Knauf Seismic Design

Knauf Seismic Design

Knauf Seismic Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

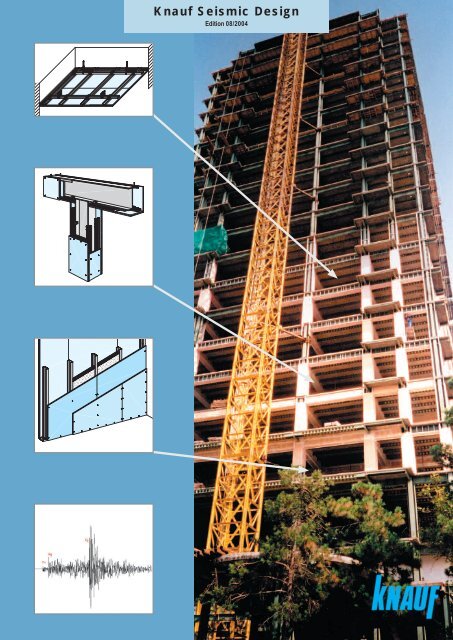

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Edition 08/2004

Earthquakes can cause huge economic<br />

losses. Primarily, however, they also cause<br />

personal distress with deaths, injuries, the<br />

loss of living space, and the devastation of<br />

living conditions.<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Earthquake Safety<br />

with <strong>Knauf</strong> Systems<br />

Most of these losses are set off by buildings<br />

that are unable to resist earthquake<br />

loads.<br />

In order to avoid, or at least reduce these<br />

damages there are three basic principles<br />

related to both cost-effective construction<br />

as well as the earthquake safety of<br />

buildings [1]:<br />

Figure 1: Earthquake-damaged building<br />

1.) In the event of slightly severe earthquakes,<br />

buildings must be able to survive<br />

without damage.<br />

2.) In the event of moderately severe<br />

earthquakes, the damage to the buildings<br />

must be negligible.<br />

3.) In the event of severe earthquakes,<br />

the buildings must be prevented from<br />

collapsing.<br />

Above all, the protection of human life<br />

must be assured by ensuring the options of<br />

survival, escape and rescue in the event of<br />

earthquakes of any severity.<br />

Figure 2: “Soft story effect”<br />

The appropriate literature [2], [3] and<br />

National Standards (DIN 4149, Eurocode<br />

8 - ENV 1998-1 etc.; see pg. 19) provide<br />

constructional guidelines for the technical<br />

implementation of these basic principles.<br />

Going by these mentioned technical guidelines,<br />

<strong>Knauf</strong> Systems present several clear<br />

advantages as compared with solid concrete<br />

and masonry constructions.<br />

2<br />

Figure 3: Collapsed “soft story”

Soft Buildings<br />

Advantages:<br />

Appropriate for rigid subsoil (higher<br />

frequency) due to low natural frequency.<br />

Required ductility is easier to achieve.<br />

An easier calculation procedure.<br />

Disadvantages:<br />

Non-load bearing elements have to<br />

be isolated (movements and deformations,<br />

load distributions).<br />

High stress in junctions due to larger<br />

movements.<br />

Rigid Buildings<br />

Advantages:<br />

Appropriate for soft subsoil due to<br />

high natural frequency.<br />

The junctions are less elaborate due<br />

to smaller movements.<br />

Joints with non-load bearing<br />

construction components with fewer<br />

problems.<br />

Disadvantages:<br />

Higher stress when subsoil is rigid.<br />

Lower ductility.<br />

The calculation procedure is more<br />

complex.<br />

a) floor plan vertical layout<br />

Structural Basics<br />

1.) Rigidity of load-bearing structure.<br />

A decision in favor of or against soft or rigid<br />

structures has to take the conditions of<br />

the foundation soil into consideration.<br />

Rigid structures should be founded on<br />

soft subsoil, and soft structures should be<br />

founded on rigid subsoil in order to avoid<br />

undesired large stresses caused by the effects<br />

of resonance.<br />

2.) Ensure a steady and symmetrical distribution<br />

of weight and rigidity in the vertical<br />

and horizontal layout taking non-load bearing<br />

construction components into consideration,<br />

in order to avoid higher torsion-related<br />

stress (fi gure 4).<br />

3.) Avoid “top heaviness” of the vertical layout<br />

related to both weight (including nonload<br />

bearing components) and rigidity. In a<br />

majority of cases, the “soft story effect” is responsible<br />

for the collapse of buildings in the<br />

event of an earthquake (fi gures 2 and 3).<br />

b) floor plan vertical layout<br />

Figure 4: a)Unfavourable layouts b) Improvement through structural subdivision<br />

4.) Use ductile materials for non-load bearing<br />

construction components. Avoid brittle<br />

materials that display unfavorable behavioral<br />

patterns in the case of a collapse (unannounced<br />

collapses, brittle fraction). They<br />

could thus lead to undesired load distribution<br />

when not installed properly, with higher<br />

destruction effects when compared with<br />

more ductile materials (fi gure 5).<br />

The objective should be to implement<br />

these basic rules in the construction of new<br />

buildings as well as in the improvement of<br />

Figure 5: Damage caused by collapsing masonry<br />

existing buildings.<br />

3

<strong>Seismic</strong> Zones<br />

Every country has different seismic zones<br />

that refer to nominal horizontal ground accelerations<br />

depending on the regional seismic activity<br />

(table 2).<br />

In table 1 the zones have been allocated to<br />

the internationally recognized EMS-98-scale<br />

(table 1) in order to ensure the international<br />

comparability of national guidelines. With 12<br />

intensity classifi cations this scale specifi es<br />

earthquake intensities based on their effects on<br />

human beings and buildings. It is a better scale<br />

than the well-known Richter scale that provides<br />

us with the energy release rate at the epicenter<br />

of earthquakes. The effect on buildings, however,<br />

depends on the epicenter‘s distance to the<br />

earth’s surface.<br />

The values stated in table 2 are the nominal<br />

ground accelerations. For calculation purposes,<br />

other mathematical factors such as behavioral,<br />

soil group, and building classifi cation factors<br />

have to be additionally applied as set down in<br />

the national standards.<br />

Usually, the vertical acceleration is neglected.<br />

It can, however, amount to up to 50 % of the horizontal<br />

acceleration. In individual cases it might<br />

have to be taken into consideration for certain<br />

construction components.<br />

Tabelle 1: European Macroseismic Scale 1998 EMS-98 [5]<br />

EMS<br />

intensity<br />

Definition Description of typical observed effects (abstracted)<br />

I Not felt Not felt.<br />

II Scarcely felt Felt only by very few individual people at rest in houses.<br />

