Colour Chronicle - Sept 2012 - Clariant

Colour Chronicle - Sept 2012 - Clariant

Colour Chronicle - Sept 2012 - Clariant

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

textile<br />

Orange and scarlet shades<br />

Golden Yellow HF-CD<br />

Scarlet HF-3G<br />

Red HF-3B<br />

What are the main problems faced by the<br />

continuous dyer?<br />

Shade transfer from lab to production.<br />

Shade reproducibility from batch to<br />

batch in production.<br />

Meeting modern retailer and brand<br />

house fastness requirements.<br />

Shade reproducibility from batch to batch<br />

in production.<br />

What are the main issues faced by the<br />

continuous dyer?<br />

Fabric appearance, penetration and<br />

levelling.<br />

Dyestuff solubility.<br />

Face to back shade variation (emerized<br />

fabrics).<br />

Shade continuity along the length and<br />

width of the fabric (tailing/listing).<br />

Dyestuff migration during pre-drying.<br />

Dyestuff stability to alkaline hydrolysis.<br />

Washing off and wet fastness.<br />

Photochromism.<br />

Fastness properties of the individual<br />

dyestuff.<br />

Improving fabric appearance, penetration<br />

and levelling with Drimaren ® HF dyes.<br />

Dyestuffs with high diffusion are essential<br />

for:<br />

Tightly woven fabrics.<br />

Fabrics constructed from high twist<br />

yarns.<br />

Mercerized fabrics.<br />

Regenerated cellulose, linen and<br />

cellulosic blends (CO:CV, CO:FL).<br />

Emerized fabrics (to improve face to<br />

back shade difference).<br />

Dyestuff stability to alkaline hydrolysis<br />

What can be done to minimize alkaline<br />

hydrolysis?<br />

Automatic liquor dosing systems (ratio<br />

4:1).<br />

Low volume economizer trough (fast<br />

pad liquor turnover time).<br />

Increase the amount of sodium silicate<br />

in the pad batch process (70 ml/l /<br />

38°Bé).<br />

Control of the fixation time and<br />

temperature.<br />

Control of the washing off conditions<br />

(mono VS dyes sensitive to alkaline<br />

washing).<br />

Cooling cylinders are used to cool and<br />

level out the fabric temperature before<br />

padding.<br />

Cooling water jackets around the pad<br />

trough are used to maintain the desired<br />

pad liquor temperature.<br />

Process water cooling systems for<br />

preparation of the dye and alkali<br />

solutions.<br />

Use reactive dyestuffs with high<br />

alkaline stability.<br />

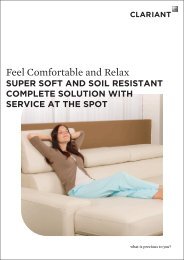

Washing off reactive dyes<br />

Excellent wash and wet fastness properties<br />

can only be achieved by complete removal<br />

of the hydrolyzed dye, alkali and auxiliary<br />

chemicals during a washing off process.<br />

Very high fixation values.<br />

A high level of fixation is essential for<br />

good shade reproducibility, easier washing<br />

out of the unfixed dye and to minimize<br />

the amount of color that passes into the<br />

effluent.<br />

Brill. Yellow HF-RL .................. 96%<br />

Golden Yellow HF-CD ............... 96%<br />

Yellow HF-CD ............................. 92%<br />

Red HF-CD ................................. 90%<br />

Red HF-3B .................................. 97%<br />

Dark Red HF-CD ........................ 98%<br />

Aquamarine HF-CD .................. 90%<br />

Blue HF-RL ................................. 90%<br />

Dark Blue HF-CD ....................... 93%<br />

Royal Blue HF-CD ..................... 90%<br />

Navy HF-GN ............................... 95%<br />

Navy HF-B .................................. 97%<br />

Exchange Phase 1 > Diffusion & Desorption Phase > Exchange Phase 2<br />

10<br />

colour chronicle 3 | <strong>2012</strong>