MT-VP Series

MT-VP Series

MT-VP Series

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

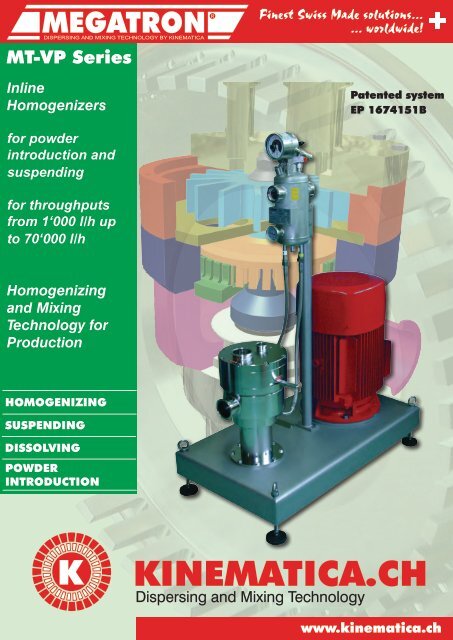

MEGATRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

<strong>MT</strong>-<strong>VP</strong> <strong>Series</strong><br />

R<br />

Finest Swiss Made solutions...<br />

... worldwide!<br />

Inline<br />

Homogenizers<br />

for powder<br />

introduction and<br />

suspending<br />

for throughputs<br />

from 1‘000 l/h up<br />

to 70‘000 l/h<br />

Patented system<br />

EP 1674151B<br />

Homogenizing<br />

and Mixing<br />

Technology for<br />

Production<br />

HOMOGENIZING<br />

SUSPENDING<br />

DISSOLVING<br />

POWDER<br />

INTRODUCTION<br />

KINEMATICA.CH<br />

Dispersing and Mixing Technology<br />

www.kinematica.ch

POWDER INTRODUCTION / SUSPENDING / DISSOLVING / HOMOGENIZING<br />

After several years of<br />

development KINEMATICA<br />

succeeded in introducing to the<br />

market an extremely efficient<br />

powder dispersing machine with<br />

the series MEGATRON ® <strong>MT</strong>-<strong>VP</strong>.<br />

The most notably advantage of<br />

the new developed system is<br />

the strongly improved suction<br />

capacity which avoids unwanted<br />

lumps during powder sucking and<br />

wetting; this averts for one thing<br />

a plugging of the powder supply<br />

line and improves at the same<br />

time the add-on homogeneous<br />

dispersing.<br />

The generated high vacuum<br />

with a simultaneous high<br />

suction capacity is substantially<br />

independent of the liquid<br />

throughput and to a certain<br />

extent, also independent of the<br />

pressure at the outlet; this grants<br />

a dust-free incorporation into the<br />

liquid. It has been shown that<br />

the generated suction capacity<br />

is sufficiently high that heavy<br />

powders, e.g. metal containing<br />

powders, can also be sucked in.<br />

The new MEGATRON ® <strong>MT</strong>-<strong>VP</strong><br />

powder dispersing machine with<br />

its convincing powder wetting<br />

system and a wide range of<br />

various dispersing generators<br />

enlarges the applications in<br />

the field of chemistry, pharma,<br />

cosmetic and food.<br />

The series includes at present<br />

various sizes with a throughput<br />

from approx. 1’000 l/h to 70’000 l/h<br />

related to water and depending on<br />

the used dispersing generator.<br />

<strong>MT</strong>-<strong>VP</strong> SERIES<br />

MODE OF OPERATION<br />

Fluid<br />

Powder<br />

Dispersion<br />

• MEGATRON ® <strong>MT</strong>-<strong>VP</strong> machineries<br />

are inline processors combining in a<br />

two-stage working chamber an effective<br />

powder introduction stage with a<br />

homogenizing / suspending stage<br />

• the <strong>MT</strong>-<strong>VP</strong> series are specially invented<br />

