BEN-V CREEL - KARL MAYER Textilmaschinenfabrik GmbH

BEN-V CREEL - KARL MAYER Textilmaschinenfabrik GmbH

BEN-V CREEL - KARL MAYER Textilmaschinenfabrik GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

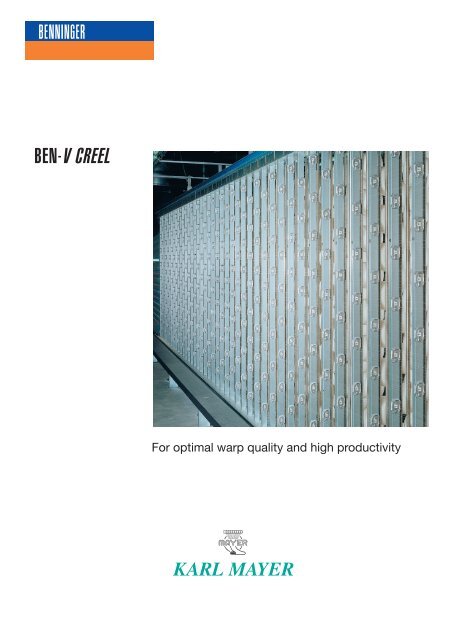

<strong>BEN</strong>-V <strong>CREEL</strong><br />

For optimal warp quality and high productivity

Constant thread tension, over the entire length and width<br />

of the warp<br />

Your benefits<br />

Highest quality<br />

• Little stress on the threads<br />

• Low thread tension<br />

• Uniform thread tension, from back<br />

to front<br />

• No snarling<br />

High productivity<br />

• Speeds in practice of up to<br />

1200 m/min<br />

• Free yarn route<br />

• No knotting when changing<br />

package or lot<br />

• Reduced cleaning and<br />

maintenance outlay<br />

• Simple package loading<br />

• Automatic rotation of package<br />

frames<br />

• Simple placing of the threads in<br />

the stop tensioner<br />

Universal application<br />

• Coarse to the finest staple fibre<br />

yarns<br />

• Single and doubled yarns<br />

• Optional package formats usable<br />

First-rate warp quality<br />

The basis of the outstanding warp quality<br />

is a low and uniform thread tensile force<br />

and the free yarn route. The low tension<br />

level results in a gentle yarn draw-off and<br />

minimal end break frequency, positively<br />

influencing the subsequent sizing and<br />

weaving operations.<br />

Wide field of application<br />

Because lot changing involves no knotting,<br />

but just redrawing-in, there are no prob -<br />

lems, even when changing from single to<br />

doubled or from extremely coarse to very<br />

fine yarns. Also, differing yarn counts<br />

between lots are no longer a problem, be -<br />

cause the OPTOSTOP thread tensioners<br />

are automatically activated.<br />

Low tension level<br />

Due to the absence of guiding elements<br />

and deflection points, the thread tensile<br />

force level is very low, even at speeds of<br />

up to 1200 m/min.<br />

The offset package arrangement permits<br />

optimal space utilisation. The resulting<br />

shorter creel length reduces air resistance<br />

and hence, thread tension.<br />

High productivity<br />

The low level of tension is the most im -<br />

portant requirement for high production<br />

speeds. Accordingly with V-<strong>CREEL</strong>,<br />

speeds in practice of 1200 m/min are by<br />

no means uncommon. Moreover, the free<br />

yarn route reduces down times with end<br />

breaks and lot changing, as placing<br />

threads in guiding elements is a thing of<br />

the past.<br />

2

Simple and practical package loading<br />

1 2<br />

3<br />

Simple and practical package loading<br />

As the threads are neither broken or knotted<br />

on lot changing, it is simply a matter of<br />

placing the packages on a spindle with<br />

retaining disks.<br />

No snarling<br />

An automatic pretensioner prevents snarling<br />

which can occur on stopping the<br />

machine. The pretensioner automatically<br />

takes up the correct position depending on<br />

the phase in the warping process.<br />

1. Extreme position on starting for the<br />

correction of snarls<br />

2. Working position for optimal thread<br />

tension<br />

3. Full opening on stop, for optimal<br />

package access<br />

Equalized thread tension<br />

The pretensioners installed by <strong>BEN</strong>NINGER<br />

automatically compensate the thread<br />

tension differences occurring due to the<br />

variation in thread length from the rearmost<br />

to the foremost package, permitting a uniform<br />

thread tension and winding over the<br />

entire warp width.<br />

The automatic pretensioner is set so that a<br />

corresponding wrap compensates the difference<br />

in tension between the front and<br />

rear threads.<br />

Efficient balloon limiting<br />

Due to their structure, rotor yarns have<br />

special balloon dynamics. Ballooning is<br />

three times greater with rotor yarns than<br />

with ring spun yarns and has its maximum<br />

elongation in the spaces between package<br />

and tensioner.<br />

Two round metal rods with a smooth and<br />

friction-resistant surface achieve effective<br />

balloon reduction.<br />

Cut-off device<br />

A cut-off device is provided for separating<br />

the thread for lot changing.<br />

The effortless running of the cutter bar with<br />

rotating blades along the creel severs the<br />

thread in a single action.<br />

3

OPTOSTOP<br />

Thread tensioner for warping creels with high productivity and<br />

low thread tension<br />

A universal stop tensioner<br />

OPTOSTOP has been specially developed<br />

for the direct beaming of staple fibre yarns<br />

at high speed and an application range from<br />

5 to 170 tex. The shape and the large jaw<br />

area treat the yarn surface gently and avoid<br />

twist push-back with resulting snarling.<br />

Your benefits<br />

Highest quality<br />

