nyabarong hydro-electric project (28 mw) - JantERmantER

nyabarong hydro-electric project (28 mw) - JantERmantER

nyabarong hydro-electric project (28 mw) - JantERmantER

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

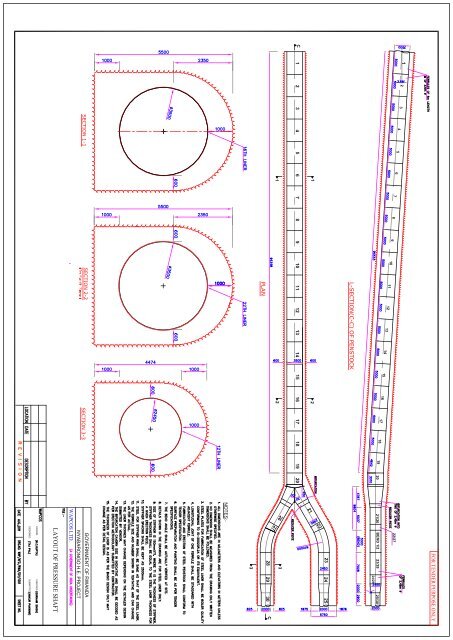

Section-3 : Penstock<br />

(Erection methodology of Wye-Piece<br />

for<br />

Nyaborongo <strong>hydro</strong> <strong>electric</strong> Project, Rwanda)

1 Purpose<br />

This document provide the brief particulars regarding Erection & installation<br />

method for Wye - piece steel liner at Nyaborongo Hydro Electric Project,<br />

Rwanda<br />

2 Scope of Work<br />

The scope of work includes<br />

‣ Fabrication of the Wye-piece in the workshop<br />

‣ Hydrostatic testing of the wye piece.<br />

‣ Transportation of Wye –piece from fabrication yard to erection site<br />

‣ Erection of Wye -piece/ferrules<br />

‣ NDT<br />

‣ Final painting<br />

‣ Commissioning<br />

3 Equipments and Instruments<br />

3.1 Testing equipment.<br />

3.2 Equipments for erection and installation.<br />

3.1 Testing equipments<br />

All necessary equipments and materials required for carrying Ultrasonic<br />

Testing.<br />

3.2 Equipment and Machinery for erection.<br />

<br />

<br />

<br />

<br />

<br />

<br />

Welding Rectifiers<br />

Cranes and trucks for material handling<br />

Winch for linear erection at horizontal pressure tunnels<br />

Gantry cranes at ferrule erection chamber-2 nos.of 30T capacity<br />

Chain Pulley Blocks<br />

Miscellaneous tools & tackles.

4 Proposed Methodology for Erection of pressure Shaft Linear<br />

General:<br />

The Bifurcation as proposed shall be fabricated in workshop with proper quality<br />

control so as to ensure Structural safety Combined with Hydraulic efficiency. The<br />

Branch pipes of shall be proportioned to ensure smooth stream line flow from the<br />

Header (3500 mm Dia to the branch2710mm dia) and to minimize hydraulic loses<br />

by introducing conical Reducers and Keeping the angle of deflection small (about 7<br />

degrees). A reducer piece is used to reduce the overall length of the penstock<br />

bifurcation. The reducer piece has a larger diameter of 2710 mm and smaller<br />

diameter of 2450 mm. The reducer piece will have the same angle of deflection as<br />

that of the bifurcation piece. The sickle plate is used as reinforcement system in the<br />

bifurcation which shall be properly welded to the bifurcation and ring girder.<br />

Proper Care Shall be taken while welding the reinforcement plate(sickle plate) / Tie<br />

rod /Ring Girder / with the plates of Wye piece and welding, cleaning & painting<br />

procedure enumerated elsewhere in this specification should be strictly adhered to.<br />

The methodology for erection of ferrule in the pressure shaft would consist of the<br />

following steps:<br />

1. Fabrication of the Wye-piece in the workshop.<br />

2. Hydrostatic testing<br />

3. Erection Setup.<br />

4. Loading of Wye Piecein the trailer.<br />

5. Transporation of Wye piece<br />

6. Lowering of Wye piece<br />

7. Matching and Pre-heat Treatment<br />

8. Final Welding<br />

9. NDT,Inspection and rectification<br />

10. Cleaning<br />

11. Final Coat of Painting<br />

12. Final Leakage testing/ acceptance test of the complete line and its<br />

Commissioning.

1. Fabrication of the Wye-piece<br />

The wye-piece is proposed to be erected in the workshop. The pieces should<br />

be erected as per the approved drawings from the client. The plate cutting<br />

profiles, Welding details, erection procedure, markings, cutting and beveling of<br />

the chamfers, rolling details etc should be approved by client before the<br />

fabrication of the wye-piece.<br />

a) Marking: The plates shall be laid out, marked as per the desired profile<br />

and trimmed to true shapes with great accuracy.<br />

b) Cutting and Beveling: Chamfers shall be prepared by flame cutting,<br />

shearing, planning or milling.<br />

c) Rolling: the plates shall be rolled to true curvature in a bending machine.<br />

d) Welding: The welding sequence shall be determined in advance and got<br />

approved before fabrication.<br />

e) The fabricator shall be responsible for the quality control.<br />

f) Stress Relieving: After fabrication, the bifurcation piece shall go undergo<br />

stress relieving locally or as a whole, if required.<br />

2. Hydrostatic Testing<br />

A <strong>hydro</strong>static test shall be conducted in the shop with a test pressure of 1.5<br />

times the design pressure or to a pressure which will develop a stress equal to<br />

0.8 times the yield point, whichever is more with the help of bulk heads.<br />

The bifurcation piece shall be completely filled with the water and pressure<br />

shall be applied three times successively increasing and decreasing at uniform<br />

rate.<br />

3. Erection Set Up:<br />

a. Gantry crane: capacity 30mt, capable of lowering up to 300m,span 9mtr<br />

c/c and for both the shaft, for unloading, lowering and matching of ferrules.<br />

b. Auxiliary Winch: Suitable capacity, height of lift 300m with attached<br />

closed bucket for carrying workmen, materials, machinery, tools &<br />

tackles, working platform.

c. Working platform/ Inspection Trolley: Circular platform for dia<br />

5800mm would be fabricated<br />

The platform would be of removable type and it would be welded to<br />

the ferrule by ISMC 100 inserted through the box of ISMC 250<br />

welded to the top of platform at eight locations. The platform is<br />

fixed from the top only and there is no need of any workmen to go<br />

below the platform to fix it. This is essential to safety of the<br />

workmen.<br />

The platform base would be formed from ISMB 200 with a circular<br />

ring of ISMC 200.<br />

It would be covered by a steel grating of 25 mmx25mm box and a<br />

circular plate of 1m dia of 20mm thickness at the center.<br />

d. Bucket: A bucket of size 2m x 2m x 2.5m would be fabricated with covered<br />

top and removable railing of for safety precautions, to be attached to the<br />

auxiliary winch.<br />

e. Illumination: Proper illumination would be done inside the shaft at an interval<br />

of 50m. Halogen lights would be fixed to the wall of the shaft with proper<br />

anchors. A separate power cable arrangement will be installed and would be<br />

independent from other works.<br />

4. Loading of Wye- Piece<br />

The Wye-piece would be lifted by the crane of capacity of 30 m and shall be put<br />

on the rolling platform in a vertical position. The Wye-piece shall be properly tuck<br />

welded to assure the proper transportation through rails.<br />

5 .Transportation of Wye Piece:<br />

a. As transport by rail of Wye-piece over 3.5m in Diameter is usually not feasible,<br />

W-Piece of the size Should be Fabricated in a Field fabricating plant near the<br />

site of installation, either from the plates shaped directly from the mill or from<br />

plates pre-fabricated at the contractor home plant, the plates were to be

fabricated cut to size, edged, enrolled then transported to the field fabricating<br />

plant for compaction internal spiders, were used during fabrication to keep the<br />

Y piece in shape perfect with its stiffeners and bi furcation.<br />

b. The Y piece should be transported either from the nearest railway station or<br />

from the field fabricated plant to the site nearest to the installation by truck,<br />

trailers, barge, or other means suited at the site. Upon arrival at the site of<br />

installation, the Y piece lifted in place by cable way, gantry crane or by other<br />

means.<br />

c. The finished Y piece will be placed on low bed trailer and will properly clamped<br />

with temporary cleats welded to the truck bed and also tightened with turn<br />

buckles to avoid any displacement of Y piece during transportation through<br />

tunnel approach number B1 to the desired location of the junction of the<br />

bifurcation.<br />

d. 2 or more no. of lifting hooks around periphery of the Y piece will be welded at<br />

suitable points of the Y piece.<br />

e. Then the Y piece would be transported to the desired location of the junction of<br />

bi furcation.<br />

6. Lowering of Wye- Piece in the final position:<br />

<br />

As the trailer reaches the Erection Point in the cavern, all temporary cleats etc<br />

would be removed and, turn buckles are released. The gantry positioned to<br />

the center of wye-piece would lift the wye-piece from the lifting hooks<br />

attached so as to free the trailer.<br />

After the Wye- Piece is rested on the ground, the working platform is welded<br />

inside the Wye- Piece to assist the workmen for sitting. All welding machines,<br />

cutting sets, mother oven and other tools & tackles required, would be loaded<br />

on the platform.<br />

3 skilled riggers and one foreman with required safety apparatus and<br />

communication wireless set are deputed at the platform to guide the exact<br />

position and lowering of Wye- Piece.