for powder introduction of light<br />

to heavy powders and making finest<br />

suspensions and solutions<br />

• the maximum generated vacuum at<br />

the powder introduction is approx. 25<br />

mbar<br />

• pressure up to 6 bar standard, higher<br />

pressures possible on request<br />

• temperature up to 90 °C standard,<br />

higher temp. possible on request<br />

• viscosity aqueous up to paste-like<br />

• Six different sizes available<br />

• Throughputs from 1‘000 l/h up to<br />

70‘000 l/h<br />

• No unwanted lumps<br />

• No plugging of the powder supply<br />

line<br />

• High vacuum<br />

• High suction capacity<br />

• patented system EP 1674151B<br />

The mixing area is situated in the<br />

dynamic part (pumping head).<br />

Therewith an intensive wetting of the<br />

powder takes place. A generation of<br />

unwanted lumps is almost completely<br />

excluded. The special pumping /<br />

suction head - similar to a water ring<br />

pump - generates a high vacuum with<br />

a simmultaneous high suction capacity<br />

which is substantially independent of<br />

the liquid throughput and to a certain<br />

extent, also independent of the pressure<br />

at the outlet.<br />

Technical design:<br />

Vertical shaft with two working<br />

chambers. In the first chamber the fluid<br />

phase is dispersed and pumped into<br />

the second chamber. In the second<br />

chamber the powder will be sucked<br />

from above into the suction area and<br />

mixed with the fluid.<br />

Continuously additional fluid will be<br />

pumped into the neutral area from below<br />

and will be mixed with the powder.<br />

On the pressure side (outlet) the<br />

suspension will be pumped into a<br />

process vessel. From this vessel the<br />

first chamber will be fed again. There<br />

the powder will be suspended into the<br />

fluid at finest level.<br />

Finest Swiss Made solutions... worldwide!

System MEGATRON ® <strong>MT</strong>-<strong>VP</strong> 45 System MEGATRON ® <strong>MT</strong>-<strong>VP</strong> 65 System MEGATRON® <strong>MT</strong>-<strong>VP</strong> 95 System MEGATRON ® <strong>MT</strong>-<strong>VP</strong> 160<br />

Model / <strong>Series</strong><br />

Throughput<br />

liquid max.<br />

Suction capacity<br />

max.<br />

tip speed<br />

max.<br />

rpm max.<br />

(@50Hz)<br />

Rotor-Ø Drive Power<br />

<strong>MT</strong>-<strong>VP</strong> 45 1000 l/h 70 kg/h 25 m/s 10‘600 rpm 45 mm up to 4.0 kW<br />

<strong>MT</strong>-<strong>VP</strong> 65 3000 l/h 200 kg/h 25 m/s 7‘700 rpm 65 mm up to 11.0 kW<br />

<strong>MT</strong>-<strong>VP</strong> 95 9‘000 l/h 500 kg/h 25 m/s 5‘200 rpm 95 mm up to 22.0 kW<br />

<strong>MT</strong>-<strong>VP</strong> 160 25‘000 l/h 1‘200 kg/h 25 m/s 3‘000 rpm 160 mm up to 37.0 kW<br />

<strong>MT</strong>-<strong>VP</strong> 220 40‘000 l/h 2‘000 kg/h 25 m/s 2‘300 rpm 220 mm up to 55.0 kW<br />

<strong>MT</strong>-<strong>VP</strong> 300 70‘000 l/h 3‘500 kg/h 25 m/s 1‘700 rpm 300 mm up to 75.0 kW<br />

