Palfinger Crane Passion 10 2014 ENGLISH VERSION

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

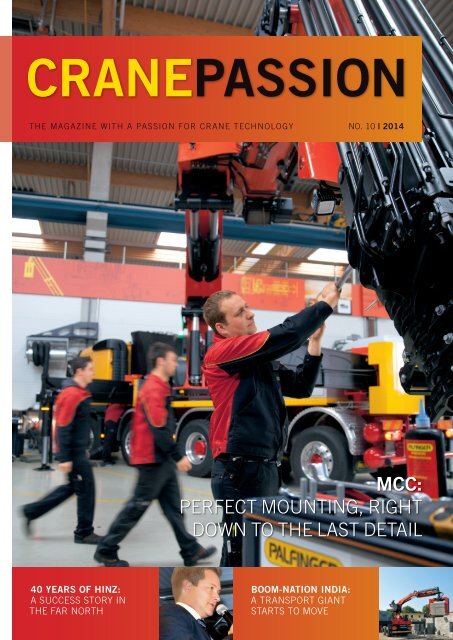

CRANEPASSION<br />

THe MaGaZIne WITH a PaSSIOn FOr <strong>Crane</strong> TeCHnOLOGY nO. <strong>10</strong> | <strong>2014</strong><br />

mcc:<br />

PERFECT MoUNTING, RIGHT<br />

DoWN To THE LAST DETAIL<br />

40 YEARS OF HINZ:<br />

a SUCCeSS STOrY In<br />

THe Far nOrTH<br />

BOOM-NATION INDIA:<br />

a TranSPOrT GIanT<br />

STarTS TO MOVe

CONTENTS | CRANE <strong>Passion</strong><br />

12<br />

SRC<br />

04 NEWS<br />

News from the world of PALFINGER.<br />

09 VEHICLE BODY CALCULATION<br />

SOFTWARE PACWIN<br />

With Pacwin, PALFINGER offers a new version of<br />

a planning tool for crane mounting that covers over<br />

three million commercial vehicle variants.<br />

14 Hybrid TechnologY<br />

Motor pump group enables quiet, emission-free crane<br />

operation.<br />

15 ANNIVERSARY<br />

Hinz in Sweden has been working for PALFINGER<br />

for 40 years.<br />

16 Job Report<br />

The new long-arm crane PALFINGER PK 200002 L SH<br />

transports fully-grown trees for a roof garden at a height<br />

of 30 metres.<br />

06<br />

MCC<br />

18<br />

International<br />

IMPRINT:<br />

Editor:<br />

PALFINGER AG, Franz-Wolfram-Schererstrasse 24,<br />

A 5020 Salzburg/Austria<br />

Phone: +43 (0) 662/46 84-0, www.palfinger.com<br />

INFORMATION FOR CUSTOMERS AND<br />

PARTNERS OF PALFINGER<br />

Employees involved in this issue:<br />

Paul Göttl, Eveline Gruber, Peter Lukas,<br />

Hubert Meschnark, Michael Völker, Oliver Willms<br />

Photos:<br />

PALFINGER AG, Oliver Willms<br />

Graphic:<br />

Simone Strobel<br />

Conception and implementation:<br />

Paul Göttl, ETMservices, a business division of ETM publishing house, Stuttgart<br />

PREVIEW of<br />

<strong>Crane</strong> <strong>Passion</strong> 11<br />

Palcom P7<br />

New remote control revolutionises<br />

crane operation.<br />

Publisher:<br />

ETM Verlag, Handwerkstraße 15, D-70565 Stuttgart, www.etmservices.de<br />

© by ETMservices <strong>2014</strong><br />

2

InternatIonalIsatIon<br />

InnovatIon<br />

flexIbIlIsatIon<br />

dear Partners and frIends of PalfInger!<br />

our aspiration of being an innovation leader and offering you "LIFETIME EXCELLENCE" is paying<br />

off: the PALFINGER Group grew at an above-average rate in 2013 compared to other competitors,<br />

which means that we have further strengthened our market position. our customers obviously appreciate<br />

the fact that we provide them with the right industrial solutions for their work around the<br />

globe. We see potential for the future as well, mainly in Brazil, India and China. We have already<br />

positioned ourselves well in these markets – more about this on page 18 of this issue.<br />

Working together with our Chinese partner, SANY, is bearing initial fruits. Both the Sany <strong>Palfinger</strong><br />

joint venture in China as well as PALFINGER SANY, the marketing joint venture for Europe and the<br />

CIS, have already reported good sales successes. Up to the end of 2013, PALFINGER SANY had<br />

sold 34 units, Sany <strong>Palfinger</strong> 425. The mutual corporate holdings of PALFINGER and SANY were<br />

recently sealed in a contract-signing ceremony. With our three strategic pillars of internationalisation,<br />

innovation and flexibilisation, we will continue to achieve profitable growth in the long term in<br />

the future as well. And this is not an end in itself, but will also allow us to remain the driving force<br />

behind innovations in our industry and offer our customers the best possible solutions.<br />

In this issue, among other things we will be taking a look at our new PALFINGER Mounting Competence<br />

Center MCC in Lengau, where we produce complete solutions of this type for the most demanding<br />

crane and vehicle combinations. The advantage to you, the customer: by having the<br />

crane mounted directly in the factory, we can combine our full competence and know-how to ensure<br />

that the finished vehicle is perfectly coordinated. You can read all about this in our cover story<br />

from page 6 onwards. Exclusively for our readers of CRANE PASSIoN, we will also be lifting the curtain<br />

on our new control unit PALcom P7 to whet your appetite for an innovation that, in our opinion,<br />

will revolutionise the world of radio remote control. But for the full details you will have to wait to the<br />

market launch, which is set to take place in spring <strong>2014</strong>.<br />

I am sure you will enjoy reading CRANE PASSIoN and wish you a successful year.<br />

