'O' Ring Guide

'O' Ring Guide

'O' Ring Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Header Non-standard sizes<br />

Methods of production<br />

Using one of the following techniques, we<br />

are able to produce any size of ‘O’ ring<br />

you require.<br />

Precision moulded<br />

For this, our main method of production,<br />

we hold a growing inventory of over 8,000<br />

mould tools. We also have one of the<br />

largest presses of its type in Europe for<br />

moulding endless rings up to 2.2m (87<br />

inch) diameter.<br />

This press is used to produce highintegrity<br />

seals, including those for nuclear<br />

fuel transportation flasks. The nature of<br />

such an application demands stringent<br />

quality procedures. James Walker design<br />

technologists worked closely with our<br />

customer with this successful project.<br />

Extruded & mould joined<br />

This approach is particularly economical<br />

when a high degree of precision is<br />

unnecessary: for example, large diameter<br />

non-standard ‘O’ rings for static duties.<br />

The ring is made from extruded cord<br />

by vulcanising the ends together in a<br />

mould tool. <strong>Ring</strong>s must have a minimum<br />

section diameter of 3mm (0.12 inch)<br />

and a minimum ID of 200mm (7.9 inch).<br />

Maximum ID is unlimited.<br />

NOTE: This method must not be confused<br />

with rings joined by contact adhesive.<br />

Generally, the use of such adhesives<br />

results in a less secure join, with operating<br />

temperature limits below that of the cord<br />

material.<br />

Mould & mould-joined<br />

This method is used when the nonstandard<br />

‘O’ ring must have a diameter<br />

section to very close tolerances and a<br />

mould-join is acceptable.<br />

It is often applied to sizes above 2.2m<br />

diameter, when two or more smaller rings<br />

are manufactured, then cut and mouldjoined.<br />

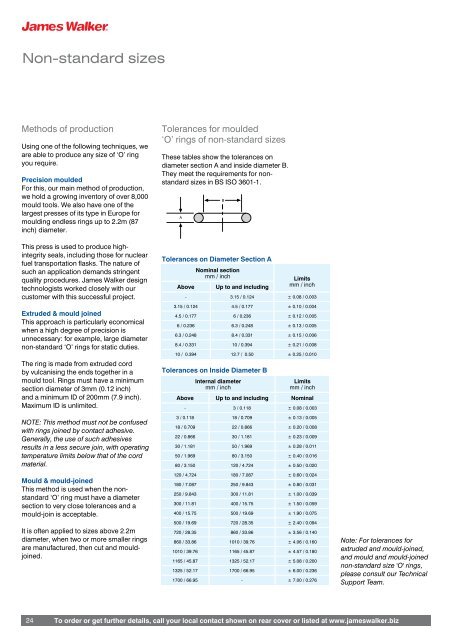

Tolerances for moulded<br />

‘O’ rings of non-standard sizes<br />

These tables show the tolerances on<br />

diameter section A and inside diameter B.<br />

They meet the requirements for nonstandard<br />

sizes in BS ISO 3601-1.<br />

A<br />

Tolerances on Diameter Section A<br />

Above<br />

Nominal section<br />

mm / inch<br />

Up to and including<br />

Limits<br />

mm / inch<br />

- 3.15 / 0.124 ± 0.08 / 0.003<br />

3.15 / 0.124 4.5 / 0.177 ± 0.10 / 0.004<br />

4.5 / 0.177 6 / 0.236 ± 0.12 / 0.005<br />

6 / 0.236 6.3 / 0.248 ± 0.13 / 0.005<br />

6.3 / 0.248 8.4 / 0.331 ± 0.15 / 0.006<br />

8.4 / 0.331 10 / 0.394 ± 0.21 / 0.008<br />

10 / 0.394 12.7 / 0.50 ± 0.25 / 0.010<br />

Tolerances on Inside Diameter B<br />

B<br />

Internal diameter<br />

mm / inch<br />

Limits<br />

mm / inch<br />

Above Up to and including Nominal<br />

- 3 / 0.118 ± 0.08 / 0.003<br />

3 / 0.118 18 / 0.709 ± 0.13 / 0.005<br />

18 / 0.709 22 / 0.866 ± 0.20 / 0.008<br />

22 / 0.866 30 / 1.181 ± 0.23 / 0.009<br />

30 / 1.181 50 / 1.969 ± 0.28 / 0.011<br />

50 / 1.969 80 / 3.150 ± 0.40 / 0.016<br />

80 / 3.150 120 / 4.724 ± 0.50 / 0.020<br />

120 / 4.724 180 / 7.087 ± 0.60 / 0.024<br />

180 / 7.087 250 / 9.843 ± 0.80 / 0.031<br />

250 / 9.843 300 / 11.81 ± 1.00 / 0.039<br />

300 / 11.81 400 / 15.75 ± 1.50 / 0.059<br />

400 / 15.75 500 / 19.69 ± 1.90 / 0.075<br />

500 / 19.69 720 / 28.35 ± 2.40 / 0.094<br />

720 / 28.35 860 / 33.86 ± 3.56 / 0.140<br />

860 / 33.86 1010 / 39.76 ± 4.06 / 0.160<br />

1010 / 39.76 1165 / 45.87 ± 4.57 / 0.180<br />

1165 / 45.87 1325 / 52.17 ± 5.08 / 0.200<br />

1325 / 52.17 1700 / 66.95 ± 6.00 / 0.236<br />

1700 / 66.95 - ± 7.00 / 0.276<br />

Note: For tolerances for<br />

extruded and mould-joined,<br />

and mould and mould-joined<br />

non-standard size <strong>'O'</strong> rings,<br />

please consult our Technical<br />

Support Team.<br />

24<br />

To order or get further details, call your local contact shown on rear cover or listed at www.jameswalker.biz