At least 3 skilled workmen must be ready for assistance stationed in the<br />

important requisite locations of the ground to monitor the lowering of Wye-<br />

Piece.<br />

Now the Wye- Piece 3.5 dia. side of the Wye- Piece is positioned towards the<br />

header along the alignment and well matched to the bi furcating pieces by<br />

starting to lower with the main hook of the gantry crane. A set of workmen<br />

must be there to monitor the lowering Wye- Piece and provide assistance if<br />

required.<br />

The entire activity is monitored and coordinated with the crane operator and<br />

the foreman sitting inside the Wye- Piece.<br />

Once the Wye- Piece reaches its position, then the matching gang with fitters,<br />

tank welders, workmen and <strong>electric</strong>ian along with tha main power cable are<br />

positioned for the further job.<br />

7. Matching & pre-heat treatment:<br />

After the position of Wye- Piece perfect to the header and the branches of the<br />

pressure conduit, the <strong>electric</strong>ian will connect the welding machines with the<br />

power cable and the edge matching of the joint starts.<br />

Matching of all the joints in Wye- Piece and adjoining header and branch<br />

pipes will be done from the outside the ferrule which will ensure the following<br />

benefits:<br />

a. Welder will be free of any hindrance of the locking cleats, L-keys,<br />

Matching screws, etc.<br />

b. No cleaning and grinding of inner surface would be required as the<br />

surface would be free from tack welds.<br />

For matching from outside arrangement suitable to the site specific are made.<br />

The edges may be matched with the help of wedge, L-keys and cleats. The<br />

root gap may be maintained throughout the joint with the help of short turn<br />

buckles installed at the joint.<br />

After matching, the backing strip is welded from outside at the joint.

Pre Heat Treatment<br />

a. Preheating coil (width 300mm) and insulation wool arrangement may<br />

be required outside Wye Piece, adjoining header and Branch pipes.<br />

b. This arrangement is tack welded to the Wye Piece for heating and<br />

connected to the heating panel having requisite sensitivity.<br />

c. A current regulator is installed to regulate the heating process in<br />

controlled manner.<br />

The complete process of matching and start of pre-heating would take<br />

around 4-5 hours.<br />

8. Welding of Joint:<br />

After the matching gang completes its Job, Welders and helpers along with<br />

the required tools & tackles are sent to the Welding Job.<br />

The welder would start welding, once the pre-heat temperature reaches<br />

200 o C which may be checked with help of thermo pens.<br />

The temperature would be maintained during welding of joint.<br />

The welding would be done as per the relevant Specification as approved<br />

by the <strong>project</strong> authority and according to the specification of ASME Section<br />

VIII & IX.<br />

After the welding is complete, the heating arrangement would be still kept<br />

ON for another 2 hrs. acting as post heat/stress relieving treatment.<br />

After 2 hours, the heating panel is switched OFF but the coils and insulting<br />

are not removed from the joint until the joint reaches back to the ambient<br />

temperature gradually.<br />

The reducer piece shall be welded to the Wye-piece and entire weld-length<br />

shall be checked by radiographic testing. The<br />

The sequence of operation may be outlined as specified below:<br />

A. Take over from civil team for erection.<br />

B. Lowering, matching and preheating of joints.

C. Welding of 2-3 joints.<br />

D. NDT and Inspection<br />

E. Removal of all temporary cleats, platform, Support, tools & tackles.<br />

F. Handover for backfill concreting.<br />

9. NDT, Inspection and rectification:<br />

All the erection circumferential joints would be 100% tested ultrasonically.<br />

The radiographic examination shall be carried at all the welds too. The<br />

longitudinal joints of entire length of the penstock shall be radiographed for<br />

100% length. The circumferential joints shall be spot radiographed for 10%<br />

length of each joint plus 100 mm on both sides of weld section.<br />

All the T junctions between longitudinal and circumferential joint shall be<br />

radiographed.<br />

After erection and welded of Wye Piece and adjoining Header and Branches are<br />

complete, NDT technician along with the department inspector is sent platform<br />

for easy access to all the joints.<br />

100% Ultrasonic testing (UT) would be performed on all the welded joints in front<br />

of the inspector and if any repair is found, it would be marked for rectification.<br />

All marked repairs are rectified from inside surface only and rechecked for<br />

conformation.<br />

After NDT is successfully completed the portion is handed over for backfilling<br />

concreting.<br />

10. Cleaning of the inner side of the wye-piece:<br />

After backfilling concreting of the entire length is completed, grouting is done by<br />

civil people through the grout holes provided in the ferrules.<br />

Once grouting is finished a team of welders, fitters and helpers are sent on the<br />

platform to fit and weld the grout holes which are already fabricated as per the<br />

drawing.<br />

The workmen would also clean and remove all tack welds, cleats, temporary<br />

structures, etc from the inner surface of the Wye-piece for final painting.

11. Final Leakage testing/ acceptance test of the complete line and its<br />

Commissioning.<br />

On completion of penstock erection, and before the final painting, the<br />

penstock is filled and checked for stability and tightness.<br />

The filling of the penstock shall be done at a slow rate and during filling the<br />

closing and tightness of all the valves, inspection openings and other<br />

accessories shall be checked and the penstock shall be properly vented at<br />

high points to prevent formation of air pockets.<br />

<br />

Any joint leakage shall be repaired and retested<br />

12. Final Painting:<br />

Final coat of painting would be applied on the entire length of Wye-piece along with the<br />

Header and Branch pipes by airless spray system.

NYABARONG HYDRO-ELECTRIC PROJECT (<strong>28</strong> MW)<br />

RWANDA, AFRICA<br />

TECHNICAL SPECIFICATIONS<br />

HYDRO-MECHANICAL WORKS

NYABARONG HYDRO-ELECTRIC PROJECT (<strong>28</strong> MW)<br />

RWANDA, AFRICA<br />

TECHNICAL SPECIFICATIONS<br />

HYDRO-MECHANICAL WORKS<br />

Prepared By___________________<br />

(AZHAR NAQVI)<br />

Checked By____________________<br />

(J.SAHU)<br />

Verified By____________________<br />

(S. R. DAS)<br />

Submitted By___________________<br />

(O. P. CHIBBER)

NYABARONG HYDRO-ELECTRIC PROJECT (<strong>28</strong> MW)<br />

RWANDA, AFRICA<br />

Technical Specifications<br />

(Hydro-Mechanical Works)<br />

CONTENTS<br />

SECTION NO. TITLE Page No.<br />

Section - 1 Intent of Technical Specifications and Scope of Works I<br />

Section - 2 Standards and Materials II<br />

Section - 3 Technical Documents III<br />

Section - 4 Spare Parts and Tools IV<br />

Section – 5 Description and Design Criteria V<br />

Section - 6 Manufacture X<br />

Section - 7 Electrical Works XI<br />

Section – 8 Erection XII<br />

Section – 9 Transportation and Storage XIII<br />

Section – 10 Quality Assurance, Inspection, Testing and Final Acceptance XIV<br />