Scale-up<br />

• The MEGATRON ® <strong>MT</strong>-<strong>VP</strong> series includes<br />

six different sizes for liquid throughputs of<br />

approx. 1‘000 l/h and 70‘000 l/h suitable for<br />

suction capacities between approx. 70 kg/h<br />

and 3‘500 kg/h.<br />

• The test results obtained with pilot plant or<br />

smaller production units can be used as a<br />

reliable data source for a scale-up step to<br />

the larger MEGATRON ® production machines.<br />

• Get in contact with our project engineers or<br />

application engineers to discuss scale-up<br />

possibilities.<br />

Throughput [l/h] (1000-70‘000)<br />

Size of MEGATRON ® Inline Homogenizer<br />

Dispersing Generators (choice) - Types, Diameters, Applications<br />

<strong>MT</strong>G ../2G<br />

standard generator<br />

rotor/stator with one teeth<br />

row each<br />

<strong>MT</strong>G ../4M<br />

standard generator, rotor and<br />

stator with two teeth rows<br />

each<br />

<strong>MT</strong>G ../6F<br />

standard generator, rotor and<br />

stator with three teeth rows<br />

each<br />

<strong>MT</strong>G ../6FF<br />

standard generator, rotor and<br />

stator with three teeth rows<br />

each<br />

<strong>MT</strong>G ../6FV<br />

special generator, rotor and<br />

stator with three teeth rows<br />

each and reduced gaps<br />

<strong>MT</strong>G ../P<br />

powder introduction stage<br />

including housing and<br />

propeller<br />

Ø 45 - 300 mm Ø 45 - 300 mm Ø 45 - 300 mm Ø 45 - 300 mm Ø 45 - 300 mm Ø 45 - 300 mm<br />