Wolfgang Pilz (CMo)<br />

3

NEWS | CRANE <strong>Passion</strong><br />

PALFINGER SUPPORTS<br />

THE L.I.S.I PROJECT<br />

FOR MORE THAN TEN YEARS, the US Department of Energy in California<br />

has organized the "Solar Decathlon". 20 passive houses developed by<br />

university teams are set up on site, and their suitability for daily use is then<br />

tested over a period of ten days. In October 2013, a house developed in<br />

Austria took part for the first time. It was presented by the Vienna University<br />

of Technology under the participation of the St. Pölten University of<br />

Applied Sciences, the Salzburg University of Applied Sciences and the<br />

Austrian Institute of Technology – one of only two European universities to<br />

do so. The project team competed against 200 competitors worldwide<br />

with the high-tech "LISI" house ("Living Inspired by Sustainable Innovation").<br />

With the aid of ultra-modern technologies and techniques, LISI is a<br />

so-called "plus-energy home", i.e. it generates more energy that it consumes.<br />

More than 90 percent of the LISI house construction is made up of<br />

wood. But how does an entire house make its way from Austria to California?<br />

Dismantled into small units and packaged in overseas shipping containers,<br />

it was sent on the long trip to America. And PALFINGER came into<br />

play here during loading. In light of the very limited space available in the<br />

assembly hall where the LISI house was pre-assembled and the very heavy<br />

and bulky nature of the load, the use of a knuckle boom crane with a large<br />

lifting moment was a basic pre-requisite for loading. The only company<br />

that came into consideration here was PALFINGER, with its recently<br />

launched PK 200002 L SH. Thanks to the good overall relationship between<br />

PALFINGER and the universities and research institutions, it went<br />

without saying that the company would support this project. PALFINGER<br />

congratulates the project team on this outstanding success!<br />

„<br />

LIFETIME EXCELLENCE DESCRIBES OUR CORE BRAND VALUES OF<br />

EFFICIENCY, RELIABILITY AND INNOVATION.<br />

“<br />

Wolfgang Pilz, CMO PALFINGER<br />

TRADE FAIR NEWS INTERNATIONAL<br />

MATEXPO, Belgium<br />

PALFINGER was awarded the Innovation<br />

Award 2013 at Matexpo, the largest<br />

trade fair for machinery and equipment<br />

for the construction industry, industry<br />

and environment in Kortrijk, Belgium. A<br />

five-member jury awarded the main prize<br />

to the intelligent rope winch solution SRC<br />

(synchronised rope control) (see report<br />

on page 13).<br />

BAUMA AFRICA, South Africa<br />

South Africa. Around 700 exhibitors took<br />

part in this trade fair in Johannesburg,<br />

and they were clearly very pleased that<br />

there is now a trade fair in Africa that<br />

focuses on construction equipment.<br />

Most of the companies came from South<br />

Africa and its neighbouring countries.<br />

PALFINGER exhibited the entire product<br />

and model range that is offered in South<br />

Africa.<br />

FENATRAN, Brazil<br />

Just under 400 exhibitors took part in<br />

this international trade fair for the transport<br />

industry in Sao Paulo. Around<br />

57,000 visitors had an opportunity to see<br />

the latest trends in the industry at an<br />

event that is extremely important for<br />

South America. PALFINGER presented<br />

important solutions for the South American<br />

market here. They were successful,<br />

as the influx of more than 950 visitors at<br />

the PALFINGER stand showed.<br />

4

PalfInger and sany PlannIng<br />

further exPansIon<br />

of theIr PartnershIP<br />

the strategIc partnership between Austria's PALFINGER AG and China's<br />

SANY Group agreed upon last year has already been translated into two<br />

joint ventures. To this end, the holding of SANY Heavy Industries in<br />

PALFINGER AG will be created through the issue of new shares from the<br />

authorised capital of PALFINGER AG to SANY, and the other half will be<br />

secured through the acquisition of existing shares from the <strong>Palfinger</strong> family.<br />

In return, PALFINGER AG will have a <strong>10</strong> percent holding in the SANY Lifting<br />

business. SANY Lifting is the division of the SANY Group specialising in mobile<br />

cranes, tower cranes and crawler cranes, and it is comparable to<br />

PALFINGER AG in terms of size. Xiang Wenbo, CEo of the SANY Group, had<br />

this to say about this key decision: "our close cooperation with PALFINGER<br />

is an important step towards the global market for SANY. By working<br />

together with PALFINGER, we can develop the globalisation of SANY from a<br />

Chinese perspective. We are very impressed with the rapid success of the<br />

two joint ventures," adds a delighted Herbert ortner, CEo of PALFINGER AG.<br />

"This desired strengthening of our strategic partnership is the building block<br />

for further expansion of our successful cooperation. We have achieved a lot<br />

