E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

29<br />

AGIE experience<br />

No <strong>28</strong> January 2007<br />

Automated EDM<br />

for 100-percent<br />

fitting accuracy<br />

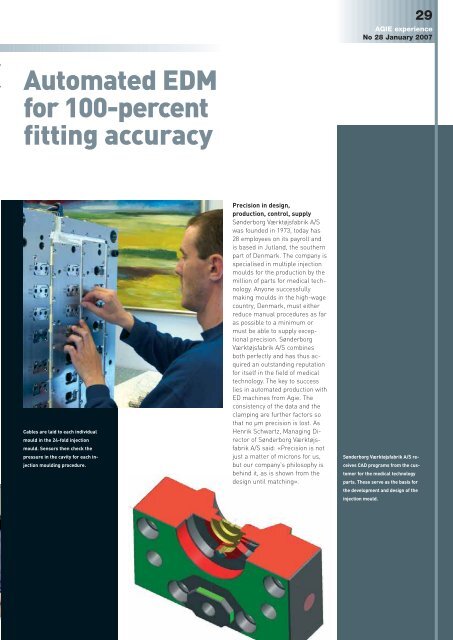

Cables are laid to each individual<br />

mould in the 24-fold injection<br />

mould. Sensors then check the<br />

pressure in the cavity for each injection<br />

moulding procedure.<br />

Precision in design,<br />

production, control, supply<br />

Sønderborg Værktøjsfabrik A/S<br />

was founded in 1973, today has<br />

<strong>28</strong> employees on its payroll and<br />

is based in Jutland, the southern<br />

part of Denmark. The company is<br />

specialised in multiple injection<br />

moulds for the production by the<br />

million of parts for medical technology.<br />

Anyone successfully<br />

making moulds in the high-wage<br />

country, Denmark, must either<br />

reduce manual procedures as far<br />

as possible to a minimum or<br />

must be able to supply exceptional<br />

precision. Sønderborg<br />

Værktøjsfabrik A/S combines<br />

both perfectly and has thus acquired<br />

an outstanding reputation<br />

for itself in the field of medical<br />

technology. The key to success<br />

lies in automated production with<br />

ED machines from Agie. The<br />

consistency of the data and the<br />

clamping are further factors so<br />

that no µm precision is lost. As<br />

Henrik Schwartz, Managing Director<br />

of Sønderborg Værktøjsfabrik<br />

A/S said: «Precision is not<br />

just a matter of microns for us,<br />

but our company's philosophy is<br />

behind it, as is shown from the<br />

design until matching».<br />

Sønderborg Værktøjsfabrik A/S receives<br />

CAD programs from the customer<br />

for the medical technology<br />

parts. These serve as the basis for<br />

the development and design of the<br />

injection mould.