'O' Ring Guide

'O' Ring Guide

'O' Ring Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

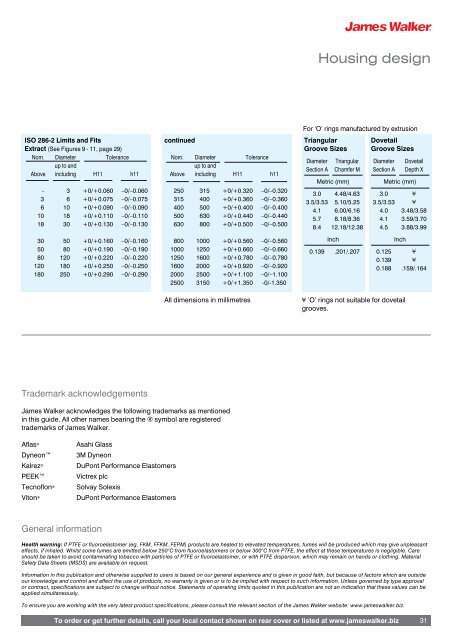

Housing design<br />

ISO 286-2 Limits and Fits<br />

Extract (See Figures 9 - 11, page 29)<br />

Nom. Diameter Tolerance<br />

up to and<br />

Above including H11 h11<br />

- 3 +0/+0.060 –0/–0.060<br />

3 6 +0/+0.075 –0/–0.075<br />

6 10 +0/+0.090 –0/–0.090<br />

10 18 +0/+0.110 –0/–0.110<br />

18 30 +0/+0.130 –0/–0.130<br />

30 50 +0/+0.160 –0/–0.160<br />

50 80 +0/+0.190 –0/–0.190<br />

80 120 +0/+0.220 –0/–0.220<br />

120 180 +0/+0.250 –0/–0.250<br />

180 250 +0/+0.290 –0/–0.290<br />

continued<br />

Nom. Diameter Tolerance<br />

up to and<br />

Above including H11 h11<br />

250 315 +0/+0.320 –0/–0.320<br />

315 400 +0/+0.360 –0/–0.360<br />

400 500 +0/+0.400 –0/–0.400<br />

500 630 +0/+0.440 –0/–0.440<br />

630 800 +0/+0.500 –0/–0.500<br />

800 1000 +0/+0.560 –0/–0.560<br />

1000 1250 +0/+0.660 –0/–0.660<br />

1250 1600 +0/+0.780 –0/–0.780<br />

1600 2000 +0/+0.920 –0/–0.920<br />

2000 2500 +0/+1.100 –0/–1.100<br />

2500 3150 +0/+1.350 -0/-1.350<br />

All dimensions in millimetres<br />

For ‘O’ rings manufactured by extrusion<br />

Triangular<br />

Groove Sizes<br />

Dovetail<br />

Groove Sizes<br />

Diameter Triangular Diameter Dovetail<br />

Section A Chamfer M Section A Depth X<br />

Metric (mm)<br />

Metric (mm)<br />

3.0 4.48/4.63 3.0 ¥<br />

3.5/3.53 5.10/5.25 3.5/3.53 ¥<br />

4.1 6.00/6.16 4.0 3.48/3.58<br />

5.7 8.18/8.36 4.1 3.59/3.70<br />

8.4 12.18/12.38 4.5 3.88/3.99<br />

Inch<br />

Inch<br />

0.139 .201/.207 0.125 ¥<br />

0.139 ¥<br />

0.188 .159/.164<br />

¥ ’O’ rings not suitable for dovetail<br />

grooves.<br />

Trademark acknowledgements<br />

James Walker acknowledges the following trademarks as mentioned<br />

in this guide. All other names bearing the ® symbol are registered<br />

trademarks of James Walker.<br />

Aflas ®<br />

Dyneon<br />

Kalrez ®<br />

PEEK<br />

Tecnoflon ®<br />

Viton ®<br />

Asahi Glass<br />

3M Dyneon<br />

DuPont Performance Elastomers<br />

Victrex plc<br />

Solvay Solexis<br />

DuPont Performance Elastomers<br />

General information<br />

Health warning: If PTFE or fluoroelastomer (eg, FKM, FFKM, FEPM) products are heated to elevated temperatures, fumes will be produced which may give unpleasant<br />

effects, if inhaled. Whilst some fumes are emitted below 250°C from fluoroelastomers or below 300°C from PTFE, the effect at these temperatures is negligible. Care<br />

should be taken to avoid contaminating tobacco with particles of PTFE or fluoroelastomer, or with PTFE dispersion, which may remain on hands or clothing. Material<br />

Safety Data Sheets (MSDS) are available on request.<br />

Information in this publication and otherwise supplied to users is based on our general experience and is given in good faith, but because of factors which are outside<br />

our knowledge and control and affect the use of products, no warranty is given or is to be implied with respect to such information. Unless governed by type approval<br />

or contract, specifications are subject to change without notice. Statements of operating limits quoted in this publication are not an indication that these values can be<br />

applied simultaneously.<br />

To ensure you are working with the very latest product specifications, please consult the relevant section of the James Walker website: www.jameswalker.biz.<br />

To order or get further details, call your local contact shown on rear cover or listed at www.jameswalker.biz 31