together in one year and are very happy with the successes achieved on the<br />

Chinese market." Following the agreement in principle, the final contract<br />

documentation is now to be drafted.<br />

PalfInger In Israel<br />

PresentatIon In Israel: PALFINGER's new flagship,<br />

the PK 200002 L SH crane, was recently shown<br />

to Hovaloth Hamifraz in front of an Israeli audience. It<br />

is thanks to the success of local importer Palran that<br />

the new model could be shown off in action, as three<br />

versions of the crane (which has only been available<br />

since early 2013) are already in use in Israel. Area<br />

Sales Manager Klaus Wieland had travelled especially<br />

from Austria to demonstrate the performance capability<br />

of the new PK 200002 L SH to the Israeli customers.<br />

With success: the transport professionals were<br />

visibly impressed with the diverse range of uses to<br />

which the new crane can be put.<br />

CENTRAL<br />

COMMAND FOR<br />

MARITIME EMER-<br />

GENCIES USES<br />

A PALFINGER<br />

CRANE<br />

The Central Command for Maritime<br />

Emergencies in Cuxhaven recently<br />

started using an 8x8 Tatra Phoenix<br />

for disaster control and emergency<br />

management. This vehicle features a<br />

PK 4<strong>10</strong>02 EH loading crane with a<br />

range of 16.30 metres. In the event of<br />

a disaster or emergency, the<br />

34-tonne vehicle will bring the necessary<br />

materials required to combat oil<br />

spills and damage on dump bodies to<br />

the beach and transport contaminated<br />

material from there back onto the<br />

paved roads. It is being used on the<br />

North Sea coast off East Frisia by the<br />

Lower Saxon State Department for<br />

Waterway, Coastal and Nature Conservation.<br />

truck race: PalfInger suPPorts<br />

euroPean chamPIon Jochen hahn<br />

euroPean chamPIon in the European<br />

Truck Race for the third time in a row, Jochen<br />

Hahn's achievements speak for<br />

themselves. Right up to the end, the result<br />

was in the air; the toughest competitor, Antonio<br />

Albacete, led the way for almost the<br />

entire season. In the heart-stopping finale<br />

in Le Mans, the tension did not let up until<br />

the very last day of the season. Hahn battled<br />

his way into the lead in the last qualifying<br />

round, putting him onto the front row of<br />

the starting grid. By contrast, Albacete was<br />

stuck back in the fourth row – in seventh<br />

place. Jochen Hahn once again defended<br />

his title with an extremely narrow lead of<br />

just five points. "It was close, but I am overjoyed<br />

that I managed it in the end," declared<br />

the old and new European champion.<br />

In particular, Hahn thanked his<br />

sponsors, who actively supported him<br />

throughout the entire season. one of these<br />

is PALFINGER, who has been supporting<br />

the racing team for many years now. During<br />

the truck race, Jochen Hahn's team relies<br />

on the quality of PALFINGER products. A<br />

PK 12502 has been mounted on the MAN<br />

service truck, with its optimised power- toweight<br />

ratio making it the ideal attachment<br />

for the 2-axle truck. Thanks to the hydraulic<br />

tiltable stabilizers, the crane can be supported<br />

even in the presence of obstacles<br />

such as guide rails, walls or fences, and the<br />

Power Link Plus system makes it possible to<br />

work even in the tightest spaces. The crane<br />

is thus the perfect choice for working efficiently<br />

and flexibly in the driver's paddock.<br />

5

Job rePort | CRANE PASSIoN<br />

At its Mounting Competence Center<br />

(MCC) in Lengau, PALFINGER produces<br />

complete solutions for the most<br />

challenging crane and vehicle<br />

combinations. By mounting the cranes<br />

directly in the factory, PALFINGER can<br />

draw on the full competence, knowhow<br />

and motivation of its employees.<br />

Customers benefit directly from this.<br />

comPlete solutIon<br />

dIrectly from the factory:<br />

THE INSTALLATION ON THE<br />

FIVE-AXLE SCANIA WAS<br />

PERFORMED IN THE MCC IN<br />

CLOSE CONSULTATION WITH THE<br />

SWISS PALFINGER PARTNER AND<br />

THE CUSTOMER.<br />

6

CRANE PASSIoN | mountIng comPetence center<br />

taIlor-made<br />

mountIng<br />

comPetence<br />

"looks good to me!" – Heinrich Heggli's spontaneous<br />

judgement is a genuine compliment, coming from the<br />

mouth of a down-to-earth, matter-of-fact Swiss man.<br />

The Swiss CEo of Heggli AG carefully inspects all of the<br />

vehicle details during a meeting with his new flagship<br />

crane, a Scania-based PK 200002 L SH. As required,<br />

the impressive crane structure sits on a platform fitted<br />

with platform gates, which in turn is mounted on the<br />

auxiliary frame. Delivered especially from Switzerland,<br />

the stainless steel mudguards seem to be in competition<br />

with the aluminium rims to see who shines brighter.<br />

The MCC team in the PALFINGER plant in Lengau has<br />

obviously done a perfect job of meeting the requirements<br />

of the vehicle expert from Kriens.<br />

For MCC boss, Gernot Pichorner, the handover of the<br />

five-axle vehicle painted in bright green to his Swiss<br />

customer is anything but an everyday event. The exchange<br />

of keys is<br />

always a highly<br />

emotional moment<br />

for all participants:<br />

"For<br />

the customer,<br />

who new sees his<br />

now equipment<br />

in full working order<br />

before his<br />

very own eyes.<br />

And naturally, for<br />

us MCC employees,<br />

who are<br />

handing over our work to the happy purchaser after<br />

several weeks of installation and adjustments." The<br />

roll-out of such a special PALFINGER crane as Heggli's<br />

440 HP Scania is the final step in a development process<br />

requiring intensive coordination between customer,<br />

dealer and the PALFINGER Mounting Competence<br />

Center. Heinrich Heggli's first question during the introductory<br />

theoretical<br />

presentation of his „ THIS VEHICLE CONCEPT HAS BEEN A<br />

new truck focuses<br />

WISH OF MINE FOR A LONG TIME. OTHER<br />

immediately on the<br />

overall weight. Gernot<br />

Pichorner's MCC DELIVER IN THIS FIELD!<br />

CRANE MANUFACTURERS COULD NOT<br />

“<br />

team managed to<br />

heInrIch hegglI, 71, ceo of hegglI ag ch krIens<br />

impress the Heggli<br />

CEo with an overall<br />

operational weight of 40 tonnes. This is because, in future,<br />

use of the heavy five-axle vehicle without a special<br />

license will only be permitted in the Canton<br />

of Lucerne if the vehicle is below the<br />

40-tonne limit. Here, it is set to really<br />

come into its own covering roofs, roof<br />

structures and renovating terraces. The<br />

new PALFINGER PK 200002 L SH impressed<br />

transport expert Heggli, who is<br />

currently handling the procurement of<br />

spare parts for the fleet that encompasses<br />

over a hundred vehicles. He is replacing<br />

the mobile construction cranes currently<br />

being used. These are not always suitable<br />

for use in cities as they require more space<br />

during installation.<br />

emotIonal moments: KEY HANDOVER CER-<br />

EMONY FOR THE NEW PALFINGER PK 200002 L SH<br />

FROM MCC MANAGER GERNOT PICHORNER (LEFT)<br />

TO HEGGLI CEO HEINRICH HEGGLI.<br />

7

mountIng comPetence center | CRANE PASSIoN<br />

„<br />

ESTABLISHING EXPERTISE VIA THE NEW<br />

