to<br />

meet high service<br />

standards.<br />

<strong>IPAF</strong> is the world authority in powered access. Find out how membership<br />

can give you the same authority in the eyes of your customers.<br />

Head Office: <strong>IPAF</strong> Ltd, Bridge End Business Park, Milnthorpe LA7 7RH, UK<br />

Tel: +44 (0)15395 62444 Fax: +44 (0)15395 64686 info@ipaf.org www.ipaf.org<br />

<strong>IPAF</strong>-Basel<br />

Tel: +41 (0)61 225 4407 basel@ipaf.org<br />

<strong>IPAF</strong>-Deutschland<br />

Tel: +49 (0)421 6260 310 deutschland@ipaf.org<br />

<strong>IPAF</strong>-Italia<br />

Tel: +39 02 93581873 italia@ipaf.org<br />

<strong>IPAF</strong>-France<br />

Tel: +33 (0)1 30 99 16 68 france@ipaf.org<br />

<strong>IPAF</strong>-Benelux<br />

Tel: +31 (0)6 3042 1042 benelux@ipaf.org<br />

AWPT Inc-USA<br />

Tel: +1 717 762 1911 mail@awpt.org<br />

The world authority<br />

in powered access<br />

www.ipaf.org

HAULOTTE GROUP, THE PEOPLE AND MATERIAL LIFTING EQUIPMENT SPECIALIST<br />

A product range that reaches<br />

every stage of your business<br />

ARTICULATING BOOMS<br />

VERTICAL MASTS<br />

TELESCOPIC BOOMS<br />

SCISSOR LIFTS<br />

PUSH AROUND<br />

TRAILERS<br />

TRUCK MOUNTED PLATFORMS<br />

TELESCOPIC HANDLERS<br />

SELF PROPELLED CRANES<br />

MULTIJOB MJX :<br />

FULL ROTATING BACKHOE-LOADERS<br />

Choosing Haulotte makes you benefit from<br />

a guaranteed after-sales service.<br />

More than 40.000 spare parts shipped within<br />

24 hours all over the world<br />

Training<br />

Technical support<br />

www.haulotte.com<br />

Haulotte UK Ltd - Stafford Park 6 - Telford - Shropshire TF3 3AT • TEL :+44 (0)1952 292753 - FAX :+44 (0)1952 292758 - E-mail : haulotte@haulotte.co.uk<br />

Haulotte Group - La Péronnière - BP 9 - 42152 l’Horme - France • Tél : +33 (0)4 77 29 24 24 - Fax : +33 (0)4 77 29 43 95 - email : haulotte@haulotte.com

NEWS<br />

250,000 PAL Cards boost safety<br />

<strong>IPAF</strong> has issued its 250,000th PAL Card<br />

(Powered Access Licence), announced<br />

managing director Tim Whiteman at the<br />

Professional Development Seminar for<br />

<strong>IPAF</strong> instructors in September 2006.<br />

“A quarter of a million people<br />

have taken the time to get trained,<br />

which makes the industry safer,” said<br />

Whiteman. “But there are at least a million<br />

more to be trained.”<br />

The PAL Card is awarded to people<br />

who successfully complete training on<br />

powered access equipment. A PAL Card<br />

is valid for five years and shows the<br />

equipment categories that the holder<br />

has been trained to operate. More than<br />

200,000 people currently hold a valid<br />

PAL Card.<br />

The strong demand for training was<br />

also confirmed by Kevin Appleton, CEO<br />

of the Lavendon Group, which owns<br />

Nationwide Access.<br />

“We’re starting to see more customers<br />

from outside of construction,<br />

driven mainly by the Work at Height<br />

Regulations,” said Appleton during his<br />

talk at the <strong>IPAF</strong> Summit in April 2006.<br />

“Construction-oriented customers are<br />

a mature segment. The WAHRs and<br />

increasing awareness of access safety<br />

are driving growth among smaller, nonconstruction<br />

businesses.”<br />

DO OR DIE: This man was wearing a full body harness which saved his life when he overloaded the<br />

basket by using it to lift a Christmas tree. But too many accidents happen for want of a harness, says<br />

<strong>IPAF</strong>. Site managers who do not insist that their employees use one on boom lifts are taking a deliberate<br />

decision to put lives at risk. <strong>IPAF</strong> advises users of boom type platforms to wear a full body harness with<br />

an adjustable lanyard set as short as is possible. <strong>IPAF</strong>’s H1 technical guidance note on harnesses, issued<br />

with the support of bodies such as the UK’s HSE, BGFE in Germany, Suva in Switzerland and other<br />