III Weak Felt indoors by a few people. People at rest feel a swaying<br />

or light trembling.<br />

IV<br />

Largely<br />

observed<br />

Felt indoors by many people, outdoors by very few. A<br />

few people are awakened. Windows, doors and dishes<br />

rattle.<br />

V Strong Felt indoors by most, outdoors by few. Many sleeping<br />

people awake. A few are frightened. Buildings tremble<br />

throughout. Hanging objects swing considerably. Small<br />

objects are shifted. Doors and windows swing open or<br />

shut.<br />

VI<br />

Slightly<br />

damaging<br />

Many people are frightened and run outdoors. Some objects<br />

fall. Many houses suffer slight non-structural damage<br />

like hair-line cracks and fall of small pieces of plaster.<br />

VII Damaging Most people are frightened and run outdoors. Furniture<br />

is shifted and objects fall from shelves in large numbers.<br />

Many well built ordinary buildings suffer moderate damage:<br />

small cracks in walls, fall of plaster, parts of chimneys<br />

fall down; older buildings may show large cracks in walls<br />

and failure of fi ll-in walls.<br />

VIII<br />

Heavily<br />

damaging<br />

Many people fi nd it diffi cult to stand. Many houses have<br />

large cracks in walls. A few well built ordinary buildings<br />

show serious failure of walls, while weak older structures<br />

may collapse.<br />

IX Destructive General panic. Many weak constructions collapse. Even<br />

well built ordinary buildings show very heavy damage:<br />

serious failure of walls and partial structural failure.<br />

X<br />

Very<br />

destructive<br />

Many ordinary well built buildings collapse.<br />

XI Devastating Most ordinary well built buildings collapse, even some<br />

with good earthquake resistant design are destroyed.<br />

XII<br />

Completely<br />

devastating<br />

Almost all buildings are destroyed.<br />

4

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

<strong>Seismic</strong> Zones and <strong>Seismic</strong> Intensities<br />

Table 2: <strong>Seismic</strong> zones in selected countries<br />

EMS-<br />

98-<br />

Scale<br />

Appropriate<br />

horizontal<br />

ground<br />

acceleration<br />

Argentina<br />

INPRES-CIRSOC<br />

103 Part I<br />

1991<br />

Austria<br />

ÖNORM B4015<br />

2002<br />

Bulgaria<br />

Code for<br />

seismic <strong>Design</strong><br />

1987<br />

Chile<br />

NCH 433 Of 96<br />

1996<br />

China<br />

GB/T177742<br />

1999<br />

CIS<br />

SNiP II-7-81*<br />

2000<br />

Germany<br />

DIN 4149-1<br />

1981<br />

a [m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²]<br />

I < 0.01<br />

II 0.01-0.025<br />

III 0.025-0.05<br />

0 0-0.35<br />

A 0<br />

IV 0.05-0.12 0 ≤ 0.39<br />

0<br />

V 0.12 -<br />

0.25<br />

1 1.96<br />

0.22-0.44<br />

VI 0.25 -<br />

VI 0.49<br />

1 0.35-0.50<br />

0 0<br />

0.50<br />

1 0.40-0.98 0.45-0.89<br />

VII 0.50 - 2 0.50-0.75 VII 0.98<br />

1 0.25<br />

1.0<br />

1.0<br />

3 0.75-1.00<br />

2 0.40<br />

2 0.99-1.77<br />

0.90-1.77<br />

VIII 1.0 -<br />

VIII 1.47<br />

3 0.65<br />

2.0<br />

2.0<br />

4 1.00<br />

3 1.78-2.45 2 1.96-2.94 1.78-3.53<br />

IX 2.0- IX 2.65<br />

4.0<br />

4.0 4 2.46-3.43 3 2.94-3.92<br />

3.54-7.07<br />

X 4.0 -<br />

4 >1.00<br />

8.0<br />

XI 8.0 -<br />

16.0<br />

XII > 16.0<br />

7.08-<br />

14.14<br />

EMS- Appropriate Greece Iran<br />

Italy<br />

Romania Switzerland Turkey<br />

98- horizontal EAK 2000 Document technical government<br />

order<br />

P 100-92 SIA 261 ABYYHY<br />

Scale ground<br />

No. 2800 2 nd ed.<br />

acceleration 2000<br />

1999<br />

2004<br />

1992<br />

2003<br />

1998<br />

a [m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²] Zone a 0<br />

[m/s²]<br />

I < 0.01<br />

II 0.01-0.025<br />

III 0.025-0.05<br />

IV 0.05-0.12<br />

4 ≤ 0.49<br />

V 0.12 -<br />

0.25<br />

4 1.96<br />

VI 0.25 -<br />

0.50<br />

VII 0.50 -<br />

1 0.6<br />

F 0.78<br />

1.0 3 0.5-1.47<br />

2 1.0<br />

VIII 1.0 - I 1.18 E 1.18 3a 1.3<br />

4 ≤1.0<br />

2.0 II 1.57<br />

D 1.57 3b 1.6<br />

2 1.47-2.45<br />

IX 2.0<br />

3 2.45 C 1.96 3 2.0<br />

III 2.53<br />

- 2 2.94<br />

B 2.45 2 3.0<br />

4.0 IV 3.53 1 3.43 A 3.14<br />

X 4.0 -<br />

1 4.0<br />

8.0<br />

1 > 2.45<br />

XI 8.0 -<br />

16.0<br />

XII > 16.0<br />

5

Types of Collapse and Damage<br />

The collapse of buildings can either be<br />

global or local. The term local implies that<br />

only a part of the load-bearing structure or<br />

a single construction component collapses.<br />

When a collapse is termed global, the<br />

whole structure is considered to have been<br />

destroyed.<br />

Cracks, plastic displacements etc. are<br />

damages which can cause the loss of a<br />

building’s usability, as well.<br />

Apart from basic “under dimensioning,”<br />

the following types of collapses may occur<br />

due to errors in either the conception or<br />

execution of buildings:<br />

The “soft story effect” (fi gures 2 and 3)<br />

occurs due to a story with little rigidity (for<br />

architectural reasons mostly the ground<br />

fl oor) that attracts stresses from rigid stories<br />

and subsequently collapses. It is the<br />

weakest part of the structure. Strictly speaking,<br />

it is a local collapse, but it can cause<br />

a global collapse and lead to the ultimate<br />

loss of the building.<br />

The “short columns effect” (fi gure<br />

7) is caused by undesired load swaps into<br />

construction components that are not divided<br />

well enough from the load-bearing<br />

structure. The reason is the subsequent increase<br />

of rigidity through masonry and the<br />

following higher seismic load due to the<br />

shortening of the swing period.<br />

The sudden and unannounced collapse<br />