• Dispersing and Mixing of coarse<br />

solid particles into liquid<br />

• Size reduction (wet milling) of<br />

coarse solids in liquid<br />

• Extractions<br />

• Mixing of fluids<br />

• Crushing of lumps<br />

• Intensive mixing<br />

• Dissolving<br />

• Producing of emulsions and suspensions<br />

with medium droplet<br />

and particle sizes<br />

• Wet milling of solids up to medium<br />

particle sizes<br />

• Extractions<br />

• Accelerating of reactions<br />

• Intensive mixing<br />

• Crushing of lumps<br />

• Dissolving<br />

• Producing of emulsions and<br />

suspensions with fine droplet<br />

and particle sizes<br />

• Wet milling of fine solids<br />

• Extractions<br />

• Accelerating of reactions<br />

• Gassing of fluids<br />

• Cell pulping<br />

• Desagglomerations<br />

• Producing of finest emulsions and<br />

suspensions with finest droplet<br />

and particle sizes<br />

• Wet milling of fine solids<br />

• Extractions<br />

• Accelerating of reactions<br />

• Gassing of fluids<br />

• Cell pulping<br />

• Desagglomerations<br />

• Producing of finest emulsions and<br />

suspensions with finest droplet<br />

and particle sizes<br />

• Extractions<br />

• Gassing of fluids<br />

• Cell pulping<br />

• Desagglomerations<br />

• powder introduction of light<br />

to heavy powders<br />

• suitable for powders used in<br />

chemical, pharmaceutical,<br />

cosmetical, biochemical<br />

and food industries

R<br />

R<br />

R<br />

R<br />

R<br />

R<br />

R<br />

R<br />

R<br />

HOMOGENIZING AND MIXING TECHNOLOGY<br />

POLYTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

BIOTRONA<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

POLYMIX<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

MEGATRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

R<br />

R<br />

R<br />

R<br />

POLYTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMAT ICA<br />

PT 3100 D<br />

Digital High-End<br />

Benchtop<br />

Homogenizer<br />

with PC interface<br />

Homogenizing<br />

and Mixing<br />

Technology for<br />

the Laboratory<br />

Finest Swiss Made Solutions...<br />

... worldwide!<br />

NEW<br />

REACTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

A wide range of products with the finest<br />

solution for every application, matched by<br />

the superior quality of all components make<br />

KINEMATICA a world leader for Dispersing<br />

and Mixing technology.<br />

With Keen Eyes ...<br />

Development knows no rest at KINEMA-<br />

TICA. Our systems are constantly upgraded<br />

to reflect the state-of-the-art technology and<br />

the needs of the market. KINEMATICA has<br />

always had a keen eye for major advances,<br />

as proven by various patents.<br />

The rotor/stator principle for dispersing<br />

technology was conceived and developed<br />

at KINEMATICA and has become the world<br />

standard.<br />

... For Your Needs<br />

Applications for Dispersing/Homogenizing<br />

Technology are always on the increase.<br />

KINEMATICA continually creates new<br />

areas of processing applications based on<br />

innovations. We do not neglect the human<br />

factor as it is exemplified by the noise<br />

reduction of our high-speed systems.<br />

Please, get in touch with us, our local<br />

appointed agent or your preferred dealer.<br />

We will be pleased to supply more details<br />

or arrange a personal demonstration of our<br />

POLYTRON ® and MEGATRON ® systems.<br />

Subsidiaries<br />

KINEMATICA, INC.<br />

1648 Locust Ave, Unit C<br />

Bohemia, NY 11716<br />

USA<br />

Tel. +1-631-750-6653<br />

Fax +1-631-750-6657<br />

e-Mail info@kinematica-inc.com<br />

R<br />

Printed in Switzerland (SIII) PPP 5/2008, Subject to technical modifications<br />

Homogenizing and<br />

Dispersing Technology<br />

for<br />

POLYTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMAT ICA<br />

POLYMIX<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

MEGATRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

REACTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

Laboratory &<br />

Pilot Plant<br />

HOMOGENIZING<br />

EMULSIFYING<br />

SUSPENDING<br />

WET MILLING<br />

MIXING<br />

DRY MILLING<br />

FOAM PRODUCTION<br />

POWDER INTRODUCTION<br />

Finest Swiss Made solutions... worldwide!<br />

KINEMATICA.CH<br />

Dispersing and Mixing Technology<br />

www.kinematica.ch<br />

Homogenizing and<br />

Dispersing Technology<br />

KINEMATICA AG<br />

12516-03<br />

Dispersing and Mixing Dispersing and Mixing Technology<br />

TechnologyReg-No.<br />

KINEMATICA AG<br />

Dispersing and Mixing Technology<br />

Office Eastern Europe<br />

Ul. Gnata Yuri 9, Office 414<br />

UA - Kyiv 03148<br />

Tel. / Fax +380-44-422 6127<br />

Mobile +380-99-050 3023<br />

e-Mail kinematicaua@cc.com.ua<br />

web www.kinematica.com.ua<br />

Printed in Switzerland (SIIII) PT3100D e 4/2008, Subject to technical modifications<br />

DISPERSING<br />

HOMOGENIZING<br />

EMULSIFYING<br />

SUSPENDING<br />

WET MILLING<br />

MIXING<br />

KINEMATICA.CH<br />

Dispersing and Mixing Technology<br />

Headquarters<br />

www.kinematica.ch<br />

Luzernerstrasse 147a<br />

6014 Littau / Lucerne<br />

Switzerland<br />

Tel. +41-41-259 65 65<br />

Fax +41-41-259 65 75<br />

e-Mail info@kinematica.ch<br />

Your distrubutor / Appointed Agent:<br />

Printed in Switzerland (SIII) PPP 6/2008, Subject to technical modifications<br />

for<br />

POLYTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMAT ICA<br />

MEGATRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

POLYMIX<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

REACTRON<br />

DISPERSING AND MIXING TECHNOLOGY BY KINEMATICA<br />

Pilot Plant &<br />

Production<br />

HOMOGENIZING<br />

EMULSIFYING<br />

SUSPENDING<br />

WET MILLING<br />

MIXING<br />

POWDER<br />

INTRODUCTION<br />

FOAM PRODUCTION<br />

Finest Swiss Made solutions... worldwide!<br />

KINEMATICA.CH<br />

Dispersing and Mixing Technology<br />

www.kinematica.ch<br />

Printed in Switzerland <strong>MT</strong>-<strong>VP</strong> <strong>Series</strong> 10/2008, Subject to technical modifications<br />

Finest Swiss Made solutions... worldwide!