organisations, can be downloaded at www.ipaf.org.<br />

(Photo: Stuart Walker).<br />

<strong>IPAF</strong> lobbies the EU for good sense on<br />

amendments to Machinery Directive<br />

The 3rd Amendment of the Machinery Directive<br />

(2006/42/EC) was published in June 2006 and member<br />

states’ regulations must come into force by 29<br />

December 2009. New EU regulations governing the<br />

design of all machinery, including powered access<br />

platforms, will be introduced in the UK soon.<br />

<strong>IPAF</strong> is carrying out an analysis of the old and<br />

new versions of the Directive. “We are developing<br />

ideas on what guidance <strong>IPAF</strong> members would<br />

like, to help them understand and implement the<br />

new version of the Directive,” said Gil Male, <strong>IPAF</strong><br />

technical officer. “The European Commission plans<br />

to issue guidance on the new Directive and work<br />

should start on this in 2007.”<br />

Warning: Don’t tie up sliding mid-rails<br />

<strong>IPAF</strong> is calling on all platform users to never tie<br />

up sliding mid-rails. This follows concerns raised<br />

by the Brussels-based committee monitoring the<br />

implementation of the Machinery Directive.<br />

Many <strong>IPAF</strong> manufacturer members have placed<br />

decals on machines indicating that mid-rails and<br />

drop-bars should never be tied up and <strong>IPAF</strong> is calling<br />

for rental companies to follow suit.<br />

“If you see a mid-rail tied up on your site, you<br />

should immediately cut the tie or you could be<br />

breaking the law,” said <strong>IPAF</strong> managing director<br />

Tim Whiteman.<br />

PAL Card goes<br />

international<br />

The PAL Card (Powered Access Licence)<br />

is recognised in a growing number of<br />

countries and this is helping to facilitate<br />

cross-border working, says <strong>IPAF</strong>.<br />

In the UK, the training programme<br />

is approved by the Major Contractors<br />

Group (MCG) and operators holding an<br />

<strong>IPAF</strong> PAL Card should be welcomed on<br />

any MCG site.<br />

The PAL Card is recognised, among<br />

others, by the Berufsgenossenschaften<br />

in Germany, by Assodimi in Italy, by<br />

the Scaffold Industry Association in<br />

the USA and by Asociace ZZ-CR in the<br />

Czech Republic. More than 50,000 PAL<br />

Cards are issued each year through a<br />

network of over 230 <strong>IPAF</strong>-approved<br />

training centres worldwide.<br />

Tim Whiteman, managing director<br />

of <strong>IPAF</strong>, said: “If you have migrant<br />

workers on site and they show you a<br />

PAL Card issued in another language,<br />

you can be sure that they have received<br />

95% of the same top-quality training<br />

certified as conforming to ISO 18878.<br />

The 5% difference lies in the language<br />

and country-specific health and safety<br />

legislation.”<br />

<strong>IPAF</strong> gets right<br />

behind BS8454<br />

<strong>IPAF</strong> conforms to the recently introduced<br />

BS 8454 Delivery of Training for<br />

Work at Height, confirmed managing<br />

director Tim Whiteman at the 2006<br />

Access Industry Forum conference.<br />

“<strong>IPAF</strong> has performed an internal audit<br />

and this will also be audited by a third,<br />

independent party,” said Whiteman.<br />

“Our advice is to make sure that your<br />

training providers comply with the<br />

standard.”<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007<br />

7

NEWS<br />

JLG chairman awarded PAL Card<br />

Bill Lasky, chairman of the board, president<br />

and CEO of JLG Industries, Inc, has<br />

become the proud holder of a PAL Card.<br />

Lasky, who is also deputy president of<br />

the <strong>IPAF</strong> Board, successfully completed<br />

an AWPT platform operator course at<br />

JLG’s McConnellsburg training centre<br />

in the United States. AWPT (Aerial<br />

Work Platform Training) is <strong>IPAF</strong>’s North<br />

American subsidiary.<br />

Bill Lasky (right),<br />

Lasky said: “I took the <strong>IPAF</strong> training<br />

JLG chairman,<br />

course to develop a deeper understanding<br />

of the equipment at the end-user<br />

CEO, receives his<br />

president and<br />

level so I can continue to lead the<br />

AWPT PAL Card<br />

company in providing new solutions to<br />

and certificate<br />

access challenges. It keeps me in touch<br />

from Mike<br />

with the industry and how our products<br />

Popovich, JLG<br />

are being used.”<br />

training director.<br />

MEWP users urged to<br />

have a clean bill of health<br />

<strong>IPAF</strong> has issued a health and<br />

fitness statement stressing<br />

that MEWP users should be<br />

physically fit, in good health<br />

and generally not have problems<br />

with eyesight, hearing,<br />

literacy and language comprehension.<br />

Those with such<br />

problems need not be precluded<br />

from using MEWPs,<br />

provided that their employer<br />

implements adequate measures<br />

to take account of any<br />

difficulties they may have.<br />

Visit www.ipaf.org to view<br />

<strong>IPAF</strong>’s policy.<br />

Truck-mounted platforms<br />

win battle for red diesel<br />

Truck-mounted platforms will not be<br />

banned from using red diesel following<br />

representations to the Treasury by<br />

<strong>IPAF</strong>.<br />

Amendments to the Excepted Vehicle<br />

Schedule relating to Hydrocarbon Oils<br />

will come into effect on 1 April 2007.<br />

These will see mobile cranes, truckmounted<br />

access platforms and mobile<br />

concrete pumps with a revenue weight<br />

exceeding 3.5t allowed to use red<br />

diesel.<br />

From that date, the Road Construction<br />

Category will be removed and the<br />

exception for street lighting van mounts<br />

goes with it. Therefore, with effect<br />

from 1 April 2007, all van-mounted<br />

platforms (including small vehiclemounted<br />

platforms under 3.5t) must run<br />

on white diesel.<br />

A new platform for<br />

success – ipaf.org<br />

CAP IN HAND: The CAP Card shows that the<br />

holder is certified as a competent person to<br />

carry out machine examinations as required by<br />

legislation. Engineers who carry a CAP Card from<br />

<strong>IPAF</strong> are certified as competent persons to plan,<br />

manage or carry out examinations of platforms<br />

in the context of current legislation (including the<br />

Work at Height Regulations, LOLER and PUWER<br />

98). CAP stands for Competent Assessed Person<br />

and the card is issued following assessment by<br />

experienced engineers from <strong>IPAF</strong>-approved<br />

training centres. A list of CAP assessment centres<br />

can be found at www.ipaf.org.<br />

Stop by the re-designed website<br />

www.ipaf.org, which is packed with<br />

resources on platform use and training,<br />

links and guidelines.<br />

Find your nearest training centre<br />

and get a listing of all <strong>IPAF</strong> events,<br />

including the Access Summit on 27<br />

March 2007 and the Professional<br />

Development Seminar in September<br />

2007.<br />

8<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

APPROVED TRAINING CENTRE<br />

FOR ALL<br />

YOUR HEIGHT<br />

SAFETY<br />

SOLUTIONS<br />

HSS have a reputation for providing Height Safety Solutions<br />

to our customers, offering the right kit, in the right place, at<br />

the right time.<br />

Changes in legislation have meant that more and more<br />

of our customers are contacting us looking for quality<br />

equipment that offers them the most cost-effective solution<br />

to a working at height issue.<br />

With our large range of powered access equipment<br />

providing high-level access for indoor or outdoor<br />

maintenance and construction work, we can deliver direct<br />

to your doorstep without delay.<br />

HSS Training delivers<br />

courses through our<br />

network of 19 training<br />

centres and are proud<br />

to be one of the<br />

leading providers of<br />

<strong>IPAF</strong> powered access<br />

training in the UK.<br />

SERIOUS ABOUT SAFETY<br />

To Train 08457 66 77 99<br />

To Hire 08457 28 28 28<br />

Booking on line at www.hss.com/training

WORK AT HEIGHT<br />

High-level<br />

management<br />

Since the arrival of the Work at Height Regulations, site managers have more<br />

responsibility for safety than ever before. But are they aware of what they<br />

should be doing? Contract Journal’s Will Mann finds out in a discussion with<br />

HSE inspector Justine Lee, <strong>IPAF</strong> managing director Tim Whiteman, Bovis Lend<br />