Section – 11 Schedule for Hydro-mechanical Works XV

TABLE OF CONTENTS<br />

SECTION – 1<br />

INTENT OF TECHINICAL SPECIFICATIONS AND SCOPE OF WORK<br />

Clause No. Title Page No.<br />

1.1.0 Intent of Technical Specification 1<br />

1.1.1 General 1<br />

1.2 Scope of work 1<br />

1.2.1 General 1<br />

1.2.2 Spillway Radial Gates 2<br />

1.2.3 Stoplogs for Spillways 2<br />

1.2.4 Diversion Tunnel Gate 3<br />

1.2.5 Intake Trash Racks 3<br />

1.2.6 Power Intake Service Gate 4<br />

1.2.7 Power Intake Emergency Gate 4<br />

1.2.8 Draft Tube Gates 4<br />

1.2.9 Miscellaneous Systems and Equipment 5<br />

1.3.0 Conditions for Particulars Application 6<br />

1.3.1 General 6<br />

1.3.2 Inspection and Quality Assurance Plan 7<br />

1.3.3 Wastage of Steel 7<br />

1.3.4 Schedule and progress 7<br />

1.3.5 Delivery period 8<br />

1.3.6 Responsibilities of Contractor 8<br />

1.4.0 General Requirement 9<br />

1.5.0 Atmospheric Conditions 9<br />

1.6.0 Warranty 9

SECTION – 2<br />

I<br />

STANDARDS AND MATERIALS<br />

Clause No. Title Page No.<br />

2.1.0 Standards and Codes 11<br />

2.2.0 Standards for General Application 11<br />

2.2.1 General 11<br />

2.2.2 Standards for Design & Testing 12<br />

2.2.3 System of Units 14<br />

2.3.0 Material Standard 14<br />

2.3.1 General 14<br />

2.3.2 Spillway Radial Gate 15<br />

2.3.3 Vertical Lift Fixed Wheel Gates for Diversion 16<br />

Tunnel / Intake / Draft Tube<br />

2.3.4 Stoplogs for Spillway Radial Gates 17<br />

2.3.5 Electrically Operated Rope Drum Hoists 18<br />

2.3.6 Lifting Beam 19<br />

2.3.7 Gantry Crane 19<br />

2.3.8 Hoist Bridge, Trestles, Walkway railing, gantry girder etc. 21<br />

2.3.9 Hydraulic Hoist 21<br />

2.3.10 Trash Rack Cleaning Machine 22

SECTION – 3<br />

II<br />

TECHNICAL DOCUMENTS<br />

Clause No. Title Page No.<br />

3.1.0 Technical Documents 23<br />

3.1.1 General 23<br />

3.2.0 Designs & Drawings 24<br />

3.2.1 Drawings and data to be furnished by the bidders 24<br />

along with the Bid<br />

3.2.1.1 Radial Gates for Spillways 24<br />

3.2.1.2 Hydraulic Hoists for Radial Gates 24<br />

3.2.1.3 Support Structure for Hydraulic Hoist of Radial Gates 25<br />

3.2.1.4 Stoplogs for Spillways 25<br />

3.2.1.5 Lifting Beam for Spillway Stoplogs 25<br />

3.2.1.6 10 t Capacity (Tentative) Gantry Crane for Spillway Stoplogs 25<br />

3.2.1.7 Diversion Tunnel Gate / Power Intake Service Gate / 25<br />

Power Intake Emergency Gate / Draft Tube Gate<br />

3.2.1.8 Rope Drum Hoists for Diversion Tunnel Gate / Power 25<br />

Intake Service Gate / Power Intake Emergency Gate /<br />

Draft Tube Gate<br />

3.2.1.9 Hoist Support Structures for Diversion Tunnel Gate / 26<br />

Power Intake Service Gate / Power Intake Emergency<br />

Gate / Draft Tube Gate<br />

3.2.1.10 Intake Trash Rack 26<br />

3.2.1.11 Lifting Beam for Intake Trash Rack 26<br />

3.2.1.12 Trash Rack Cleaning Machine 26<br />

3.2.2 Drawings and Data to be furnished by contractor after 26<br />

award of work<br />

3.2. 3 Diagrams <strong>28</strong><br />

3.2.4 List of Schedules 29<br />

3.3.0 Progress Reports 32<br />

3.4.0 Installation, Operation & Maintenance Manual 32<br />

3.5.0 Inspection and Test Records 33

SECTION - 4<br />

III<br />

SPARE PARTS AND TOOLS<br />

Clause No. Title Page No.<br />

4.1.0 Spare Parts 34<br />

4.1.1 General 34<br />

4.1.2 General Spare Parts 34<br />

4.1.3 Mandatory Spares 35<br />

4.1.4 Additional Spares 37<br />

4.1.5 Tools and Appliances 37

SECTION – 5<br />

IV<br />

DESCRIPTION AND DESIGN CRITERIA<br />

Clause No. Title Page No.<br />

5.1.0 Design and Construction Requirements 38<br />

5.1.1 General 38<br />

5.1.2 Design Criteria 39<br />

5.2.0 Spillway Radial Gates 39<br />

5.2.1 General 39<br />

5.2.2 Specification Drawings 40<br />

5.2.3 Design Parameters 40<br />

5.2.4 Description and Design Criteria 40<br />

5.2.5 Description of Components and Design Criteria 41<br />

5.2.5.1 General 41<br />

5.2.5.2 Skin Plate 42<br />

5.2.5.3 Horizontal Girders and Stiffeners 42<br />

5.2.5.4 Arms 42<br />

5.2.5.5 Trunnion Hubs 43<br />

5.2.5.6 Trunnion Pins 43<br />

5.2.5.7 Trunnion Bush / Bearings 43<br />

5.2.5.8 Trunnion Brackets 43<br />

5.2.5.9 Trunnion Ties 43<br />

5.2.5.10 Seals 43<br />

5.2.5.11 Seal Seat, Seal Bases and Sill Beams 44<br />

5.2.5.12 Guide Rollers 44<br />

5.2.5.13 Load Carrying Anchorages 44<br />

5.2.5.14 Trunnion Girders or Yoke Girders and Anchor Girders 45<br />

5.2.5.15 Anchor Bolts or Anchor Plates 45<br />

5.2.5.16 Tolerance 45<br />

5.3.0 Stoplogs for Spillway Radial Gates 45<br />

5.3.1 General 45<br />

5.3.2 Specification Drawings 46<br />

5.3.3 Design Parameters 46<br />

5.3.4 Description and Design Criteria 46<br />

5.4.0 Vertical Lift Wheel Gates 47<br />

5.4.1 Diversion Tunnel Gate 47<br />

5.4.2 Specification Drawings 47<br />

5.4.3 Design Parameters 47<br />

5.4.4 Description and Design Criteria 48<br />

5.5.0 Power Intake Service and Emergency Gate 48<br />

5.5.1 General 48<br />

5.5.2 Specification Drawings 49<br />

5.5.3 Design Parameters 49

Clause No. Title Page No.<br />

V<br />

5.5.4 Description and Design Criteria 49<br />

5.6.0 Draft Tube Gates 50<br />

5.6.1 General 50<br />

5.6.2 Specification Drawings 50<br />

5.6.3 Design Parameters 50<br />

5.6.4 Description and Design Criteria 51<br />

5.7.0 Intake Trash Rack 51<br />

5.7.1 Design Parameters 51<br />

5.7.2 Description and Design Criteria 52<br />

5.8.0 Gantry Crane for Spillway Stoplogs 52<br />

5.8.1 Design Data for Gantry Cranes 52<br />

5.9.0 Trash Rack Cleaning Machine 53<br />

5.9.1 Design Data for Trash Rack Cleaning Machine 53<br />

5.10.0 Lifting Beams for operation of Spillway 53<br />

Stoplogs & Trash Racks<br />

5.11.0 Hoist Support Structures 53<br />

5.12. 0 Description of Components of Vertical Lift 54<br />

Gates and Embedded Parts<br />

5.12.1 Fixed Wheel Gates 54<br />

5.12.2 Spillway Stoplogs 55<br />

5.12.3 Skin Plate 55<br />

5.12.4 Horizontal Girders, Stiffeners and End Vertical Girder 56<br />

5.12.5 Seal 56<br />

5.12.6 Seal Seats, Seal Bases and Sill Beams 56<br />

5.12.7 Wheel Assembly 57<br />

5.12.8 Track / Bearing Plates & Bases 57<br />

5.12.9 Guide Plates & Guide Shoes / Guide Rollers 58<br />

5.12.10 Ballast 58<br />

5.12.11 Lifting Arrangement 58<br />

5.12.12 Anchor Bolts or Anchor Plates 59<br />

5.12.13 Tolerances 59<br />

5.13.0 Hydraulic Hoists for Spillway Radial Gates 59<br />

5.13.1 General 59<br />

5.13.2 Description 59<br />

5.13.3 Hydraulic Cylinder Assembly 60<br />

5.13.4 Cylinder Assembly Mounting and Support Structure 63<br />

5.13.5 Connecting Pipe 64<br />

5.13.6 Hoist Control module 66<br />

5.13.7 Hydraulic Fluids 71<br />

5.13.8 System Cleanliness 71<br />

5.13.9 Flushing 71

5.13.10 Miscellaneous Equipment Details 72<br />

5.13.11 Design Criteria of Hydraulic Hoists 72<br />

VI<br />

Clause No. Title Page No.<br />

5.13.12 Hoist Cylinder Assembly 75<br />

5.13.13 Cylinder Mounting Support Structure 75<br />

5.13.14 Design criteria for Piping 76<br />

5.13.15 Hydraulic Power Unit 76<br />

5.13.16 Miscellaneous Design Criteria 76<br />

5.13.17 Controls 77<br />

5.13.18 Life Expectancy 77<br />

5.13.19 Hoist Electrical Control Cabinet 77<br />

5.13.20 Enclosure 78<br />

5.13.21 Contactors 78<br />

5.13.21 Control Cabinet Lighting and Outlets 78<br />

5.14.0 Rope drum Hoists for operation of Diversion Tunnel 79<br />

Gate / Power Intake Service / Emergency Gate and<br />

Draft Tube Gates<br />

5.14.1 General 79<br />

5.14.2 Hoist Capacity 79<br />

5.14.3 Design Data for Rope drum Hoists 80<br />

5.14.4 Hoisting Speed 80<br />

5.14.5 Hoist Supporting Structure 80<br />

5.14.6 Components of the Hoists 81<br />

5.14.7 Mechanical Equipment 81<br />

5.14.7.1 Hoisting Ropes 81<br />

5.14.7.2 Rope Drums 82<br />

5.14.7.3 Gears 82<br />

5.14.7.4 Speed Reducers 82<br />

5.14.7.5 Gate Position Indicator 83<br />

5.14.8 Shafts 83<br />

5.14.8.1 General 83<br />

5.14.8.2 Dimensioning of Shafts 83<br />

5.14.8.3 Allowable Stresses 83<br />

5.14.8.4 Sheaves and Pulleys 83<br />