of infill masonry (fi gures 6 and 8) is extremely<br />

dangerous to people in the building.<br />

It can even lead to a complete collapse<br />

of the whole building (fi gure 5). The reason<br />

is the higher rigidity of infi ll masonry,<br />

as compared with the softer columns, that<br />

causes the swapping of loads into the masonry.<br />

The brittle material collapses in an<br />

explosion-like manner.<br />

6<br />

Figure 6: Collapse of infi ll masonry<br />

Figure 7: Short columns effect<br />

Figure 8: Collapsed infi ll masonry

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Less Weight<br />

- Less Trouble<br />

Example according to<br />

Eurocode 8 (EN 1998: 1997): (figure 9)<br />

● 7-story residential building<br />

● Reinforced skeleton construction<br />

● Total height: 19 m<br />

● Ground area 18 x 12 m<br />

● Reference value of horizontal ground<br />

acceleration: 0.4 g<br />

● Total weight of load-bearing compo -<br />

nents: 1095 t<br />

● Total weight of walls (masonry incl.<br />

plaster = 200 kg/m² interior / 240 kg/m²<br />

exterior)): 518 t<br />

● Total weight of walls<br />

(interior: <strong>Knauf</strong> W112, 49 kg/m²,<br />

exterior: Aquapanel, 42 kg/m²) : 109 t<br />

● Total weight of building:<br />

Figure 9: Skeletal frame of a 7-story building<br />

Table 3: Load values for cited example<br />

Interior Walls<br />

Exterior Walls<br />

Total vertical load for<br />

earthquake calculation<br />

Masonry<br />

(200 kg/m²)<br />

(240 kg/m²)<br />

<strong>Knauf</strong> Systems<br />

W112<br />

(49 kg/m²)<br />

Aquapanel<br />

(42 kg/m²)<br />

17.8 MN 13.7 MN<br />

with masonry: 1614 t<br />

with <strong>Knauf</strong> systems: 1204 t<br />

(25 % less weight when <strong>Knauf</strong> Systems<br />

are used instead of masonry)<br />

By calculating the earthquake loads<br />

according to Eurocode 8 it can be determined<br />

that these loads are decreased by<br />

Total horizontal<br />

earthquake load<br />

according to EC 8<br />

at a 0<br />

= 0.4 g<br />

4.0 MN 3.1 MN<br />

approx. 23 % when using <strong>Knauf</strong> W112 for<br />

interior partitions and <strong>Knauf</strong> Aquapanel for<br />

exterior walls.<br />

Ratio 100 % 77 %<br />

A more economic dimensioning of the<br />

expensive reinforced concrete structure<br />

thus becomes possible for both static and<br />

earthquake loads.<br />

Additionally, earthquake safety is<br />

improved due to the better deformation and<br />

collapse behavior of drywall constructions<br />

in the event of an earthquake.<br />

7

Advantages<br />

●Low dead load ( ˆ= lower earthquake<br />

loads)<br />

● Sound insulation<br />

● Drywall materials are a major<br />

advantage in remodelling and<br />

renovation<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Advantages of <strong>Knauf</strong><br />

Drywall Systems as<br />

Compared with Solid<br />

Constructions<br />

● Fire protection (ceilings, panelling<br />

of beams and columns)<br />

● Flexible for rededications<br />

● Ductile behavior of deformation<br />

and collapse; no unannounced<br />

collapse<br />

● Preservation of enclosing function<br />

even after possible collapse<br />

8<br />

Figure 10: <strong>Knauf</strong> suspended ceiling D112

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Applications<br />

Non-load bearing Partitions /<br />

Suspended Ceilings (pp. 10 / 12)<br />

As construction components, the wellknown<br />

<strong>Knauf</strong> partitions and ceiling systems<br />

are earthquake proof by themselves [6].<br />

Additionally, they add a considerable<br />

amount of earthquake safety to a building<br />

based on the benefi ts mentioned earlier in<br />

this brochure.<br />

Application is possible both in new<br />

buildings as well as for the retrofi tting or<br />

renovation of existing buildings.<br />

Shear Walls (pg. 14)<br />

Figure 11: <strong>Knauf</strong> partition W112<br />

<strong>Knauf</strong> drywall partitions can bear horizontal<br />

shear forces like wind and earthquake<br />

loads if they are adapted to brace<br />

load-bearing structures. With that, the<br />

advantages of <strong>Knauf</strong> drywall partitions can<br />

be exploited for walls in new buildings and<br />

in the case of renovation and retrofi ttings<br />

with structural requirements.<br />

Bracing Wall and Ceiling Panels for<br />

Steel Framework Buildings (pg. 16)<br />

Prefabricated or on-site fabricated wall<br />

and ceiling panels can be used for new<br />

steel framework buildings.<br />

These panels link the advantages of dry<br />

construction systems with a highly effective<br />

execution process.<br />

The <strong>Knauf</strong> partner company, Danogips,<br />

offers the SBS (Steel Building System)<br />

which will shortly be adapted for use in<br />

Figure 12: The Danogips SBS (Steel Building System)<br />

earthquake endangered buildings.<br />

9

The main advantages of <strong>Knauf</strong> nonload<br />

bearing partitions are the reduction<br />

of construction weight (see table 3, page<br />

7 and table 4) and the ductile behavior of<br />

deformation. The dead load decrease of<br />

non-load bearing construction components<br />

leads to a massive reduction of loads in the<br />

event of an earthquake.<br />

The most ideal application of <strong>Knauf</strong><br />

partitions in connection with earthquake<br />

safety is their use as infi ll walls for skeleton<br />

constructions.<br />

The brittle and comparatively rigid<br />

deformation behavioral patterns of the<br />

infi ll masonry used generally causes load<br />

transfer with dangerous, explosion-like and<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Non-load bearing<br />

Partitions<br />

Table 4: Weight comparison of infill masonry and <strong>Knauf</strong> Drywall Systems W111/ W112<br />