Lease head of health and safety Andrew Brown, and Taylor Woodrow acting<br />

head of health and safety Steve Derbyshire.<br />

WM: Perhaps you could start, Justine,<br />

by telling us a bit about how the HSE’s<br />

‘Height Aware’ campaign has been<br />

going.<br />

JL: In spring this year, HSE participated<br />

in the campaign aimed at increasing<br />

awareness of the risks of falls from<br />

height. It was aimed at those who procure<br />

work and those who carry out the<br />

work in the building and plant maintenance<br />

sectors.<br />

We want people to understand the<br />

risks of working at height better, and<br />

show them some simple and sensible<br />

measures they can take to minimise the<br />

risks. We are trying to influence attitudes<br />

and behaviour, so that people are<br />

using equipment that is most appropriate,<br />

not what’s most readily available.<br />

We’ve done this by holding educational<br />

events such as safety awareness days<br />

and breakfast meetings. We also ran a<br />

media campaign, plus the traditional<br />

site inspections.<br />

WM: What sort of things have you<br />

found around the country – are people<br />

aware of the implications of the Work at<br />

Height Regulations (WAHRs)?<br />

JL: We’ve found lots of examples of<br />

good practice. For instance, one housing<br />

association had done a cost-benefit<br />

analysis for work on their domestic housing<br />

stock, such as roof repairs, gutter<br />

cleaning, aerial installation, that sort<br />

of thing, and established that MEWPs<br />

came out as the best option: there was<br />

no security issue, they were less disruptive<br />

to the householder, the MEWP was<br />

trailer-mounted so it was easily transported<br />

to site, and the purchase cost<br />

included operator training.<br />

WM: What has been the feeling among<br />

contractors about the post-WAHRs era?<br />

SD: I think the problem with the culture<br />

change that came in with the WAHRs<br />

was that a lot of rumours started<br />

because the regs were not prescriptive.<br />

TW: What would contractors like to see<br />

from the HSE in terms of guidance?<br />

SD: The problem our guys have is that<br />

– post WAHRs – there hasn’t been guidance<br />

on what to do in a certain situation.<br />

It’s perceived that ladders are a<br />

complete ‘no no’, and that if you end up<br />

having an accident involving a ladder,<br />

you’ve made a bad error of judgement.<br />

JL: Well ladders are certainly not<br />

banned. And in fairness, the HSE<br />

and the British Ladder Manufacturers<br />

Debating<br />

work at height<br />

responsibilities:<br />

Do managers<br />

know the pitfalls<br />

to avoid?<br />

10<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

“We are trying<br />

to influence<br />

attitudes and<br />

behaviour, so<br />

that people are<br />

using equipment<br />

that is most<br />

appropriate,<br />

not what’s<br />

most readily<br />

available.”<br />

Justine Lee<br />

Association both prepared guidance<br />

on this, not long after the WAHRs came<br />

into effect. The HSE guidance is available<br />

on our website.<br />

AB: When the regulations came in,<br />

I think there should have been more<br />

communication about what actually<br />

changes. The guys at site level have to<br />

have knowledge about everything that<br />

affects them. But have they had enough<br />

guidance on how to make a judgement<br />

when it comes to choosing what kit to<br />

use in a work at height situation?<br />

SD: We had an incident where someone<br />

was injured using a podium tower where<br />

they should really just have used a stepladder.<br />

HSE guidance would be helpful<br />

on such areas.<br />

JL: There are two questions I’d raise in<br />

a situation like that. First, had the person<br />

received sufficient training for the<br />

equipment he was using? Second, had<br />

they assessed whether it was the most<br />

appropriate piece of equipment to use in<br />

the circumstances?<br />

AB: It’s hard for a site manager when<br />

you don’t understand the WAHRs in as<br />

much detail as an inspector does.<br />

JL: But little has changed compared<br />

to the old CHSW Regulations and if<br />

you were complying before, you’ll be<br />

complying now. We just want people<br />

to think carefully about the work, and<br />

rather than turning up with a ladder<br />

on the van and getting the job done,<br />

using that ladder because it’s what<br />

they happen to have with them, they<br />

should select the right equipment for<br />

the job.<br />

WM: How have contractors reacted to<br />

the scrapping of the old 2m rule?<br />

SD: The old system needed changing,<br />

but now there is just confusion. Should<br />

there be a new minimum height level? It<br />

would make it easier for our guys on site<br />

to make the right decision.<br />

JL: The WAHRs were signed by the<br />

Minister on the basis that there would<br />

be a review of the 2m rule. That review<br />

is now underway and a paper should<br />

go to the Health & Safety Commission<br />

towards the end of November 2006.<br />

WM: One point that has emerged from<br />

the WAHRs is how much pressure and<br />

responsibility it puts on site managers.<br />

SD: Yes, and I sometimes think that<br />

as an industry, we have a tendency to<br />

overestimate the capabilities and experience<br />

of our site managers. I think that<br />

when they’re choosing kit, they see the<br />

work at height hierarchy, which places<br />

a MEWP above a ladder and often use a<br />

MEWP when they don’t really need to.<br />

JL: With any kit, I would expect<br />

people to have had training so they<br />

understand how the kit is supposed to<br />

be used. There is the perception that<br />

if someone uses a ladder and things<br />

go wrong, they’ll be automatically<br />

criticised by the HSE, and that isn’t the<br />

case. The WAHRs have been written in<br />

such a way to allow ladders to be used<br />

in certain circumstances. It’s about<br />

doing the risk assessment, referring to<br />

the work at height hierarchy and then<br />

selecting the right equipment.<br />

WM: But the hierarchy does indicate<br />

that a ladder comes below a MEWP – do<br />

you think it makes it a little confusing<br />

for site managers, and makes them<br />

automatically choose a MEWP?<br />

JL: It shouldn’t do, the hierarchy is there<br />

to help people do their risk assessment.<br />

AB: We’re trying to bring in our own<br />

interpretation of the hierarchy – perhaps<br />

involving a graphical system, or some<br />

kind of matrix – that makes it easier for<br />

site managers to make a decision.<br />

SD: Does the HSE see site managers’<br />

awareness of what kit should be selected<br />

as a problem within the industry?<br />

JL: Well the person who is doing the<br />

planning has to be competent. That’s<br />

the aim of the one-day MEWPs for<br />

Managers course that <strong>IPAF</strong> have developed.<br />

AB: Would you expect any site manager<br />

on site to have done the course?<br />

JL: It would certainly help. There’s<br />

nothing else out there for managers. The<br />

use of MEWPs has gone up considerably<br />

in recent years, and that’s why <strong>IPAF</strong><br />

devised this course.<br />

WM: What’s the contractor view on<br />

that?<br />

SD: I certainly think it would be a help.<br />

In fact any course that raises both<br />

awareness and competency is welcome.<br />

MEWPs are increasingly being used<br />

in all areas of the industry. The issue<br />

for us is how can we (as an industry)<br />

obtain the appropriate levels of awareness<br />

training so that our managers can<br />

competently choose, or discuss with<br />

contractors, which MEWP or piece of kit<br />

continued on page 13<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007 11

ACCESS<br />

PLATFORMS LTD<br />

A. J. ACCESS PLATFORMS LTD.<br />

PILL WAY, SEVERN BRIDGE IND. ESTATE CALDICOT, GWENT NP26 5PU, UK<br />

<strong>IPAF</strong><br />

TRAINING<br />

COURSES AVAILABLE<br />

NATIONWIDE<br />

Tel: +44 (0) 1291 421155<br />

Fax: +44 (0) 1291 423236<br />

Mike Fenn<br />

Mobile: +44 (0) 7980 764021<br />

Email: training@accessplatforms.com<br />

www.accessplatforms.com<br />

Our Vision<br />

To be the powered access<br />