MOUNTING COMPETENCE CENTER IS AN<br />

IMPORTANT INVESTMENT FOR THE<br />

FUTURE AND ALSO MOTIVATION FOR OUR<br />

EMPLOYEES. OUR TEAM IS VERY PROUD<br />

WHEN A COMPLETE VEHICLE LEAVES THE<br />

PLANT.<br />

“<br />

PalfInger lengau head of ProductIon<br />

gernot PIchorner, 39<br />

In actual fact, according to Heinrich<br />

Heggli, the range of applications for<br />

the new top crane in his 15-vehicle<br />

fleet is almost unlimited. "This concept<br />

has been a wish of mine for a<br />

long time," reports the dynamic CEo,<br />

who used to spend a lot of time at the<br />

steering wheel in the past and has an<br />

outstanding knowledge of the recovery<br />

business. "other manufacturers<br />

just could not deliver in this area!"<br />

While inspecting the powerful fiveaxle<br />

vehicle, he checks all details on<br />

the truck and crane meticulously.<br />

3QUESTIoNS FoR<br />

GERNoT PICHoRNER<br />

PalfInger Is the only crane Producer to offer a<br />

mountIng servIce from the factory. what were<br />

the reasons behInd settIng uP the mountIng com-<br />

Petence center (mcc) here In lengau ?<br />

For complex structures such as large cranes, the overall<br />

performance of the complete vehicle is implemented and<br />

optimised in the MCC. In the case of our new top crane model,<br />

the PK 200002 L SH with a dead weight of 23 tonnes, mounting<br />

in the factory simply makes more sense as not every service<br />

partner has the necessary lifting and mounting technology. In<br />

the MCC, we are building up mounting and product development<br />

expertise, which we want to share with our PALFINGER<br />

subsidiaries worldwide.<br />

so no comPetItIon for the dealershIPs?<br />

Definitely not! We do not want to compete with the dealers for<br />

the mounting business. Instead, we want to expand our<br />

expertise-related lead in cooperation with our partners in the<br />

entire PALFINGER world. The MCC is a clear investment in the<br />

future, in which we can market a high-tech, sophisticated<br />

product in emerging nations.<br />

... and thIs wIll be contInuously develoPed as<br />

exPertIse Is buIlt uP In the mcc?<br />

Exactly! our employees in the MCC are continuously developing<br />

and refining our standard solutions, thereby minimising<br />

mounting costs and meeting order peaks flexibly. And for our<br />

customers, collecting the vehicle in the MCC is a highly emotional<br />

experience!<br />

only then will the PK 200002 L SH celebrate its launch<br />

into commercial operation on the testing ground. MCC<br />

expert, Hannes Furthner, has monitored the bright green<br />

crane from the very first hour in the MCC workshop right<br />

up to the final setting. The setting of all functions and the<br />

careful fine-tuning with the carrier vehicle is a job for experienced<br />

crane experts like him. The friendly MCC instructor<br />

is now sharing his expertise with Heggli driver,<br />

Armin Höller. With nine years experience of working at<br />

Heggli he is anything but a novice, but he candidly admits:<br />

"It takes around two months until you're completely<br />

familiar with the new crane, and it takes another year to<br />

become a genuine master!"<br />

Step by step, detail by detail, instructor Hannes Furthner<br />

explains all the special and unique features of the fiveaxle<br />

vehicle to him. Intuitive operation of the radio remote<br />

control makes it easier for him to take the first working<br />

steps with his new working vehicle. Heggli driver, Armin,<br />

now decked out with a high-quality PALFINGER jacket as<br />

a welcome gift, is visibly looking forward to the impressive<br />

new working equipment.<br />

Awaiting him is another entire afternoon of instructions<br />

and tips while Heinrich Heggli discusses detailed solutions<br />

for day-to-day applications with the PALFINGER crane expert.<br />

Incorporation of the Euro-6 construction components<br />

such as exhaust gas filters and the AdBlue tank on the<br />

frame further complicates crane mounting today. It is precisely<br />

this expertise that MCC, as a competence centre for<br />

crane mounting, gathers centrally in order to further develop<br />

it to meet the challenges of the future.<br />

Accordingly, MCC manager, Gernot Pichorner, is not going<br />

to miss the opportunity to get to know the PK 200002 L SH<br />

and customers in detail. Yet the focus here is not exclusively<br />

on valuable feedback from the user. "It is not just our customers<br />

who are proud of their new vehicle. The handover<br />

and the direct feedback from the purchaser is also a wonderful<br />

experience for us," declares the Lengau-based Head<br />

of Production, who has been working for PALFINGER for 19<br />

years. "After all, we are all crane constructors at heart!"<br />

8

CRANE PASSIoN | Palcom<br />

„<br />

AS A PREMIUM RADIO REMOTE CONTROL,<br />

THE PALFINGER PALCOM P7 SETS NEW<br />

BENCHMARKS FOR INNOVATIVE<br />

OPERATION, SAFETY AND FATIGUE-<br />

FREE CONTINUOUS OPERATION.<br />

chrIstIan hora, Product management<br />

“<br />

hIghtech<br />

InnovatIve remote control<br />

PALFINGER is revolutionising the operation of modern loading cranes by developing a<br />

completely new remote control of its own. Perfect ergonomics, intuitive operation and maximised<br />

operational safety have made the new development the benchmark for the industry.<br />

form follows function – at PALFINGER, the traditional<br />

designer credo applies not only to cranes. Anyone who<br />

uses high-tech devices also expects innovative solutions<br />

for the operating and control elements. PALFINGER<br />

is heading in a new direction by developing the future<br />

generation of radio remote controls in-house. Together<br />

with ergonomics experts and product designers from<br />

renowned universities, a new operating philosophy has<br />

been developed that is entirely in keeping with intuitive,<br />

fatigue-free use in daily practice.<br />

In the dialogue between users and industrial designers,<br />

a clear direction emerged – one that set out the future<br />

setup for control levers, operating buttons and the<br />

re-shaped joystick. Using different design models,<br />

experts and selected customers tested the PALFINGER<br />

radio remote control PALcom P7 in real-life situations.<br />

The product of elaborate development work is called<br />

PALcom P7 and sets completely new accents in modern<br />

crane control.<br />

colour display, it ensures easy, safe operation. The large<br />

colour display is easily legible, even in blazing sunlight,<br />

but it is nevertheless very energy-saving. This results in<br />

a long service life. The accessories of the new<br />

PALcom P7 also include two re-designed strap systems<br />

that allow people to work with the new PALFINGER Premium<br />

crane remote control for hours on end without becoming<br />

tired.<br />

The innovative design of the new crane remote control<br />

not only looks modern. It also significantly reduces<br />

training time and eliminates operating mistakes for the<br />

control panel, which is available exclusively from<br />

PALFINGER: perfect proof of the designer's desire for<br />

an appealing shape, which is organically based on<br />

perfect functionality.<br />

Have we awoken your interest? Learn more about this<br />

innovative product in the next issue of <strong>Crane</strong> <strong>Passion</strong>.<br />

