E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

21<br />

AGIE experience<br />

No <strong>28</strong> January 2007<br />

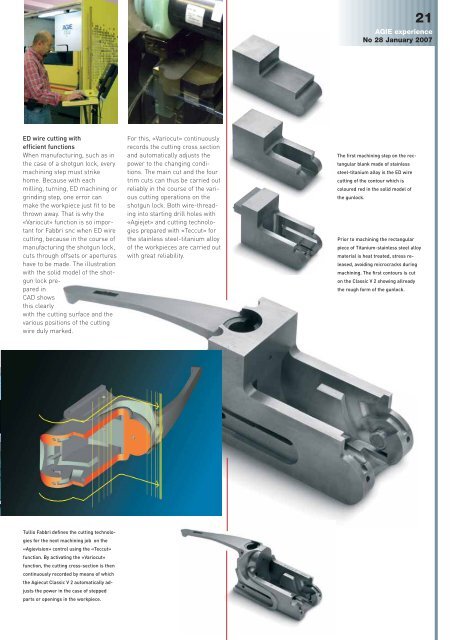

ED wire cutting with<br />

efficient functions<br />

When manufacturing, such as in<br />

the case of a shotgun lock, every<br />

machining step must strike<br />

home. Because with each<br />

milling, turning, ED machining or<br />

grinding step, one error can<br />

make the workpiece just fit to be<br />

thrown away. That is why the<br />

«Variocut» function is so important<br />

for Fabbri snc when ED wire<br />

cutting, because in the course of<br />

manufacturing the shotgun lock,<br />

cuts through offsets or apertures<br />

have to be made. The illustration<br />

with the solid model of the shotgun<br />

lock prepared<br />

in<br />

CAD shows<br />

this clearly<br />

with the cutting surface and the<br />

various positions of the cutting<br />

wire duly marked.<br />

For this, «Variocut» continuously<br />

records the cutting cross section<br />

and automatically adjusts the<br />

power to the changing conditions.<br />

The main cut and the four<br />

trim cuts can thus be carried out<br />

reliably in the course of the various<br />

cutting operations on the<br />

shotgun lock. Both wire-threading<br />

into starting drill holes with<br />

«Agiejet» and cutting technologies<br />

prepared with «Teccut» for<br />

the stainless steel-titanium alloy<br />

of the workpieces are carried out<br />

with great reliability.<br />

The first machining step on the rectangular<br />

blank made of stainless<br />

steel-titanium alloy is the ED wire<br />

cutting of the contour which is<br />

coloured red in the solid model of<br />

the gunlock.<br />

Prior to machining the rectangular<br />

piece of Titanium-stainless steel alloy<br />

material is heat treated, stress released,<br />

avoiding microcracks during<br />

machining. The first contours is cut<br />

on the Classic V 2 showing allready<br />

the rough form of the gunlock.<br />

Tullio Fabbri defines the cutting technologies<br />

for the next machining job on the<br />

«Agievision» control using the «Teccut»<br />

function. By activating the «Variocut»<br />

function, the cutting cross-section is then<br />

continuously recorded by means of which<br />

the Agiecut Classic V 2 automatically adjusts<br />

the power in the case of stepped<br />

parts or openings in the workpiece.