training provider of choice<br />

throughout the United<br />

Kingdom<br />

SCISSOR LIFTS<br />

SUB ZERO<br />

BOOMS<br />

SELF PROPELLED<br />

BOOMS<br />

VEHICLE MOUNTED<br />

PLATFORMS<br />

Courses<br />

■ Scissor Lift<br />

■ Self-Propelled Boom<br />

■ Vertical Personnel Lift<br />

■ Trailer Mount<br />

■ Van Mount<br />

■ Insulated Aerial Device<br />

■ Spiders & Crawlers<br />

■ Harness Training<br />

■ Work at Height Training<br />

■ Risk Assessment<br />

Contact us<br />

Tel: 08700 771709<br />

Fax: 08700 771609<br />

training@heightmaster.uk.com<br />

www.heightmaster.uk.com<br />

Raising Standards<br />

National Coverage<br />

Hire<br />

Sales<br />

Training<br />

Servicing<br />

National<br />

Coverage<br />

0800 0181823<br />

FOR ALL YOUR POWERED ACCESS SOLUTIONS<br />

www.amp-access.co.uk<br />

Part of the Lavendon<br />

Group of companies

“<strong>IPAF</strong>’s MEWPs for<br />

Managers course will<br />

give those making these<br />

decisions the knowledge<br />

to help them decide<br />

whether a MEWP is the<br />

most suitable piece of<br />

equipment for the work.”<br />

Tim Whiteman<br />

continued from page 11<br />

is appropriate. It appears this course will<br />

provide that awareness training.<br />

AB: I agree with the idea, but I’d like to<br />

know more about the content.<br />

TW: <strong>IPAF</strong>’s MEWPs for Managers<br />

course, developed with the HSE, covers<br />

regulations on health and safety<br />

and MEWP usage, accident prevention<br />

and control, the importance of<br />

machine familiarisation, as well as<br />

pre-use and daily maintenance of<br />

machines. It is a one-day course targeted<br />

at managers who have MEWPs<br />

being used on site. In a nutshell, it<br />

aims to give managers everything<br />

they need to know about planning,<br />

selecting and co-ordinating the use<br />

of MEWPs on site.<br />

JL: It is management’s responsibility to<br />

ensure that all work at height is properly<br />

planned and organised in advance, by a<br />

competent person, and if work can be<br />

planned so that having someone working<br />

at height can be avoided, then this<br />

should be done. This forms part of the<br />

risk assessment.<br />

Where it is not possible to avoid<br />

working at height, management must<br />

ensure that the most appropriate equipment<br />

is selected and used and that<br />

people are trained and competent to<br />

undertake the work. This course will<br />

give those making these decisions the<br />

knowledge to help them decide whether<br />

a MEWP is the most suitable piece of<br />

equipment for the work.<br />

WM: Justine, do you have any specific<br />

concerns regarding the use of MEWPs<br />

on site?<br />

JL: I think the lack of familiarisation<br />

training is a concern. Each MEWP has<br />

it own unique controls according to the<br />

manufacturer.<br />

WM: Is familiarisation training down to<br />

the supplier?<br />

JL: Yes, but whoever’s hiring the kit<br />

should be asking for familiarisation<br />

training as well.<br />

AB: It’s an interesting point because, if<br />

you take the car analogy, you must have<br />

a driving licence to hire a car. Should<br />

hire companies only be allowed to hire<br />

MEWPs to, let’s say, PAL Card holders?<br />

JL: I would agree in principle. It’s in<br />

their interest to ensure that only properly<br />

trained operators use their kit.<br />

continued on page 14<br />

“MEWPs are increasingly<br />

being used in all areas of<br />

the industry. Any course<br />

that raises both awareness<br />

and competency is<br />

welcome.”<br />

Steve Derbyshire<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007 13

“There is big growth<br />

in MEWPs at the<br />

moment, and there is<br />

the perception that<br />

they’re safer, but of<br />

course, they’re only<br />

as safe as the person<br />

using them.”<br />

Andrew Brown<br />

continued from page 13<br />

AB: I would also argue that for an electrician,<br />

for instance, a MEWP should<br />

be regarded as a tool of his trade in the<br />

same way that a drill is. Why shouldn’t<br />

it be part of an electrician’s training?<br />

TW: We’re trying to persuade the colleges<br />

to do that.<br />

AB: There is big growth in MEWPs at<br />

the moment, and there is the perception<br />

that they’re safer, but of course,<br />

they’re only as safe as the person using<br />

them, and they are very technical bits<br />

of kit. If you extend the car analogy,<br />

people think 30 to 40 lessons are necessary<br />

to pass – yet we say MEWPs are<br />

more technical than cranes and we ask<br />

for less training!<br />

TW: Though you could argue that traffic<br />

conditions are more dangerous than<br />

average site conditions, which is why<br />

you need all those lessons.<br />

AB: I would hate to be a site manager<br />

at present: there are so many cards out<br />

there it must be almost impossible to<br />

establish if someone is competent to use<br />

a certain item of kit.<br />

SD: With CSCS, there have been more<br />

and more fraudulent cards about. An<br />

agency might supply us with labour<br />

that either did not have the appropriate<br />

cards, or had fraudulent cards, but they<br />

are not prosecuted. We try to manage<br />

this as best we can, but there’s no real<br />

deterrent. However, if someone was<br />

caught with a fake driving licence, they<br />

would quickly be prosecuted.<br />

AB: And if it was established someone<br />

on our site was using kit they were not<br />

qualified for, the HSE will quickly come<br />

down on us.<br />

SD: There needs to be some sort of<br />

central controlling authority to suspend<br />

these agencies. We can say we’ll never<br />

use them again, but they will still work<br />

elsewhere in the industry. At present,<br />

agencies don’t want to be responsible<br />

for who they have on their books.<br />

AB: Would the HSE ever take enforcement<br />

action against an individual who<br />

had procured a fraudulent card?<br />

JL: The HSE can take enforcement<br />

action for lack of training, but fraud<br />

would be investigated by the police.<br />

SD: One thing that could make a difference<br />

to the fraudulent cards issue is<br />

online authentication – if you could do<br />

a simple check on the web to authenticate<br />

the operator, that would be a huge<br />

help to our site managers.<br />

TW: It’s certainly something we could<br />

look at. I also wonder if some kind of<br />

swipe system could be integrated into<br />

the ignition system?<br />

WM: I guess that would be an issue for<br />

manufacturers, but it raises an interesting<br />

question: should there be pressure<br />

on manufacturers to bring features into<br />

their kit that help make the industry<br />

safer? Should there be greater standardisation<br />

in their kit to cut down on<br />

confusion?<br />

SD: Yes, better ergonomic design is<br />

needed, with standardised controls. It’s<br />

ridiculous that you could pull the lever<br />

one way with one kind of MEWP to go<br />

up, but the other way with a different<br />

manufacturer’s machine and you would<br />

go down! In a car, you know the accelerator,<br />

brake and clutch will all be in the<br />

same place.<br />

WM: But how do you get the manufacturers<br />

onside?<br />

SD: It’s difficult. They’re strong.<br />

TW: Well, we’ve got EN280, which<br />

eventually brought dramatic safety<br />

improvements and one of the issues<br />

that the <strong>IPAF</strong> Manufacturers’ Technical<br />

Committee is looking into is how to<br />

standardise controls on machines.<br />

WM: Maybe when we next do this<br />

debate, we need to have a manufacturer<br />

representative here as well!<br />

14<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

Access Safety Training<br />

WE OFFER <strong>IPAF</strong> AND PASMA<br />

APPROVED ACCESS SAFETY<br />

TRAINING COURSES.<br />

Available from the following A-Plant locations or at your own premises:<br />

Aberdeen, Avonmouth, Birmingham, Brentwood, Bridgend,<br />

Egremont (PASMA only), Gatwick (PASMA only), Kendal, Manchester,<br />

Northampton, Nottingham, Southampton, Staines and Stockton.<br />

For further information on our <strong>IPAF</strong> and PASMA training courses please contact:<br />

