Palfinger Crane Passion 10 2014 ENGLISH VERSION

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

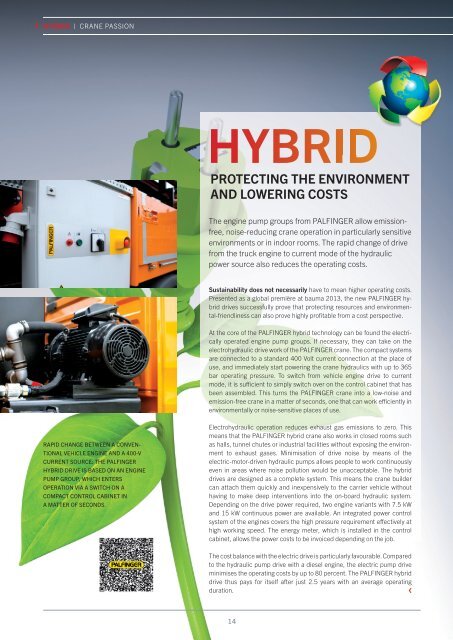

hybrId | CRANE PASSIoN<br />

hybrId<br />

ProtectIng the envIronment<br />

and lowerIng costs<br />

The engine pump groups from PALFINGER allow emissionfree,<br />

noise-reducing crane operation in particularly sensitive<br />

environments or in indoor rooms. The rapid change of drive<br />

from the truck engine to current mode of the hydraulic<br />

power source also reduces the operating costs.<br />

sustainability does not necessarily have to mean higher operating costs.<br />

Presented as a global première at bauma 2013, the new PALFINGER hybrid<br />

drives successfully prove that protecting resources and environmental-friendliness<br />

can also prove highly profitable from a cost perspective.<br />

At the core of the PALFINGER hybrid technology can be found the electrically<br />

operated engine pump groups. If necessary, they can take on the<br />

electrohydraulic drive work of the PALFINGER crane. The compact systems<br />

are connected to a standard 400 Volt current connection at the place of<br />

use, and immediately start powering the crane hydraulics with up to 365<br />

bar operating pressure. To switch from vehicle engine drive to current<br />

mode, it is sufficient to simply switch over on the control cabinet that has<br />

been assembled. This turns the PALFINGER crane into a low-noise and<br />

emission-free crane in a matter of seconds, one that can work efficiently in<br />

environmentally or noise-sensitive places of use.<br />

RAPID CHANGE BETWEEN A CONVEN-<br />

TIONAL VEHICLE ENGINE AND A 400-V<br />

CURRENT SOURCE: THE PALFINGER<br />

HYBRID DRIVE IS BASED ON AN ENGINE<br />

PUMP GROUP, WHICH ENTERS<br />

OPERATION VIA A SWITCH ON A<br />

COMPACT CONTROL CABINET IN<br />

A MATTER OF SECONDS.<br />

Electrohydraulic operation reduces exhaust gas emissions to zero. This<br />

means that the PALFINGER hybrid crane also works in closed rooms such<br />

as halls, tunnel chutes or industrial facilities without exposing the environment<br />

to exhaust gases. Minimisation of drive noise by means of the<br />

electric-motor-driven hydraulic pumps allows people to work continuously<br />

even in areas where noise pollution would be unacceptable. The hybrid<br />

drives are designed as a complete system. This means the crane builder<br />

can attach them quickly and inexpensively to the carrier vehicle without<br />

having to make deep interventions into the on-board hydraulic system.<br />

Depending on the drive power required, two engine variants with 7.5 kW<br />

and 15 kW continuous power are available. An integrated power control<br />

system of the engines covers the high pressure requirement effectively at<br />

high working speed. The energy meter, which is installed in the control<br />

cabinet, allows the power costs to be invoiced depending on the job.<br />

The cost balance with the electric drive is particularly favourable. Compared<br />

to the hydraulic pump drive with a diesel engine, the electric pump drive<br />

minimises the operating costs by up to 80 percent. The PALFINGER hybrid<br />

drive thus pays for itself after just 2.5 years with an average operating<br />

duration.<br />

14