The "PALdrive" control knob is located<br />

centrally on the radio remote control. Together<br />

with an intuitive menu guide with a large<br />

InnovatIon In combInatIon wIth Perfect ergonomIcs:<br />

DEMANDING WORK VIA THE REMOTE CONTROL PANEL IS MADE MUCH<br />

EASIER THANKS TO THE COMPLETELY NEW OPERATING CONCEPT OF<br />

THE NEW PALCOM P7 RADIO REMOTE CONTROL (DESIGN DRAFT).<br />

9

Pacwin.net | CRANE <strong>Passion</strong><br />

VIRTUALLY<br />

SIMULATED<br />

WITH PACWIN.NET VEHICLE BODY<br />

CALCULATION SOFTWARE<br />

PALFINGER offers the ideal tool for planning the vehicle body<br />

with the Pacwin.NET software. This product can be used to<br />

calculate axle loads, load curves, stability and dynamic<br />

movements.<br />

WITH THE MULTIFUNCTIONAL<br />

SOFTWARE TOOL, IT IS POSSIBLE<br />

TO SIMULATE EVERY SINGLE<br />

WORKING POSITION OF THE<br />

AVAILABLE DEVICES.<br />

Precise planning helps to simulate complex vehicle body<br />

situations on the computer and to implement customer<br />

requirements efficiently and cost-effectively, long before<br />

hands touch the vehicle for the first time. The fifth version<br />

of Pacwin.NET will already be available in <strong>2014</strong>.<br />

The latest version of the successful PALFINGER calculation<br />

software provides over three million items of basic data<br />

from the most renowned international commercial vehicle<br />

manufacturers in order to perform a realistic pre-calculation<br />

of axle loads, crane loads and stability analyses on the PC.<br />

Above and beyond the model series of the commercial<br />

vehicle manufacturer, the database (which is constantly<br />

being updated) also offers selection options between different<br />

cab variants, engine types and wheelbases. With the<br />

help of the exclusive PALFINGER software, the vehicle<br />

body manufacturer calculates the height, extension and<br />

lifting capacity of the PALFINGER cranes precisely on the<br />

appropriately configured carrier vehicle. The new automated<br />

pre-calculation of the HPSC load curves offers a virtual<br />

view of the performance data of the future crane vehicle.<br />

In addition to the current data records for the up-andcoming<br />

Euro 6 vehicles, Pacwin.NET <strong>2014</strong> also contains a<br />

calculation module for skip loaders as a new development.<br />

Automatic kinematic calculations of the movements in skip<br />

loaders and hookloaders accurately document the dynamic<br />

work process and the resulting space requirements. To<br />

<strong>10</strong>

AN INDIVIDUALLY CONFIGURED<br />

CARRIER VEHICLE WITH ALL BODY-<br />

RELEVANT MEASUREMENTS AND THE<br />

LIVE CALCULATION OF THE USEFUL<br />

LOAD AND AXLE LOADS.<br />

WITH JUST A FEW<br />

CLICKS, ULTIMATE<br />

LOAD CURVES CAN BE<br />

GENERATED IN ORDER<br />

TO OBTAIN REQUIRED<br />

INFORMATION ABOUT<br />

THE LIFTING CAPACITY<br />

OF THE SELECTED<br />

CRANE MODEL<br />

DIRECTLY.<br />

complement the basic vehicle, the body builder can<br />

include special equipment such as trailer couplings, underride<br />

guards or other add-on elements in the calculation in<br />

the computer simulation.<br />

The modular structure of Pacwin.NET allows stability<br />

calculations of cranes and/or container handling systems<br />

to be performed as well as ultimate load diagrams to be<br />

licensed individually. To implement the project, it is possible<br />

to print out all major load kinematic diagrams, together<br />

with the useful load and ultimate load calculations.<br />

Available in 15 different languages, the software tool runs<br />

on Windows and offers the option of module expansion as a<br />

flexible license system.<br />

IN THE NEW <strong>VERSION</strong><br />

OF THE VEHICLE BODY<br />

CALCULATION SOFTWARE<br />

PACWIN.NET <strong>2014</strong>, THE HPSC<br />

ULTIMATE LOAD CURVES ARE PRE-<br />

CALCULATED INDIVIDUALLY FOR CARRIER<br />

VEHICLE AND CRANE MODEL ALIKE.<br />

11

INNOVATIVE OPERATING METHOD OF THE SRC:<br />

CONSTANT DISTANCE BETWEEN PULLEY HEAD<br />

AND HOOK BLOCK DURING ROPE-LENGTHENING<br />

AND ROPE-SHORTENING CRANE MOVEMENTS.<br />

„<br />

THE MAJORITY OF INNOVATIONS RELATE TO THE IMPACT OF<br />

TECHNOLOGY ON THE ENVIRONMENT. IN THE AWARD-WINNING<br />

PALFINGER SRC, ENERGY EFFICIENCY IS PERFECTLY COMBINED<br />

WITH VERSATILITY, FUNCTIONALITY, OPERATOR-FRIENDLINESS<br />

AND COST SAVINGS.<br />

“<br />

INNOVATION AWARD 2013 JURY CHAIRMAN LEO VAN HOORICK<br />

12

CRANE PASSIoN | src<br />

Perfect<br />

dIstance<br />

electronIcally controlled<br />

With the new Synchronised Rope Control (SRC), PALFINGER has set a<br />

milestone in the optimisation of loading crane operation. Intelligent control<br />

electronics automatically adjusts the rope length during every crane movement.<br />

The crane driver can concentrate even better on his loading work thanks<br />

to the innovative SRC system, and this increases operational efficiency.<br />

challenging crane deployments require full concentration from all employees. The new<br />

Synchronised Rope Control (SRC) from PALFINGER makes a major contribution to increased<br />

work speed and operational safety during rope winch operation when cranes are being used.<br />