A-Plant Access Safety Training<br />

Tel: 0845 600 8573<br />

E-mail: accesstrainingcentre@aplant.com

PRESIDENT IN PROFILE<br />

View from<br />

the top<br />

Andrew Reid, the new president of <strong>IPAF</strong>, is<br />

one of the pioneers of powered access. Phil<br />

Bishop talks to him about the policy to get<br />

tough with rogues and corner-cutters in<br />

the industry.<br />

tion to detail was lost, accidents began<br />

to happen and mast climbers fell out of<br />

favour.<br />

Specialist offering<br />

Reid returned to the industry in 1996,<br />

establishing Mastclimbers as a specialist<br />

rental company. “When I started<br />

Mastclimbers it was a case of buying<br />

back kit that had been lying around in<br />

yards with nettles growing over it,“ he<br />

says. But with a good scrub and a lick of<br />

paint, it was as good as new.<br />

The first purchase was the fleet of<br />

Foulis, which had 70 machines. Three<br />

days later, while dismantling a mast<br />

climber that Foulis had erected in<br />

Glasgow, the platform collapsed. “That<br />

was my relaunch back into the mastclimbing<br />

industry,” says Reid. “During<br />

the investigations into that accident,<br />

I was informed by the HSE that they<br />

were within a whisker of banning them.<br />

There had been a couple of fatalities the<br />

year before with the EPL fleet. The use<br />

of the product was beginning to be an<br />

embarrassment because of the number<br />

of accidents,” he recalls.<br />

When Andrew Reid looks around the<br />

construction industry today he is “gobsmacked”,<br />

he says, “at the number of<br />

powered access products and the level<br />

of acceptance they now have”. This<br />

is because he can recall the days, 25<br />

years ago, when he would drive around<br />

construction sites with a boom lift or<br />

scissor lift on the back of a trailer trying<br />

to persuade people to try it. “I look back<br />

at how we had to knock down doors to<br />

get people to even look at the thing,” he<br />

says. “It was true pioneering stuff. We<br />

were literally forcing people to try it.”<br />

Over the past 30 years, Reid – now<br />

60 – has played a key role in getting<br />

firstly boom and scissor lifts, and then<br />

mast climbing work platforms, accepted<br />

in the UK. And he has worked in manufacturing,<br />

distribution and the rental<br />

side as well.<br />

Career move<br />

Reid’s first contact with the powered<br />

access industry was in 1975. He was<br />

working in marketing for Coles Cranes<br />

at the time. John L Grove had been<br />

squeezed out of the Grove Crane company<br />

that he had founded and so, having<br />

signed a non-compete agreement,<br />

established JLG Industries to produce<br />

powered access platforms.<br />

JLG approached Coles with a proposal<br />

for the latter to produce its platforms in<br />

the UK. The talks came to nothing, but<br />

they paved the way for a team from<br />

Coles to move to JLG in 1979 to set up a<br />

new factory in Cumbernauld. So it was<br />

that Reid returned to his native Scotland<br />

after eight years in London with Coles<br />

as sales and marketing director of JLG.<br />

In 1985 he left JLG to set up his own<br />

business, Anca Work Platforms, importing<br />

mast-climbing equipment made<br />

in Sweden by Malmqvist Svenska, in<br />

which he was also a major shareholder<br />

until its sale to HEK of Holland six years<br />

later.<br />

“Mast climbers were still an embryonic<br />

product”, he says, but Reid was<br />

sufficiently successful in persuading the<br />

industry that they represented the next<br />

revolution in access that he made sales<br />

to the major rental companies of the<br />

day, such as PTP, Scott Greenham and<br />

Hewden Stewart. “PTP built up a fleet of<br />

a couple of hundred units,” he recalls.<br />

In fact, Anca Work Platforms was<br />

sold to PTP in 1986, and eventually<br />

became the core of BET and Rentokil’s<br />

mast-climbing subsidiary.<br />

However, the image of mast climbers<br />

came to take a battering. They are<br />

a specialist piece of kit, but as rental<br />

companies changed hands, they began<br />

to be treated as commodity items. “The<br />

product lost its specialised support from<br />

people who knew how to handle them,<br />

and they got parcelled in with scissors<br />

and booms,” Reid explains. As atten-<br />

Raising standards<br />

This experience informs Reid’s close<br />

involvement with <strong>IPAF</strong> and the role<br />

he has played in the development of<br />

standards. He has chaired <strong>IPAF</strong>’s mastclimbers<br />

committee since its formation<br />

20 years ago, when it got together with<br />

the HSE to define the regime for this<br />

new product. “We have gone from a lack<br />

of definition, to a European harmonised<br />

design standard adopted by ISO and a<br />

British standard for safe use. That’s been<br />

achieved through <strong>IPAF</strong>,” he says.<br />

The standards agenda was given a<br />

major push after the Glasgow accident.<br />

“That accident led me to delve very<br />

deeply into all manner of legislation,” he<br />

says. Within five years, all the European<br />

and British standards had been re-written.<br />

“And – dangerous as it is to say – I<br />

am delighted that there hasn’t been an<br />

MCWP accident in the UK in the past<br />

three years,” he adds.<br />

Tough regulation<br />

With first-hand experience of how<br />

accidents, and the headlines that they<br />

generate, can impact on the perception<br />

of a product and the reputation of an<br />

industry, Reid is a firm believer in tough<br />

regulation to promote best practice and<br />

safety.<br />

“What happens in every industry,<br />

companies, people, individuals are basically<br />

out to make a buck. If they can cut<br />

a corner this way, cut a corner that way<br />

“There is nothing more sickening than seeing certain<br />

organisations disregard standards and put the whole<br />

industry at risk.”<br />

Andrew Reid<br />

16<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

“My vision is that a day will come when no serious contractor or<br />

industry user will buy or hire a piece of access equipment from<br />

anybody other than an <strong>IPAF</strong> member.”<br />

Andrew Reid<br />

to make an extra buck, unfortunately<br />

they will do it. There is nothing more<br />

sickening than seeing certain organisations<br />

disregard standards and put the<br />

whole industry at risk. Any incident<br />

that hits the press of a scaffold collapse,<br />

a mast-climber collapse or a boom lift<br />

tipover tends to lead people to revert to<br />

traditional methods of access. We don’t<br />

want corner-cutters reducing usage,”<br />

he says.<br />

Avoiding delays<br />

This is to be the major theme of<br />

Reid’s two-year term of office. In his<br />

inaugural presidential address to the<br />

<strong>IPAF</strong> AGM in April 2006, he said:<br />

“Accidents will happen and when they<br />

do every one of us suffers. It gives<br />

the luddites a further excuse to delay<br />

progress; progress being the adoption<br />

of our technology that goes forward<br />

to progress the industry. It is all of our<br />

duty to minimise this.<br />

“My vision is that a day will come<br />

when no serious contractor or industry<br />

user will buy or hire a piece of access<br />

equipment from anybody other than an<br />

<strong>IPAF</strong> member and that they will do that<br />

with the complete confidence that they<br />

are going to receive a fit-for-purpose<br />

product supported by trained people<br />

who know their business.<br />