Weight Reduction<br />

1 m² masonry d = 11.5 cm;<br />

Weight per unit area: approx. 145 kg/m²<br />

1 m² metal stud partition, single layer;<br />

Weight per unit area: approx. 25 kg/m²<br />

1 m² metal stud partition, double layer;<br />

Weight per unit area: approx. 50 kg/m²<br />

→ Weight reduction by 65 % to 83 %<br />

unannounced collapse that can even lead<br />

Table 5: Stress resultants from lateral horizontal loads<br />

System<br />

W111<br />

d = 100 mm<br />

W112<br />

d = 125 mm<br />

Horizontal<br />

acceleration<br />

0.5 g<br />

(4.9 m/s²)<br />

Max.<br />

shift<br />

[mm]<br />

Maximum<br />

bending<br />

moment<br />

[kNm]<br />

2.5 - 14 0.1 - 0.3 2.0<br />

11.6 - 25 0.3 - 0.6 2.6<br />

Bending<br />

moment<br />

capacity<br />

[kNm]<br />

to the total collapse of the whole building.<br />

Even when highly deformed, drywall<br />

partitions maintain their enclosing function<br />

and do not collapse completely. [7]<br />

According to the “Report of Earthquake<br />

Proof Execution of Partitions and Suspended<br />

Ceilings” by Dr. Rainer Flesch of the<br />

“Bundesforschungs- und Prüfzentrum Arsenal”<br />

(Federal Research and Test Centre<br />

Arsenal) [6], <strong>Knauf</strong> metal stud partitions<br />

can effectively resist and absorb lateral<br />

loads caused by earthquake acceleration<br />

and their own weight.<br />

Table 5 shows calculated stress resultants<br />

for a lateral horizontal acceleration of<br />

2.5 m h 3.5 m<br />

U ; V´<br />

0.5 g on <strong>Knauf</strong> partitions W111 and W112.<br />

2.5 m l 15.0 m<br />

Figure 13: Lateral horizontal loading<br />

10

Table 6: Maximum Resistible Horizontal Acceleration<br />

<strong>Knauf</strong> gypsum<br />

board partition<br />

system<br />

W111<br />

single layer<br />

(1x12.5 mm)<br />

25 kg/m²<br />

W112<br />

double layer<br />

(2x12.5 mm)<br />

50 kg/m²<br />

Size of stud /<br />

thickness of wall<br />

[mm] / [mm]<br />

Maximum<br />

wall height<br />

[m]<br />

Bending<br />

moment<br />

capacity<br />

[kNm]<br />

50 / 75 3.0 1.5 ≤ 5.4 g<br />

75 / 100 4.5 2.0 ≤ 3.1 g<br />

100 / 125 5.0 2.5 ≤ 3.2 g<br />

50 / 100 4.0 2.0 ≤ 2.0 g<br />

75 / 125 5.5 2.6 ≤ 1.4 g<br />

100 / 150 6.0 3.2 ≤ 1.4 g<br />

Maximum resistible<br />

horizontal<br />

acceleration<br />

Values for the maximum acceptable horizontal<br />

acceleration based on load capacities<br />

according to [8] are stated in table 6.<br />

However, going by the following assumption<br />

horizontal in-plane loads caused by<br />

story shift cannot be borne by these partitions<br />

[6] (fi gure 14).<br />

With an assumed story shift of 1 % to 1.5 %,<br />

a maximum height of wall of 3.5 m, and the<br />

resulting story shift of ∆l = 3.5 to 5.3 cm,<br />

F M<br />

l<br />

the resulting stresses cannot be absorbed<br />

by the partition without cracks developing.<br />

The enclosing function would still be retained,<br />

but a big enough joint is necessary<br />

h 3.5 m<br />

in order to absorb the deformation of the<br />

structure.<br />

2.5 m l 15.0 m<br />

Figure 14: Horizontal in-plane load<br />

30 mm<br />

V' x<br />

A viable solution according to the example<br />

cited above is shown in fi gure 15.<br />

In individual cases the necessary size of<br />

the joint has to be determined exactly through<br />

a calculation of the expected deformation.<br />

U Runner (d = 1.0 mm)<br />

spacing of dowels = 0.5 m<br />

Figure 15: Detail of deformation joint<br />

Figure 16: Statical separation of non-load bearing partitions<br />

11

<strong>Knauf</strong> suspended ceilings keep the dead<br />

load of non-load bearing construction components<br />

low and fulfi l the enhanced building<br />

requirements of sound insulation, fi re protection<br />

and thermal insulation. Furthermore,<br />

<strong>Knauf</strong> suspended ceiling systems create<br />

additional space for service or sanitary<br />

installations.<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Suspended Ceilings<br />

