'O' Ring Guide

'O' Ring Guide

'O' Ring Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Materials & properties<br />

FEP encapsulated ‘O’ rings<br />

These have a core of elastomer that is<br />

completely covered with a seamless<br />

sheath of fluorinated ethylene propylene<br />

(FEP). The core is normally fluorocarbon<br />

(FKM) or silicone (VMQ).<br />

Encapsulated ‘O’ rings are generally used<br />

when:<br />

l A standard elastomeric ‘O’ ring has<br />

inadequate chemical resistance for a<br />

specific application, and<br />

l A solid PTFE ‘O’ ring does not offer<br />

sufficient elasticity for reliable, long-term<br />

fluid sealing.<br />

They are used where high levels of<br />

chemical resistance or hygiene are<br />

needed — typically in petrochemical,<br />

chemical, food or pharmaceutical plant.<br />

Although FEP encapsulated ‘O’ rings are<br />

most suited to static duties, they may be<br />

used with slow short movements on rotary<br />

applications such as valve stem sealing.<br />

Their advantages are manifold, including:<br />

l Excellent chemical resistance to a wide<br />

range of media. Please contact our<br />

Technical Support Team for details.<br />

l Operational temperature ranges of:<br />

-60°C to +200°C with silicone core.<br />

-20°C to +200°C with fluorocarbon core.<br />

l Low friction and low ‘stick-slip’ effect.<br />

l Far greater elasticity than solid PTFE.<br />

Our FEP encapsulated ‘O’ rings are fully<br />

interchangeable with standard ‘O’ rings.<br />

However, due to the FEP sheath, they are<br />

less flexible than elastomeric rings and<br />

have limited stretch with higher permanent<br />

deformation. Auxiliary tools may be<br />

needed to facilitate efficient fitting.<br />

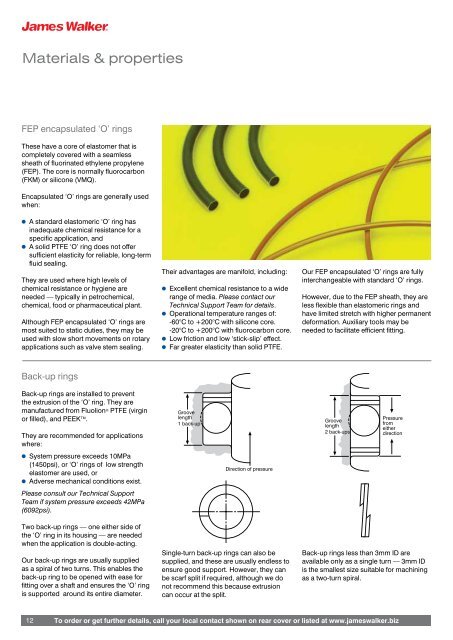

Back-up rings<br />

Back-up rings are installed to prevent<br />

the extrusion of the ‘O’ ring. They are<br />

manufactured from Fluolion ® PTFE (virgin<br />

or filled), and PEEK TM .<br />

They are recommended for applications<br />

where:<br />

Groove<br />

length<br />

1 back-up<br />

Groove<br />

length<br />

1 back-up<br />

Groove<br />

length<br />

1 back-up<br />

Groove<br />

length<br />

2 back-ups<br />

Groove Pressure<br />

length from<br />

2 back-ups either<br />

direction<br />

Groove<br />

length<br />

Groove<br />

Groove<br />

Pressure<br />

1 back-up<br />

length<br />

length<br />

from<br />

Direction of pressure Direction of pressure<br />

either<br />

2 back-ups 2 back-ups direction<br />

Pressure<br />

from<br />

either<br />

direction<br />

Pressure<br />

from<br />

either<br />

direction<br />

l System pressure exceeds 10MPa<br />

(1450psi), or ‘O’ rings of low strength<br />

elastomer are used, or<br />

l Adverse mechanical conditions exist.<br />

Direction of pressure Direction of pressure<br />

Please consult our Technical Support<br />

Team if system pressure exceeds 42MPa<br />

(6092psi).<br />

Two back-up rings — one either side of<br />

the ‘O’ ring in its housing — are needed<br />

when the application is double-acting.<br />

Our back-up rings are usually supplied<br />

as a spiral of two turns. This enables the<br />

back-up ring to be opened with ease for<br />

fitting over a shaft and ensures the ‘O’ ring<br />

is supported around its entire diameter.<br />

Single-turn back-up rings can also be<br />

supplied, and these are usually endless to<br />

ensure good support. However, they can<br />

be scarf split if required, although we do<br />

not recommend this because extrusion<br />

can occur at the split.<br />

Back-up rings less than 3mm ID are<br />

available only as a single turn — 3mm ID<br />

is the smallest size suitable for machining<br />

as a two-turn spiral.<br />

12<br />

To order or get further details, call your local contact shown on rear cover or listed at www.jameswalker.biz