“Non-compliance or corner-cutting<br />

by <strong>IPAF</strong> members will be highlighted,<br />

leading to exposure, leading to name<br />

and shame, and ultimately leading to<br />

expulsion from <strong>IPAF</strong>.<br />

“It is a sorry fact that in most of the<br />

Western world the safety authorities, the<br />

HSE, OSHA in the USA, other bodies<br />

throughout Europe – they do not police<br />

– nobody polices. They wait until things<br />

go wrong and then the lawyers pounce<br />

on the situation.<br />

“I see a role here to improve the<br />

adherence to safety standards in some<br />

form of diligent policing that raises the<br />

standard of all <strong>IPAF</strong> members. Other<br />

bodies have done this and they have<br />

achieved a level of acceptance and a<br />

level of professionalism that is the envy<br />

of all. It is my objective to project <strong>IPAF</strong><br />

towards this goal over the course of the<br />

next two years.”<br />

Expanding on the theme today, he<br />

acknowledges that it is hard for <strong>IPAF</strong><br />

to refuse membership for companies<br />

applying to join, since it could be construed<br />

as restraint of trade. However,<br />

where existing established <strong>IPAF</strong> members<br />

have voiced concerns about new<br />

applicants – sometimes well-founded<br />

and sometimes not – entry has sometimes<br />

been made conditional on them<br />

demonstrating adherence to certain<br />

quality standards.<br />

Warning signs<br />

That said, Reid is a pragmatist and not a<br />

safety fanatic. He recalls a vigorous dispute<br />

between the industry (which eventually<br />

won) and the HSE some years ago<br />

over a proposal that gates on platforms<br />

should have warning signs saying that<br />

gates should not be opened while in use.<br />

“You don’t have signs on the inside of<br />

car doors warning you not to open them<br />

while moving, do you?” he says.<br />

Reid sees the <strong>IPAF</strong> Rental+ scheme as<br />

a key plank in the strategy to promote<br />

best practice and adherence to standards.<br />

However, eliminating corner-cutting<br />

will be a gradual, evolutionary<br />

process. “It’s nothing that’s going to<br />

be immediately and earth-shatteringly<br />

realised. It’s just something I want to get<br />

people talking about. It’s the old story<br />

of throwing mud at a wall and hoping<br />

some of it sticks,” he says.<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007 17

Working at Height?<br />

APPROVED TRAINING<br />

Working at height is<br />

a challenging task<br />

changes in the law,<br />

growing time restraints<br />

and constant pressure<br />

on budgets mean you<br />

need a partner whom<br />

you can trust.<br />

The Platform Company<br />

are experts in powered<br />

access. Through a<br />

network of branches<br />

across the UK we offer<br />

packages of equipment,<br />

training and advice that<br />

are individually tailored<br />

to help you work safer<br />

at height.<br />

Glasgow<br />

Newcastle<br />

Leeds<br />

Liverpool<br />

Leicester<br />

Birmingham<br />

Barking (London East)<br />

Heathrow (London West)<br />

Bristol<br />

Southampton<br />

Slough (Central Admin)<br />

We deliver<br />

Hire ● Sales ● Safety Training ● Platform Accessories ● Harnesses<br />

Site Surveys ● Demonstrations ● Contract Servicing<br />

Platform<br />

the<br />

company<br />

0800 028 18 08<br />

www.platformcompany.co.uk

TRAINING<br />

Training faces<br />

<strong>IPAF</strong>’s mobile elevating work platform training courses<br />

attract a wide variety of operators from all areas of<br />

industry. Geoff Ashcroft spoke with three recently trained<br />

operators to find out what they gained from their courses.<br />

Electrical and mechanical engineering<br />

contractor John Frizell has found that<br />

attending a MEWP training course and<br />

getting a PAL Card (Powered Access<br />

Licence) for a self-propelled boom has<br />

encouraged safer and more productive<br />

operating techniques while on site.<br />

“Most of our work is off the ground,<br />

so diesel-powered booms tend to feature<br />

heavily in what we do,” explains Frizell,<br />

who is currently working on Heathrow’s<br />

T5 project for his employer, Dartfordbased<br />

Crown House Technology.<br />

“The increasing amount of high-level<br />

work we now handle means we need to<br />

have more operators with PAL Cards, so<br />

that we can get over the workload safely<br />

and be more productive.”<br />

“As work progresses, often to tight<br />

time schedules, it’s important for us<br />

to have more colleagues capable of<br />

operating these types of machinery, and<br />

having a day’s specialist training and<br />

assessment is essential,” he reckons.<br />

Frizell says booms are the platform of<br />

choice for the work he’s involved with<br />

at T5, given the reach they offer to carry<br />

out electrical installation work among<br />

multi-level car parking facilities.<br />

“Some of the equipment we currently<br />

use extends to 10m,” he says. “Training<br />

is essential – you can’t put just anyone<br />

on this type of kit anymore.”<br />

Learning curve<br />

While he admits to being no stranger<br />

to booms, having spent several years<br />

working with kit that offered much less<br />

reach and height, he accepts that learning<br />

more about the latest equipment and<br />

how it operates has been a useful step.<br />

“Training took place on site, which<br />

was really useful as it gave me an<br />

insight specifically into the equipment<br />

we’re currently using,” he says.<br />

“Attending the course has made me look<br />

at things differently. The training has<br />

helped me to make more thorough risk<br />

assessments, and enabled me to identify<br />

safety issues that could have been easily<br />

overlooked.”<br />

While he concedes that much of the<br />

training course is common-sense based,<br />

there were additional elements of powered<br />

access operation that have been<br />

brought to his attention.<br />

“Machine manoeuvrability around<br />

site, in addition to safe working at<br />

height, is an area that can easily be<br />

overlooked,” he says. “But after attending<br />

the course, I feel much more aware<br />

of what is going on around me while I’m<br />

working with the platform.”<br />

Devon-based carpenter Mark Pardoe<br />

recently attended an <strong>IPAF</strong> course to<br />

acquire his PAL Card for booms and<br />

scissor lifts.<br />

“It does everyone some good to be<br />

made more aware of your working<br />

environment and the safety issues that<br />

go with it,” says the chippy, who is one<br />

of 20 craftsmen working for Jim Davis<br />

Carpenters in Exmouth, Devon.<br />

Currently working on the refurbishment<br />

of a five-storey, 200-year-old<br />

pottery, which is being transformed into<br />

luxury apartments, he sees his PAL Card<br />

as a useful qualification that should<br />

ensure continuity of work on site.<br />

“In the safety-driven industry we<br />

work in, there seems to be more and<br />

more emphasis on having tickets and<br />

licences for what you are required to<br />

do, and that goes way beyond our own<br />

trade’s skills,” he says. “But when you’re<br />

working 30 feet in the air, you just can’t<br />

Training is split<br />

into theory and<br />

practice, including<br />

a written and<br />

a practical test<br />

where trainees<br />

are assessed<br />

by a certified<br />

instructor.<br />

A trained platform operator is able to get the job done safely, effectively and productively.<br />

continued on page 20<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007<br />

