'O' Ring Guide

'O' Ring Guide

'O' Ring Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

General design notes<br />

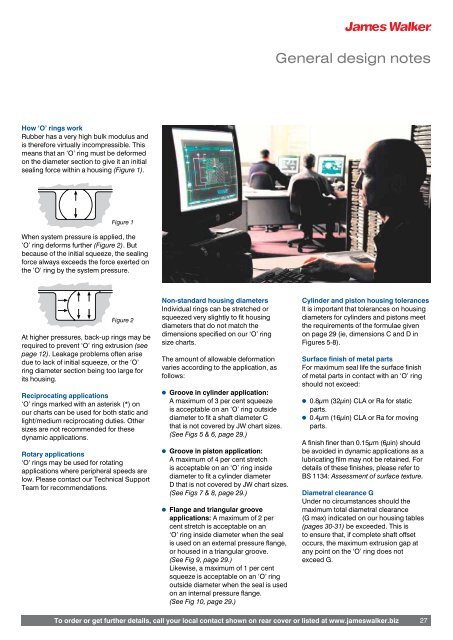

How ‘O’ rings work<br />

Rubber has a very high bulk modulus and<br />

is therefore virtually incompressible. This<br />

means that an ‘O’ ring must be deformed<br />

on the diameter section to give it an initial<br />

sealing force within a housing (Figure 1).<br />

G<br />

2<br />

G<br />

2<br />

Figure 1<br />

Pressure<br />

When system pressure is applied, the<br />

‘O’ ring deforms further (Figure 2). But<br />

Pressure<br />

because of the initial squeeze, the sealing<br />

force always exceeds the force exerted on<br />

the ‘O’ ring by the system pressure.<br />

Figure 2<br />

At higher pressures, back-up rings may be<br />

required to prevent ‘O’ ring extrusion (see<br />

page 12). Leakage problems often arise<br />

due to lack of initial squeeze, or the ‘O’ Pressure<br />

ring diameter section being too large for<br />

Pressure<br />

its housing.<br />

Reciprocating applications<br />

‘O’ rings marked with an asterisk (*) on<br />

our charts can be used for both static and<br />

light/medium reciprocating duties. Other<br />

sizes are not recommended for these<br />

dynamic applications.<br />

Rotary applications<br />

‘O’ rings may be used for rotating<br />

applications where peripheral speeds are<br />

low. Please contact our Technical Support<br />

Team for recommendations.<br />

G<br />

2<br />

Non-standard housing diameters<br />

Individual Grings 2<br />

can be stretched or<br />

squeezed very slightly to fit housing<br />

diameters Gthat do not match the<br />

dimensions 2<br />

specified on our ‘O’ ring<br />

size charts.<br />

The amount of allowable deformation<br />

varies according to the application, as<br />

follows:<br />

l Groove in cylinder application:<br />

A maximum of 3 per cent squeeze<br />

is acceptable on an ‘O’ ring outside<br />

diameter G to fit a shaft diameter C<br />

that is not 2 covered by JW chart sizes.<br />

(See Figs G 5 & 6, page 29.)<br />

2<br />

l Groove in piston application:<br />

A maximum of 4 per cent stretch<br />

is acceptable on an ‘O’ ring inside<br />

diameter to fit a cylinder diameter<br />

D that is not covered by JW chart sizes.<br />

(See Figs 7 & 8, page 29.)<br />

l Flange and triangular groove<br />

applications: A maximum of 2 per<br />

cent stretch is acceptable on an<br />

‘O’ ring inside diameter when the seal<br />

is used on an external pressure flange,<br />

or housed in a triangular groove.<br />

(See Fig 9, page 29.)<br />

Likewise, a maximum of 1 per cent<br />

squeeze is acceptable on an ‘O’ ring<br />

outside diameter when the seal is used<br />

on an internal pressure flange.<br />

(See Fig 10, page 29.)<br />

Cylinder and piston housing tolerances<br />

It is important that tolerances on housing<br />

diameters for cylinders and pistons meet<br />

the requirements of the formulae given<br />

on page 29 (ie, dimensions C and D in<br />

Figures 5-8).<br />

Surface finish of metal parts<br />

For maximum seal life the surface finish<br />

of metal parts in contact with an ‘O’ ring<br />

should not exceed:<br />

l 0.8µm (32µin) CLA or Ra for static<br />

parts.<br />

l 0.4µm (16µin) CLA or Ra for moving<br />

parts.<br />

A finish finer than 0.15µm (6µin) should<br />

be avoided in dynamic applications as a<br />

lubricating film may not be retained. For<br />

details of these finishes, please refer to<br />

BS 1134: Assessment of surface texture.<br />

Diametral clearance G<br />

Under no circumstances should the<br />

maximum total diametral clearance<br />

(G max) indicated on our housing tables<br />

(pages 30-31) be exceeded. This is<br />

to ensure that, if complete shaft offset<br />

occurs, the maximum extrusion gap at<br />

any point on the ‘O’ ring does not<br />

exceed G.<br />

To order or get further details, call your local contact shown on rear cover or listed at www.jameswalker.biz 27