5.14.8.5 Sockets for Wire Ropes 84<br />

5.14.8.6 Turn Buckles & Equalizer Bars 84<br />

5.14.8.7 Bearings 84<br />

5.14.8.8 Couplings 84<br />

5.14.9 Electrical Equipment 84<br />

5.14.9.1 Efficiency of System 85<br />

5.14.9.2 Motors 85<br />

5.14.9.3 Electro-Magnetic Brakes 85<br />

5.14.9.4 Limit Switches 86

5.14.9.5 Wiring 86<br />

5.14.9.6 Manual Operation 87<br />

Clause No. Title Page No.<br />

VII<br />

5.14.9.7 Interlocking and Earthing 87<br />

5.14.9.8 Lubrication 87<br />

5.14.9.9 Miscellaneous 87<br />

5.15.0 Hoist Supporting Structure 88<br />

5.15.1 General 88<br />

5.16.0 Gantry Cranes for operation of Stoplogs for 88<br />

Spillway Radial Gates<br />

5.16.1 General 88<br />

5.16.1.1 Design Criteria 89<br />

5.16.2 Structural Components 90<br />

5.16.2.1 General 90<br />

5.16.2.2 Frame 90<br />

5.16.2.3 Legs 90<br />

5.16.2.4 Machinery Housing 91<br />

5.16.2.5 Operator’s Cabin 91<br />

5.16.2.6 Walkways, Ladders and Handrails 91<br />

5.16.2.7 Buffers 91<br />

5.16.3 Mechanical Equipment 92<br />

5.16.3.1 General 92<br />

5.16.3.2 Wheels and Axles 92<br />

5.16.3.3 Gantry Drive 93<br />

5.16.3.4 Hoisting Ropes 93<br />

5.16.3.5 Rope Drums 94<br />

5.16.3.6 Sheaves and Pulleys 94<br />

5.16.3.7 Gears and Speed Reducers 95<br />

5.16.3.8 Brakes 95<br />

5.16.3.9 Shafts 96<br />

5.16.3.10 Bearings 96<br />

5.16.3.11 Couplings 97<br />

5.16.3.12 Lifting Hook and Pulley Block 97<br />

5.16.3.13 Gear Box Cover 97<br />

5.16.3.14 Counter Weight 97<br />

5.16.3.15 Keys and keyways 97<br />

5.16.4.0 Electrical Equipment 97<br />

5.16.4.1 General 97<br />

5.16.4.2 Electric Motor 98<br />

5.16.4.3 Master Control Equipment 98<br />

5.16.4.4 Cables and Reels 99<br />

5.16.4.5 Wiring 100<br />

5.16.4.6 Limit Switch 100

5.16.4.7 Isolating Switches 100<br />

5.16.4.8 Protective Equipments 101<br />

5.16.4.9 Emergency Push Button 101<br />

Clause No. Title Page No.<br />

VIII<br />

5.16.4.10 Lighting at convenient outlets 101<br />

5.16.4.11 Interlocking and Earthing 101<br />

5.16.5.1 Wrenches and Tools 101<br />

5.16.5.2 Lubrication 101<br />

5.17.0 Lifting Beam for operation of Spillway Stoplogs 102<br />

and Trash Racks<br />

5.17.1 General 102<br />

5.17.2 Design Loading 102<br />

5.17.3 Structural design 103<br />

5.17.4 Component Details 103<br />

5.17.5 Design Data 104

SECTION – 6<br />

IX<br />

MANUFACTURE<br />

Clause No. Title Page No.<br />

6.1.0 Manufacture 105<br />

6.1.1 General Workmanship 105<br />

6.2.1 Tolerances and Fits 106<br />

6.2.2 Fabrication Tolerances 106<br />

6.2.3 Installation Tolerance 106<br />

6.3.0 Machine Finish 107<br />

6.4.0 Casting 107<br />

6.5.0 Forging 107<br />

6.6.0 Fabrication of Structural Steel 108<br />

6.6.1 Welding 108<br />

6.6.2 Riveting 110<br />

6.6.3 Turned and Fitted Bolts 110<br />

6.6.4 Set Screws 110<br />

6.6.5 Drilling and Reaming 110<br />

6.6.6 Punching 110<br />

6.7.0 Stress Relieving 110<br />

6.8.0 Painting 111<br />

6.8.1 General 111<br />

6.8.2 Painting Schedule 112<br />

6.8.2.1 Gates and Embedded parts 112<br />

6.8.2.2 Cranes, Hoists, Trash Rack Cleaning Machine and 113<br />

Supporting Structures<br />

6.8.2.3 Finishing Coats 113<br />

6.8.2.4 Embedded Parts in contact with concrete 114<br />

6.8.3 Surfaces not to painted 114<br />

6.8.4 Colour Scheme 114<br />

6.8.5 Handling of painted metal works 114<br />

6.8.6 Inspection and testing 114<br />

6.8.7 Field Painting 115<br />

6.8.8 Repair of Primer and Finished Coats 115<br />

6.9.0 Galvanizing 115<br />

6.10.0 Tests & Inspection 116<br />

6.10.1 General 116<br />

6.10.2 Tests of materials 116

SECTION – 7<br />

X<br />

ELECTRICAL WORKS<br />

Clause No. Title Page No.<br />

7.1.0 General 117<br />

7.1.1 Scope of Work 117<br />

7.1.2 Standards 117<br />

7.1.3 Colour Code 117<br />

7.2.0 Electric Motors 118<br />

7.2.1 General 118<br />

7.2.2 Rating 118<br />

7.2.3 Starting 118<br />

7.2.4 Windings and Insulation Class 119<br />

7.2.5 Ventilation and Type of Enclosure 119<br />

7.2.6 Bearings 119<br />

7.2.7 Shafts and Couplings 120<br />

7.2.8 Terminal Boxes and Earthing 120<br />

7.2.9 Noise Level and Vibrations 120<br />

7.2.10 Tests 121<br />

7.3.0 Auxiliary Works 121<br />

7.3.1 Auxiliary Switches 121<br />

7.3.2 Control Switches 121<br />

7.3.3 Anti-Condensation Heaters 122<br />

7.3.4 Protection Devices 122<br />

7.4.0 Terminal Points 123<br />

7.4.1 Scope of work 123<br />

7.4.2 Supply Tolerances 123<br />

7.5.0 Cables 123<br />

7.5.1 General 123<br />

7.5.2 Colour Code 123<br />

7.6.0 Earthing System 124<br />

7.7.0 Labels and Plates 124<br />

7.7.1 General 124<br />

7.7.2 Equipment Labels and Instruction Plates 124<br />

7.7.3 Instruction Plates 125

SECTION – 8<br />

XI<br />

ERECTION<br />

Clause No. Title Page No.<br />

8.1.0 General 126<br />

8.2.0 Installation of I st stage Embedded parts 126<br />

8.3.0 Installation of 2 nd stage Embedded Parts 126<br />

8.4.0 Installation of Gates, Hoists & Operating Mechanism 126<br />

8.5.0 Guidelines for Field Erection 126<br />

8.6.0 Placing of Concrete 127<br />

8.7.0 Erection Personnel 127<br />

8.8.0 Erection Limitation 127<br />

8.9.0 Notification 127<br />

8.10.0 Cooperation with other Contractors 127

SECTION – 9<br />

XII<br />

TRANSPORTATION AND STORAGE<br />

Clause No. Title Page No.<br />

9.1.0 Transportation 1<strong>28</strong><br />

9.2.0 Preparation for Dispatch 1<strong>28</strong><br />

9.3.0 Weights 1<strong>28</strong><br />

9.4.0 Marking 1<strong>28</strong><br />

9.5.0 Packing 129<br />

9.6.0 Storage 129

SECTION – 10<br />

XIII<br />

QUALITY ASSURANCE, INSPECTION, TESTING AND FINAL ACCEPTANCE<br />

Clause No. Title Page No.<br />

10.1.0 Quality Assurance 131<br />

10.2.0 Inspection, Testing and Maintenance 132<br />

10.2.1 General 132<br />

10.2.2 Place of Manufacture and Inspection 132<br />

10.3.0 Inspection 133<br />

10.4.0 Witnessing Shop Test, Inspection and Training 133<br />

10.5.0 Operational Tests 134<br />

10.5.1 General 134<br />

10.5.2 Dry Test 134<br />

10.5.3 Wet Test 134<br />

10.5.4 Leakage Tests 135<br />

10.5.5 Non-Destructive Tests 135<br />

10.5.5.1 General 135<br />

10.5.5.2 Radiographic and Ultrasonic Inspection 135<br />

10.6.0 Shop Assembly and Tests 137<br />

10.6.1 Gates / Stoplogs 137<br />

10.6.2 Gantry Cranes 137<br />

10.6.3 Lifting Beam 138<br />

10.6.4 Load Testing 139<br />

10.6.5 Load Testing of Anchorage Assemblies 139<br />

10.6.6 Shop Assembly Tests 139<br />

10.7.1 Field Tests 139<br />

10.7.1 Gates / Stoplogs 139<br />

10.7.2 Hoists / Gantry Crane 140<br />

10.7.3 Lifting Beam 140<br />

10.8.0 Final Acceptance 141<br />

10.9.0 Guarantee 141<br />

10.9.1 Failure to Meet Guarantee 141<br />

10.9.2 Defective Equipment 142<br />

10.9.3 Operation of Unsatisfactory Equipment 142

SECTION – 11<br />

XIV<br />

SCHEDULE OF UNIT RATES FOR HYDRO-MECHANICAL EQUIPMENT<br />

Clause No. Title Page No.<br />

11.1.0 Schedule of unit rates for 3500 mm x 5100 mm Spillway Radial Gates 143<br />

11.2.0 Schedule of unit rates for 3500 mm x 8260 mm Spillway Stoplogs 145<br />

11.3.0 Schedule of unit rates for 6700 mm x 6700 mm Diversion Tunnel Gate 146<br />

11.4.0 Schedule of unit rates for 6806 mm x 6850 mm Intake Trash Racks 148<br />

11.5.0 Schedule of unit rates for 4100 mm x 4100 mm Service Gate for Power Intake 149<br />

11.6.0 Schedule of unit rates for 4100 mm x 4100 mm Emergency Gate<br />

for Power Intake 151<br />

11.7.0 Schedule of unit rates for 4762 mm x 2480 mm Draft Tube Gate<br />

for Power House 152<br />

11.8.0 Schedule of unit rates for 10 t capacity Gantry Crane for Spillway Stoplogs 154<br />

11.9.0 Schedule of unit rates for Trash Rack Cleaning Machine 155

SECTION – 1<br />

XV<br />

INTENT OF TECHNICAL SPECIFICATIONS AND SCOPE OF WORK<br />

1.1.0 Intent of Technical Specifications<br />

1.1.1 General<br />

These Specifications are part of the requirements for various items related to the Work<br />

which are to be provided according to the stipulations of the contract. Hence, the<br />

