Colour Chronicle - Sept 2012 - Clariant

Colour Chronicle - Sept 2012 - Clariant

Colour Chronicle - Sept 2012 - Clariant

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

textile<br />

Technical advantages<br />

– Processing on common finishing<br />

lines.<br />

– Suitable for cotton and selected<br />

natural and regenerated cellulosic<br />

fibres as well as blends with<br />

synthetics.<br />

– Very low impact on fabric strength<br />

allowing wider range of fabric<br />

selection and end-uses.<br />

– Safer processing due to absence of<br />

formaldehyde emissions.<br />

– No oily deposit formation in stenter<br />

compartments, as easily removable<br />

deposits are formed.<br />

– No ‘bad smell’ formation as<br />

observed with established reactive<br />

phosphonate chemistry.<br />

Novel technology for home<br />

textiles<br />

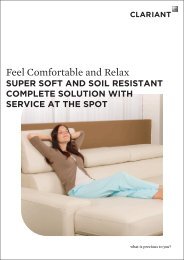

Pekoflam ® ECO/SYN liq.<br />

FR test* according to BS5852 source 5<br />

on a 260 gsm cotton interlining fabric:<br />

– Untreated fabric burns for more<br />

than 120s, whereas treated<br />

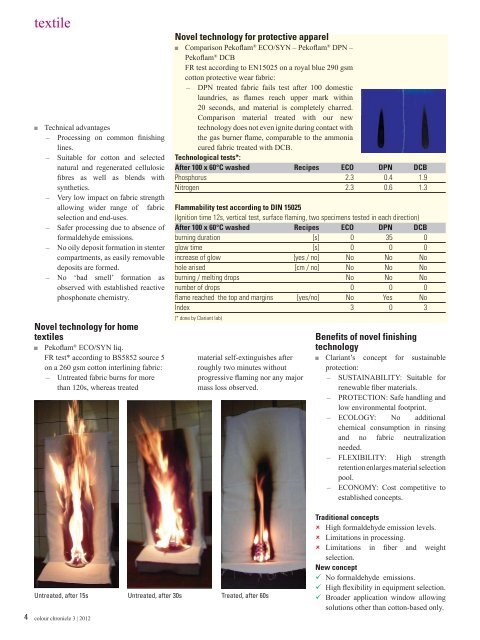

Novel technology for protective apparel<br />

Comparison Pekoflam ® ECO/SYN – Pekoflam ® DPN –<br />

Pekoflam ® DCB<br />

FR test according to EN15025 on a royal blue 290 gsm<br />

cotton protective wear fabric:<br />

– DPN treated fabric fails test after 100 domestic<br />

laundries, as flames reach upper mark within<br />

20 seconds, and material is completely charred.<br />

Comparison material treated with our new<br />

technology does not even ignite during contact with<br />

the gas burner flame, comparable to the ammonia<br />

cured fabric treated with DCB.<br />

Technological tests*:<br />

After 100 x 60°C washed Recipes ECO DPN DCB<br />

Phosphorus 2.3 0.4 1.9<br />

Nitrogen 2.3 0.6 1.3<br />

Flammability test according to DIN 15025<br />

(Ignition time 12s, vertical test, surface flaming, two specimens tested in each direction)<br />

After 100 x 60°C washed Recipes ECO DPN DCB<br />

burning duration [s] 0 35 0<br />

glow time [s] 0 0 0<br />

increase of glow [yes / no] No No No<br />

hole arised [cm / no] No No No<br />

burning / melting drops No No No<br />

number of drops 0 0 0<br />

flame reached the top and margins [yes/no] No Yes No<br />

Index 3 0 3<br />

(* done by <strong>Clariant</strong> lab)<br />

material self-extinguishes after<br />

roughly two minutes without<br />

progressive flaming nor any major<br />

mass loss observed.<br />

Benefits of novel finishing<br />

technology<br />

<strong>Clariant</strong>’s concept for sustainable<br />

protection:<br />

– SUSTAINABILITY: Suitable for<br />

renewable fiber materials.<br />

– PROTECTION: Safe handling and<br />

low environmental footprint.<br />

– ECOLOGY: No additional<br />

chemical consumption in rinsing<br />

and no fabric neutralization<br />

needed.<br />

– FLEXIBILITY: High strength<br />

retention enlarges material selection<br />

pool.<br />

– ECONOMY: Cost competitive to<br />

established concepts.<br />

4<br />

Untreated, after 15s Untreated, after 30s Treated, after 60s<br />

colour chronicle 3 | <strong>2012</strong><br />

Traditional concepts<br />

High formaldehyde emission levels.<br />

Limitations in processing.<br />

Limitations in fiber and weight<br />

selection.<br />

New concept<br />

No formaldehyde emissions.<br />

High flexibility in equipment selection.<br />

Broader application window allowing<br />

solutions other than cotton-based only.