Olympic Runners with Sinumerik and ShopMill Olympic Runners ...

Olympic Runners with Sinumerik and ShopMill Olympic Runners ...

Olympic Runners with Sinumerik and ShopMill Olympic Runners ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

14<br />

CASE STUDY<br />

Laser Machining<br />

Modular laser cell for flexible 3D<br />

material machining<br />

Dynamic<br />

<strong>and</strong> Flexible<br />

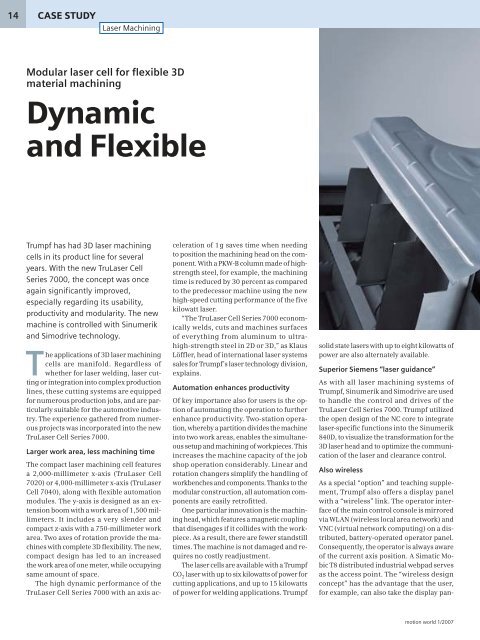

Trumpf has had 3D laser machining<br />

cells in its product line for several<br />

years. With the new TruLaser Cell<br />

Series 7000, the concept was once<br />

again significantly improved,<br />

especially regarding its usability,<br />

productivity <strong>and</strong> modularity. The new<br />

machine is controlled <strong>with</strong> <strong>Sinumerik</strong><br />

<strong>and</strong> Simodrive technology.<br />

The applications of 3D laser machining<br />

cells are manifold. Regardless of<br />

whether for laser welding, laser cutting<br />

or integration into complex production<br />

lines, these cutting systems are equipped<br />

for numerous production jobs, <strong>and</strong> are particularly<br />

suitable for the automotive industry.<br />

The experience gathered from numerous<br />

projects was incorporated into the new<br />

TruLaser Cell Series 7000.<br />

Larger work area, less machining time<br />

The compact laser machining cell features<br />

a 2,000-millimeter x-axis (TruLaser Cell<br />

7020) or 4,000-millimeter x-axis (TruLaser<br />

Cell 7040), along <strong>with</strong> flexible automation<br />

modules. The y-axis is designed as an extension<br />

boom <strong>with</strong> a work area of 1,500 millimeters.<br />

It includes a very slender <strong>and</strong><br />

compact z-axis <strong>with</strong> a 750-millimeter work<br />

area. Two axes of rotation provide the machines<br />

<strong>with</strong> complete 3D flexibility. The new,<br />

compact design has led to an increased<br />

the work area of one meter, while occupying<br />

same amount of space.<br />

The high dynamic performance of the<br />

TruLaser Cell Series 7000 <strong>with</strong> an axis acceleration<br />

of 1g saves time when needing<br />

to position the machining head on the component.<br />

With a PKW-B column made of highstrength<br />

steel, for example, the machining<br />

time is reduced by 30 percent as compared<br />

to the predecessor machine using the new<br />

high-speed cutting performance of the five<br />

kilowatt laser.<br />

“The TruLaser Cell Series 7000 economically<br />

welds, cuts <strong>and</strong> machines surfaces<br />

of everything from aluminum to ultrahigh-strength<br />

steel in 2D or 3D,” as Klaus<br />

Löffler, head of international laser systems<br />

sales for Trumpf’s laser technology division,<br />

explains.<br />

Automation enhances productivity<br />

Of key importance also for users is the option<br />

of automating the operation to further<br />

enhance productivity. Two-station operation,<br />

whereby a partition divides the machine<br />

into two work areas, enables the simultaneous<br />

setup <strong>and</strong> machining of workpieces. This<br />

increases the machine capacity of the job<br />

shop operation considerably. Linear <strong>and</strong><br />

rotation changers simplify the h<strong>and</strong>ling of<br />

workbenches <strong>and</strong> components. Thanks to the<br />

modular construction, all automation components<br />

are easily retrofitted.<br />

One particular innovation is the machining<br />

head, which features a magnetic coupling<br />

that disengages if it collides <strong>with</strong> the workpiece.<br />

As a result, there are fewer st<strong>and</strong>still<br />

times. The machine is not damaged <strong>and</strong> requires<br />

no costly readjustment.<br />

The laser cells are available <strong>with</strong> a Trumpf<br />

CO 2 laser <strong>with</strong> up to six kilowatts of power for<br />

cutting applications, <strong>and</strong> up to 15 kilowatts<br />

of power for welding applications. Trumpf<br />

solid state lasers <strong>with</strong> up to eight kilowatts of<br />

power are also alternately available.<br />

Superior Siemens “laser guidance”<br />

As <strong>with</strong> all laser machining systems of<br />

Trumpf, <strong>Sinumerik</strong> <strong>and</strong> Simodrive are used<br />

to h<strong>and</strong>le the control <strong>and</strong> drives of the<br />

TruLaser Cell Series 7000. Trumpf utilized<br />

the open design of the NC core to integrate<br />

laser-specific functions into the <strong>Sinumerik</strong><br />

840D, to visualize the transformation for the<br />

3D laser head <strong>and</strong> to optimize the communication<br />

of the laser <strong>and</strong> clearance control.<br />

Also wireless<br />

As a special “option” <strong>and</strong> teaching supplement,<br />

Trumpf also offers a display panel<br />

<strong>with</strong> a “wireless” link. The operator interface<br />

of the main control console is mirrored<br />

via WLAN (wireless local area network) <strong>and</strong><br />

VNC (virtual network computing) on a distributed,<br />

battery-operated operator panel.<br />

Consequently, the operator is always aware<br />

of the current axis position. A Simatic Mobic<br />

T8 distributed industrial webpad serves<br />

as the access point. The “wireless design<br />

concept” has the advantage that the user,<br />

for example, can also take the display pan-<br />

motion world 1/2007