instructions given herein form an integral part of, and are applicable to the Bidding<br />

Documents issued for the Works. Addendum to these Specifications may be issued, as<br />

required, during bidding and construction phases.<br />

These Specifications shall be read in conjunction with the Conditions of Contract, the<br />

specification Drawings and the schedule of prices and the Contractor shall comply with all<br />

provisions contained within the Bidding Documents and instructions of the Purchaser.<br />

Certain performance requirements, materials, features, design requirements and basic<br />

arrangement for Gates, hoist, stoplogs, cranes etc. are indicated herein. It is not the<br />

intention in these specifications to specify the complete details of the various components<br />

of the equipment. This is left to the experience and practice of Contractor who shall<br />

perform the complete design of all the equipment structure and furnish equipment which<br />

shall meet, in all respects the specified requirements in regard to performance, durability<br />

and satisfactory operation. However, certain features, materials and design requirement are<br />

specified and are intended to establish minimum standard for the work and to enable the<br />

bidder to submit a well planned bid.<br />

It is the intent of these specifications to establish acceptable standards of quality.<br />

Deviation from these specifications shall be considered for acceptance, provided that, in<br />

the opinion of the Engineer-in-Charge, the proposed substitutions are equal or superior in<br />

quality to those specified.<br />

All works shall be executed according to the Technical Specifications and Specification<br />

Drawings and requirements specified by Engineer-in-Charge, in professional and diligent<br />

manner and all supplies and works shall comply with the quality requirements defined in<br />

the relevant chapters of these Specifications and other Bidding Documents. The<br />

Contractor shall endeavor to provide all such necessary efforts in order to comply with the<br />

intent of these Specifications to the satisfaction of the Engineer-in-Charge.<br />

1.2 Scope of Work<br />

1.2.1 General<br />

These specifications cover the requirements of design, fabrication, shop assembly, shop as<br />

well as field painting, transportation, supply, erection, testing, commissioning, (including<br />

provision for all labour, plant, material) satisfactory operation and equipment performance<br />

guarantee of the following equipment at site complete in all respects for Nyabarongo<br />

Hydro-<strong>electric</strong> Project, Rwanda, Africa in accordance with these Technical Specifications

and Specification Drawings. The materials, workmanship, technical requirements,<br />

equipment, accessories, supplies and services required, shall be as set forth in this<br />

Technical Specifications.<br />

It shall also include the spares required for satisfactory operation and maintenance of<br />

Gates, Hoists and allied equipment for a period of five years from the date of<br />

commissioning of the equipment as set forth in this Technical Specifications and<br />

Specification Drawings. The description and quantity of spares required for various gates,<br />

hoists and their associate equipment have been indicated Section - 4 of these<br />

specifications.<br />

The scope of work also covers unloading, stacking operation, storage and preservation of<br />

components of gates and their hoisting arrangement, stoplogs, lifting beams, Gantry<br />

Cranes and their accessories in the stockyards of the contractor at the <strong>project</strong> site before<br />

they are transported, installed, tested and commissioned at their respective Sites.<br />

1.2.2 Spillway Radial Gates<br />

1.2.2.1 3 (Three) sets of Radial gates suitable for 3(three) openings of 3500 mm x 5100 mm<br />

each for spillway complete in all respects with skin plate, vertical stiffeners, horizontal<br />

girders, radial arms, trunnion, trunnion brackets, trunnion tie beam, walkway bridge,<br />

approach ladder along with all accessories such as seals, guide rollers, lifting brackets,<br />

trunnion brackets etc., and other appurtenances. Each gate will be operated by means of<br />

twin cylinder hydraulic hoist.<br />

1.2.2.2 3 (Three) sets of embedded parts for Radial Gates for 3(three) openings of spillway<br />

such as wall plates, guide roller path, sill beams, seal seats, yoke girder, anchor girder,<br />

anchor tie flats, load carrying anchors, 1 st stage anchor bolts and 2 nd stage embedded parts<br />

etc. complete in all respects.<br />

1.2.2.2 (a) Walkway of 1200 mm width to access trunnion assemblies.<br />

1.2.2.3 3 (Three) sets of hydraulic hoists (two cylinders per set) of adequate capacity for<br />

operation of Spillway Radial gates mentioned under para 1.2.2.1 above consisting of<br />

hydraulic cylinder assembly, cylinder assembly mounting and support structure,<br />

connecting piping, hoist control module including hydraulic power unit, <strong>electric</strong>al control<br />

cabinet, <strong>electric</strong> motor, gate position indicator, frame and housing along with all<br />

accessories and appurtenances and hydraulic fluid as per these specifications and<br />

arrangements complete in all respects.<br />

1.2.2.4 3 (Three) sets of hoist supporting structure / frame of adequate capacity for supporting<br />

the hydraulic hoists for Spillway Radial Gate as defined at 1.2.2.3 including Trunnion<br />

Pedestal, anchors etc. complete in all respects.<br />

1.2.3 Stoplogs for Spillways<br />

1.2.3.1 1 (one) set of sliding type stoplogs (consisting of 3 units) suitable for 3(three) openings<br />

of 3500 mm x 8260 mm each for spillway consisting of non-interchangeable top,<br />

intermediate and bottom unit of size 3500 mm x <strong>28</strong>00 mm each complete in all respects<br />

with skin plate, vertical stiffeners, horizontal girders, guide shoes, sliding blocks, seals,<br />

lifting lugs etc. and other appurtenances to be used for isolating spillways for the<br />

maintenance of radial gates.

1.2.3.2 3 (three) sets of embedded parts for Stoplogs for 3(three) openings of spillway such as<br />

anchor bolts, sill beams, seal seats and bases, tracks and bases, guides, 1 st stage anchor<br />

bolts and 2 nd stage embedded parts etc. complete in all respects including 3(three) sets of<br />

anchor bolts, dogging devices at top of its groove for storage of Stoplog units.<br />

1.2.3.3 10 t Capacity (Tentative) Gantry Crane for operation of Spillway Stoplogs<br />

10 t Capacity (tentative) Gantry Crane shall have <strong>electric</strong>ally operated rope drum hoist for<br />

operation of spillway stoplogs through a lifting beam of adequate capacity with all<br />

accessories including cross travel mechanism, gantry frame, gantry structure, counter<br />

weight, L T mechanism, operator’s cabin, gantry travel rails and rail fixing fixtures,<br />

operators cabin etc. complete in all respects.<br />

1.2.3.4 1 (one) no. of lifting beam of adequate capacity for Spillway Stoplogs with automatic<br />

engaging and disengaging device hooks, side guide shoes/rollers, link bars/ flats etc.,<br />

complete in all respects to operate the stoplog units.<br />

1.2.4. Diversion Tunnel Gate<br />

1.2.4.1 1(One) No. fixed wheel type vertical lift gate suitable for 1(one) opening of 6700 mm x<br />

6700 mm for Diversion Tunnel comprising of three units spliced together and operated by<br />

rope drum hoist of adequate capacity complete in all respects with skin plate, vertical<br />

stiffeners, horizontal girders, wheel assemblies, guide shoes, seals, lifting lugs, lifting<br />

arrangement etc. and other appurtenances for the purpose of plugging of diversion tunnel.<br />

1.2.4.2 1(One) set of rope drum hoists of adequate capacity mounted on steel trestles for<br />

operation of Diversion Tunnel gate mentioned under para 1.2.4.1 above consisting of<br />

wire ropes, drums, end reduction units, central drive units including worm reducers, DC E.<br />