• No loose ends shooting forwards<br />

when stopping<br />

• No snarling caused by twist<br />

pushback<br />

• Stop motions are self-activated by<br />

pushbutton<br />

• Warning display after repeated<br />

breaks on the same end<br />

• Continuous display of number of<br />

running ends<br />

• No threads lost at end break<br />

High productivity<br />

• Wide application range<br />

• Low thread tensions for high<br />

speeds<br />

• End breaks are rapidly located<br />

Safe stopping with no loose ends<br />

No loose ends occur at high speed, even<br />

with coarse yarns and long distances,<br />

because the jaws close immediately when<br />

the machine is stopped.<br />

High speeds with low thread tensile<br />

force<br />

The jaws of the thread tensioner open<br />

automatically shortly after the start of the<br />

beamer. Thread tensile force from the<br />

package is the sole determining factor for<br />

a steady and dependable thread run. This<br />

ensures that the tensile load on the<br />

threads is low, even at high beaming<br />

speeds.<br />

Back beams with no missing ends<br />

The optoelectronic stop motion integrated<br />

in the OPTOSTOP tensioner monitors the<br />

thread run right from crawl speed. It<br />

detects an end break at once, whether this<br />

occurs on the package or at the comb of<br />

the beamer. In the event of a thread stoppage,<br />

it responds in milliseconds, so that<br />

no ends are lost.<br />

4

Thread monitoring made easy<br />

Signalling on the display permits the monitoring<br />

of all running threads. Agreement<br />

between beamer and creel is checked<br />

before start enabling. Time-consuming<br />

manual counting of threads is dispensed<br />

with. Also a thing of the past is the manual<br />

switching on and off of tensioner positions<br />

with yarn count changes.<br />

Integrated individual blow-off<br />

An intermitten individual tensioner blow-off<br />

assures a sure and clean tensioner function,<br />

even with dust-sheeding yarns.<br />

Each tensioner contains fine air jets which<br />

keep the tensioner z one clean durin<br />

beaming by intermitten pulses of air.<br />

The air supply ist automatically controlled<br />

and takes place cycically for two tensioner<br />

posts simultaneously, to keep air consumption<br />

to a minimum.<br />

Support with end break repair<br />

Signal lamps on the front of the creel and<br />

on the relevant tensioner post indicate the<br />

broken end. Flashing lamps signal re -<br />

peated end breaks from the same<br />

package, so that bad packages can be<br />

identified and replaced where necessary.<br />

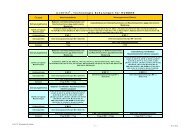

<strong>BEN</strong>-V <strong>CREEL</strong> pitch program with number of running threads<br />

horiz. vertical max. number running threads<br />

pitch pitch packages ∅ of tiers<br />

240 230 9 504 576 648 720 792 864 936 1008 1080 1152 1224 1296<br />

270 255 8 448 512 576 640 704 768 832 896 960 1024 1088 1152<br />

240 305 265 7 392 448 504 560 616 672 728 784 840 896 952 1008<br />

350 278 6 384 432 480 528 576 624 672 720 768 816 864<br />

435 305 5 320 360 400 440 480 520 560 600 640 680 720<br />

horiz. vertical max. number running threads<br />

pitch pitch packages ∅ of tiers<br />

240 230 9 378 432 486 540 594 648 702 756 810 864 918 972<br />

270 260 8 336 384 432 480 528 576 624 672 720 768 816 864<br />

320 305 295 7 336 378 420 462 504 546 588 630 672 714 756<br />

350 340 6 324 360 396 432 468 504 540 576 612 648<br />

435 365 5 300 330 360 390 420 450 480 510 540<br />

5

Integrated system solutions for better process safety.<br />

• Direct<br />

beaming<br />

• Sectional<br />

warping<br />

• Sizing<br />

• Indigo-dyeing<br />

The excellent process know-how<br />

of our employees and the quality of our<br />

products and services are the guarantee<br />

for reliable processes and low life cycle<br />

costs.<br />

Modular system concepts<br />

ensure a high level of flexibility and<br />

competitive strength.<br />

<strong>BEN</strong>-SERVICE, the customer service<br />

which ensures highest availability of the<br />

plants, excellent yield and finest quality,<br />

even after years.<br />

The data and illustrations in the document correspond<br />

to the technical level at the time of printing and do not constitute<br />

a part of any offer. The right to make alterations is reserved.<br />

<strong>KARL</strong> <strong>MAYER</strong> <strong>Textilmaschinenfabrik</strong> <strong>GmbH</strong><br />

Brühlstrasse 25<br />

63179 Obertshausen / Germany<br />

Phone +49 6104 4020<br />

Fax +49 6104 402 600<br />

E-Mail: info@karlmayer.de<br />

www.karlmayer.de<br />

<strong>KARL</strong> <strong>MAYER</strong> Textilmaschinen AG<br />

Fabrikstrasse<br />

CH-9240 Uzwil / Switzerland<br />

Tel. +41 71 955 84 00<br />

Fax +41 71 955 84 87<br />

E-Mail: info@karlmayer.ch<br />

www.karlmayer.ch<br />

© Copyright Benninger AG, 676-d DF Ben-V Gatter_03.07/en/We-A 1027