In the new development from PALFINGER,<br />

electronic sensors in the pully head measure<br />

the movements during crane operation and<br />

forward the signals directly to the Paltronic 150.<br />

The extent of the rope-shortening or ropelengthening<br />

movement is calculated there in a<br />

fraction of a second, and the rope length<br />

automatically re-adjusted. The<br />

control electronics automatically<br />

adjust the constant rope length<br />

between the pully head and the<br />

hook block by extending or<br />

retracting the extension boom,<br />

the outer boom, or lowering<br />

the fly jib. In this way, the load<br />

remains at a constant distance<br />

from the pully head.<br />

The crane driver does not have to re-adjust the<br />

rope length at all when using the SRC. An automatic<br />

synchronised rope control system is<br />

available as an option for the SH crane models.<br />

This allows the operator to concentrate completely<br />

on controlling the crane and moving the<br />

load accurately.<br />

InnovatIve oPeratIng method of<br />

the src: CONSTANT ROPE LENGTH<br />

WITH THE EXTENSION BOOM EXTENDED<br />

AT DIFFERENT LENGTHS<br />

InnovatIon award-matexPo 2013<br />

PALFINGER won the main prize in the<br />

Innovation Award 2013 at Matexpo in<br />

Kortrijk, Belgium. An expert jury honoured<br />

the new PALFINGER synchronised rope<br />

control system SRC as the most advanced<br />

technical development at the world's<br />

largest trade fair for machines, devices and<br />

systems. International manufacturers<br />

compete for the innovation award with their<br />

new developments every two years. An<br />

expert jury nominates five projects in<br />

advance and names the winner of the main<br />

prize at the Matexpo opening ceremony. All<br />

the new developments are sustainable,<br />

trend-setting solutions. As the fourth winner<br />

of the Innovation Award, PALFINGER<br />

joints the ranks of reputable companies<br />

such as Tramac, Schnell and Liebherr.<br />

13

hybrId | CRANE PASSIoN<br />

hybrId<br />

ProtectIng the envIronment<br />

and lowerIng costs<br />

The engine pump groups from PALFINGER allow emissionfree,<br />

noise-reducing crane operation in particularly sensitive<br />

environments or in indoor rooms. The rapid change of drive<br />

from the truck engine to current mode of the hydraulic<br />

power source also reduces the operating costs.<br />

sustainability does not necessarily have to mean higher operating costs.<br />

Presented as a global première at bauma 2013, the new PALFINGER hybrid<br />

drives successfully prove that protecting resources and environmental-friendliness<br />

can also prove highly profitable from a cost perspective.<br />

At the core of the PALFINGER hybrid technology can be found the electrically<br />

operated engine pump groups. If necessary, they can take on the<br />

electrohydraulic drive work of the PALFINGER crane. The compact systems<br />

are connected to a standard 400 Volt current connection at the place of<br />

use, and immediately start powering the crane hydraulics with up to 365<br />

bar operating pressure. To switch from vehicle engine drive to current<br />

mode, it is sufficient to simply switch over on the control cabinet that has<br />

been assembled. This turns the PALFINGER crane into a low-noise and<br />

emission-free crane in a matter of seconds, one that can work efficiently in<br />

environmentally or noise-sensitive places of use.<br />

RAPID CHANGE BETWEEN A CONVEN-<br />

TIONAL VEHICLE ENGINE AND A 400-V<br />

CURRENT SOURCE: THE PALFINGER<br />

HYBRID DRIVE IS BASED ON AN ENGINE<br />

PUMP GROUP, WHICH ENTERS<br />

OPERATION VIA A SWITCH ON A<br />

COMPACT CONTROL CABINET IN<br />

A MATTER OF SECONDS.<br />

Electrohydraulic operation reduces exhaust gas emissions to zero. This<br />

means that the PALFINGER hybrid crane also works in closed rooms such<br />

as halls, tunnel chutes or industrial facilities without exposing the environment<br />

to exhaust gases. Minimisation of drive noise by means of the<br />

electric-motor-driven hydraulic pumps allows people to work continuously<br />

even in areas where noise pollution would be unacceptable. The hybrid<br />

drives are designed as a complete system. This means the crane builder<br />

can attach them quickly and inexpensively to the carrier vehicle without<br />

having to make deep interventions into the on-board hydraulic system.<br />

Depending on the drive power required, two engine variants with 7.5 kW<br />

and 15 kW continuous power are available. An integrated power control<br />

system of the engines covers the high pressure requirement effectively at<br />

high working speed. The energy meter, which is installed in the control<br />

cabinet, allows the power costs to be invoiced depending on the job.<br />

The cost balance with the electric drive is particularly favourable. Compared<br />

to the hydraulic pump drive with a diesel engine, the electric pump drive<br />

minimises the operating costs by up to 80 percent. The PALFINGER hybrid<br />

drive thus pays for itself after just 2.5 years with an average operating<br />

duration.<br />

14

CRANE PASSIoN | hInz annIversary<br />

„<br />

THE MOST IMPORTANT THING IN COOP-<br />

ERATION ACROSS GENERATIONS IS THE<br />

CERTAINTY THAT ONE CAN RELY ON ONE'S<br />

PARTNER AT ALL TIMES DURING DAILY<br />

WORK. AFTER A BUSINESS RELATIONSHIP<br />

WITH PALFINGER LASTING SO MANY<br />

YEARS, ONE BELONGS, SO TO SPEAK,<br />

TO THE FAMILY.<br />

“<br />

magnus hInz, ceo of hInz<br />

40 years of<br />

hInz<br />

strong In the north<br />

Hinz has been flying the flag for PALFINGER in Sweden for<br />

40 years. A success story in the far north, which also offers<br />

considerable potential for the future.<br />

It all started with a letter. The success story of the Swedish PALFINGER<br />

partner, Hinz, started in 1973 and has continued without interruption to the<br />

present day. 40 years ago, Bertil Hinz saw the first PALFINGER crane on a test<br />

bench and was immediately impressed with the Austrian product. The Swedish<br />

crane expert contacted the then head of export sales and subsequent CEo,<br />

Herbert Ziegelböck, in the PALFINGER headquarters in Salzburg. Bertil Hinz<br />

showed considerable interest in marketing the PALFINGER products in<br />

Sweden. After a competitor in the duel for the title of importer had been<br />

outdone and the first test crane passed an endurance test spanning several<br />

weeks without any problems, Bertil Hinz was convinced: "I have to work with<br />