Table 7: Load values in ceiling studs with vertical acceleration of 0.5 g<br />

Suspended ceiling<br />

Gypsum<br />

board layer<br />

layout<br />

[m]<br />

Maximum bending<br />

moment<br />

[kNm]<br />

Maximum shift<br />

[mm]<br />

Breaking<br />

moment of<br />

channels [kNm]<br />

Suspension Suspension Suspension<br />

soft rigid soft rigid soft rigid<br />

The behavior of suspended ceilings in the<br />

event of an earthquake also has been an<br />

object of investigation in the report mentioned<br />

earlier [6].<br />

Different variations were analyzed in order<br />

to detect any links between behavior under<br />

dynamic loads, the rigidity of the suspension,<br />

and the layout (table 7, fi gure 17).<br />

The rigidity of the suspension is infl u-<br />

enced by the number, the alignment and<br />

single<br />

(1 x 12.5 mm)<br />

12.5 kg/m²<br />

double<br />

(2 x 12.5 mm)<br />

25 kg/m²<br />

3 x 5<br />

0.02 22.3<br />

0.20<br />

7 x 15<br />

27<br />

0.005<br />

10 x 10 0.15 25<br />

3 x 5<br />

0.05 44 7.4<br />

7 x 15 0.35<br />

50 7.5<br />

0.015<br />

10 x 10 48 8.0<br />

V' (0.5 g) z<br />

3.0 0.186 0.186<br />

0.222 0.222<br />

the rigidity of the suspenders. (fi gure 17,<br />

table 8).<br />

The results show that a rigid suspension<br />

is better than a soft suspension when dynamic<br />

loads are applied.<br />

Due to the effects of resonance, both defl<br />

ection and the bending moment are signifi -<br />

cantly lower with rigid suspensions as compared<br />

with soft suspensions.<br />

The bending moment capacity is reached<br />

or partially overstepped with a soft suspension.<br />

Another remarkable characteristic is that<br />

the layout does not have a signifi cant infl u-<br />

ence on the defl ection. Single layer board<br />

application is preferable due to the lower<br />

weight. However, this is not always possib-<br />

1.25 m<br />

1.25 m<br />

1.25 m 1.25 m<br />

"soft" suspension<br />

suspenders at every 2nd crossing<br />

0.50 m<br />

"rigid" suspension<br />

suspenders at each crossing<br />

CD channel<br />

suspended CD channel<br />

CD channel<br />

suspended CD channel<br />

le as fi re safety requirements might have to<br />

be taken into consideration.<br />

0.50 m<br />

Figure 17: Constructional set-up for rigid or soft suspensions<br />

12

Table 8: <strong>Knauf</strong> Suspenders<br />

0.25 kN<br />

Anchor Fix<br />

0.4 kN<br />

Nonius Hanger<br />

0,4 kN <strong>Knauf</strong><br />

Universal Bracket<br />

The following constructional demands<br />

have to be taken into consideration for application:<br />

● Place suspenders as close as possible<br />

to the cross-alignment points of the<br />

104 200<br />

270<br />

Rigidity [kN/m]<br />

channels.<br />

● The connectors have to be screwed together<br />

with channels and suspenders.<br />

10 mm<br />

10 mm<br />

12.5 mm 12.5 mm<br />

● The suspension height should be as<br />

short as possible.<br />

● The weight should be as low as possible<br />

to reduce earthquake loads. One<br />

layer is better than two layers.<br />

10 mm<br />

10 mm<br />

25 mm<br />

● The lateral connection should slide<br />

Rigid suspension<br />

● do not fasten cladding to<br />

perimeter channel<br />

Figure 18 :Layouts<br />

Soft suspension<br />

● single layer cladding<br />

● square layout<br />

● connection to perimeter<br />

channel on one side<br />

horizontally but be vertically fixed.<br />

● The edge distance of first channel grid<br />

from flanking component should be<br />

approx. 100 mm.<br />

Construction examples can be seen in fi -<br />

load-bearing structure<br />

gures 19 and 20.<br />

The use of the soft suspension as shown<br />

open joint<br />

suspended ceiling<br />

mold<br />

Figure 19: Section of suspended ceiling<br />

horizontal<br />

fixing<br />

in fi gure 17 and table 7 is limited. In buildings<br />

classifi ed as I and II according to Eurocode<br />

8-1-2 and areas with high seismic<br />

activity soft suspension systems cannot be<br />

used. Even for building classifi cation III the<br />

Connection without<br />

fire protection requirements<br />

● shifting substructure<br />

Figure 20: Joint details<br />

Connection with<br />

1.5 hr fire protection<br />

● Shifting substructure<br />

● Rigid connection of cladding<br />

(tightness)<br />

● Alternative: expanding<br />

sealing strip<br />

(with / without mold)<br />

use is limited. Furthermore, constructional<br />

demands according to fi gure 18 should also<br />

be taken into account.<br />

All elements in the plenum (above the<br />

suspended ceilings) that are not part of<br />

the suspended ceiling must have a separate<br />

suspension and are not allowed to apply<br />

their weight on any component of the suspended<br />

ceiling.<br />

This requirement should be fulfi lled both<br />

for earthquake safety purposes and for fi re<br />

protection reasons.<br />

13

<strong>Knauf</strong> partitions such as the wooden panel<br />

partitions and the metal stud partitions<br />

can be used as shear walls for horizontal<br />

loads from wind and earthquakes for both<br />

new buildings and the renovation of buildings.<br />

Shear walls are well-known building<br />

methods in the USA and New Zealand where<br />

wooden constructions are mainly used.<br />

The values and application guidelines<br />

of non-load bearing partitions can be applied<br />

to lateral loads. No resonance effects<br />

should be expected for in-plane loads due<br />

to the high natural frequency in case of<br />

shear loads.<br />

Consequently, no dynamic effects need<br />

to be taken into consideration, and structural<br />

loads can be assumed accordingly.<br />

Table 9 shows the permissible in-plane<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Shear Walls<br />

Table 9: Horizontal load capacity of wooden panel partitions according to<br />

„Allgemeinen bauaufsichtlichen Zulassungen“ (General Building Supervisory Permits)<br />

Z-9.1-339 (<strong>Knauf</strong> gypsum fiber boards) and Z-9.1-199 (<strong>Knauf</strong> gypsum boards)<br />