19

continued from page 19<br />

compromise on safety issues, nor can<br />

you afford to have someone working<br />

with you, just to lift you up and put<br />

you down.”<br />

“Where scaffolding used to be the<br />

preferred means of working on the<br />

outside of buildings, powered access has<br />

taken over – it just offers so much more<br />

flexibility and productivity, particularly<br />

for trades like us replacing external<br />

windows,” he says.<br />

Informative training<br />

While Pardoe reckons the bulk of the<br />

course hinges around certain fundamental<br />

elements, he found some aspects<br />

of the day’s training to be refreshingly<br />

informative.<br />

“Our instructor was very much to the<br />

point,” he says. “While there are lots of<br />

common-sense issues and reminders,<br />

you do tend to overlook and forget<br />

about them when complacency sets in<br />

– and that’s inevitable when you do the<br />

same tasks over and over again.”<br />

“I’d never before considered planning<br />

how I would use a battery powered<br />

machine to conserve its energy or ensure<br />

that I planned my working time to suit<br />

the battery life available,” he adds.<br />

He also reckons that the course provided<br />

useful additional information that<br />

goes beyond the safe operation of the<br />

work platform. He says the use of harnesses,<br />

being tied on and ensuring tools<br />

are secured too while working from the<br />

platform, have all helped him to be safer<br />

and more productive in what he does.<br />

“Attending the course has had a<br />

direct impact on how my colleagues and<br />

I now interact when we work at height,”<br />

he says.<br />

Lofty ambitions<br />

Working on all manner of contracts for<br />

West Sussex Joinery, Mike Younge has<br />

found increasingly that more and more<br />

time is spent working at height – which<br />

prompted his attendance at a recent<br />

training course to earn a PAL Card.<br />

“We’re busy putting up dry linings<br />

and plasterboard partition walls, but<br />

About <strong>IPAF</strong> training and the PAL Card<br />

The <strong>IPAF</strong> training programme for<br />

operators of mobile elevating<br />

work platforms is certified by<br />

TüV as conforming to ISO 18878.<br />

Training is provided through a<br />

worldwide network of over 250<br />

<strong>IPAF</strong>-approved training centres.<br />

Successful trainees are<br />

awarded the PAL Card (Powered<br />

Access Licence). A PAL Card is<br />

valid for five years and shows<br />

the equipment categories that<br />

the holder has been trained<br />

to operate. More than 50,000<br />

people are trained each year<br />

to use platforms safely and<br />

effectively.<br />

The PAL Card is recognised in many countries as proof of platform operator training. In the UK, the<br />

<strong>IPAF</strong> training programme is approved by the Major Contractors Group (MCG) and operators holding an<br />

<strong>IPAF</strong> PAL Card are welcomed on any MCG site.<br />

To find out more, visit www.ipaf.org.<br />

most of them are in large, open buildings,<br />

which requires almost constant<br />

working at height,” he says.<br />

“Quite often we’re finding that partition<br />

walling in large buildings takes<br />

us up to working heights of 11m, and<br />

it makes sense to have more than one<br />

person qualified for the safe operation<br />

of a scissor lift. This way, we have<br />

operational flexibility in what we do,”<br />

he explains.<br />

Additionally, Younge believes that<br />

more and more firms are being increasingly<br />

asked for licences and tickets by<br />

site agents to prove that proper equipment<br />

training has been carried out,<br />

before they are allowed on site.<br />

“I see what I’ve achieved as being yet<br />

another skill that makes our firm much<br />

more valuable to those who employ our<br />

specialist services,” he says.<br />

In August 2006, Younge was trained<br />

on-site, using a scissor lift that is onhire<br />

to West Sussex Joinery.<br />

“I found it very useful to be trained<br />

on-site using our own equipment and in<br />

a working environment that is familiar<br />

to me,” he says. “Given the choice, it’s<br />

much less intimidating than going to<br />

a training centre or perhaps having<br />

to return to a college to get specialist<br />

training and assessments carried out.”<br />

Younge attended the training session<br />

with an open mind.<br />

“You look at kit and think that it’s<br />

easy enough to operate, which, to a<br />

degree is true,” he says. “But you don’t<br />

always see the risks associated with<br />

what you’re doing, or see how others<br />

around your working area can put you<br />

at risk.<br />

“It’s easy to take straightforward<br />

things for granted, without thinking<br />

about how a situation can quickly<br />

change, and the course was useful in<br />

addressing some of those scenarios to<br />

make you much more aware of what is<br />

going on around you.”<br />

“I learnt a lot about how to assess and<br />

identify ground conditions, and how<br />

different surfaces can affect machine<br />

stability too,” he says. “With a PAL<br />

Card, I can work independently of others,<br />

which makes our team much more<br />

productive.”<br />

Thanks to Nationwide Access for<br />

their assistance with this article.<br />

See what the MCG says about the PAL Card at<br />

www.citb-constructionskills.co.uk/cardschemes.<br />

The PAL Card:<br />

Validity can be<br />

checked with a<br />

single call to the<br />

<strong>IPAF</strong> hotline at<br />

0845 1307775.<br />

20<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007

Multi-trade Access Curtain Walling Tower Block Overcladding<br />

Rainscreen Cladding<br />

Registered <strong>IPAF</strong> training<br />

centres for Mast Climbing<br />

Work Platforms (MCWP)<br />

Industrial Cladding<br />

To book a place on a course<br />

or for further information:<br />

Commercial Glazing<br />

www.sgbmastclimbers.co.uk<br />

0845 6000 878<br />

Goods Transport Platform<br />

Tower Block Refurbishment Bricklaying Inclined Access

Z-51/30J RT<br />

ARTICULATING BOOM<br />

engineered FROM THE<br />

ground up<br />

Genie’s product range is renowned throughout the<br />

industry for being rugged and reliable. There is a<br />

machine for just about every need and condition.<br />

Genie aerial work platforms offer you superior<br />

performance, safety and reliability.<br />

Copyright © 2006 Genie Industries, Inc. All rights reserved.<br />

TELESCOPIC BOOMS ARTICULATING BOOMS SCISSOR LIFTS TRAILER MOUNTED BOOMS TELEHANDLERS MATERIAL LIFTS AERIAL WORK PLATFORMS<br />