PALFINGER!"<br />

In July 1974, Hubert <strong>Palfinger</strong> and Bertil Hinz finally put the seal on the joint<br />

cooperation, which would later develop into a deep friendship. The first<br />

PALFINGER crane to be sold, a PK 7500, went to a local cement factor where<br />

it performed its heavy work for many years. over the next 40 years, many<br />

thousand PALFINGER products would follow.<br />

Today, Hinz AB in Sweden, is the clear market leader in the domestic market of<br />

the largest competitor. Magnus Hinz took over the plant from his father, Bertil,<br />

and systematically expanded the market presence with a sophisticated<br />

marketing and publicity concept. The special Hinz advertising themes such as<br />

an elk or a submarine on the hook of a PALFINGER crane are among the most<br />

striking and creative advertisements in the industry. To mark the company's<br />

40th anniversary, Magnus Hinz once again came up with something special. In<br />

the recently opened Hinz branch in Malmö, over 200 invited customers,<br />

employees and friends of the company celebrated a glittering company<br />

anniversary. It was a great occasion – and of course it took place side by side<br />

with the PALFINGER cranes.<br />

swedIsh days of celebratIon: TO CELEBRATE THE COMPANY'S 40TH<br />

ANNIVERSARY, MAGNUS HINZ ISSUED INVITATIONS TO THE GALA DINNER<br />

IN THE NEW COMPANY BRANCH IN MALMÖ.<br />

15

ePort | CRANE PASSIoN<br />

„<br />

THE CHALLENGE, EVEN DURING<br />

THE PLANNING PHASE, WAS TO<br />

SET UP A COMPREHENSIVE<br />

SAFETY CONCEPT WITHOUT<br />

USING COST-INTENSIVE<br />

ROPE-ACCESS TECHNICIANS.<br />

alPha-rotex constructIon<br />

manager sven mÜnch<br />

“<br />

a wIde-rangIng Job:<br />

THE PALFINGER PK 200002 L SH<br />

MANOEUVRES TREES AND EARTH FOR FIVE<br />

WINTER GARDENS AT A HEIGHT OF 30<br />

METERS PRECISELY THANKS TO A SINGLE<br />

OPEN WINDOW SEGMENT.<br />

TECHNoLoGY FACTS<br />

With the new PALFINGER PK 200002 L SH,<br />

PALFINGER combines a knuckle boom<br />

crane with a loading crane in long boom<br />

design. Eight hydraulic extensions designed<br />

in a polygon shape for particular stability<br />

and lightweight construction as well as the<br />

fly-jib enable a hydraulic lifting height of<br />

more than 49 metres. When being deployed,<br />

the PK 200002 L SH supports itself<br />

stably against the front and rear of the<br />

carrier vehicle by means of four side outriggers<br />

as well as additional stabiliser rams.<br />

The intelligent stability control system HP-<br />

SC ensures maximum comfort and safety.<br />

The intuitively operational radio remote<br />

control system allows precise and errorproof<br />

work.<br />

With a total mounting height of 3.8 metres<br />

and a particularly low dead weight, the<br />

PK 200002 L SH can be set up without any<br />

problem on four or five-axle trucks as a complete<br />

solution straight from the factory. The<br />

heavily reduced scope of maintenance work<br />

and the extremely short set-up time contribute<br />

directly to the unrivalled economic efficiency<br />

of PALFINGER’s new long-boom<br />

crane in daily use.

green cargo on the safe hook:<br />

THANKS TO THE SENSITIVE PALFINGER CRANE<br />

CONTROL SYSTEM ALL TRANSPORT DAMAGE<br />

WAS AVOIDED – EVEN EIGHT STOREYS UP.<br />

a heavenly<br />

garden<br />

Is beIng<br />

created<br />

wIth a Pk 200002 l sh<br />

With its unique crane technology, the outstanding new long-boom crane PALFINGER<br />

PK 200002 L SH unerringly transported numerous fully grown trees into the newly laid out<br />