Cladding<br />

both sides<br />

one side<br />

Stud<br />

spacing<br />

Standard<br />

b S<br />

Spacing<br />

of nails /<br />

staples<br />

e R<br />

Gypsum fiber<br />

boards perm. F H<br />

in<br />

kN for panel height<br />

h in m<br />

Gypsum boards<br />

perm. F H<br />

in kN<br />

for panel height<br />

h in m<br />

mm mm ≤ 2.60 ≤ 3.00 ≤ 2.60 ≤ 3.00<br />

600-625<br />

1200-<br />

1250<br />

1200-<br />

1250<br />

min. 50 3.3<br />

max. 75 3.3<br />

max. 150 1.3<br />

min. 50 6.0 5.5<br />

max. 75 7.5 6.3<br />

max. 150 2.7 2.7<br />

min. 50 3.3<br />

max. 75 4.4 2.8<br />

max. 150 1.5<br />

1)<br />

Linear interpolation is allowed for values of perm. F H<br />

between e R<br />

= 50 mm and 150 mm, likewise between h = 2.60 m and<br />

3.0 m.<br />

loads for <strong>Knauf</strong> wooden panel partitions<br />

according to the “Allgemeine bauaufsichtliche<br />

Zulassung Z-9.1-199” (The General<br />

Building Supervisory Permit) [10] (Further<br />

information about reduction factors is cited<br />

Half panel<br />

F H<br />

e R<br />

F V<br />

Full size panel<br />

e R<br />

F V<br />

here).<br />

The German Standard for wooden<br />

constructions DIN 1052 (08/2004) includes<br />

detailed information for the dimensioning<br />

of wooden panel partitions with gypsum<br />

boards and in-plane loading.<br />

Bernd Naujoks (TU Darmstadt, Institut für<br />

Stahlbau und Werkstoffmechanik/ Technical<br />

R<br />

e R<br />

R<br />

e R<br />

h 2600 mm<br />

F H<br />

R M R<br />

e R<br />

max. e M = 150<br />

e R<br />

h 3000 mm<br />

(only with double sided cladding and b 1200)<br />

s<br />

University of Darmstadt) did a report on me-<br />

e R<br />

e R<br />

tal stud constructions, “Tragverhalten von<br />

Wandtafeln mit Kaltprofi len unter horizontalen<br />

Lasten“ [11]. Among other tests me-<br />

Z A<br />

b = 600 to 625 mm<br />

s<br />

Z A<br />

bs<br />

625 to 1250 mm<br />

tal stud partitions with gypsum fi ber board<br />

Figure 21: Loading set-up for Table 9<br />

application under in-plane load (horizontal,<br />

and combined with vertical load) ...<br />

Continuation on page 15<br />

14

Table 10: Collapse loads for metal stud shear walls from [9]<br />

Cladding 1 Cladding 2 Spacing of<br />

screws s r<br />

[mm] at<br />

perimeter<br />

Horizontal<br />

load F H<br />

at<br />

collapse<br />

[kN]<br />

Vertical<br />

load F V<br />

at<br />

collapse<br />

[kN]<br />

Number<br />

of tests<br />

Continuation from page 14<br />

...by varying the spacing of the screw<br />

attachment were tested for this research<br />

paper. A dimensioning calculation has been<br />

Gypsum<br />

fi ber board<br />

(e.g. <strong>Knauf</strong><br />

Vidiwall)<br />

Cementous<br />

fi ber board<br />

(e.g. <strong>Knauf</strong><br />

Aquapanel)<br />

Gypsum<br />

fi ber<br />

board<br />

(e.g. <strong>Knauf</strong><br />

Vidiwall)<br />

100 39.8 0 3<br />

150 33.1 0 3<br />

150 43.6 0 3<br />

Chipboard 150 39.9 0 3<br />

Trapezoid<br />

metal sheet<br />

172/150 39.0 0 3<br />

none 200 12.2 30 1<br />

also developed by Bernd Naujoks.<br />

The test results shown in table 10 are not<br />

dimensioning values ; these are breaking<br />

loads with defi ned collapse criteria without<br />

statistical consideration or safety factors.<br />

The collapse of wooden panel partitions is<br />

usually caused by the connections between<br />

the board and the wooden framing members.<br />

For metal stud partitions, however, the col-<br />

1<br />

3<br />

1<br />

3<br />

1<br />

3<br />

F V<br />

F V<br />

F V<br />

F H<br />

lapse can be caused by the buckling of the<br />

lower end of the pressure-impacted stud if<br />

the spacing of screws is small enough. [11]<br />

Additional reinforcements in this area, e.g.<br />

corner bracing components increase the<br />

load capacity of metal stud shear walls.<br />

260 cm<br />

It should, however, be borne in mind that<br />

the fi gures stated do not take into account<br />

Figure 22: Load set-up for Table 10<br />

125 cm<br />

any effects of creeping under permanent<br />

loads. Hence, it should be ensured that no<br />

permanent loads occur through plastic deformations<br />

or the restraint of fl anking components.<br />

Drywall shear walls can be used up to 5<br />

stories.<br />

Table 11: Comparison of shear capacity of masonry walls and<br />

<strong>Knauf</strong> shear walls<br />

Wall type<br />

(l=5m, h=3m)<br />

Total capacity<br />

kN<br />

Capacity<br />

kN/m<br />

Weight of wall<br />

kg/m²<br />

120 mm masonry 1) 9 1.8 194<br />

180 mm masonry 1) 15 3.0 299<br />

240 mm masonry 1) 20 4.0 405<br />

≥ 75 mm <strong>Knauf</strong> W 111 2) 12 2.4 25<br />

≥ 100 mm <strong>Knauf</strong> W 112 2) 19 3.8 50<br />

1)<br />

Strength of bricks = 15.0 N/mm²<br />

2)<br />

Studs c/c 600 mm. Screw spacing around perimeter 200 mm in both layers.<br />

In table 11 the shear load capacity of masonry<br />

and <strong>Knauf</strong> shear walls is stated for<br />

walls 3 m high and 5 m long.<br />

It shows that the shear capacity of <strong>Knauf</strong><br />

partitions is comparable to the capacity of<br />

conventional masonry with a signifi cantly<br />

lower weight.<br />

Material values for dimensioning are stated<br />

in tables 12 and 13, pg 17.<br />

15

The <strong>Knauf</strong> partner company, Danogips,<br />

offers the SBS (Steel Building System) as<br />

an effi cient constructional option for new<br />

steel framework buildings.<br />

The wall and ceiling panels used in this<br />

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Bracing Wall and<br />

Ceiling Panels<br />

system are prefabricated to various degrees<br />

and can bear horizontal loads from<br />

wind and earthquakes.<br />

To date the system can only be used for<br />

static loads. <strong>Knauf</strong> and Danogips are currently<br />

working together to adapt it for use<br />

under dynamic loads, such as in earthquake<br />

endangered areas, in the next few<br />

months.<br />

All the previously mentioned advantages<br />

of drywall constructions can be applied to<br />

the SBS. Additionally, there is the cost-saving<br />

option on expensive reinforced concrete<br />

or steel constructions as the SBS system<br />

is able to to bear loads.<br />

Figure 23: Facade with Danogips SBS (Steel Building System)<br />

Figure 24: Ceiling panel<br />

16

<strong>Knauf</strong> <strong>Seismic</strong> <strong>Design</strong><br />

Material Values<br />

Table 12:<br />

Shear capacity [kN] of connection of cladding to metal<br />

stud (0.6 mm) per TN drywall screw in kN<br />

Gypsum board<br />

according to EN 520<br />

Screw in<br />

1 st layer<br />

Screw in<br />

2 nd layer<br />

12.5 mm Type E 0.25 0.14<br />

The material data according to DIN 1052<br />

(08/2004) (table 13) and the shear capacities<br />

of the screw connectors (table 12) as<br />

determined by Danogips can be used as dimensioning<br />

values for metal stud partitions<br />

with shear load. Load capacity values for<br />

<strong>Knauf</strong> Systems will be available shortly.<br />

12.5 mm Type F 0.25 0.14<br />

12.5 mm Type A 0.25 0.14<br />

12.5 mm Type I 0.30 0.17<br />

15 mm Type F 0.30 0.17<br />

Table 13: Characteristic values of rigidity and strength for gypsum boards according to DIN 1052 (08/2004) in N/mm²<br />

