CANexpert DQI Module Flyer - ISRA VISION AG

CANexpert DQI Module Flyer - ISRA VISION AG

CANexpert DQI Module Flyer - ISRA VISION AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Can & Packaging<br />

<strong>ISRA</strong><br />

<strong>VISION</strong><br />

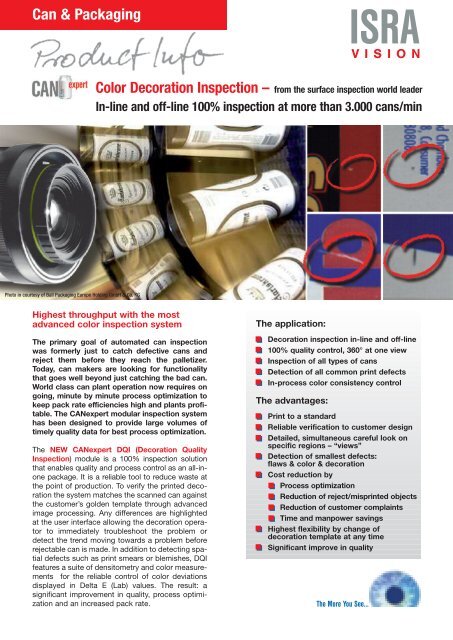

Color Decoration Inspection – from the surface inspection world leader<br />

In-line and off-line 100% inspection at more than 3.000 cans/min<br />

Photo in courtesy of Ball Packaging Europe Holding GmbH & Co. KG<br />

Highest throughput with the most<br />

advanced color inspection system<br />

The primary goal of automated can inspection<br />

was formerly just to catch defective cans and<br />

reject them before they reach the palletizer.<br />

Today, can makers are looking for functionality<br />

that goes well beyond just catching the bad can.<br />

World class can plant operation now requires on<br />

going, minute by minute process optimization to<br />

keep pack rate efficiencies high and plants profitable.<br />

The <strong>CANexpert</strong> modular inspection system<br />

has been designed to provide large volumes of<br />

timely quality data for best process optimization.<br />

The NEW <strong>CANexpert</strong> <strong>DQI</strong> (Decoration Quality<br />

Inspection) module is a 100% inspection solution<br />

that enables quality and process control as an all-inone<br />

package. It is a reliable tool to reduce waste at<br />

the point of production. To verify the printed decoration<br />

the system matches the scanned can against<br />

the customer’s golden template through advanced<br />

image processing. Any differences are highlighted<br />

at the user interface allowing the decoration operator<br />

to immediately troubleshoot the problem or<br />

detect the trend moving towards a problem before<br />

rejectable can is made. In addition to detecting spatial<br />

defects such as print smears or blemishes, <strong>DQI</strong><br />

features a suite of densitometry and color measurements<br />

for the reliable control of color deviations<br />

displayed in Delta E (Lab) values. The result: a<br />

significant improvement in quality, process optimization<br />

and an increased pack rate.<br />

The application:<br />

Decoration inspection in-line and off-line<br />

100% quality control, 360° at one view<br />

Inspection of all types of cans<br />

Detection of all common print defects<br />

In-process color consistency control<br />

The advantages:<br />

Print to a standard<br />

Reliable verification to customer design<br />

Detailed, simultaneous careful look on<br />

specific regions – “views”<br />

Detection of smallest defects:<br />

flaws & color & decoration<br />

Cost reduction by<br />

Process optimization<br />

Reduction of reject/misprinted objects<br />

Reduction of customer complaints<br />

Time and manpower savings<br />

Highest flexibility by change of<br />

decoration template at any time<br />

Significant improve in quality<br />

The More You See...

Quality control meets process control<br />

The <strong>CANexpert</strong> <strong>DQI</strong> does more than just 100%<br />

inspection with one 360° view. It enables the user to<br />

observe all live views simultaniously in real-time. This<br />

provides the operator with graphical feedback on the<br />

process. <strong>CANexpert</strong> <strong>DQI</strong> detects all typical defects<br />

like:<br />

drying-in<br />

missing print<br />

splashing<br />

spackling<br />

smearing<br />

bleeding<br />

scratches<br />

and many more…<br />

contamination<br />

miss register<br />

streaks<br />

drags<br />

color variations<br />

hazing and fogging<br />

blankett issues<br />

The monitoring and evaluation of specific color areas<br />

assures the detailed analysis of color deviations.<br />

Subtile color defects such as hazing, fogging or<br />

smearing can be detected before it comes visible to<br />

the human eye. All inspection results are stored internally<br />

for further analysis. Together with optional<br />

reporting and analysis tools, a sustainable basis for<br />

process improvement is offered, to achieve highest<br />

productivity. Because of the modular system design,<br />

a network-enabled visualization unit can easily be<br />

added which displays informations and results right<br />

at the production stations. This enables production<br />

personnel to react quickly and reduce spoilage.<br />

The <strong>DQI</strong> Features<br />

In-line and off-line version available<br />

Color tracking<br />

ImageView of last cans with defect<br />

Defect history<br />

User-defined alarm signals<br />

Wizard for new decoration type<br />

Reliable machine vision for defect detection at the smallest<br />

detail (here offline version)<br />

Additional <strong>CANexpert</strong> modules<br />

The <strong>CANexpert</strong> product line provides 100%<br />

quality inspection for all inspection tasks within<br />

the can production process, in-line and off-line:<br />

Coil Inspection<br />

Metal Sheet Inspection<br />

Outside Can Inspection<br />

Body Maker Number Identification<br />

Total Can Inspection<br />

Neck Inspection<br />

Neck Plug Gauging<br />

Shell, Compound & End Inspection<br />

<strong>ISRA</strong> <strong>VISION</strong><br />

Germany<br />

Tel.: +49 (6151) 948-0<br />

Fax: +49 (6151) 948-140<br />

Italy<br />

Tel.: +39 (0464) 490 603<br />

Fax: +39 (0464) 498 875<br />

USA<br />

Tel.: +1 (517) 887-8878<br />

Fax: +1 (517) 887-8444<br />

P.R. China<br />

Tel.: +86 (21) 6891 6286-0<br />

Fax: +86 (21) 6891 6286-888<br />

Japan<br />

Tel.: +81 (3) 3253-5771<br />

Fax: +81 (3) 3253-5772<br />

UK<br />

Tel.: +44 (1322) 520410<br />

Fax: +44 (1322) 559419<br />

France<br />

Tel.: +33 (4) 7211 4067<br />

Fax: +33 (4) 7211 4068<br />

Brazil<br />

Tel.: +55 (11) 3476-1132<br />

Fax: +55 (11) 3476-1132<br />

Korea<br />

Tel.: +82 (2) 790-1326<br />

Fax: +82 (2) 790-1329<br />

Taiwan (R.O.C.)<br />

Tel.: +886 (3) 2500-148<br />

Fax: +886 (3) 2500-149<br />

Turkey<br />

Tel.: +90 (216) 688 1015<br />

Fax: +90 (216) 688 1016<br />

Belgium<br />

Tel.: +32 (2) 6523-866<br />

Fax: +32 (2) 6523-728<br />

India<br />

Tel.: +91 (99) 33 399 642<br />

Fax: +49 (2366) 9300-230<br />

Spain<br />

Tel.: +34 (93) 589 71 79<br />

Fax: +34 (93) 589 71 79<br />

Ireland<br />

Tel.: +353 (61) 748411<br />

Fax: +353 (61) 748411<br />

www.isravision.com<br />

The More You See...