M. brakes, <strong>electric</strong> motors, gate position indicators, arrangements for manual drive,<br />

suitable cover for the hoist equipment etc. complete in all respects.<br />

1.2.4.3 1 (One) set of hoist supporting structure of adequate capacity for supporting the rope<br />

drum hoist for Diversion Tunnel Gate as defined at 1.2.4.2 including removable<br />

guides, trestle, base plates, anchors etc. complete in all respects.<br />

1.2.5 Intake Trash Rack<br />

1.2.5.1 1 (One) set of Trash Rack suitable for 1(one) opening of 6806 mm x 6850 mm for Power<br />

Intake consists of two panels. Trash Racks will comprise of trash bars, horizontal girders,<br />

end girders / framing channels and lifting lugs etc. and other appurtenances.<br />

1.2.5.2 1 (one) set of embedded parts for Intake Trash Rack for 1(one) opening of Power Intake<br />

including framing channels, sill beam, and anchorages. 1 st stage anchor bolts and 2 nd stage<br />

embedded parts etc. complete in all respects.<br />

1.2.5.3 1 (one) No. of Trash Rack Cleaning machine for removing trashes collected on the trash<br />

rack panels mentioned under para 1.2.5.1 above. An auxiliary hoist shall also be provided<br />

on Trash Rack Cleaning Machine for raising and lowering of Trash Rack Panels during<br />

maintenance etc. complete in all respects.<br />

1.2.5.4 1 (one) no. of lifting beam of adequate capacity for handling of Trash Racks under<br />

water with automatic engaging and disengaging device hooks, side guide shoes/rollers,<br />

link bars/ flats etc., complete in all respects to operate the stoplog units.

1.2.6 Power Intake Service Gate<br />

1.2.6.1 1(One) No. fixed wheel type vertical lift Service Gate suitable for 1(one) opening of<br />

4100 mm x 4100 mm for Power Intake comprising of two units spliced together and<br />

operated by rope drum hoist of adequate capacity complete in all respects with skin plate,<br />

vertical stiffeners, horizontal girders, end vertical girder, seal assemblies, wheel<br />

assemblies, guide shoes, seals, lifting lugs etc. and other appurtenances.<br />

1.2.6.2 1(One) set of embedded parts for Power Intake Service Gate for 1(one) opening of<br />

Power Intake including stainless steel tracks, seal seats, sill beam, guides, bases and<br />

anchorages including latching / dogging arrangement, 1 st stage anchor bolts and 2 nd stage<br />

embedded parts etc. complete in all respects.<br />

1.2.6.3 1(One) set of rope drum hoists of adequate capacity mounted on steel trestles for<br />

operation of Power Intake Service Gate mentioned under para 1.2.6.1 above consisting<br />

of wire ropes, drums, end reduction units, central drive units including worm reducers, DC<br />

E. M. brakes, motors, gate position indicators, arrangements for manual drive, suitable<br />

cover for the hoist equipment etc. complete in all respects.<br />

1.2.7 Power Intake Emergency Gate<br />

1.2.7.1 1 (one) No. fixed wheel type vertical lift Emergency Gate suitable for 1(one) opening of<br />

4100 mm x 4100 mm for Power Intake comprising of two units spliced together and<br />

operated by rope drum hoist of adequate capacity complete in all respects with skin plate,<br />

vertical stiffeners, horizontal girders, end vertical girder, seal assemblies, wheel<br />

assemblies, guide shoes, seals, lifting lugs etc. and other appurtenances.<br />

1.2.7.2 1(One) set of embedded parts for Power Intake Emergency Gate for 1(one) opening of<br />

Power Intake including stainless steel tracks, seal seats, sill beam, guides, bases and<br />

anchorages including latching / dogging arrangement, 1 st stage anchor bolts and 2 nd stage<br />

embedded parts etc. complete in all respects.<br />

1.2.7.3 1(One) set of rope drum hoists of adequate capacity mounted on steel trestles for<br />

operation of Power Intake Emergency Gate mentioned under para 1.2.7.1 above<br />

consisting of wire ropes, drums, end reduction units, central drive units including worm<br />

reducers, DC E. M. brakes, motors, gate position indicators, arrangements for manual<br />

drive, suitable cover for the hoist equipment etc. complete in all respects.<br />

1.2.7.4 1 (One) set of hoist supporting structure of adequate capacity for supporting the rope<br />

drum hoist for Power Intake Service Gate as defined at 1.2.6.3 and Power Intake<br />

Emergency Gate as defined at 1.2.7.3 including removable guides, trestle, base plates,<br />

anchors etc. complete in all respects.<br />

1.2.8 Draft Tube Gates<br />

1.2.8.1 2 (Two) sets of Draft Tube Gates suitable for 2(two) openings of 4762 mm x 2480 mm<br />

for Draft Tube of the power house complete in all respects with skin plate, seal assemblies,<br />

guide shoes, stiffeners, end vertical girders, horizontal girders, slide blocks, collapsible<br />

spring loaded guides, lifting arrangements, latch arrangements, filling valves, lifting lugs<br />

etc. and other appurtenances.

1.2.8.2 2 (Two) sets of embedded parts for 2(two) openings of Draft Tubes including stainless<br />

steel tracks, seals, sill beams, guides, 1 st stage anchor bolts and 2 nd stage embedded parts<br />

etc. complete in all respects.<br />

1.2.8.3 2 (Two) sets of rope drum hoists of adequate capacity mounted on steel trestles for<br />

operation of Draft Tube Gates mentioned under para 1.2.8.1 above consisting of wire<br />

ropes, drums, end reduction units, central drive units including worm reducers, DC E. M.<br />

brakes, motors, gate position indicators, arrangements for manual drive, suitable cover for<br />

the hoist equipment etc. complete in all respects.<br />

1.2.8.4 2 (Two) sets of hoist supporting structures of adequate capacity for supporting the rope<br />

drum hoists for Draft Tube Gates as defined at 1.2.8.3 including removable guides,<br />

trestle, base plates, anchors etc. complete in all respects<br />

1.2.9 Miscellaneous Systems and Equipment<br />

1.2.9.1 Reservoir Control, Instruments and Remote Control<br />

i) One complete set of remote controls for automatic reservoir level control system.<br />

ii)<br />

iii)<br />

Two sets of water level measuring instruments.<br />

Four sets of gate position measuring equipment<br />

The remote control system which is microprocessor control based shall consist of one<br />

operator station located at the top of dam and shall be supplemented by indication status<br />

stations at powerhouse control room.<br />

The main items of control and equipment shall comprise the following:<br />

a) Control and operation of Spillway radial gates.<br />

b) Gate position indication of Spillway radial gates, Intake service gate, Intake<br />

emergency gate and Draft tube gates.<br />

c) Two sets of water level indication and monitoring along with necessary alarms<br />

provided near spillway.<br />

d) Monitoring and indication of discharge measurements for discharge through spillway<br />

radial gates.<br />

e) System for ascertaining balancing of intake gate and draft tube gate.<br />

f) Inter-lock for preventing accidental opening of intake gate when draft tube gates are<br />

lowered.<br />

All the necessary transducers and instrumentation, terminals, contacts, cabling etc. for<br />

above at various locations shall be provided and incorporated in the remote control<br />

system.<br />

Operator’s station shall include operator’s consoles, which comprise colour C.R.T.<br />

(minimum 35 cm) screen with push buttons for operation and mimic panel, which indicate<br />

the gate movement. The operator shall be able to view the gate position or any gate status<br />

with the help of graphic display in the C.R.T screen.<br />

The system shall also have a printer (minimum 30 cps) for printing various logs,<br />

instructions and reports. Interlocking shall be provided between the operator’s station at<br />

dam top and the local control panels provided for individual gate operation. System design<br />

should be such that the operation can be done from local control panels, only with the<br />

permission of operator of station.

All the input display from field including water level of reservoir shall be displayed at<br />

both the C.R.T. screens. The system should continuously monitor the reservoir level and<br />

depending upon its level, it shall be able to calculate the input discharge into reservoir. In<br />

addition to this, the gate openings of spillway gates should be displayed in the form of<br />

graphic displays. The system shall be able to display the output discharge through spillway<br />

radial gates so that the operation of spillway gates can be carried out in auto mode.<br />

The system shall include various instructions like water level transmitters, sensors for<br />

opening indication of spillway gates, intake gate and height (opening) measurements.<br />

One uninterrupted power supply to provide back-up (minimum 30 minutes) to the system<br />

in case of failure of main power supply to equipment shall also be provided.<br />

1.2.9.2 Diesel Generating Set<br />

A 3 phase synchronous type diesel generating set of 250 KVA, 415 Volts, 50 Hz is<br />

envisaged for the emergency operations of the <strong>hydro</strong>-mechanical equipment at the dam<br />

site. The diesel generating set shall be located in the dam area to provide back-up supply<br />

to gate operating equipment and to the computerized control system in case of power<br />

failure.<br />

1.3.0 Conditions of Particular Application<br />

1.3.1 General<br />

(a) Dry as well as wet tests are to be carried out for all the gates and stoplogs by the supplier<br />

free of cost and rectification of defects noticed during tests or during the guarantee period<br />

(not less than 12 months after commissioning and handing over) are within the scope<br />

of supply.<br />

(b) Shop as well as field painting is included in the scope of supply.<br />

(c) 1 st and 2 nd stage concreting shall be done under supervision of gate contractor. The<br />

responsibility of correctness and accuracy of alignments would rest with the Contractor. It<br />

has to be ensured that appropriate erection tolerances are maintained and gate and<br />

embedment match perfectly.<br />

Ladders and rungs on concrete face for approaching the trunnion piers, the cat walkways<br />

on the downstream of the pier for approaching the trunnions for maintenance is in the<br />

scope of supply.<br />

The design, fabrication, supply and erection of 1 st stage embedded parts and 2 nd stage<br />

embedded parts are included in this scope of works. The contractor when ordered in<br />

writing by the Engineer-in-Charge shall perform extra work in furnishing the items not<br />

covered in the specifications or included in the schedule but forming an inseparable part of<br />

the work contracted for. Extra work and materials will ordinarily be paid for at a lump<br />

sum or unit price agreed upon by the contractor and the Engineer-in-Charge, as stated in<br />

the orders; whenever, in the judgement of the Purchaser, it is impracticable because of<br />

nature of the work or for any other reason whatsoever, to fix the price in the order, the<br />

payment of extra works and materials shall be made on the basis of actual cost as<br />

determined by the Engineer-in-Charge plus 10% allowance for superintendence, use of<br />

tools, tackles and shop etc.