Load direction Value Gypsum Board GKB/GKBI<br />

d [mm]<br />

Gypsum Board GKB/GKBI<br />

d [mm]<br />

12.5 15 18 12.5 15 18<br />

Gross Density ρ k<br />

[kg/m³] 680 680 680 800 800 800<br />

Shear load Shear Modulus G mean<br />

1)<br />

700 700 700 700 700 700<br />

Shear Strength f v,k<br />

1.0 1.0 1.0 1.0 1.0 1.0<br />

Transverse direction E Modulus E mean<br />

1)<br />

1000 1000 1000 1000 1000 1000<br />

Flexural Strength f m,k<br />

2.0 1.7 1.4 2.0 1.7 1.4<br />

Compressive Strength f c,k<br />

4.2 4.2 4.2 4.8 4.8 4.8<br />

Tensile Strength f t,k<br />

0.7 0.7 0.7 0.7 0.7 0.7<br />

Longitudinal direction E Modulus E mean<br />

1)<br />

1200 1200 1200 1200 1200 1200<br />

Flexural Strength f m,k<br />

4.0 3.8 3.6 4.0 3.8 3.6<br />

Compressive Strength f c,k<br />

3.5 3.5 3.5 5.5 5.5 5.5<br />

Tensile Strength f t,k<br />

1.7 1.4 1.1 1.7 1.4 1.1<br />

Lateral Load Compressive Strength f c,k<br />

3.5 3.5 3.5 5.5 5.5 5.5<br />

Transverse direction E Modulus E mean<br />

1)<br />

2200 2200 2200 2200 2200 2200<br />

Flexural Strength f m,k<br />

2.0 1.8 1.5 2.0 1.8 1.5<br />

Longitudinal direction E Modulus E mean<br />

1)<br />

2800 2800 2800 2800 2800 2800<br />

Flexural Strength f m,k<br />

6.5 5.4 4.2 6.5 5.4 4.2<br />

1)<br />

For the characteristic rigidity values E 05<br />

and G 05<br />

, use E 05<br />

= 0.5 • E mean<br />

G 05<br />

= 0,9 • G mean<br />

for calculation.<br />

17

[8] Naujoks, Bernd „Tragverhalten von<br />

Wandtafeln mit Kaltprofi len unter horizontalen<br />

und vertikalen Lasten“, Veröffentlichungen<br />

des Instituts für Stahlbau<br />

und Werkstoffmechanik der Technischen<br />

Universität Darmstadt, Heft 66,<br />

2002<br />

[9] Dr.-Ing. Meier-Dörnberg „Erdbebensicherheit<br />

von leichten Trennwänden<br />

- <strong>Knauf</strong> Ständerwände mit Gipsplatten<br />

W111 und W112“, TH Darmstadt, Institut<br />

für Mechanik, 1984<br />

[10] Allgemeines bauaufsichtliches Prüfungszeugnis<br />

„Wände in Holztafelbauart<br />

mit Beplankungen aus KNAUF-<br />

Gipsplatten“, Deutsches Institut für<br />

Bautechnik, 2001<br />

[11] Naujoks, Bernd „Tragverhalten von<br />

Wandtafeln mit Kaltprofi len unter horizontalen<br />

Lasten“, TU Darmstadt, Institut<br />

für Stahlbau und Werkstoffmechanik<br />

2002<br />

References<br />

[1] Univ. Doz. Dr. Rainer Flesch<br />

„Grundlagen des erdbebensicheren<br />

Konstruierens“, Österreichische Ingenieur-<br />

und Architekten-Zeitschrift Heft<br />

9, Jahrgang 131 (1986)<br />

[2] Dowrik, D. J. „Earthquake Resistant<br />

<strong>Design</strong>“, John Wiley & Sons, 1977<br />

[3] Müller, Keintzel „Erdbebensicherung<br />

von Hochbauten“, 2. Aufl ., Wilhelm<br />

Ernst & Sohn, 1985<br />

[4] Rosman, Riko „Erdbebenwiderstandsfähiges<br />

Bauen“, Wilhelm Ernst &<br />

Sohn, 1983<br />

[5] „European Macroseismic Scale 1998<br />

EMS-98“, G. Grünthal, ESC Working<br />

Group „Macroseismic Scales“, 1998<br />

[6] Univ. Doz. Dr. Rainer Flesch „Gutachten<br />

über erdbebensichere Ausführung<br />

von Ständerwänden und Plattendecken“,<br />

Bundesforschungs- und Prüfzentrum<br />

Arsenal (Wien), 1995<br />

[7] Dr. Tschirgin/ Dr. Tscherkaschin „Gutachten<br />

über die Anwendungsmöglichkeit<br />

von Trennwand- und Wandbekleidungskonstruktionen<br />

aus Gips-/<br />

Gipsfaserplatten in Erdbebengebieten“,<br />

Kutscherenko-Forschungsinstitut<br />

„ZNIISK“, 2004<br />

18

Table 14: Selected international standards<br />

International ISO 3010 Basis for design of structures - <strong>Seismic</strong> actions on structures 12/01<br />

Germany<br />

(Pre-standard) DIN V ENV 1998-1-1 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-1: General rules;<br />

seismic actions and general requirements for structure; German version ENV 1998-1-1:1994<br />

(Pre-standard) DIN V ENV 1998-1-2 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-2: General rules;<br />

general rules for building; German version ENV 1998-1-2:1994<br />

(Pre-standard) DIN V ENV 1998-1-3 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-3: General rules;<br />

specifi c rules for various materials and elements; German version ENV 1998-1-3:1995<br />

(Pre-standard) DIN V ENV 1998-1-4 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-4: General rules;<br />

strengthening and repair of buildings; German version ENV 1998-1-4:1996<br />

(Draft standard) DIN 4149 Buildings in German earthquake areas - <strong>Design</strong> loads, analysis and structural design of buildings<br />

DIN 4149-1 Buildings in German Earthquake Zones; <strong>Design</strong> Loads, Dimensioning, <strong>Design</strong> and Construction of Conventional Buildings<br />

DIN 4149-1 Beiblatt 1 Buildings in German earthquake areas; relation of administration areas with earthquake areas<br />

DIN 4149-1/A1 Buildings in German earthquake areas; design loads, analysis and structural design, usual buildings; amendment 1, map<br />

showing earthquake areas<br />

06/97<br />

06/97<br />

06/97<br />

09/99<br />

10/02<br />

04/81<br />

04/81<br />

12/92<br />

France NF P06-013 Earthquake resistant construction rules. Earthquake resistant rules applicable to buildings, called PS 92.<br />

NF P06-013/A1 Earthquake resistant construction rules. Earthquake resistant rules applicable to buildings, called PS 92<br />

XP P06-031-1 Eurocode 8 : <strong>Design</strong> provisions for earthquake resistance of structures and national application document - Part 1-1 : general<br />

rules - <strong>Seismic</strong> actions and requirements for structures.<br />

XP P06-031-2 Eurocode 8 : <strong>Design</strong> provisions for earthquake resistance of structures and national application document - Part 1-2 : general<br />

rules for buildings.<br />

XP P06-031-3 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures and national application document - Part 1-3 : general<br />

rules - Specifi c rules for various materials and elements.<br />

(Draft standard) P06-033PR Eurocode 8 : <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-4 : general rules - Strengthening<br />

and repair of buildings.<br />

12/95<br />

02/01<br />

12/01<br />

12/00<br />

03/03<br />

Great Britain<br />

(Pre-standard) BS DD ENV 1998-1-1 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - General rules - <strong>Seismic</strong><br />

actions and general requirements for structures<br />

(Pre-standard) BS DD ENV 1998-1-2 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - General rules - General rules<br />

for buildings<br />

(Pre-standard) BS DD ENV 1998-1-3 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - General rules - Specifi c rules<br />

for various materials and elements<br />

(Pre-standard) BS DD ENV 1998-1-4 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - General rules - Strengthening<br />

and repair of buildings<br />

05/96<br />

05/96<br />

05/96<br />

05/96<br />

CIS SniP II 7-81 Bauen in erdbebengefährdeten Gebieten 2000<br />

Italy D.M.L.P. 24. Januar 1986 Technische Normen für erdbebensichere Gebäude 01/86<br />

Austria<br />

(Draft standard) OENORM EN 1998-1 Eurocode 8: <strong>Design</strong> of structures for earthquake resistance - Part 1: General rules, seismic actions<br />

and rules for buildings<br />

(Pre-standard) OENORM ENV 1998-1-1 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-1: General rules<br />

- <strong>Seismic</strong> actions and general requirements for structures<br />

(Pre-standard) OENORM ENV 1998-1-2 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-2: General rules<br />

- General rules for buildings<br />

(Pre-standard) OENORM ENV 1998-1-3 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-3: General rules<br />

- Specifi c rules for various materials and elements<br />

(Pre-standard) OENORM ENV 1998-1-4 Eurocode 8: <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-4: General rules<br />

- Strengthening and repair of buildings<br />

OENORM B 4015 <strong>Design</strong> loads in building - Accidental actions - <strong>Seismic</strong> actions - General principles and methods of calculation<br />

05/04<br />

06/97<br />

06/97<br />

06/97<br />

12/99<br />

06/02<br />

Switzerland<br />

SIA 260 Basis of structural design<br />

SIA 261 Actions on Structures<br />

SIA 261/1 Actions on Structures - Supplementary Specifi cations<br />

(Pre-standard) SN ENV 1998-1-1 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-1: General rules; seismic<br />

actions and general requirements for structure<br />

(Pre-standard) SN ENV 1998-1-2 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-2: General rules; general<br />

rules for building<br />

(Pre-standard) SN ENV 1998-1-3 Eurocode 8 - <strong>Design</strong> provisions for earthquake resistance of structures - Part 1-3: General rules; specifi c<br />

rules for various materials and element<br />

01/03<br />

01/03<br />

01/03<br />

1998<br />

1994<br />

1995<br />

Turkey ABYYHY Specifi cations for Structures to be Built in Disaster Areas Part III - Earthquake Disaster Prevention 07/98<br />