winter garden of a Frankfurt office complex at a height of 30 metres.<br />

In the truest sense of the word, the crane operator of<br />

special transport company Meister had to aim high in this<br />

spectacular job. The professional operating the remote<br />

control system literally had to work through a single open<br />

window segment of the new Alpha Rotex Building<br />

complex. This difficult task was to lift stately palm trees,<br />

eight-metre-long silky oaks, as well as the entire material<br />

for constructing a winter garden. The delicate part of the<br />

precision work with the new PALFINGER PK 200002 L SH:<br />

the fully grown trees had to be transported at a dizzy<br />

height of over 30 metres through the eye of the window<br />

element with millimetre accuracy into the interior of the<br />

futuristic office complex at Frankfurt Airport. There, in<br />

five newly constructed winter gardens, they are to find<br />

their location in the eight-storey high interior atrium.<br />

The new technology of the biggest loading crane in the<br />

PALFINGER programme was crucial to the success of<br />

this extremely challenging job. Equipped with eight<br />

hydraulic extensions and a fly-jib, the crane can achieve<br />

a hydraulic outreach of 45.3 metres, which corresponds<br />

to a lifting height of more than 49 metres. However, the<br />

reachable height alone was not the most important<br />

criterion in this spectacular crane manoeuvre. The new<br />

long-boom crane shows its full potential with its<br />

multifunctionality. With its second knuckle boom system<br />

at the top, the professional crane operator accurately<br />

positioned the bulky load at a height of 30 metres at the<br />

predetermined location in the atrium of the multi-storey<br />

building. The electronically regulated stability control<br />

system HPSC of the new PALFINGER loading crane<br />

means maximum comfort and safety at every moment of<br />

what could be record-breaking activities. Even the<br />

slightest contact of the plant cargo with the expensive<br />

glass window fronts would have caused huge damage to<br />

the building.<br />

delIcate and PInPoInt control<br />

Thanks to the sensitive proportional controller of the<br />

imposing long-boom crane operated by Meister, all trees<br />

and all the equipment including plant tubs, soil and<br />

special earth for five winter gardens found their way<br />

undamaged into the interior of the multi-storey building<br />

that features a triangular layout. This is how the new<br />

PALFINGER PK 200002 L SH helped to create a green<br />

oasis at a height of more than 30 metres.<br />

17

InternatIonal | CRANE PASSIoN<br />

CoUNTRY REPoRT<br />

brazIl<br />

Brazil is top of the class – not just<br />

in terms of economic growth but<br />

also the up-and-coming global<br />

sport events such as the World<br />

Cup and the olympics. With<br />

powerful growth rates in the highly<br />

competitive market for loading<br />

cranes, PALFINGER is also<br />

benefiting from the construction<br />

boom for the major ports events.<br />

With the recently launched<br />

loading crane MD 45007,<br />

PALFINGER achieved a major<br />

sales success on the domestic<br />

market.<br />

russIa<br />

The infinite size of Russia demands<br />

special solutions. PALFINGER Area<br />

CIS contributed a powerful<br />

PALFINGER PK <strong>10</strong>0002 for a crosscountry<br />

special vehicle that will be<br />

used in emergency deployments<br />

and repairs of the power lines in<br />

inhospitable regions. on behalf of<br />

the power supplier, Ural Electricity<br />

Network, PALFINGER is helping to<br />

erect the 32-metre high electricity<br />

masts in marshes.<br />

canada<br />

The 15-year cooperation between<br />

the Canadian hydraulic specialist<br />

FRF in Brantford/ontario and<br />

PALFINGER is a perfect example<br />

of successful international<br />

cooperation. Since 1999, FRF has<br />

been dealing with a wide range of<br />

conveyance vehicles and special<br />

attachments such as concrete<br />

pump, wood loaders, loading<br />

tailgate and other add-on units.<br />

For 15 years, the Canadians have<br />

been "speaking and thinking" like<br />

PALFINGER, a partnership of a<br />

special nature.<br />

exPendIng truck market:<br />

INDIA IS GROWING AT BREATH-TAKING<br />

SPEED TO BECOME THE WORLD'S<br />

SECOND LARGEST TRUCK MARKET<br />

AFTER CHINA.<br />

18

„<br />

Indian<br />

SOARING FLIGHT<br />

The gigantic domestic market of India is attracting vehicle manufacturers such as logistics groups to the<br />

booming subcontinent. PALFINGER is among the high-tech pioneers on the Indian transport market.<br />

INDIA IS A GENUINE BOOM MARKET BUT STILL LAGS<br />

BEHIND IN TERMS OF MODERNISATION AND SAFETY.<br />

MANUAL UNLOADING IS STILL COMMON PRACTICE. HOW-<br />

EVER, WE ARE EXPECTING A GRADUAL CHANGE TOWARDS<br />

MORE MODERN TRANSPORT TECHNOLOGY IN THE NEAR<br />

FUTURE. THE TRADITIONAL "PICK AND CARRY" CRANE IS<br />

THE MOST COMMON MODEL FOR TRANSPORTING GOODS.a<br />

NALINKUMAR DHANASEKARAN, MANAGER PRODUCT MANAGEMENT<br />

PALFINGER CRANES INDIA PVT. LTD<br />

“<br />

A mere 7,400 kilometres separate the company<br />

headquarters in Salzburg and PALFINGER<br />

<strong>Crane</strong>s India Ltd in the south eastern metropolis<br />

of Chennai. And yet, the two PALFINGER<br />

sites are, quite literally, worlds apart. The contradictions<br />

of India are not just reflected in the<br />

co-existence of poor and rich. On the roads,<br />

quaint self-built trucks can be seen travelling<br />

beside modern trucks from cooperation production<br />

facilities of western commercial vehicle<br />

manufacturers. As a result, anyone who thinks<br />

of transport in India immediately conjures up<br />

images of excessively over-filled vehicles.<br />

Maximum loading with no thought given to<br />

legal limits is part and parcel of everyday life in<br />

the goods transport industry here, which<br />

covers over 3.3 million kilometres of roads and<br />

paths in India. Handcarts, overloaded tricycles,<br />

endless truck caravans and the compulsory<br />

holy cows drastically reduce the speed; muscle<br />

power has been in demand as a loading aid for<br />

centuries. Time still plays a subordinate role in<br />

Indian road transport. Palleted goods are just<br />

as rare here as quick transport of goods.<br />

The 60 employees at <strong>Palfinger</strong> India must<br />

engage in genuine awareness training in order to<br />

make the advantages of quick and safe loading<br />

devices clear to the transport companies here.<br />

Because even on the Indian market, which is<br />

operating at full capacity on the basis of<br />

domestic demand alone, the demand for transport<br />

efficiency is growing every bit as quickly as<br />

the amazing rate of growth of the economy of<br />

the subcontinent. Nowadays, there are around<br />

five million transport vehicles, from rattling<br />

Tempo three-wheelers right up to heavy-duty<br />

long-distance trucks.<br />

Successfully negotiating the conflict between<br />

extreme price pressure and a high-quality<br />

appeal is an exciting challenge for PALFINGER.<br />

PALFINGER products are already being used<br />

successfully in the heavy-duty sector. Brick<br />

and concrete manufacturers as well as<br />

customers such as the energy corporation<br />

Bescom are among the customers who transport<br />

and safely install transformers using<br />

PALFINGER cranes. It is only now that modern<br />

road transport is beginning to develop on the<br />

Indian market. The subcontinent is enticing,<br />

with growth rates that the rest of the world can<br />

only dream of.<br />

ENGINEERS DAY INDIA:<br />

WITH A PALFINGER CRANE WITH<br />

A WORKMAN BASKET, THE<br />

STATUE OF THE FAMOUS INDIAN<br />

ENGINEER, SIR MOKSHAGUNDAM<br />

VISVESVARAYYA, IS DECORATED IN<br />

THE PRESENCE OF MINISTERS.<br />

19

Jeff Koschinski<br />

SALES REPRESENTATIVE<br />

”<br />

Innovation means to<br />

make ground-breaking,<br />

market-ready technology.”<br />

Lifetime Excellence<br />

Big tasks need a strong partner: PALFINGER products prove their strength every day,<br />

without exception. They deliver the very highest reliability regarding performance,<br />

quality and service - for the lifetime of the product. "Lifetime Excellence" –<br />

Our promise toward the utmost success for your company.<br />

www.<strong>Palfinger</strong>.com<br />

KP-<strong>Crane</strong>P<strong>10</strong>+E