Note:<br />

6<br />

Before undertaking manufacture, exact site dimensions should be verified by the<br />

Contractor and the equipment should match with site details. Engineer-in-Charge will not<br />

be responsible for any variation whatever in the site dimensions and it will be the<br />

responsibility of Contractor for matching site dimensions at no extra cost.<br />

1.3.2 Inspection and Quality Assurance Plan<br />

All supplies shall be subject to inspection and test by the Engineer-in-Charge to the extent<br />

practicable at all times and places. Shop tests shall also be subject to inspection and test by<br />

the Purchaser and the Purchaser shall depute Engineers for witnessing shop tests and<br />

training in works and designs as detailed in Section 6 of these specifications. Inspection<br />

shall be carried out in accordance with relevant Indian standards or equivalent<br />

International standards where Indian standards are not available or as described elsewhere<br />

in these specifications. The cost of carrying out the test / inspection and training shall<br />

be borne by the contractor and included in the price schedule for inspection and<br />

testing.<br />

Quality Assurance system and detailed Quality Assurance plans for the manufacture<br />

and supply of all the major components and equipment submitted by the contractor shall<br />

be finalized before the award of contract.<br />

1.3.3 Wastage of Steel<br />

1.3.4 Schedule<br />

The payment will be made only for the net weight of gates based on the sectional unit<br />

weight as per table of standard sections (supplied by SAIL) and used in the gates and<br />

hoists. The weight of nuts, bolts, rivets, welding etc., will not be considered in the net<br />

weight of gates. All the wastage of steel section supplied by the main producer will be<br />

on the contractor’s account and the contractor should consider this aspect while quoting<br />

the rates.<br />

Within 45 (Forty Five) calendar days after the date of commencement, the contractor<br />

shall submit to the Engineer-in-Charge for his approval the schedule of designs, drawings,<br />

fabrication and transportation of the equipment so as to ensure its delivery within the<br />

specified period. The schedule shall clearly state all the stages of fabrication to enable the<br />

Engineer-in-Charge to plan his inspection accordingly as stated in these specifications.<br />

The time and the date of completion of works as stipulated in the tender document shall<br />

be deemed to be the essence of the contract. However, certain alterations can be<br />

suggested by the bidder keeping in view the programme of erection, front availability and<br />

the completion date The contractor shall submit along with his bid a detailed<br />

programme based on the dates indicated in the tender document or alternatively his own<br />

time schedule giving shorter delivery / erection period taking into consideration the gate<br />

by which the erection front can be made available to him. The schedule shall be within the<br />

time frame agreed above consisting of adequate number of activities covering various key<br />

phases of the work such as designs, drawings, procurement, manufacturing, shop assembly<br />

(equipment wise), sand blasting and painting, shipment, field erection and testing<br />

activities. This network shall also indicate the interface facilities to be provided by the<br />

Engineer-in-Charge if any and the dates by which such facilities are needed. It shall

7<br />

Also indicate the details of resources like manpower/machinery envisaged in the part and<br />

to be mobilized by the contractor for all stages of erection.<br />

The contractor shall so organize his resources and perform his work as to complete it not<br />

later than the date agreed to by him. The time for completion of the works contracted for,<br />

shall be reckoned from the date of issue of commencement. During the performance of the<br />

contract, if in the opinion of the Engineer-in-Charge, proper progress is not maintained<br />

suitable changes shall be made in the contractor’s operation to ensure proper progress.<br />

1.3.5 Delivery Period<br />

Time of delivery at the <strong>project</strong> site is the essence of the contract and the contractor shall<br />

abide by milestone, the time being reckoned from the commencement. Separate schedule<br />

shall be submitted for each gates and hoisting equipment.<br />

1.3.6 Responsibilities of Contractor<br />

The contractor shall be responsible for:<br />

a. The quality of materials and workmanship in all the items of work.<br />

b. Strict adherence to the dimensions of parts shown on approved drawings unless deviations<br />

are specifically authorized in writing by the Engineer-in-Charge or Engineer-in-Charge.<br />

c. Strength of all parts of gates and hoists when operated under the worst conditions of load<br />

and under conditions of closure during periods of maximum flow/ discharge as applicable.<br />

d. It is Contractor’s responsibility to ensure that all components supplied in accordance with<br />

these specifications shall fit correctly to each other. In the event of any field modifications<br />

being required due to errors in shop fabrication, Contractor shall bear the full cost of such<br />

modifications. Any such changes shall be shown on the drawings and accepted in writing<br />

by Engineer-in-Charge, before being made by Contractor.<br />

e. Satisfactory performance of the entire work under all operating conditions without signs of<br />

undue strain and without damage, breakdown or deterioration of any of the parts due to<br />

faulty or incorrect or unsuitable material, workmanship or design.<br />

f. Freedom from vibrations of any part or parts under the most severe operating conditions<br />

beyond permissible limits.<br />

g. The water tightness of the gate seals, oil and water tightness of hoist cylinders, oil tanks,<br />

all pipes and joints, valves, bearings, stuffing boxes, pumps and controls.<br />

h. The strength, accuracy and adequacy of all parts of gates, hoists, hoist support structures<br />

and cranes etc. in all respects.<br />

i. The contract documents and specifications do not specify in complete details the various<br />

components of the equipment and only indicate a basic arrangement for the gates, hoists,<br />

cranes, and stoplogs etc. It is the contractor’s responsibility to perform the complete<br />

design of all the equipment, structure and fabrication within the parameters laid down in

8<br />

the specifications. The contractor shall supply and erect all equipment in a complete shape,<br />

which will meet the requirements regarding performance, durability and satisfactory<br />

operation.<br />

j. The principal parts of all the equipment are mentioned in these specifications which<br />

outline the general features to be adopted in design. Any deviations from the specified<br />

requirements shall be done only with the approval of the Engineer-in-Charge<br />

k. The contractor shall visit and carefully examine the site of the work and the adjacent<br />

premises and shall conduct necessary investigations to acquaint himself thoroughly with<br />

the facilities for handling the specified equipment at the site. A thorough investigation<br />

shall be made of potential interferences and difficulties that may be encountered in the<br />

proper and complete execution of the work specified. No plea of ignorance of existing or<br />

foreseeable conditions, that create difficulties or encumbrances in the execution of the<br />

work, will be accepted as an excuse for any failure on the part of the contractor to fulfill in<br />

every detail the requirements of the Contract Document. Furthermore, a plea of ignorance<br />

will not be accepted as a basis for any claim whatsoever.<br />

1.4.0 General Requirement<br />

The contractor shall carefully study the Technical Specifications and Specification<br />

Drawings and shall intimate the Engineer-in-Charge if any error / omission is discovered.<br />

As a result of such interaction, if some corrections / modifications are required, the same<br />

shall be brought to the notice of all the contractors by the Engineer-in-Charge before the<br />

date of submission of the tender.<br />

1.5,0 Atmospheric Conditions<br />

The equipment called for under these specifications shall be suitable for continuous outdoor<br />

operations in the climate at the site of Nyabarongo Hydro-<strong>electric</strong> Project, Rwanda, Africa with<br />

temperature variation from minimum to maximum and humidity etc. as specified in other chapters<br />

of this document.<br />

1.6.0 Warranty<br />

The contractor shall furnish warranty of the equipment for a minimum period of one<br />

year from the date of the final acceptance of equipment or commissioning or handing over<br />

to <strong>project</strong> authority whichever is later. The contractor shall guarantee among other things<br />

the following items.<br />

a) Quality and strength of the materials used.<br />

b) Satisfactory operation of the equipment.<br />

c) Safe stresses in all parts under all conditions of operations.<br />

d) Protection of equipment against vibration and corrosion.<br />

The Contractor shall at his own expenses, correct the defects, furnish and install new parts<br />

and materials approved by the Engineer-in-Charge in all the equipment covered under<br />

para 1.2.2. to 1.2.9 within 12 months from the date of final acceptance of equipment or<br />

commissioning or handing over to <strong>project</strong> authority whichever is later. The contractor

shall assume all responsibility for direct damages causing personal injury or property<br />

damage due to any manufacturing defects resulting in the failure of the equipment being<br />

supplied under these specifications.<br />

Final acceptance of work takes place only after completion of the tests and commissioning<br />

described elsewhere in these Specifications.<br />

9

SECTION – 2<br />

10<br />

STANDARDS AND MATERIALS<br />

2.1.0 Standards and Codes<br />

(a) General<br />

Works, design, testing, workmanship, material and supplies shall conform to the relevant<br />