19

<strong>Knauf</strong> Gips KG<br />

Am Bahnhof 7, D-97346 Iphofen<br />

Phone: +49-9323-31-0<br />

Fax: +49-9323-31-277<br />

http://www.knauf.de<br />

e-mail: info@knauf.de<br />

Danogips A/S<br />

Kløvermarksvej 4-6<br />

DK-9500 Hobro<br />

Phone: (+45) 96-573000<br />

Fax: (+45) 96-573001<br />

http://www.danogips.dk<br />

e-mail: info@danogips.dk<br />

<strong>Knauf</strong> AG<br />

Kägenstraße 17<br />

CH-4153 Reinach<br />

Phone: (+41) 61-716-10-10<br />

Fax: (+41) 61-716-10-11<br />

http://www.knauf.ch<br />

e-mail: info@knauf.ch<br />

<strong>Knauf</strong> di Lothar <strong>Knauf</strong> s.a.s.<br />

Località Paradiso<br />

I-56040 Castellina Marittima (PI)<br />

Phone: (+39) 050-692-201<br />

Fax: (+39) 050-692-301<br />

http://www.knauf.it<br />

e-mail: knauf@knauf.it<br />

<strong>Knauf</strong> Gesellschaft m.b.H.<br />

<strong>Knauf</strong>straße 1<br />

A-8940 Weißenbach/Liezen<br />

Phone: (+43) 3612-22 971<br />

Fax: (+43) 3612-24 679<br />

http://www.knauf.at<br />

e-mail: info@knauf.at<br />

<strong>Knauf</strong> Gips GmbH<br />

Region Moskau, Zentralnaja - Str. 139<br />

RUS-143400 Krasnogorsk<br />

Phone: (+7) 095-980 9848<br />

Fax: (+7) 095-980 9849<br />

http://www.knauf-msk.ru<br />

e-mail: info@knauf-msk.ru<br />

Tepe <strong>Knauf</strong> A.S.<br />

P.K. 92 Bakanliklar<br />

TR-06581 Ankara<br />

Phone: (+90) 312-29701-00<br />

Fax: (+90) 312-2664214<br />

http://www.knauf.com.tr<br />

e-mail: mailbox@knauf.com.tr<br />

<strong>Knauf</strong> Gypsopiia ABEE<br />

Leoforos Syngrou 229<br />

GR-17121 Nea Smyrni/Athen<br />

Phone: (+30) 210-931056-7/9<br />

Fax: (+30) 210-9310568<br />

http://www.knauf.gr<br />

e-mail: knauf@knauf.gr<br />

Yesos <strong>Knauf</strong> GmbH Sucursal Argentina<br />

Bartolomé Cruz 1528 - 2° piso<br />

RA-B1638BHL Vicente López, Pcia de<br />

Buenos Aires<br />

Phone: (+54) 11-4837-0700<br />

Fax: (+54) 11-4837-0707<br />

http://www.knauf.com.ar<br />

e-mail: knauf@knauf.com.ar<br />

<strong>Knauf</strong> SNC<br />

Zone d‘Activites<br />

F-68600 Wolfgantzen<br />

Phone: (+33) 389-72-1100<br />

Fax: (+33) 389-72-1203<br />

http://www.knauf.fr<br />

e-mail: info@knauf.fr<br />

<strong>Knauf</strong> d.o.o. Sarajevo<br />

Poslovni Centar SENTADA<br />

Ul. Kolodvorska 11 A<br />

BiH-71000 SARAJEVO<br />

Phone: (+387) 33/711 090<br />

Fax: (+387) 71/664 368<br />

http://www.knauf.ba<br />

e-mail: info@knauf.ba<br />

<strong>Knauf</strong> Plasterboard Tianjin Co. LTD<br />

North Yinhe Bridge, East Jingjin Road<br />

RC-300400 Tianjin, Beichen District<br />

Phone: (+86) 22 2697 2777<br />

Fax: (+86) 22 2697 3351<br />

http://www.knauf.com.cn<br />

e-mail: info@mail.knauf.com.cn<br />

<strong>Knauf</strong> EOOD<br />

Angelov Vrach Nr. 27<br />

BG-1618 SOFIA<br />

Phone: (+359) 2-9178910<br />

Fax: (+359) 2-9178911<br />

http://www.knauf.bg<br />

e-mail: info@knauf.bg<br />

<strong>Knauf</strong> d.o.o. Zagreb<br />

Ulica grada Vukovara 21<br />

HR-10000 ZAGREB<br />

Phone: (+385) 1/30 35 400<br />

Fax: (+385) 1/30 35 415<br />

http://www.knauf.hr<br />

e-mail: knauf@knauf.hr<br />

<strong>Knauf</strong> Gips S.R.L.<br />

Str. Gheorghe Bratianu Nr. 30 Sector 1<br />

RO-011413 BUKAREST<br />

Phone: (+40) 21-222 93 22<br />

Fax: (+40) 21-222 93 66<br />

http://www.knauf.ro<br />

e-mail: office@knauf.ro<br />

<strong>Knauf</strong> de Chile Ltda.<br />

Cerro San Luis Nr.9871, Mód.A-B<br />

Loteo Portezuelo<br />

Quilicura Santiago de Chile<br />

Phone: (+56) 2 747-1344/45<br />

Fax: (+56) 2 738-6986<br />

e-mail: info@knauf.cl<br />

<strong>Knauf</strong> Iran P.J.S.C.<br />

No. 31 Shahid Naghdi St.<br />

North Mofateh Ave.<br />

15766 Teheran<br />

Islamic Republic of Iran<br />

Phone: (+98) 21-8751680<br />

Fax: (+98)21-8742046<br />

e-mail: knaufiran@hotmail.com<br />

© All technical changes reserved. Only the current printed instructions are<br />

valid. Our warranty is expressly limited to our products in fl awless condition.<br />

The structural, statical properties and characteristic building physics of<br />

<strong>Knauf</strong> systems can solely be ensured with the exclusive use of <strong>Knauf</strong><br />

system components, or other products expressly recommended by <strong>Knauf</strong>.<br />

All application quantities and delivery amounts are based on empirical data<br />

that are not easily transferable to other deviating areas. All rights reserved.<br />

All amendments, reprints and photocopies as well as electronic rendering,<br />

including those of excerpts, require the express permission of <strong>Knauf</strong> Gips KG,<br />

Am Bahnhof 7, D-97346 Iphofen, Germany.<br />

SD1 / engl. / D / 08.04 / FB / D