The world leader in lifts is ready to serve you with comprehensive product<br />

support, parts, training and people who understand your business. To learn<br />

more, contact Genie today.<br />

TEL: +44 (0)1476 584333<br />

EMAIL: infoeurope@genieind.com<br />

WEB: www.genieindustries.com<br />

Plastic Card Design Services are<br />

specialists in the supply and support of<br />

Zebra Card Printers for the<br />

personalisation of plastic cards. Also<br />

offered is a bureau service where blank<br />

or pre-printed cards can be thermally<br />

printed and encoded to your specific<br />

requirements.<br />

• Photo ID<br />

• Membership<br />

• Training Certification<br />

• Conference & Events<br />

• Bureau Services<br />

• Pre-Printed Cards<br />

• Zebra Card Printers<br />

• Blank Cards, Ribbons, Peripherals<br />

• Card Accessories<br />

• Card Design Software<br />

• Installation, Training, Service & Support<br />

Zebra P330i<br />

Single Sided<br />

Card Printer<br />

(<strong>IPAF</strong> supplier of PAL Cards)<br />

For all your plastic card requirements<br />

call 01536 410557 or visit<br />

www.plasticcardsuk.com<br />

Plastic Card Design Services Ltd<br />

15 Bramshill Avenue, Kettering, Northants NN16 9FL<br />

Tel: 01536 410557 / Fax: 01536 510509<br />

Email: sales@plasticcardsuk.com<br />

Zebra P110i<br />

Single Sided<br />

Card Printer<br />

working at height?<br />

Street<br />

lighting pack<br />

Telescopic<br />

Boom models<br />

Up to 23m<br />

Jackless<br />

models<br />

Insulated<br />

models<br />

360º<br />

continuous<br />

we’ve got it!<br />

van mounted<br />

access platforms<br />

www.versalift.co.uk<br />

1 Altendiez Way, Latimer Park,<br />

Burton Latimer, Northants. NN15 5YT.<br />

Tel: 01536 721010 Fax: 01536 721111<br />

email: sales@versalift.co.uk

<strong>IPAF</strong> RENTAL+<br />

Wheat and chaff<br />

Hire companies sporting the <strong>IPAF</strong> Rental+ logo have<br />

demonstrated that they meet the very highest industry<br />

standards. Customers using these companies can be<br />

assured they are employing the industry’s best. Phil<br />

Bishop reports.<br />

When machines are delivered,<br />

<strong>IPAF</strong> Rental+ companies offer a<br />

demonstration to make sure that<br />

customers are familiar with the controls.<br />

Barriers to entry in the powered access<br />

rental business are remarkably low. A<br />

battered old machine can be bought for<br />

a snip, and if you ask for little enough<br />

rent, there will always be customers who<br />

are happy to accept the lowest levels of<br />

service, performance and reliability.<br />

The challenge for the industry as a<br />

whole is not just protecting margins<br />

against such lowest common denominators,<br />

but to drive up standards across the<br />

board to preserve and enhance safety<br />

standards. Hand in hand with this is the<br />

need to educate customers that there is<br />

a huge difference between those companies<br />

that go to great lengths to do things<br />

properly and comply with all relevant<br />

standards and regulations, and those<br />

companies that routinely cut corners.<br />

Last year the International Powered<br />

Access Federation (<strong>IPAF</strong>) introduced a<br />

new ‘kite mark’ scheme, called <strong>IPAF</strong><br />

Rental+.<br />

Companies authorised to display the<br />

<strong>IPAF</strong> Rental+ mark have been independently<br />

audited and found to meet<br />

defined standards in customer service,<br />

safety, staff training, contract terms and<br />

machine inspection (see box, overleaf).<br />

The scheme is entirely voluntary and<br />

half a dozen companies have qualified<br />

for the mark so far, including:<br />

■ Rapid Platforms Ltd, based in<br />

Bishop’s Stortford;<br />

■ Watford-based Alan Drew Ltd (which<br />

was taken over by AFI in April 2006);<br />

■ Facelift Access Hire of Hickstead; and<br />

■ Panther Platform Rentals Ltd of<br />

Dunstable.<br />

(See current list at www.ipaf.org)<br />

Although the scheme was officially<br />

launched last year, there was still a<br />

pilot phase to be gone through. “It is<br />

only beginning to crystallise now,” says<br />

<strong>IPAF</strong> managing director Tim Whiteman.<br />

“A lot of companies are now applying<br />

for it.”<br />

Whiteman says that the scheme<br />

offers companies valuable assistance<br />

in raising their game and applying the<br />

<strong>IPAF</strong> Rental+ template to their business,<br />

without the huge costs of bringing in<br />

consultants.<br />

For well-run companies such as<br />

these, achieving the required level was<br />

not a huge leap. “We just had to tighten<br />

up procedures,” says Gordon Leicester,<br />

owner and managing director of<br />

Facelift. “We were pretty much already<br />

there in the first place.”<br />

For Rapid Platforms, the first company<br />

to secure the award, it was mostly<br />

a case of formalising existing practice.<br />

“There were certain things we did but<br />

didn’t document,” says training manager<br />

Chris Buisseret. “Now we do,” he says.<br />

“Basically, it’s a matter of standards. We<br />

have always had a strong training ethos<br />

in the company.”<br />

His colleague, Colin Hall, a former<br />

director of Rapid Platforms and still<br />

retained as a consultant, explains that<br />

for the hire desk it meant being more<br />

systematic, and ensuring every team<br />

member was using the same check list<br />

of questions when talking to customers,<br />

particularly new customers.<br />

Hall says: “When you’ve been running<br />

a system for a long time, sometimes<br />

you can’t see the wood for the<br />

continued on page 24<br />

<strong>IPAF</strong> senior<br />

auditor Giles<br />

Councell (right)<br />

presents the <strong>IPAF</strong><br />

Rental+<br />

award to Brian<br />

Fleckney of<br />

Panther Platform<br />

Rentals, one of<br />

the newest<br />

companies to join<br />

the scheme.<br />

<strong>IPAF</strong> POWERED ACCESS REVIEW 2007<br />

23

“Customers should<br />

start to realise that<br />

the <strong>IPAF</strong> Rental+<br />

companies are<br />

safer companies to<br />

do business with.”<br />

Gordon Leicester<br />

Managing director<br />

Facelift<br />

The <strong>IPAF</strong><br />

Rental+ logo<br />

is a sure sign<br />

of reliability<br />

and good<br />

service.<br />

continued from page 23<br />

trees. The audit made us evaluate what<br />

we do and made us sharpen up some of<br />

our paperwork and ensure everyone on<br />

the hire desk knows about every bit of<br />

kit.”<br />

Regular inspections<br />

For customers, who may not care about<br />

the procedures and paper trails within<br />

the offices of their equipment suppliers,<br />

the real benefit from using an <strong>IPAF</strong><br />

Rental+ company is that it is safe to<br />

assume that the machines have been<br />

properly and regularly inspected.<br />

“A lot of the time, customers haven’t<br />

the faintest idea whether their machine<br />

has been inspected or not,” Leicester<br />

says. “Nowadays, when you get into a<br />

lift in a block of flats, you absolutely<br />

assume it is inspected regularly. Today<br />

they probably are, but in the 1960s there<br />

were a lot of accidents.”<br />

He continues: “Everybody assumes<br />

that all access hire companies are<br />

working to the same standards,” says<br />

Leicester. ”But there are lots of people<br />

out there who don’t inspect machines<br />

pre-hire or are not timely in their sixmonthly<br />

thorough examinations.”<br />

Both Facelift and Rapid Platforms<br />

find that, for the time being, the power<br />

of the mark to win business is limited.<br />

However, they expect this to change.<br />

Quality systems<br />

Hall says there is kudos attached to<br />

being an <strong>IPAF</strong> Rental+ company and<br />

it certainly helps relations with big<br />

customers such as Glaxo SmithKline<br />

and The Tate, who prize quality systems<br />

and safety prizes. However, its pull as a<br />

sales tool with construction contractors<br />

remains limited until awareness of the<br />