Indian Standards. Wherever the Indian Standards are not existent or silent authoritative<br />

Standards and Codes like IEC or ISO Recommendations other than Indian Standards or<br />

those specified in the Bidding Documents, which ensure an equal or higher quality, may<br />

also be acceptable.<br />

All standards and codes referred to shall be the latest current issues irrespective of the year<br />

mentioned.<br />

When IEC or ISO Recommendations or other Standards are referred to, the edition shall<br />

be that current at the time of submittal of design.<br />

The contractor shall supply three copies in English and one in original language of any<br />

national standards which are approved for use under the contract.<br />

(b) Indian Standards and Codes<br />

Throughout the duration of the contract, the materials, equipment, services, design and<br />

workmanship shall conform to the applicable Indian Codes and Standards only if not<br />

otherwise specified.<br />

It is the Contractor’s duty to acquaint himself with all Indian Codes and Standards related<br />

to the works and he shall procure and keep at his works at the site a copy of each of such<br />

applicable documents.<br />

(c) International Standards and Codes<br />

The International Standards / Codes may be adopted provided that:<br />

- The Standards /codes proposed are at least as stringent as the equivalent Indian Standards<br />

relevant to the works or higher quality compared to those specified, and approved or if<br />

there is no applicable Indian Standards / codes for the specific item concerned,<br />

furthermore, that the Contractor submits for approval copies of the standards which he<br />

proposes to use.<br />

2.2.0 Standards for General Application<br />

2.2.1 General<br />

Standard publications issued by the following organizations of standardization are<br />

considered being approved standards for the works with a priority to use Indian Standards.<br />

BIS:<br />

ASTM:<br />

ASME:<br />

Bureau of Indian Standards<br />

American Society for Testing & material<br />

American Society of Mechanical Engineers

DIN:<br />

BSI:<br />

IEC:<br />

ISO:<br />

JIS:<br />

Deutsche Industrie Norm<br />

British Standard Institution<br />

International Electromechanical Commission<br />

The International Standard Organization<br />

Japanese Industrial Standard<br />

11<br />

- The Contractor shall state, prior to starting the works, the International Standard / code he<br />

proposes to apply, giving full identification of each of them. These proposals are subject to<br />

the approval by the Engineer-in-Charge.<br />

2.2.2 Standards for Design & Testing<br />

The following publications of Indian Standard Specifications (latest editions) shall<br />

be followed for the basic designation only, form a part of these specifications.<br />

Latest editions of these standards shall be referred.<br />

• IS 4622 - Recommendation of structural design of fixed wheel gates<br />

• IS 4623 - Recommendation for structural design of radial gates<br />

• IS 5620 - Recommendations for structural design criteria for low head slide<br />

Gates<br />

• IS 9349 - Recommendations for structural design of medium and high head<br />

slide Gates<br />

• IS 7718 - Recommendation for inspection, testing & maintenance of fixed wheel<br />

& slide gates (Part I – III)<br />

• IS 10096 - Recommendation for inspection, testing & maintenance of radial gates<br />

& their hoists (Part I – III)<br />

• IS 780 - Sluice Valves & Gate Valves<br />

• IS 800 - Code of practice for use of structural steel in general building<br />

construction<br />

• IS 456 - Code of practice for plain & reinforced concrete<br />

• IS 875 - Code of practice for structural safety of buildings: Loading Std.<br />

• IS 11855 - General requirements for rubber seals for hydraulic gates<br />

• IS 13591 - Criteria for design of lifting beams<br />

• IS 11388 - Recommendations for Design of Trash Racks for Intakes<br />

• IS 3938 - Electric wire rope hoist<br />

• IS 6938 - Code of practice for design of rope drum and chain hoists for<br />

hydraulic gates<br />

• IS 3177 - Code of practice for <strong>electric</strong> overhead Traveling cranes other than<br />

steel works cranes<br />

• IS 807 - Code of practice for design manufacture erection & testing of<br />

cranes & hoists<br />

• IS 1893 - Criteria for Earthquake resistant design of structures<br />

• IS 2266 - Specifications for steel wire ropes for general Engineering purposes<br />

• IS 10210 - Criteria for design of hydraulic hoists for gates<br />

• IS 13041 - Recommendation for inspection, testing and maintenance of<br />

Hydraulic Hoists<br />

• IS 2062 - Structural Steel (Fusion Welding Quality)<br />

• IS 305 - Specifications for aluminium bronze ingots and castings

12<br />

• IS 1030 - Specifications for carbon steel castings for general Engineering<br />

purposes<br />

• IS 2004 - Specifications for carbon steel forgings for general Engineering<br />

purposes<br />

• IS 1875 - Specifications for carbon steel billets, blooms, slabs and bars for<br />

forgings<br />

• IS 1570 (Part – II) Schedule for wrought steel (stainless and heat resisting<br />

steels)<br />

• IS 1570 (Part – 5) Schedule for wrought steel, carbon steel (unalloyed steel)<br />

• IS 325 - Specification for three phase induction motors<br />

• IS <strong>28</strong>25 - Code of unfired pressure vessels<br />

• IS 1367 (Part – II) - Technical supply conditions for threaded steel fasteners<br />

(Stainless steel threaded fasteners)<br />

• IS 1365 - Specifications for slotted countersunk head screws<br />

• IS 1363 - Hexagonal head bolts, screws and nuts<br />

• IS 2485 - Specification for drop forged sockets for wire ropes foe general<br />

Engineer-in-Chargeing purposes<br />

• IS 816 - Code of practice for use of metal arc welding for general construction<br />

in mild steel<br />

• IS 817 - Code of practice for training and testing of metal arc welders<br />

• IS 2595 - Code of practice for radiographic testing<br />

• IS 3664 - Code of practice for ultrasonic tube echo testing by contact and<br />

immersion methods<br />

• IS 7307 - Approval test for welding procedures (Part – I)<br />

• IS 7310 - Approval testing of welders working to approved welding procedures<br />

(Part – I)<br />

• IS 7318 - Approval tests for welders when welding procedures approval is not<br />

required<br />

• IS 3658 - Code of practice for liquid penetrate flow detector<br />

• IS 3703 - Code of practice for magnetic flow detectors<br />

• IS 4460 - Method of rating machine cut spur and helical gears<br />

• IS 2403 - Specification for transmission steel roller chains and chain wheels<br />

• IS14177 - Guidelines for painting system for Hydraulic Gates and Hoists<br />

• IS 1477 - Code of practice for painting of ferrous metals in buildings<br />

In case of any conflict between these specifications with the above standards or codes,<br />

these specifications and drawings being part of Bidding Documents shall govern, unless<br />

otherwise directed by the Engineer-in-Charge in each particular case.<br />

Where reference is made in the Bidding Documents to the Standards / codes of a country<br />

of origin for the supply item, it shall be a recognized national Standard / code of that<br />

country where the specific supply item is manufactured and such Standards /<br />

Codes must comply in all respects with the quality requirements of above mentioned<br />

Indian Standards / codes and to be acceptable under these Specifications and must be<br />

approved by the Engineer-in-Charge.

13<br />

2.2.3 System of Units<br />

The metric system of units has been used throughout these specifications and this system<br />

of units shall be used consequently throughout the duration of contract for all technical or<br />

contractual purposes.<br />

2.3.0 Material Standard<br />

2.3.1 General<br />

i) All material used for the fabrication of the equipment shall conform to latest applicable<br />

relevant Indian Standard or equivalent International Standard as DIN, ASTM or BS unless<br />

otherwise specified.<br />

ii)<br />

iii)<br />

All the materials shall be of tested quality, new, unused, free from defects and of the grade<br />

/ classification envisaged in the designs. The contractor shall furnish the test certificate for<br />

each lot of materials, if so required by the Engineer-in-Charge. Plates with laminations<br />

discovered during welding or during inspection shall be rejected. Materials not supplied<br />

according to the approved designs / drawings shall be rejected, removed and replaced.<br />

Approval of Engineer-in-Charge shall not relieve the contractor from the responsibility of<br />

supply of suitable materials.<br />

The Contractor shall furnish a list of names of contractor(s) of the bought out complete<br />

equipment, which are contemplated for incorporation in the work, together with<br />

performance characteristics and other pertinent information pertaining to the equipment,<br />

for the approval of the Engineer-in-Charge, samples of materials, if desired and so<br />

directed, shall be submitted for approval any equipment, materials and articles used or<br />

installed without the prior approval of the Engineer-in-Charge shall at the risk and cost of<br />

the Contractor.<br />

iv) If for any reason the Contractor desires to deviate from these standards, he shall submit a<br />

statement stating the exact nature of the deviations or substitution along with complete and<br />

detailed specification and test reports for the materials, which are proposed to be used. In<br />

all such cases the prior approval of the Engineer-in-Charges has to be obtained before the<br />

fabrications work is taken in hands. All the materials, supplies and articles not<br />